Grain Structure Control in Equiaxed Crystal Casting: Enhance Toughness and Fatigue Resistance

Equiaxed crystal casting is crucial in producing high-performance superalloy components for aerospace, power generation, and oil and gas. The controlled grain structure in equiaxed crystal casting affects the final product's mechanical properties. It enhances toughness and fatigue resistance—two vital attributes for materials exposed to extreme thermal and mechanical stress.

This blog explores the manufacturing process of equiaxed crystal casting, typical superalloys used, post-processing techniques, testing methods, and prototyping processes, highlighting their applications across industries. Components produced through this method, such as turbine blades and high-temperature alloy engine parts, are essential for ensuring long-term performance and reliability in environments where extreme conditions prevail.

Grain Structure Control

The grain structure of equiaxed crystal castings plays a vital role in the overall mechanical properties of the material. Fine, uniformly distributed grains typically improve toughness and better fatigue and stress resistance. Several factors influence the grain structure during casting, including inoculants, cooling rate, and temperature gradient control. Material design optimization is essential for achieving the desired grain structure and ensuring superior mechanical properties.

Inoculants are materials added to the molten metal to promote uniform nucleation of grains. These nucleation sites help control the grain size during solidification. Fine-grain structures are achieved by controlling the cooling rate in the mold. Faster cooling rates encourage the formation of smaller grains, while slower cooling rates can lead to larger, more elongated grains. A controlled cooling system that gradually reduces the temperature in the casting mold is often used to ensure a consistent grain structure. Controlled cooling ensures the final product exhibits optimal properties by regulating solidification.

In addition to cooling rate and inoculants, temperature gradient control can help refine the grain structure. By managing how heat moves through the casting, manufacturers can direct the formation of fine equiaxed crystals, which leads to a more uniform and desirable grain structure. Optimizing manufacturing processes like these ensures that superalloys achieve superior durability and performance in high-stress, high-temperature applications.

Manufacturing Process

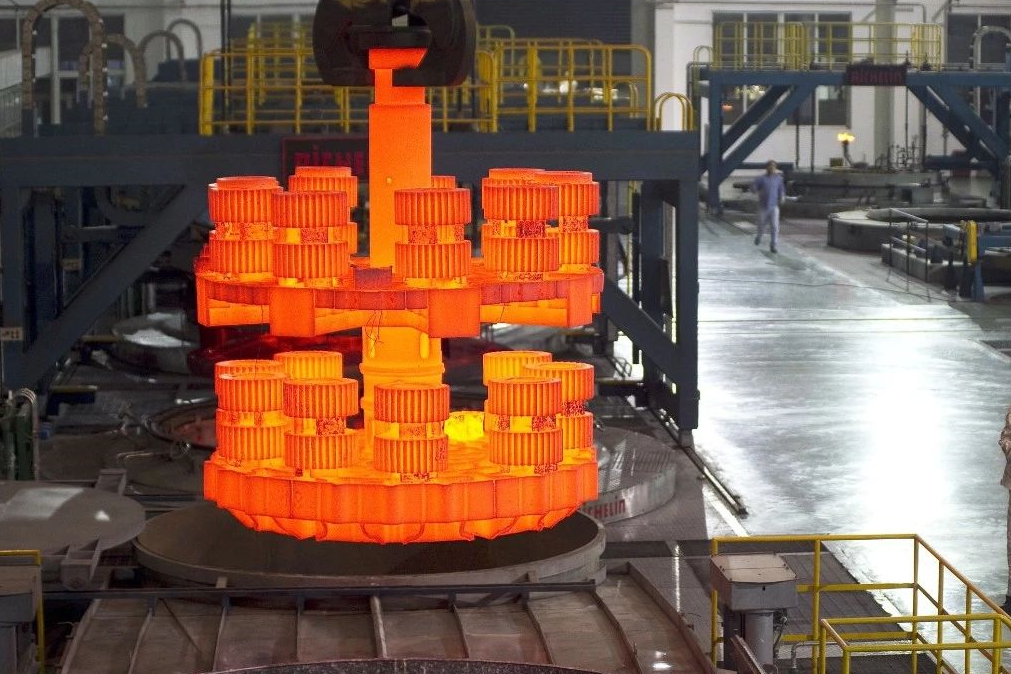

Manufacturing equiaxed crystal castings begins with controlled melting, solidification, and cooling. Each step in the process plays a vital role in determining the final grain structure, which directly influences performance characteristics such as toughness, fatigue resistance, and high-temperature strength. Controlled melting ensures the alloy’s integrity and uniformity during casting.

