Directional Solidification: Achieve Superior Mechanical Properties in Turbine Blades

Turbine blades are critical in many high-performance applications, especially in aerospace, power generation, and oil and gas industries. These components are subjected to extreme conditions such as high temperatures, mechanical stresses, and thermal cycling, making them vital for turbine engines' safe and efficient operation. One of the most effective ways to enhance the mechanical properties of turbine blades is through directional solidification, a process that promotes the growth of a single crystal or well-aligned grain structure to improve its resistance to high-temperature deformation and creep.

In this blog, we will explore how directional solidification contributes to achieving superior mechanical properties in turbine blades, detailing the manufacturing process, typical superalloys, post-processing techniques, testing, and prototyping methods, along with their industrial applications.

Manufacturing Process of Directional Solidification in Turbine Blades

Directional solidification is a specialized technique used to control how molten metal solidifies into a crystalline structure. This process is critical in turbine blade manufacturing because the resulting crystal orientation significantly impacts the material's mechanical properties, such as creep resistance, fatigue strength, and thermal stability. Manufacturers can create blades that exhibit enhanced performance under high-temperature and high-stress conditions by carefully controlling the solidification process. Superalloy Heat Treatment and Vacuum Heat Treatment are essential post-processing steps that help improve the material's mechanical properties.

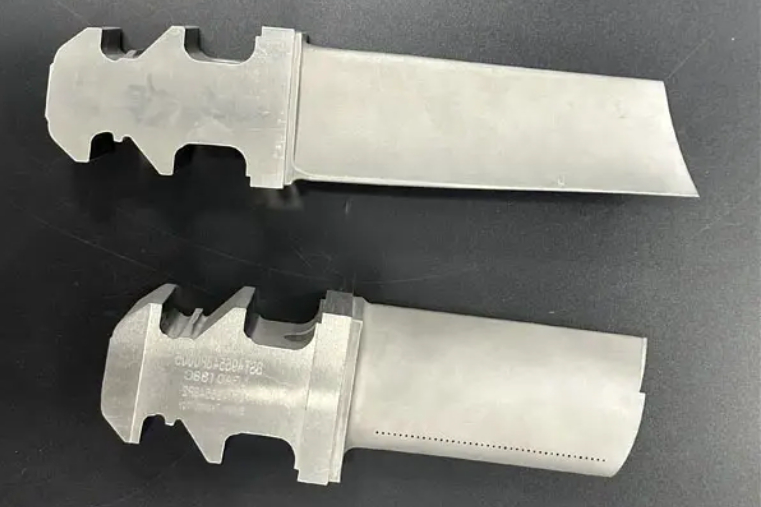

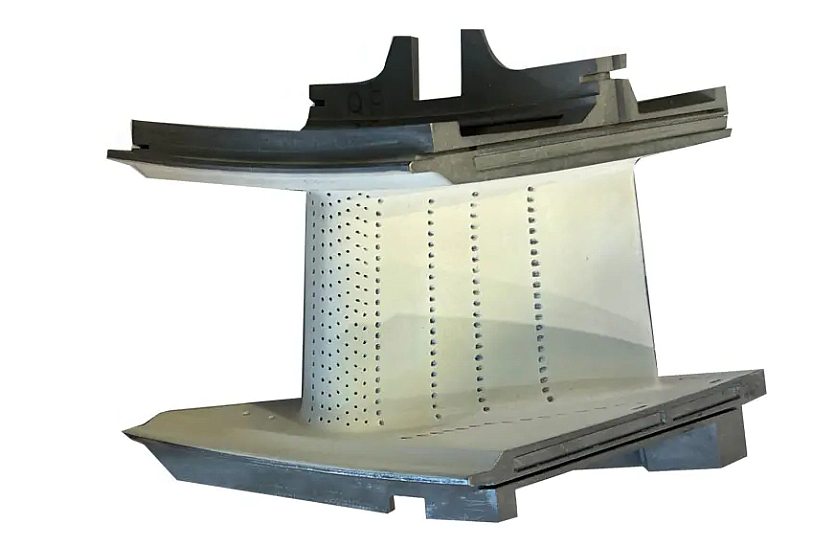

The vacuum investment casting process is the primary method for producing turbine blades with directional solidification. In this method, a ceramic mold is created around a pattern made of wax or another material. The wax pattern is then melted and drained, leaving behind a mold cavity. The mold is then heated in a vacuum environment to a temperature where molten superalloy can be poured into it, filling it and taking its shape. Hot Isostatic Pressing (HIP) is another crucial post-processing technique used to improve the overall quality and performance of the casted parts.

