Custom Melting Parameters for Advanced Superalloy Components Manufacturing

In the advanced manufacturing of superalloy components, achieving optimal performance under extreme conditions requires meticulous control over the melting process. Superalloys are designed to maintain high strength, resistance to oxidation, and exceptional thermal stability in high-temperature environments. Custom melting parameters, tailored to specific materials and processes, are crucial for ensuring these high-performance components' superior mechanical properties and reliability.

Different processes, such as vacuum investment casting, single crystal casting, powder metallurgy, forging, and 3D printing, require precise melting conditions to produce parts with the desired characteristics. By optimizing these parameters, manufacturers can meet the demanding specifications of aerospace, energy, and defense industries.

Different Superalloy Manufacturing Processes that Require Custom Melting Parameters

The melting process plays a pivotal role in shaping the microstructure and performance of superalloy components. Each manufacturing process benefits from custom melting parameters to ensure the final part meets stringent quality and performance standards.

Vacuum Investment Casting: This process is widely used to produce complex superalloy components, especially for aerospace and turbine applications. Melting under a vacuum environment ensures minimal contamination, as it prevents oxidation during the pouring process. Precisely controlling temperature, melt rate, and mold materials in vacuum casting leads to superior surface finishes and reduced porosity, which is critical for components subjected to high thermal stresses.

Single Crystal Casting: Single crystal superalloys are often used in turbine blades and other high-performance applications. In this process, custom melting parameters ensure that the alloy solidifies as a single crystal, essential for optimal mechanical properties. The right melting temperature, cooling rate, and directional solidification conditions are necessary to eliminate grain boundaries and avoid defects like hot tears and inclusions. This results in higher fatigue resistance and better creep properties at elevated temperatures.

Equiaxed Crystal Casting: Unlike single crystal casting, equiaxed crystal casting involves solidification, where the crystals form randomly in all directions. Custom melting parameters in this process are critical for achieving the right grain structure, which directly influences the strength and toughness of the material. The temperature gradient during solidification, combined with melt rate control, helps achieve a fine, uniform grain size, enhancing mechanical performance, especially for structural components like engine casings.

Directional Casting: Directional casting creates parts with improved mechanical properties, particularly at high temperatures. Custom melting parameters are essential for promoting the controlled solidification of the superalloy along a specific direction, usually from one end to the other. This results in a directional grain structure that enhances the component's strength, particularly under thermal and mechanical stress. In gas turbine blades, for example, directional casting allows the alloy to resist creep and fatigue at elevated temperatures, making it a critical process for high-performance applications.

Powder Metallurgy Turbine Disc: In powder metallurgy (PM), superalloy powders are melted and consolidated into a solid form. The melting process in PM typically involves using a plasma arc or electron beam to achieve the necessary temperature for sintering or sintering and fusion. The custom melting parameters in PM determine the powder's particle size, distribution, and flowability, which are crucial for achieving high-density components. Superalloy turbine discs and other high-performance parts benefit from this process, producing a homogeneous microstructure with improved material properties.

Superalloy Precision Forging: Superalloy forging involves heating the material to a high temperature and shaping it into the desired form using mechanical force. The custom melting process for forging ensures that the alloy reaches the correct forging temperature, improving its malleability and reducing the chances of defects during deformation. The melting parameters also influence the subsequent cooling process, essential for achieving the right balance between hardness and toughness in forged parts like turbine discs and shafts.

Superalloy CNC Machining: After casting or forging, many superalloy components undergo CNC machining for the final shape and surface finish. Custom melting parameters influence the hardness and microstructure of the material, affecting its machinability. By controlling the melting process, manufacturers ensure that the material balances strength and machinability, allowing precision machining while maintaining the required mechanical properties.

