Casting Complex Geometries: Achieving Precision in Single Crystal Turbine Blades

Turbine blades are some of the most critical components in high-performance systems such as jet engines, power generation turbines, and other industrial machinery. Their design often requires intricate and complex geometries to optimize efficiency, reduce weight, and improve durability. However, casting these complex shapes while maintaining the material’s mechanical integrity, particularly in superalloys, is a formidable challenge. Single crystal turbine blades, produced with precise solidification control, are specifically designed to resist high-temperature stresses and creep deformation.

This blog explores the precision required in the casting process, the materials used, and the testing and prototyping processes to ensure the performance of turbine blades with complex geometries. Integrating advanced casting techniques, such as vacuum investment casting, helps achieve the precise tolerances and high-performance characteristics required for these critical components.

Manufacturing Process

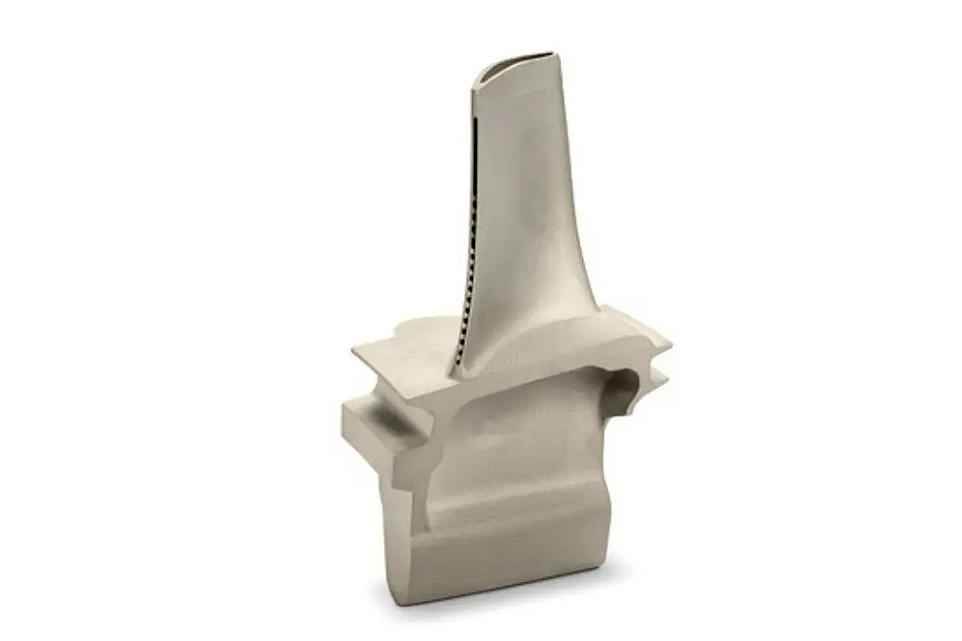

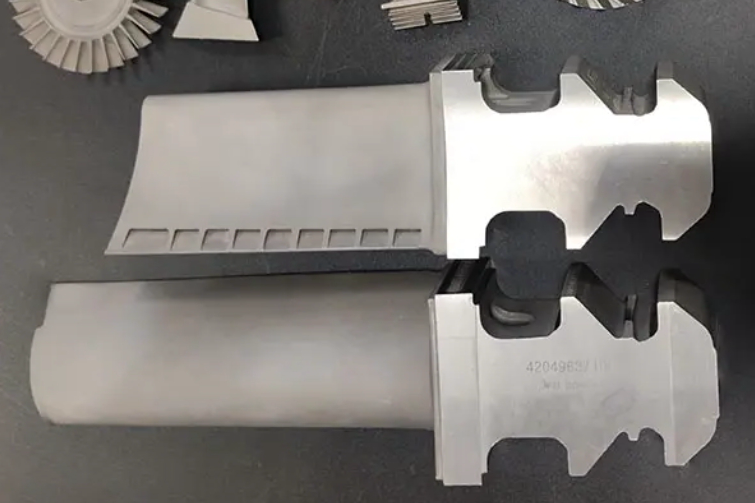

Casting turbine blades, especially those with complex geometries, requires an advanced and carefully controlled process. The most widely used method for producing these blades is vacuum investment casting. This technique is particularly suited for creating detailed, intricate shapes in high-performance alloys. In this process, a wax pattern of the turbine blade is created first. The pattern is then coated with a ceramic shell, which hardens and forms the mold. Once the shell is set, the wax is melted, leaving behind a hollow mold ready to pour molten metal. The vacuum heat treatment ensures that the final casting has the desired mechanical properties, free of oxidation or impurities.

The single crystal casting technique, which is a part of this vacuum casting process, is designed to eliminate grain boundaries, which can be a point of weakness in materials subjected to high temperatures and mechanical stresses. Single crystal casting is achieved by controlling the cooling rate during solidification, allowing the molten metal to form a continuous crystal structure from the base upwards. The result is a turbine blade with no grain boundaries, significantly improving its creep resistance and overall durability under stress. Post-process heat treatment further enhances the material's strength and performance at high temperatures.

