Advanced Manufacturing Equipments

Superalloy Parts Manufacturing Equipments

Neway's advanced manufacturing equipment for high-temperature alloy parts. It includes vacuum induction melting furnaces (ALD and CONSARC), pulverizing equipment (PREP), high-clean environment powder screening lines, and single crystal furnaces (25kg/50kg ALD). Additional specialized machines include the MPI automatic wax press, LBBC automatic dewaxing and core removal kettles, and vacuum heat treatment furnaces.

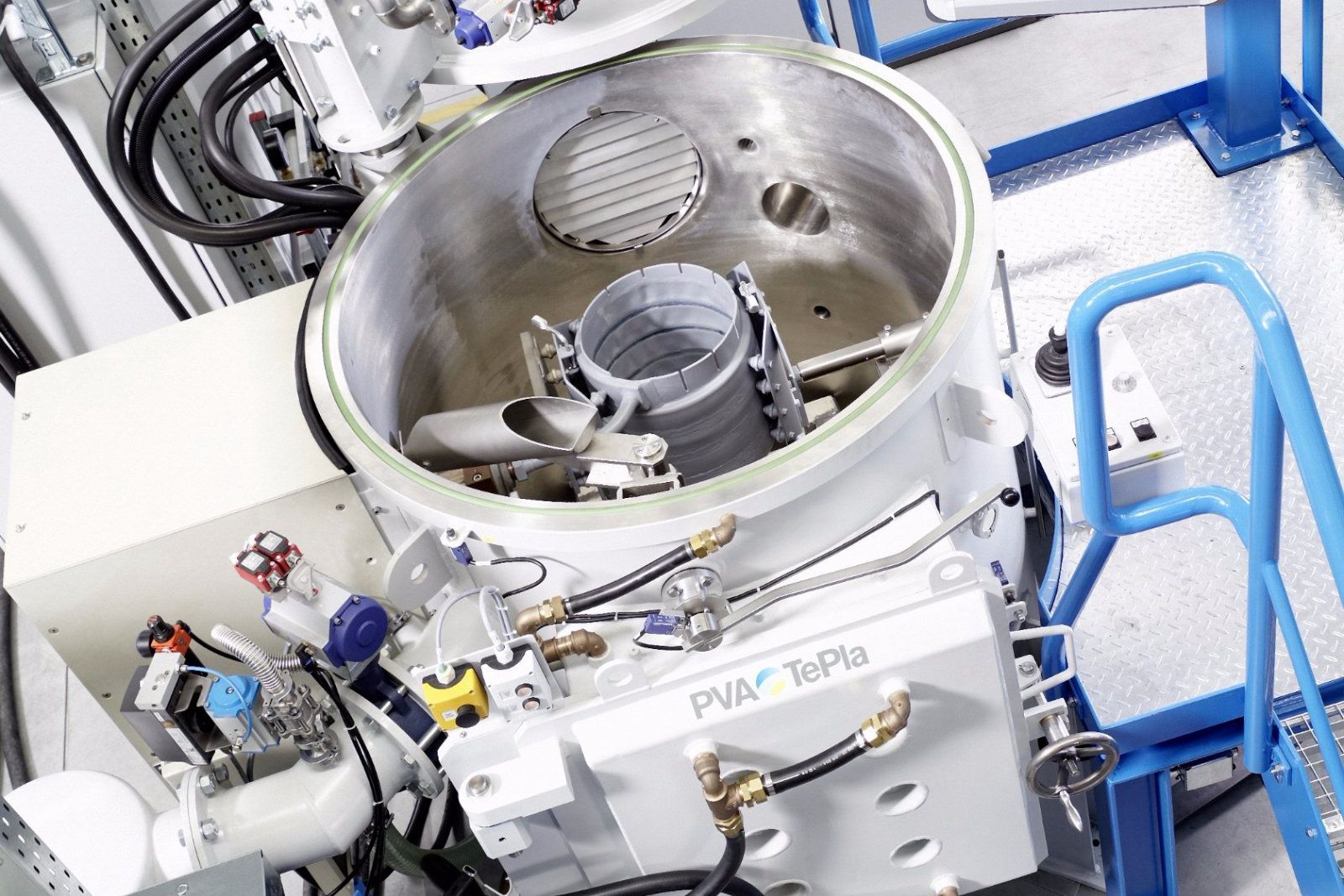

Vacuum Induction Melting Furnace

The Vacuum Induction Melting (VIM) Furnace plays a critical role in producing high-temperature alloy parts, particularly in aerospace, power generation, and chemical processing. It enables the precise melting and alloying of superalloys and other high-temperature materials in a controlled environment. The VIM process ensures that the final materials have excellent mechanical properties, high purity, and resistance to oxidation and corrosion.

Vacuum Induction Pouring Furnace

The Vacuum Induction Pouring Furnace melts high-temperature alloys in a vacuum to prevent contamination and oxidation, ensuring alloy purity. It enables precise molten metal flow control for casting complex geometries with minimal defects. This process ensures consistent microstructures, which is crucial for producing high-performance components like turbine blades used in aerospace and energy applications.

Automatic Wax Press

The Automatic Wax Press creates precise and consistent wax patterns used in the investment casting of high-temperature alloy parts. It ensures dimensional accuracy, smooth surface finishes, and repeatability, which is critical for producing complex components like turbine blades. The automation improves efficiency and productivity, making it ideal for high-volume manufacturing in aerospace and energy industries.

Automatic Shell Line

The Automatic Shell Line automates the creation of ceramic shells around wax patterns in the investment casting process. It ensures uniform coatings, enhances productivity and maintains consistent quality for high-temperature alloy parts like turbine blades. This automation improves efficiency, reduces defects, and supports the production of complex, high-performance components in aerospace and energy industries.

Automatic Dewaxing Kettle

