Boosting Productivity in Superalloy Manufacturing with Automated Shell Lines

The demand for superalloy components has grown steadily across multiple industries, including aerospace, defense, power generation, and oil and gas. These high-performance materials are required for applications that involve extreme temperatures, mechanical stress, and corrosive environments. The production of superalloy components relies heavily on investment casting—a process that offers excellent dimensional accuracy and the ability to create complex geometries.

Shell building is critical in determining the final component's quality within investment casting. With advancements in automation, automated shell lines have emerged as a game-changing technology, boosting productivity, enhancing quality, and reducing variability in superalloy manufacturing.

Manufacturing Process

Investment casting, also known as lost-wax casting, is an intricate process that allows manufacturers to create precision components with complex geometries. In this process, a wax pattern creates a ceramic shell, which acts as the mold for casting molten superalloy metal. Shell building is a crucial step that determines the quality and integrity of the final cast component. The shell must be strong enough to withstand high temperatures and mechanical stresses during the casting process while preserving the intricate details of the wax pattern. Advances in precision shell-building techniques and automated casting processes are central to achieving these goals.

Automated shell lines have transformed the shell-building process, allowing manufacturers to achieve greater efficiency, precision, and consistency. The shell-building process involves several key steps, including dipping the wax pattern in a ceramic slurry, draining off the excess slurry, applying stucco (a fine sand layer), and allowing each layer to dry. This process is repeated multiple times to build up a ceramic shell that is both strong and uniform. In manual shell building, these steps are performed by skilled operators, but the process is time-consuming and susceptible to variability. Manufacturers can overcome these challenges by leveraging automated dipping and coating systems and controlled ceramic coating techniques.

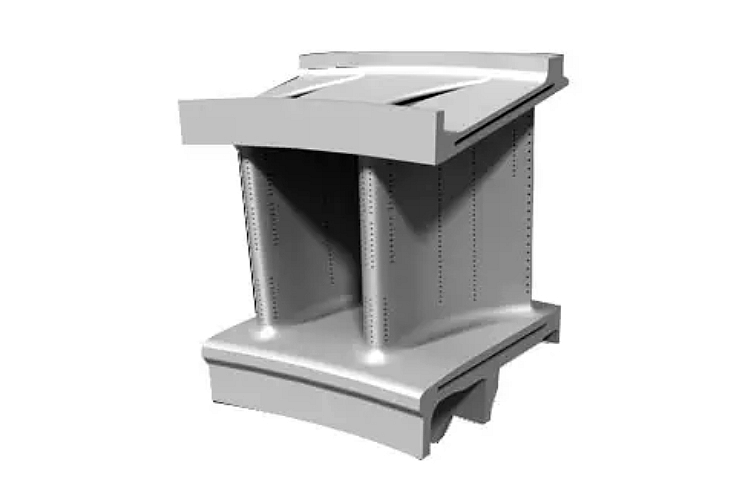

Automated shell lines control and optimize every aspect of shell building. The wax patterns are placed on a conveyor or carousel system, moving through different stations for dipping, draining, coating, and drying. Automation ensures that each layer is applied uniformly and under controlled conditions, producing a high-quality ceramic shell free from defects. Automated shell lines provide precise control over variables such as dip time, slurry viscosity, stucco application, and drying temperature, eliminating inconsistencies and achieving better repeatability. Integrating advanced process control systems and robotic automation solutions further enhances the consistency of the output.

The benefits of automation extend beyond the shell-building process. Automation also allows for faster production, as multiple wax patterns can be processed simultaneously. This leads to increased throughput, reduced cycle times, and enhanced productivity—all essential for meeting the growing demand for superalloy components in aerospace and power generation industries. In addition, automation reduces the reliance on manual labor, helping to address challenges related to labor shortages and the need for highly skilled operators. To maximize these benefits, manufacturers utilize high-capacity automated systems and innovative process enhancements to stay competitive and ensure high-quality output.

Typical Superalloys

Superalloys are widely used in investment casting because they withstand high temperatures, resist corrosion, and maintain their mechanical properties under extreme conditions. These properties make superalloys ideal for gas turbine blades, jet engine components, and chemical processing equipment applications.