Special attention is paid to the temperature gradients within the mold for directional solidification. The solidification process is controlled to promote the growth of crystals in a specific direction, typically from the root of the turbine blade upward. This is achieved by introducing a controlled cooling rate and temperature gradient within the mold. In many cases, a seed crystal is placed at the base of the mold to encourage crystal growth in a particular direction, resulting in a single crystal or directionally solidified structure. The goal is to minimize the formation of grain boundaries, which are typically weaker points in materials, thereby improving the blade’s mechanical properties, especially under high-stress conditions. Superalloy CNC Machining ensures the precision of these complex parts, making them fit for high-performance applications.

The directional solidification process is also optimized to minimize internal stresses and defects. A carefully controlled cooling rate ensures that the molten superalloy solidifies uniformly, which helps eliminate casting defects such as porosity, segregation, and cracks. By guiding the crystallization in the desired direction, manufacturers can significantly enhance the creep resistance of the final product. Post Process Heat Treatment and Thermal Barrier Coating (TBC) are key steps that further enhance the blade’s durability and performance under extreme conditions.

Typical Superalloys for Directional Solidification

The success of directional solidification in turbine blade production depends heavily on the choice of material. Nickel-based superalloys are the most commonly used materials for turbine blades due to their excellent high-temperature strength, oxidation resistance, and creep resistance. These superalloys typically contain a mixture of nickel, chromium, cobalt, and other alloying elements, which provide the required mechanical properties for high-performance applications. More information about these alloys and casting techniques can be found at Neway Aerotech and their Vacuum Investment Casting Services.

Some of the typical superalloys used for directional solidification in turbine blades include:

Inconel 718: One of the most widely used superalloys for turbine blades, Inconel 718 is known for its excellent high-temperature strength and good weldability. It is commonly used in turbine engines and gas turbines.

Rene 104: A high-performance alloy with elements like cobalt and rhenium to enhance strength and creep resistance at elevated temperatures, making it suitable for the most demanding turbine blade applications.

CMSX-486: A nickel-based superalloy explicitly designed for single crystal casting. It contains high levels of rhenium and other elements to increase creep resistance and thermal stability at very high temperatures.

Rene 80: Another superalloy often used in single crystal applications, designed to offer superior resistance to oxidation and creep at extremely high temperatures.

Post-Processing Techniques for Turbine Blades

After casting and solidifying the turbine blades, they undergo several post-processing steps to improve their mechanical properties and extend their operational life. These processes address any imperfections that may arise during casting and optimize the material for high-temperature performance, which is critical in industries like aerospace and energy.

Heat Treatment is one of the most essential post-processing steps for turbine blades. After the casting process, the blades are subjected to a heat treatment cycle that involves heating them to a specific temperature and then cooling them in a controlled manner. This process serves multiple purposes:

Relieving Residual Stresses: The casting process can introduce internal stresses that can lead to deformation or cracking. Heat treatment helps to relieve these stresses, ensuring the blade maintains its shape and mechanical integrity.

Precipitation Hardening: Heat treatment promotes the formation of fine precipitates, such as gamma prime (γ'), that enhance the strength of the alloy by hindering dislocation motion. This makes the blade more resistant to deformation under high stress.

Improving Creep Resistance: By optimizing the microstructure, heat treatment helps improve the creep resistance of the turbine blade, which is critical for maintaining its shape and performance at high temperatures over extended periods. Heat treatment enhances alloy durability, extending the life of turbine blades exposed to extreme conditions.

Hot Isostatic Pressing (HIP) is another crucial post-process that improves the quality of turbine blades. HIP involves subjecting the blades to high pressure and temperature in an inert gas environment. This process eliminates any residual porosity and densifies the material, improving its strength and ensuring that the turbine blade has the integrity required to perform under extreme conditions. HIP eliminates porosity and boosts the mechanical properties of high-temperature alloys, making it essential for turbine blade manufacturing.

Surface Coatings are applied to turbine blades to protect them from oxidation and high-temperature corrosion. The most common coating used is the thermal barrier coating (TBC). TBCs are ceramic-based coatings that provide an insulating layer, reducing the heat that reaches the underlying metal and protecting the blade from the damaging effects of high temperatures. These coatings can significantly extend the life of turbine blades, particularly in environments exposed to combustion gases and high-temperature oxidizing conditions. TBCs enhance performance and provide a critical defense against thermal cycling and oxidation.

Welding and Repair processes are also employed to repair any damage to turbine blades during service. Modern welding techniques, such as laser or electron beam welding, restore the blade’s integrity without compromising its mechanical properties or crystal structure. These advanced welding methods ensure that the repaired areas maintain the blade’s structural integrity and perform optimally in high-stress environments.