The Automatic Dewaxing Kettle removes wax from ceramic molds in the investment casting process, ensuring clean cavities for casting high-temperature alloy parts. It preserves mold integrity, reduces defects, and ensures consistent, efficient dewaxing for high-volume production. Additionally, it recycles wax, promoting material efficiency in manufacturing components like turbine blades and impellers.

Automatic Core Removal Kettle

After casting, the Automatic Core Removal Kettle removes ceramic cores from high-temperature alloy cast parts, such as turbine blades. It ensures precision by maintaining part integrity, minimizing defects, and offering consistent, automated operation. This process is critical for producing complex, high-performance components used in aerospace and energy industries while enhancing productivity and quality control.

Titanium Alloy Casting Equipment

Titanium Alloy Casting Equipment melts and casts titanium alloys in a controlled environment to prevent contamination. It ensures precise temperature control, accurate mold filling, and defect-free casting of complex components. Designed to handle titanium's reactive nature, the equipment produces high-performance parts with excellent mechanical properties ideal for aerospace, medical, and energy applications.

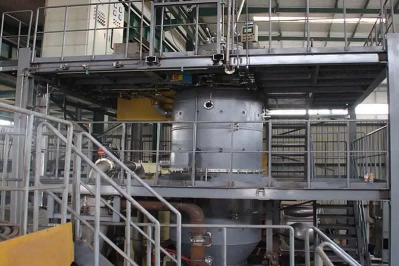

100 Kg Equiaxed Crystal Furnace

The Equiaxed Crystal Furnace melts superalloys and controls their solidification to create equiaxed grain structures, improving toughness and fatigue resistance. It ensures precise temperature management, maintains alloy composition, and reduces defects like porosity. This process is essential for producing high-performance superalloy components, such as turbine blades, used in aerospace and power generation industries.

Single Crystal Furnace

The Single Crystal Furnace melts and casts superalloys, controlling the solidification process to create crystal structures without grain boundaries. It ensures precise temperature management and directional solidification, producing high-performance parts with enhanced creep resistance and fatigue life. This process is essential for manufacturing complex, reliable superalloy components like turbine blades for aerospace and energy applications.

Electrostatic Impurity Removal System

The Electrostatic Impurity Removal System eliminates fine particulate contaminants from casting environments using electrostatic forces, ensuring cleaner molds and higher alloy purity. It reduces casting defects, improves surface finishes, and enhances the overall quality of superalloy parts. This system is essential for producing defect-free, high-performance components like turbine blades used in aerospace and energy applications.