Nickel-Based Superalloys

Nickel-based superalloys, such as Inconel, Rene alloys, and CMSX series, are the most commonly used in high-performance environments. These alloys offer excellent heat, oxidation, and mechanical stress resistance, making them ideal for components exposed to high temperatures and dynamic loads. Automated shell lines are especially beneficial when working with nickel-based superalloys, as they ensure a uniform shell that can withstand the thermal shock of molten metal pouring.

Cobalt-Based Superalloys

Cobalt-based superalloys, such as Stellite, are known for their exceptional wear resistance and ability to maintain strength at elevated temperatures. These alloys are often used in applications requiring wear and corrosion resistance. The precision offered by automated shell lines is crucial for casting cobalt-based superalloys, as it reduces the risk of defects like porosity or shell cracking, which can impact the component's wear resistance and performance.

Iron-Based Superalloys

Iron-based superalloys, such as Nimonic, are often used in applications requiring moderate heat resistance and cost-effectiveness. These alloys are suitable for industrial applications, including valves, exhaust systems, and furnace components. Automated shell lines help ensure the uniform quality of ceramic molds used for iron-based superalloys, contributing to consistent casting results and improved mechanical properties.

Importance of Shell Integrity

The shell's integrity is critical when casting these superalloys, as any defects in the mold can lead to defects in the final component, such as cracks, shrinkage, or dimensional inaccuracies. Automated shell lines minimize these risks by creating uniform, defect-free molds that help achieve high-quality castings with tight tolerances.

Post-Processes Comparison

Manual shell building has long been the traditional method for creating ceramic shells in investment casting. However, the process requires a significant amount of time and relies on the expertise of skilled operators to ensure consistency in shell building. Despite the skill involved, manual shell building is prone to variability, leading to inconsistencies in shell thickness, strength, and quality. Variability in shell quality can result in defects in the final casting, including porosity, dimensional inaccuracies, and even mold failure during metal pouring. Post-processing techniques like Hot Isostatic Pressing (HIP) are crucial in addressing porosity issues that arise from these inconsistencies.

Automated shell lines address these challenges by standardizing the shell-building process. Automation provides precise control over the application of each ceramic layer, ensuring that the shell has uniform thickness and strength throughout. Automating the dipping, draining, and stuccoing processes results in a more consistent shell, reducing the likelihood of defects such as cracking or mold deformation during the casting process. Using thermal barrier coatings (TBC) with high-quality shells can further protect castings from extreme conditions, enhancing their performance.

One of the most significant advantages of automated shell lines is the impact on production speed and capacity. In manual shell building, each wax pattern must be processed individually, and the drying time for each layer can vary depending on environmental conditions. Automated systems, on the other hand, can process multiple wax patterns simultaneously, significantly increasing production capacity. Automated shell lines also feature controlled drying environments, which help reduce drying times and ensure that each layer is properly cured before the next is applied. Post-casting methods such as heat treatment are more effective when shells are of consistent quality, as they help achieve the desired mechanical properties without rework.

Another key advantage of automation is the reduction in rework and rejection rates. Manual shell building can lead to inconsistencies that require extensive rework or even the scrapping of defective parts. Automated shell lines produce shells with consistent quality, reducing the need for rework and lowering the overall rejection rate. This leads to improved production efficiency and cost savings. Moreover, precision CNC machining further improves the dimensional accuracy of components, reducing the need for costly corrections after casting.

In post-casting operations, using high-quality shells from automated shell lines contributes to smoother downstream processes. For example, the shell removal process, known as knockout, is more efficient when the shell is uniformly applied and free from defects. Consistent shell quality facilitates subsequent processes such as heat treatment and machining, resulting in higher-quality superalloy components with better dimensional accuracy. This consistency ensures that the components meet stringent performance requirements, especially in demanding applications like aerospace and energy industries.

Testing

Testing is critical to ensuring that the ceramic shells and the final cast components meet the necessary quality standards. Shell integrity must be verified before casting to withstand molten metal pouring stresses. Similarly, the final superalloy components must be tested to verify that they meet the required mechanical and dimensional specifications.