Controlled melting and solidification are achieved by carefully managing temperature and cooling rates. A vacuum induction furnace or electromagnetic stirring is typically used to ensure uniform melting of the superalloy. The goal is to achieve consistent heat distribution and prevent temperature gradients that might lead to the formation of unwanted grain structures. If the cooling rate is too fast or slow, it can result in defects such as segregation, porosity, or unwanted coarse grain formation. Vacuum induction melting is key to maintaining an inert environment, preventing contamination, and optimizing the alloy’s properties.

Once the molten metal is ready, it is cast into molds, where cooling begins. The cooling rate during solidification is carefully controlled to promote the formation of equiaxed crystals—uniformly sized, three-dimensional grains. By controlling the cooling rate and the temperature gradient within the mold, manufacturers can achieve the fine-grained structure desired for high-performance superalloy parts. Controlled cooling is critical in preventing defects and ensuring the final casting exhibits the required mechanical properties.

Typical Superalloys Used in Equiaxed Crystal Casting

Superalloys used in equiaxed crystal casting are chosen based on their ability to withstand extreme temperatures, mechanical stress, and corrosion. Typical superalloys include nickel-based, cobalt, titanium, and iron-based alloys, each serving specific industry needs.

Nickel-Based Alloys

Nickel-based superalloys, such as Inconel 718 and Inconel 625, are famous for high-temperature applications such as turbine blades and engine components. These alloys exhibit excellent oxidation and corrosion resistance, making them ideal for harsh environments. The fine grain structure achieved in equiaxed crystal casting enhances their high-temperature strength and fatigue resistance.

Cobalt-Based Alloys

Hastelloy alloys, such as Hastelloy C-276 and Hastelloy C-22, are favored for their resistance to corrosion in extreme environments. These alloys are used in chemical processing, aerospace, and marine applications, where parts are exposed to high temperatures and aggressive chemicals. The grain refinement achieved through equiaxed casting improves their toughness, making them suitable for parts that endure dynamic stresses.

Titanium Alloys

Ti-6Al-4V (Titanium 6Al-4V) is one of the most common titanium alloys used in aerospace applications. Titanium alloys are known for their high strength-to-weight ratio and resistance to corrosion, making them ideal for components like aircraft structures and engine parts. The fine grain structure obtained through equiaxed casting helps enhance aerospace components' toughness and fatigue resistance.

Iron-Based Alloys

Iron-based alloys are commonly used for components like turbines, exhaust systems, and structural parts in the power generation, mining, and automotive industries. These alloys are cast to achieve a fine-grain structure that improves the material's resistance to wear and fatigue.

Here’s your revised content with the embedded anchor text for the relevant post-processing blog articles:

Post-Processes Comparison

After the equiaxed crystal casting process, several post-processing steps are employed to refine the material properties further and ensure optimal final product performance. The key post-processing methods include heat treatment, hot isostatic pressing (HIP), CNC machining, and welding or repairs.

Heat Treatment

One of the primary post-casting processes, heat treatment, is crucial in enhancing the mechanical properties of equiaxed crystal castings. Heat treatment processes like solution treatment, aging, and annealing improve the material's toughness, strength, and resistance to fatigue. The heat treatment can also reduce internal stresses that may have formed during solidification, further refining the grain structure. Maximizing strength with heat treatment and enhancing alloy durability are essential steps to optimize high-temperature performance.

Hot Isostatic Pressing (HIP)

HIP is used to reduce porosity in castings by applying both high temperature and high pressure. This process improves the density of the material and eliminates microscopic voids that could compromise the integrity of the casting. HIP ensures that the material has the required mechanical properties to withstand extreme environments for superalloys used in demanding applications like gas turbines or aerospace components. HIP for eliminating porosity and improving strength are critical for enhancing the performance and lifespan of cast parts.

CNC Machining

CNC machining is essential for achieving the precise dimensions and surface finish required in high-performance components. This process allows manufacturers to machine complex geometries while maintaining tight tolerances. CNC machining can also refine the grain structure by removing surface imperfections and ensuring the material's mechanical properties meet the required standards. Superalloy CNC machining ensures high-precision manufacturing, and techniques like EDM provide further refinement for complex and hard-to-machine alloys.

Welding and Repairs

Equiaxed crystal castings may sometimes require repairs or welding to address defects or to join multiple components. Welding high-temperature superalloys is challenging due to their susceptibility to thermal stress, distortion, and cracking. However, advanced techniques such as laser welding and TIG welding repair or joining superalloy parts ensure that the grain structure and mechanical properties are preserved. Superalloy welding is vital in maintaining structural integrity and performance in extreme conditions.