High Vacuum Dynamic Jacketed Equipment

The High Vacuum Dynamic Jacketed Equipment creates a vacuum environment and regulates temperature for casting superalloys. It ensures alloy purity, prevents oxidation, and minimizes defects like porosity and cracks. This device is crucial for producing high-quality, complex superalloy parts, such as turbine blades, with precise dimensional accuracy and optimal mechanical properties for aerospace and energy applications.

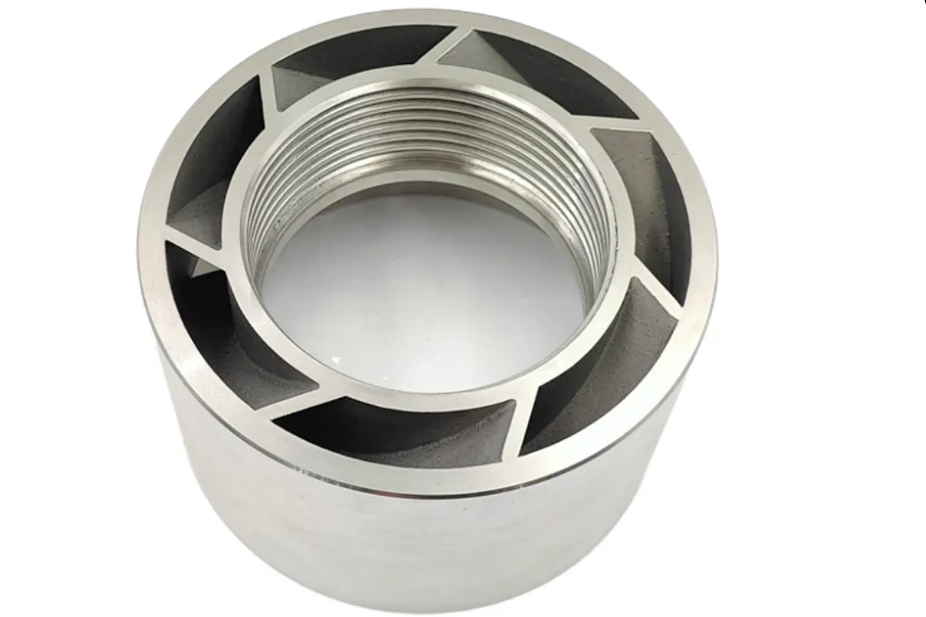

300mm Diameter Hot Isostatic Pressing (HIP) Furnace

The Hot Isostatic Pressing (HIP) Furnace uses high pressure and temperature to eliminate porosity, heal defects, and optimize the microstructure of superalloy castings. It enhances mechanical properties like strength and fatigue resistance, producing more durable and reliable parts. This process is crucial for producing high-performance components, such as turbine blades, for aerospace and energy applications.

100 Kg/250Kg Argon Atomizing Pulverizing Furnace

The Argon Atomizing Pulverizing Furnace melts superalloys and uses argon gas to atomize them into fine, spherical powder particles. It prevents contamination, ensures precise particle size control, and produces high-quality powder for advanced manufacturing processes like 3D printing and powder metallurgy. This process is crucial for creating high-performance superalloy components, such as turbine blades, used in aerospace and energy industries.

Vacuum Heat Treatment Furnace

The Vacuum Heat Treatment Furnace refines the microstructure of superalloy parts by relieving stress, improving mechanical properties, and preventing oxidation. It provides precise heating and cooling in a vacuum environment, ensuring purity and consistency in the alloy's structure. This process enhances strength, durability, and high-temperature performance, making it vital for producing components like turbine blades for aerospace and energy applications.

5-axis CNC Machining Center

A 5-axis CNC machining center offers superior precision, efficiency, and flexibility for post-processing superalloy castings. It enables complex geometries with fewer setups, improves surface finish, and reduces lead times. The multi-axis movement enhances accessibility to intricate features, ensuring tight tolerances and consistent quality for high-temperature alloy components, especially in aerospace and power generation applications.

Let's Start A New Project Today