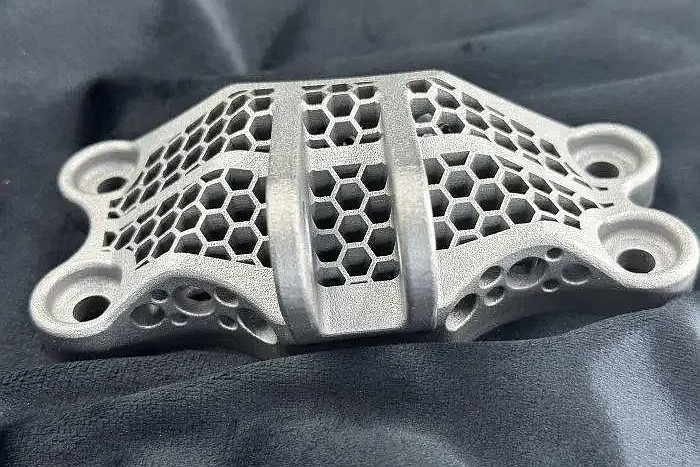

Superalloy 3D Printing: Additive manufacturing or 3D printing of superalloys is gaining traction in industries such as aerospace and defense. The custom melting parameters in 3D printing ensure the accurate fusion of metal powders layer by layer. The laser or electron beam used in 3D printing must have the power, speed, and spot size to precisely melt the powder and form strong bonds between layers. This process allows for creating complex geometries that are difficult or impossible to achieve with traditional manufacturing methods.

Typical Superalloys Used in High-Performance Applications

Different superalloys are used in various industries depending on their specific properties, such as high-temperature strength, oxidation resistance, and corrosion resistance. The choice of superalloy and its melting parameters must align with the intended application.

Inconel Alloys

Inconel alloys, such as Inconel 718 and Inconel 625, are well-known for their high-temperature strength and excellent resistance to oxidation and corrosion. They are commonly used in aerospace, power generation, and chemical processing applications. Custom melting parameters ensure the alloy has a fine, uniform grain structure and optimal mechanical properties for turbine blades, jet engine components, and heat exchangers.

CMSX Series

The CMSX series of alloys, including CMSX-10 and CMSX-486, are used for advanced single-crystal applications, particularly in gas turbines. These superalloys are designed to withstand extreme conditions at high temperatures. Custom melting parameters in single-crystal casting are crucial for achieving the defect-free, single-crystal structure needed for components like turbine blades that operate under high mechanical and thermal stresses.

Hastelloy Alloys

Hastelloy alloys, such as Hastelloy C-276 and Hastelloy X, are widely used in chemical processing, aerospace, and nuclear applications due to their excellent resistance to corrosion in aggressive environments. The melting process for Hastelloy alloys must ensure the alloy's chemical homogeneity and high oxidation resistance, especially in components exposed to high-temperature corrosive conditions, such as exhaust systems and reactor components.

Titanium Alloys

Titanium alloys like Ti-6Al-4V and Ti-5Al-5V-5Mo are essential in aerospace and marine applications due to their high strength-to-weight ratio and excellent corrosion resistance. Custom melting parameters are essential to ensure these alloys maintain their mechanical properties while being processed into complex components such as structural parts, turbine blades, and heat exchangers.

Rene Alloys

Rene alloys, including Rene 104 and Rene N6, are high-performance superalloys used in aerospace and power generation applications. These alloys require precise melting parameters to maintain their excellent high-temperature performance, oxidation resistance, and creep resistance in components that operate in harsh environments, such as gas turbines and combustion chambers.

Comparison of Post-Processes for Superalloy Components

Post-processing steps are often necessary to enhance the mechanical properties, surface finish, and overall quality of superalloy components. After the initial melting and forming processes, various post-processes, such as heat treatment, hot isostatic pressing (HIP), and welding, are performed.