Testing Methods

A range of testing methods are employed to ensure that the grain structure is optimal and that the casting will perform as expected under operational conditions. These tests assess the material's mechanical properties, including its toughness, fatigue resistance, and high-temperature performance.

Non-Destructive Testing (NDT):

Techniques such as X-ray inspection, ultrasonic testing, and CT scanning are used to identify internal defects and ensure the quality of the grain structure. NDT allows manufacturers to detect issues like porosity, cracks, or voids without damaging the casting.

Tensile and Fatigue Testing:

Tensile testing measures the material's strength and flexibility, while fatigue testing assesses its ability to withstand cyclic loading over time. The grain structure significantly influences the results of these tests, as a fine and uniform grain structure typically leads to improved tensile strength and fatigue resistance.

Corrosion and Oxidation Testing:

Superalloy components used in high-temperature and chemically aggressive environments undergo corrosion and oxidation testing to evaluate their resistance to environmental degradation. The grain structure can influence the alloy's ability to resist oxidation, as smaller grains typically provide more grain boundaries that can act as barriers to corrosion.

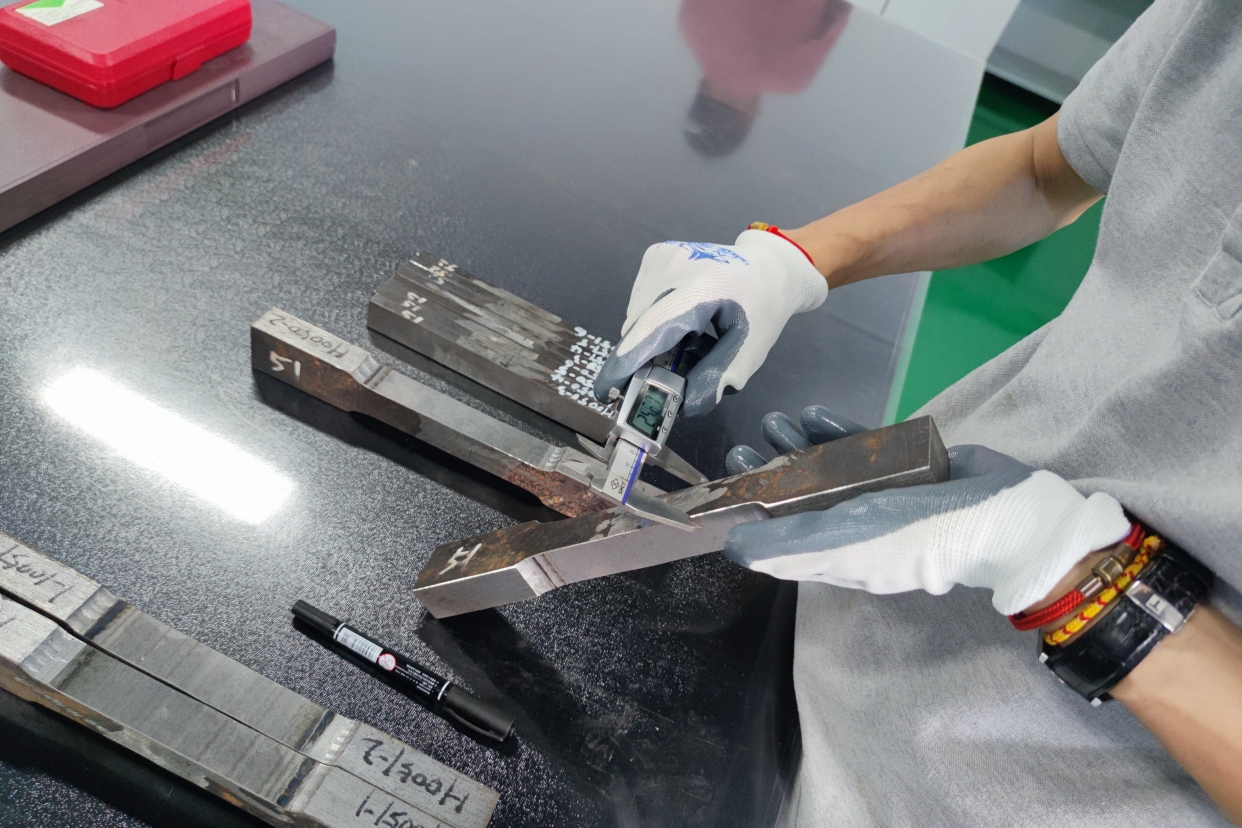

Metallographic Analysis:

Techniques like scanning electron microscopy (SEM) and optical microscopy examine the grain structure at a microscopic level. Metallographic analysis can reveal information about the grains' size, distribution, and integrity, helping manufacturers optimize the casting process and ensure consistent material properties.