Testing and Quality Assurance for Directionally Solidified Turbine Blades

Ensuring the performance and durability of turbine blades requires thorough testing and quality assurance. Several testing methods are employed to assess the mechanical properties of the blades, including their ability to withstand high temperatures, creep, and mechanical stresses.

Tensile and Creep Testing

Tensile testing and creep testing are essential for determining the blade’s strength and resistance to long-term deformation. The blade is subjected to tensile stress in tensile testing to determine its strength and flexibility. In contrast, in creep testing, the material is exposed to stress over extended periods at elevated temperatures to simulate real-world operating conditions.

X-ray and CT Scanning

X-ray and CT Scanning are non-destructive testing (NDT) methods used to detect any internal defects or voids in the blade. These methods detect defects such as porosity, cracks, or inclusions that could compromise the blade’s performance.

Metallographic Analysis

Metallographic analysis is used to examine the microstructure of the turbine blade and ensure that the desired grain structure or single crystal orientation has been achieved. Techniques such as electron backscatter diffraction (EBSD) are used to analyze the crystal structure and ensure the absence of unwanted grain boundaries or defects.

High-Temperature Testing

High-temperature testing simulates the extreme conditions that turbine blades will face in operation. This includes dynamic and static fatigue testing, where the blades are subjected to mechanical loading and thermal cycling to evaluate their long-term durability and performance.

Prototyping of Directionally Solidified Turbine Blades

The prototyping process for turbine blades typically involves advanced manufacturing techniques, including superalloy CNC machining and 3D printing. These methods allow manufacturers to produce high-quality prototypes that can be tested and refined before full-scale production.

Superalloy CNC machining is used to refine turbine blades after casting, ensuring they meet tight tolerances and surface finish requirements. CNC machines can produce exact geometries, allowing for the fine-tuning of the blade design.

Superalloy 3D printing is an emerging technology that can produce complex blade geometries that would be difficult or impossible to achieve using traditional methods. 3D printing allows for rapid prototyping and design iteration, allowing testing of different blade designs before committing to full-scale manufacturing.

Comparison of CNC Machining vs. 3D Printing

While CNC machining is highly accurate and ideal for refining turbine blades, it is limited in terms of the complexity of the geometries it can produce. On the other hand, 3D printing offers greater flexibility in design but may not consistently achieve the same level of precision as CNC machining. Both methods are complementary, and their use depends on the project's specific requirements.

Industry Applications and Benefits of Directional Solidification

Directional solidification is critical to producing turbine blades used in various industries. The benefits of this process are especially evident in sectors that demand high-performance components capable of withstanding extreme operational conditions.

Aerospace and Aviation

In aerospace and aviation, turbine blades are subjected to high temperatures and mechanical stresses in jet engines. Directionally solidified blades provide the necessary strength and durability to operate in these harsh environments, contributing to improved fuel efficiency and extended engine life. This process enhances the blades' ability to resist thermal fatigue and mechanical deformation, allowing for longer-lasting, more reliable performance in critical flight systems.

Power Generation

In the power generation industry, directional solidified turbine blades are used in gas and steam turbines to enhance efficiency and longevity. By improving the blades' creep resistance and thermal stability, power plants can operate more efficiently, reducing maintenance costs and downtime. The superior properties of directionally solidified materials, such as superalloy heat exchanger parts, contribute to power generation systems' durability and operational efficiency, making them more sustainable over time.

Oil and Gas

The oil and gas industry also benefits from directional solidification, as turbines in drilling and refining operations must withstand high temperatures and aggressive environments. Directionally solidified blades ensure these turbines maintain peak performance even under extreme conditions, such as in offshore drilling platforms or high-pressure refining operations. The process helps increase the durability of pump components, enabling consistent, high-efficiency operation under intense stress and thermal cycling.

Military and Defense

In military and defense applications, turbine blades in aircraft engines must meet the highest performance and durability standards. Directional solidification ensures that these blades can withstand the intense operational conditions of military aircraft, including extreme temperatures, high mechanical stresses, and rapid thermal cycling. The durability and strength provided by this process are critical to ensuring that military propulsion systems, such as those in military aircraft engines, perform optimally under combat conditions.

FAQs

How does directional solidification improve the mechanical properties of turbine blades?

What superalloys are typically used in directional solidification for turbine blades?

What post-processing techniques are applied to turbine blades after directional solidification?

How does CNC machining compare to 3D printing in turbine blade prototyping?

What industries benefit most from the use of directionally solidified turbine blades?