Heat Treatment

Heat treatment is crucial in superalloy manufacturing to refine the microstructure and achieve the desired mechanical properties. Custom heat treatment parameters, such as temperature, time, and cooling rate, are adjusted to optimize the alloy’s strength, hardness, and resistance to creep. For example, aging treatments can be applied to improve the yield strength of alloys like Inconel 718 and CMSX-10. The heat treatment process ensures optimal durability for components used in extreme environments.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a post-process that removes porosity and enhances material density. The process involves subjecting the superalloy components to high pressure and temperature, which helps eliminate internal voids and creates a uniform microstructure. Custom melting parameters during the casting phase help ensure the material responds well to HIP, improving fatigue resistance and component reliability. This process plays a key role in boosting strength and increasing the lifespan of critical components like turbine blades.

Welding and Joining

Welding is often required to join superalloy components, especially in large assemblies. The melting parameters for welding must be carefully controlled to avoid issues like excessive grain growth, cracks, and distortion. Superalloy welding requires precise heat input and cooling rates to ensure solid and defect-free joints that can withstand high temperatures and mechanical stresses. Welding is also critical in repairing and adding layers to enhance component strength and durability.

Surface Coatings

After forming, superalloy components may undergo surface coating processes such as thermal barrier coating (TBC) to improve oxidation resistance and thermal insulation properties. The custom melting parameters for coating application are critical to ensuring strong adhesion and uniform coverage. This is especially important for components exposed to high-temperature environments where thermal protection is essential for enhancing performance.

3D Printing Post-processing

After 3D printing, superalloy parts undergo post-processing like sintering, annealing, and surface finishing. These processes enhance the material properties by improving layer bonding, reducing internal stresses, and ensuring that the final part meets the desired specifications. Post-processing also ensures that precision is maintained for complex geometries, especially for parts with intricate cooling channels or fine features.

Testing Methods for Superalloy Components

Several testing methods are employed to ensure that superalloy components meet stringent performance standards. These methods verify the mechanical properties, integrity, and functionality of parts produced from custom-melted superalloys.

Tensile Testing: Tensile testing measures superalloy components' strength and elongation properties under applied stress. This is crucial for parts that must withstand high loads, such as turbine blades and engine components. The results help determine the alloy’s suitability for specific applications regarding strength, flexibility, and performance under stress. Tensile testing is critical for evaluating the part's ability to withstand mechanical loading, ensuring its reliability in demanding environments.

Fatigue Testing: High-temperature fatigue testing is essential to assess the ability of superalloy components to resist failure under cyclic loading conditions. This is particularly important for components in turbines and engines that experience repeated thermal and mechanical stresses. Fatigue testing helps to evaluate how parts perform under repeated stresses and ensures their long-term durability.

X-ray and Ultrasonic Testing: These non-destructive testing methods detect internal defects, such as porosity, cracks, and inclusions, that could compromise the structural integrity of the components. Custom melting parameters ensure the material is free from defects that could lead to failure in critical applications. X-ray and ultrasonic testing help manufacturers ensure that parts are free of internal defects that could compromise their performance in high-stress applications.

Metallographic Analysis: Metallographic analysis involves examining the microstructure of superalloy components using techniques such as scanning electron microscopy (SEM) and optical microscopy. This analysis helps assess grain structure, phase distribution, and the presence of defects, allowing manufacturers to verify that the components meet the required specifications. Metallographic analysis provides valuable insights into the grain structure and potential flaws that could affect the component's performance.

Thermal Conductivity and Expansion Testing: Thermal conductivity and expansion tests are essential for evaluating the performance of superalloys in high-temperature environments. Custom melting parameters can influence the thermal properties, which are critical for applications such as jet engines, where materials must efficiently conduct heat or withstand thermal expansion. Thermal conductivity and expansion testing are essential for determining how materials will perform under extreme thermal conditions, ensuring their reliability in applications like turbines and aerospace components.

Testing Methods for Superalloy Components

Several testing methods are employed to ensure that superalloy components meet stringent performance standards. These methods verify the mechanical properties, integrity, and functionality of parts produced from custom-melted superalloys.

Tensile Testing: Tensile testing measures superalloy components' strength and elongation properties under applied stress. This is crucial for parts that must withstand high loads, such as turbine blades and engine components. The results help determine the alloy’s suitability for specific applications regarding strength, flexibility, and performance under stress.