Prototyping Process (Superalloy CNC Machining, Superalloy 3D Printing)

Superalloy CNC Machining

CNC machining plays a critical role in the prototyping and production of superalloy parts. This process allows manufacturers to create intricate designs with precise geometries and tight tolerances. Superalloy CNC machining also enables testing different designs to evaluate their performance before mass production. The ability to refine the material's grain structure during machining helps ensure that the final part meets the required mechanical properties. Additionally, 5-axis CNC machining enhances the accuracy of complex geometries and optimizes tool access for tight tolerances.

Superalloy 3D Printing

3D printing or additive manufacturing has become an important tool for prototyping superalloy components. The ability to print complex geometries allows for faster iterations and testing of new designs. Additionally, superalloy 3D printing can produce parts in low quantities, making it ideal for prototyping and short-run manufacturing. As with casting, controlling the grain structure in 3D printed superalloy components is crucial to ensuring their mechanical properties are on par with traditionally manufactured parts. SLM 3D printing allows for precision in layer deposition, reducing defects and enhancing material strength for high-performance applications.

Industry and Application

The benefits of grain structure control in equiaxed crystal casting are most evident in industries where parts are exposed to extreme environments. The aerospace, power generation, and oil and gas industries rely on superalloy components to maintain the reliability and safety of their critical systems.

Aerospace and Aviation

In aerospace and aviation, equiaxed crystal castings are used in turbine blades, engine components, and structural parts that operate at high temperatures and under constant mechanical stress. The fine grain structure enhances these components' toughness and fatigue resistance, making them more reliable and longer-lasting. This is especially important for components like jet engine turbine blades, which are subjected to extreme thermal and mechanical stresses during flight.

Power Generation

In power generation, components such as gas turbines, heat exchangers, and reactor parts must withstand extreme thermal and mechanical stresses. Grain structure control in equiaxed crystal casting improves the performance and durability of these components, helping them operate efficiently for longer periods. This is crucial in power plants where continuous and reliable operation is key to maintaining energy production, especially for components like heat exchanger parts and reactor vessel components.

Oil and Gas

The oil and gas industry uses superalloy castings for components like pumps, valves, and piping systems, which must endure high temperatures and corrosive environments. Grain structure is critical in ensuring these components have excellent fatigue resistance and toughness, which are essential in preventing failures in high-pressure systems. Superalloy parts like pumps and valves benefit from the improved mechanical properties that come with well-controlled grain structures.

Marine

In the marine industry, superalloy castings are exposed to both high mechanical stresses and corrosive seawater environments. Fine grain structures improve the durability and corrosion resistance of critical components like marine pumps and propellers. The controlled grain structure ensures that these parts can withstand harsh conditions, improving their service life and reducing the risk of failure.

Automotive and Mining

The automotive and mining industries rely on high-performance alloys for critical components that endure high stress and wear. The control of grain structure in casting ensures that parts like brake system accessories and mining equipment maintain their strength and performance over time, even in harsh operating conditions.

Military and Defense

In military and defense applications, components such as missile segments, armor systems, and aircraft parts must meet high standards for toughness, fatigue resistance, and high-temperature performance. Equiaxed crystal casting ensures these superalloy parts can withstand extreme conditions, offering superior strength and durability in critical defense systems. Precisely controlling grain structure is vital to performing in parts like missile segments and armor system parts.

In summary, grain structure control in equiaxed crystal casting is essential for ensuring components' performance, reliability, and safety across these demanding industries. By optimizing the grain structure, manufacturers can improve the toughness, fatigue resistance, and overall durability of critical parts used in aerospace, power generation, oil and gas, marine, automotive, mining, and military applications.

FAQs

How does grain structure control impact superalloy components' toughness and fatigue resistance in equiaxed crystal casting?

What are the key post-processing techniques used after equiaxed crystal casting to refine grain structure?

How do different superalloys, such as Inconel and Hastelloy, benefit from equiaxed crystal casting in high-temperature applications?

What role does CNC machining play in the prototyping of superalloy parts, and how does it interact with grain structure?

Why is grain structure control crucial for the performance of superalloy components in aerospace and power generation applications?