Testing Methods for Ceramic Shell Quality

The quality of the ceramic shell is essential for producing high-quality castings. Several testing methods are used to verify shell quality:

Thickness Measurements

Ensuring that each layer of the ceramic shell is applied uniformly is critical. Automated systems can measure the thickness of the shell at various stages to ensure consistency.

Visual Inspections

Visual inspections detect surface defects such as cracks, chips, or uneven layers. Automated systems help reduce the occurrence of such defects, resulting in fewer issues during visual inspections.

Non-Destructive Testing (NDT)

Non-destructive techniques (NDT) such as ultrasonic testing or X-ray inspection are used to verify the internal quality of the shell and detect any hidden defects.

Industry and Application

Automated shell lines provide numerous benefits across industries that rely on high-quality superalloy components. Automated shell-building technology enhances precision, repeatability, and efficiency in the casting process, which is critical in aerospace, power generation, oil and gas, defense, automotive, and medical industries.

Aerospace and Aviation

The aerospace and aviation industry requires superalloy components that can operate reliably in extreme conditions, such as high temperatures, high pressures, and rapid thermal cycling. Automated shell lines produce components like turbine blades, guide vanes, and combustion chambers with tight tolerances. Automated shell lines help aerospace manufacturers meet the industry's stringent requirements by improving productivity and reducing defects. For example, superalloy jet engine components require precise casting processes to ensure reliable performance during flight operations under extreme temperatures and stresses.

Power Generation

In the power generation industry, superalloy components such as gas turbine blades, steam turbine components, and heat-resistant parts are critical for ensuring the efficiency and reliability of power plants. Automated shell lines enable the efficient casting of these components while maintaining high quality, reducing downtime, and improving plant productivity. Components like superalloy heat exchanger parts benefit from this technology by maintaining durability and performance under the extreme conditions found in power plants.

Oil and Gas

The oil and gas industry relies on durable superalloy components in harsh environments, including valves, pumps, and high-pressure equipment. Automated shell lines help produce these components uniformly, ensuring their resistance to wear, corrosion, and mechanical stress. For example, superalloy pump system assemblies benefit from precise casting processes, ensuring they can perform effectively in challenging environments.

Defense and Military

In defense and military applications, superalloy components must withstand the harsh conditions of military operations. Missile components, armor systems, and other defense-critical parts are cast using automated shell lines to ensure consistency and reliability. Superalloy missile segments are produced to meet strict performance and durability requirements, which are crucial for maintaining the effectiveness of defense systems.

Automotive

In the automotive industry, superalloys are used in turbochargers and high-performance exhaust systems. These components require precision casting to ensure proper function and reliability. Automated shell lines help automotive manufacturers produce high-quality, precision-cast components at scale, such as superalloy exhaust system parts. The precision and uniformity of automated processes ensure these parts can handle high-performance engines' high temperatures and mechanical stresses.

Medical and Chemical Processing

Precision casting is also used in the medical and chemical processing industries for components like surgical instruments, implants, and corrosion-resistant equipment. Automated shell lines help ensure that these components are manufactured with the required accuracy and consistency, which is crucial for safety and reliability. For example, superalloy reactor vessel components used in chemical processing must be cast to high standards to resist corrosion and maintain structural integrity under challenging conditions.

Automated shell lines are crucial in improving superalloy castings' quality, efficiency, and consistency across these industries. By reducing the likelihood of casting defects and improving productivity, this technology ensures that superalloy components meet the stringent standards required for applications in aerospace, power generation, oil and gas, defense, automotive, and medical fields. Automated shell lines enhance component quality and reduce production time and cost, making it an essential technology for industries that demand high-performance, durable components.

FAQs:

What are the key productivity benefits of using automated shell lines in superalloy manufacturing?

How do automated shell lines ensure consistent quality in ceramic shells?

What are the differences between manual and automated shell-building processes?

What testing methods are used to verify the quality of shells and superalloy castings?

Which industries benefit most from increased productivity due to automated shell lines in investment casting?