A critical aspect of this process is directional solidification. This refers to controlling the cooling rate and direction during the casting to ensure the metal solidifies in the desired direction, typically from the blade's root to the tip. This helps in aligning the crystal structure along the blade’s primary stress axis, further enhancing the turbine blade's strength and longevity. Proper directional solidification minimizes defects such as porosity and ensures a uniform microstructure throughout the blade. Superalloy CNC machining is used to achieve the precise finish and tight tolerances needed for complex turbine blade geometries.

Additionally, mold design and precision control are crucial when casting complex geometries. The design of the mold needs to support the detailed features of the turbine blade, including cooling channels, aerodynamic contours, and other intricacies that more straightforward casting methods cannot achieve. Advanced mold materials, like advanced ceramics, are used to withstand the high temperatures involved in the casting process while allowing for the creation of fine features and tight tolerances. Superalloy precision forging can also be integrated into the process to refine the shape and mechanical properties of the turbine blade, ensuring optimal performance.

Typical Superalloys Used for Complex Geometries

The alloys used in the casting of turbine blades need to be highly resistant to oxidation, thermal fatigue, and creep. Nickel-based superalloys are the most commonly chosen materials for turbine blades due to their ability to withstand extreme temperatures and stresses. These superalloys, such as Inconel 718, CMSX-10, Rene 104, and CMSX-486, are engineered to perform well in the high-temperature environments found in gas turbines and jet engines. For more details on casting superalloys, visit Neway's Casting Services.

Inconel 718 is one of the most widely used alloys for turbine blades due to its excellent resistance to high-temperature oxidation and creep. This alloy balances high strength, good weldability, and ease of processing, making it ideal for turbine blades that need to withstand high thermal and mechanical stresses.

CMSX-10 and CMSX-486 are examples of single-crystal alloys specifically designed for use in turbine blades. These alloys contain high levels of rhenium, tantalum, and molybdenum, which enhance their high-temperature creep resistance, making them suitable for the hottest sections of turbine engines. The presence of these elements ensures the blades can perform in temperatures exceeding 1,000°C.

Rene 104 is another advanced alloy used in the aerospace and power generation sectors. Known for its high strength at elevated temperatures, it is often used to produce critical turbine components, including blades that require high thermal stability and resistance to oxidation.

The alloy selection process is critical when casting complex geometries, as the alloy must not only withstand the extreme conditions in which the turbine operates but also retain its mechanical properties when shaped into intricate forms. The precise control of alloy composition helps to ensure that the blade can perform efficiently in these challenging conditions.

Post-Processing for Precision and Performance

After the turbine blade is cast, several post-processing steps are necessary to enhance its mechanical properties further and ensure it meets industry standards. These post-processes are particularly important for turbine blades with complex geometries, as the intricate shapes can challenge achieving uniform material properties and surface finishes. Post-processing techniques like superalloy CNC machining and superalloy deep hole drilling are often employed to achieve the precision needed for these critical components.

Heat treatment is one of the most critical post-processing steps for turbine blades. The cast blade is heated to a specific temperature during heat treatment and then cooled under controlled conditions. This process allows the material to undergo phase transformations that improve its mechanical properties, such as precipitation hardening and stress relief. Heat treatment enhances properties like creep resistance, while thermal barrier coatings (TBC) further protect the blade’s surface from extreme temperatures.

Hot Isostatic Pressing (HIP) eliminates the cast blade's internal voids or porosity. HIP involves subjecting the blade to high pressure and temperature in an inert gas environment, which forces the material to densify and eliminates any gas pockets that could affect its performance. This process is beneficial for ensuring that the final product has uniform density and structural integrity, especially in complex geometries where defects are more difficult to detect. The benefits of HIP are evident in the enhanced durability and strength of high-temperature alloy components, particularly for aerospace and energy applications.

Surface finishing techniques like grinding and polishing are essential to ensure that the blade has a smooth surface, is free from defects, and has the desired aerodynamic properties. The complex geometries of turbine blades mean that small imperfections or rough areas on the surface can significantly affect their performance. After the surface is finished, thermal barrier coatings (TBC) are often applied to the blades to enhance their thermal resistance. TBCs act as a protective layer that insulates the blade from extreme temperatures, thereby reducing heat transfer and improving the overall longevity of the turbine.

These post-processing techniques, including heat treatment, superalloy welding, HIP, and surface finishing, are crucial in optimizing turbine blade performance and ensuring it can withstand the demanding conditions in the aerospace and energy sectors. By implementing these processes, manufacturers can significantly enhance the lifespan and reliability of turbine blades and other high-temperature components.

Testing and Quality Control

To ensure that turbine blades with complex geometries perform as expected, they undergo a rigorous testing and quality control process. Various non-destructive testing (NDT) methods are used to detect internal defects, ensure the precision of the blade’s geometry, and verify that the material properties meet the required standards.