Fatigue Testing: High-temperature fatigue testing is essential to assess the ability of superalloy components to resist failure under cyclic loading conditions. This is particularly important for components in turbines and engines that experience repeated thermal and mechanical stresses. Fatigue testing ensures that superalloy parts meet the rigorous demands of high-temperature environments and maintain performance over extended operational cycles.

X-ray and Ultrasonic Testing: These non-destructive testing methods detect internal defects, such as porosity, cracks, and inclusions, that could compromise the structural integrity of the components. Custom melting parameters ensure the material is free from defects that could lead to failure in critical applications. Non-destructive testing for superalloy components helps preserve material integrity while identifying potential risks.

Metallographic Analysis: Metallographic analysis involves examining the microstructure of superalloy components using techniques such as scanning electron microscopy (SEM) and optical microscopy. This analysis helps assess grain structure, phase distribution, and the presence of defects, allowing manufacturers to verify that the components meet the required specifications. Techniques such as Electron Backscattering Diffractometer (EBSD) provide insights into the crystallographic orientation and phase distributions, improving the understanding of component reliability.

Thermal Conductivity and Expansion Testing: Thermal conductivity and expansion tests are important for evaluating the performance of superalloys in high-temperature environments. Custom melting parameters can influence the thermal properties, which are critical for applications such as jet engines, where materials must efficiently conduct heat or withstand thermal expansion. Thermal testing ensures that materials perform as required under extreme thermal conditions.

Industry Applications and Importance of Custom Melting Parameters

Superalloys are essential in various industries where components must withstand extreme conditions, such as high temperatures, corrosion, and mechanical stresses. Custom melting parameters are critical for tailoring superalloy properties to meet each industry's specific requirements.

Aerospace

Superalloys are used extensively in the aerospace and aviation industry for turbine blades, engine components, and exhaust systems. Custom melting ensures that these components can operate reliably under high temperatures and mechanical stresses in jet engines. Additionally, for high-performance applications, the superalloy jet engine components require precise melting parameters to ensure superior thermal stability and resistance to oxidation.

Energy and Power Generation

In power generation, superalloys are used in gas turbines, reactors, and heat exchangers. Custom melting parameters optimize these materials for high thermal resistance and long-term durability, ensuring the efficiency and safety of energy systems. Components like superalloy heat exchanger parts are crucial for maintaining thermal efficiency under harsh operating conditions, where precise alloy composition ensures longevity and reduced maintenance costs.

Oil & Gas

The oil and gas industry relies on superalloys for drilling tools, pumps, and valves, where custom melting parameters are crucial for ensuring resistance to corrosion and high-pressure environments. High-performance pump components and related parts must be fabricated using specific melting techniques to resist the harsh chemical and physical stresses encountered during oil extraction and transportation.

Chemical and Pharmaceutical Industries

Superalloys are used in reactors, valves, and pumps where resistance to corrosive chemicals and high temperatures is essential. In the chemical processing and pharmaceutical and food industries, custom melting ensures that the alloys maintain their strength and durability under harsh operating conditions. Components such as superalloy reactor vessel parts are critical in maintaining structural integrity and minimizing downtime in chemical and pharmaceutical plants.

Marine and Military Applications

In marine and military and defense applications, superalloys are used for components like propellers, exhaust systems, and armor plates. Custom melting ensures that these components can withstand the mechanical and environmental challenges they face in service. For instance, superalloy armor system parts ensure high strength and durability in extreme conditions, offering protection against physical and thermal stresses.

FAQs

What are the key factors that influence custom melting parameters in superalloy manufacturing?

How does single crystal casting differ from other casting processes regarding melting parameters?

What role does powder metallurgy play in the production of high-performance superalloy components?

Why is post-processing essential for enhancing the properties of superalloy components after casting or forging?

How do testing methods help ensure the quality and performance of superalloy components in critical applications?