X-ray Inspection and CT Scanning

X-ray inspection and CT scanning are commonly used to detect internal defects, such as voids, cracks, and inclusions, that may compromise the strength of the turbine blade. These non-invasive techniques allow manufacturers to ensure that the complex internal structures of the blade are free from flaws, which is particularly important in components with intricate geometries.

Metallographic Analysis

Metallographic analysis is another crucial part of quality control. This process examines the material's microstructure to verify that the crystal orientation and grain structure align with the specifications. Techniques like electron backscattering diffraction (EBSD) are used to analyze the alignment of the crystal lattice and confirm that the blade’s structure is consistent with the desired single-crystal orientation.

Mechanical Testing

Mechanical testing also evaluates the blade’s strength, flexibility, and fatigue resistance. Tensile testing measures the material’s response to stretching forces, while creep testing evaluates the material’s ability to resist deformation under constant stress at high temperatures. Fatigue testing simulates the stresses the blade will experience during its operational life, helping engineers assess its durability.

High-Temperature Testing

Additionally, high-temperature testing is carried out to ensure the blade performs well under the extreme conditions it will face in service. This testing includes thermal cycling, where the blade is exposed to repeated heating and cooling to simulate the operational environment of gas turbines and jet engines.

Prototyping Process for Complex Turbine Blades

Prototyping is a key step in developing turbine blades with complex geometries. As manufacturing techniques evolve, superalloy CNC machining and superalloy 3D printing are increasingly important for producing and refining these components.

Superalloy CNC machining is widely used to refine the shape and dimensions of turbine blades post-casting. CNC machines can achieve precise tolerances and surface finishes, even for complex geometries. This method is particularly effective for removing excess material and fine-tuning the blade to the required specifications.

Superalloy 3D printing is another emerging technology that rapidly produces prototypes with highly intricate geometries. 3D printing enables the creation of turbine blades with features such as cooling channels and complex airfoil shapes that would be difficult to achieve using traditional casting or machining methods. Additionally, 3D printing offers faster iteration cycles, which allows engineers to test multiple design variations before settling on the optimal configuration.

When comparing CNC machining and 3D printing, both techniques have their strengths. CNC machining is highly accurate and ideal for parts with tight tolerances, but it is limited by the complexity of the shapes that can be produced. On the other hand, 3D printing offers more design freedom and allows for creating complex, lightweight structures, but may not always provide the same level of precision as traditional machining.

Industry Applications and Benefits

Single crystal turbine blades with complex geometries are critical to system performance across various industries. These blades offer unparalleled mechanical properties and thermal stability, making them ideal for demanding applications where high efficiency, durability, and performance are crucial.

Aerospace and Aviation

In the aerospace and aviation, turbine blades are essential for efficient and reliable jet engines. These blades must withstand extremely high temperatures and stresses, and their complex geometries help optimize fuel efficiency, reduce weight, and enhance performance. Single crystal turbine blades with intricate designs are especially important in jet engine components, where they can improve thermal resistance and strength under load, allowing aircraft engines to operate at peak performance over extended periods.

Power Generation

In the power generation industry, turbine blades are used in gas and steam turbines to generate electricity. The blades' precision directly impacts the turbines' efficiency and overall energy output. Complex geometries, made possible by advanced casting techniques like single crystal casting, allow for more effective heat and stress distribution within the turbine, significantly improving the efficiency and longevity of power generation systems.

Oil and Gas

The oil and gas industry also relies on turbine blades with complex geometries for pumps, compressors, and other critical components used in extreme conditions. The ability to cast intricate, durable turbine blades ensures performance in harsh environments such as offshore rigs or petrochemical refineries. These complex blades offer enhanced resistance to high temperatures, corrosion, and mechanical stress, ensuring that the high-temperature alloy pump components can operate reliably even in the most demanding applications.

Military and Defense

In the military and defense sectors, turbine blades with complex geometries are used in propulsion systems for aircraft and naval vessels. The precision and durability of these blades are essential for ensuring the performance and safety of military engines. Whether in jet engines or missile components, the ability to cast intricate turbine blades allows for superior performance under extreme operational conditions.

Energy and Renewable Sectors

As the demand for cleaner and more efficient energy systems grows, turbine blades with complex geometries will play an increasingly important role in energy and renewable sectors like wind power. The ability to manufacture highly optimized, durable blades will enhance energy conversion efficiency and increase the overall reliability of turbines used in both traditional and renewable power generation.

FAQs

What are the key challenges in casting complex geometries for turbine blades?

How does single crystal casting improve the performance of turbine blades?

What are the advantages of using Inconel 718 in turbine blade manufacturing?

How do post-processing techniques like HIP and heat treatment affect the performance of turbine blades?

What are the main differences between CNC machining and 3D printing in turbine blade prototyping?