3D Printing Prototyping Service

Neway offers advanced 3D printing services for high-temperature, stainless steel, aluminum alloys, and plastics. Our capabilities ensure precise, complex geometries and rapid prototyping with superior mechanical properties. We deliver tailored solutions for aerospace, energy, marine, and chemical industries, including functional prototypes and production components, ensuring performance, durability, and efficiency in demanding environments.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Our 3D Printing Service

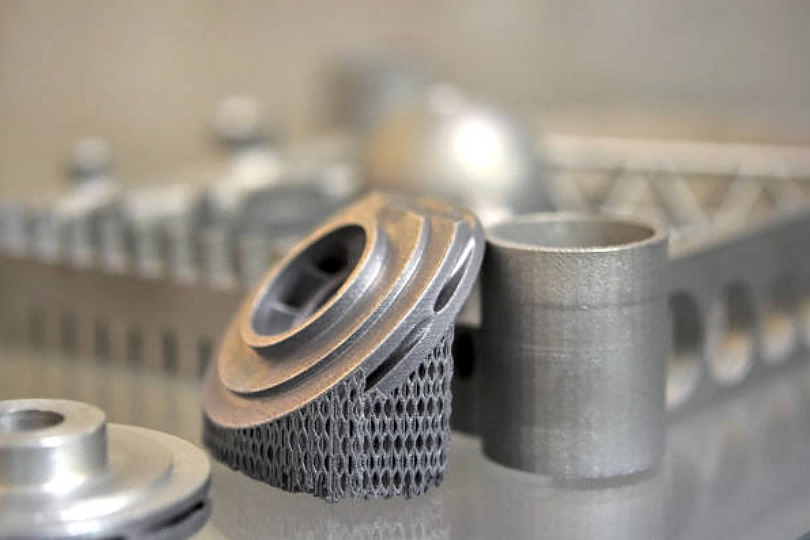

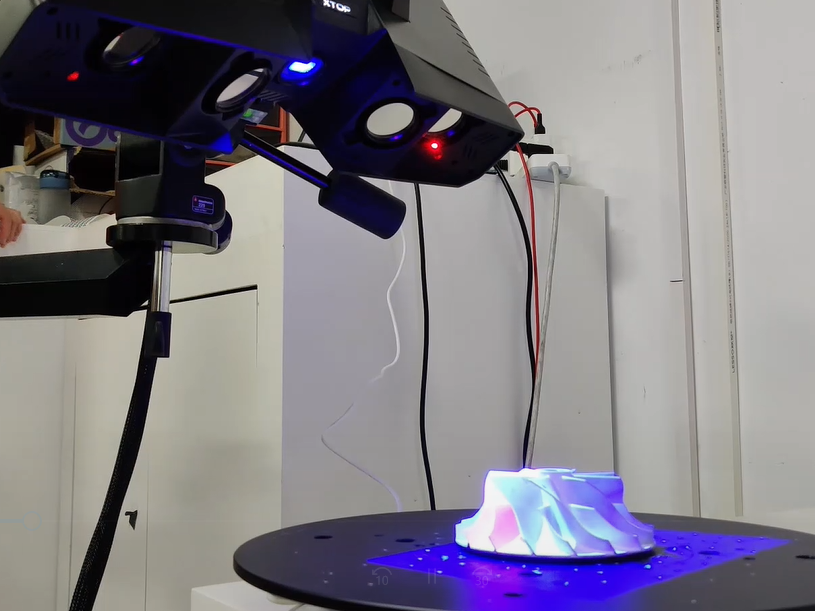

Neway focuses on custom parts manufacturing, among which 3D printing rapid prototyping services are the most outstanding. We support plastics, aluminum alloys, stainless steel, and superalloy 3D printing services. Provide you with the fastest prototyping without MOQ limits.

3D printing Service Materials

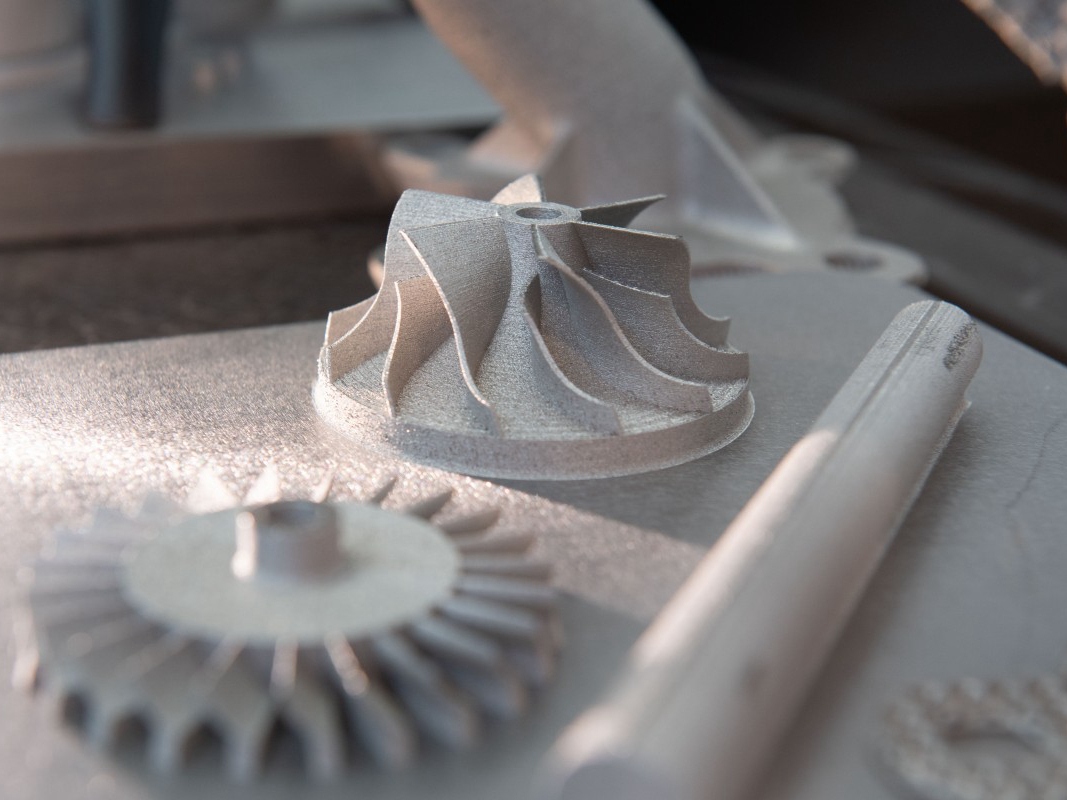

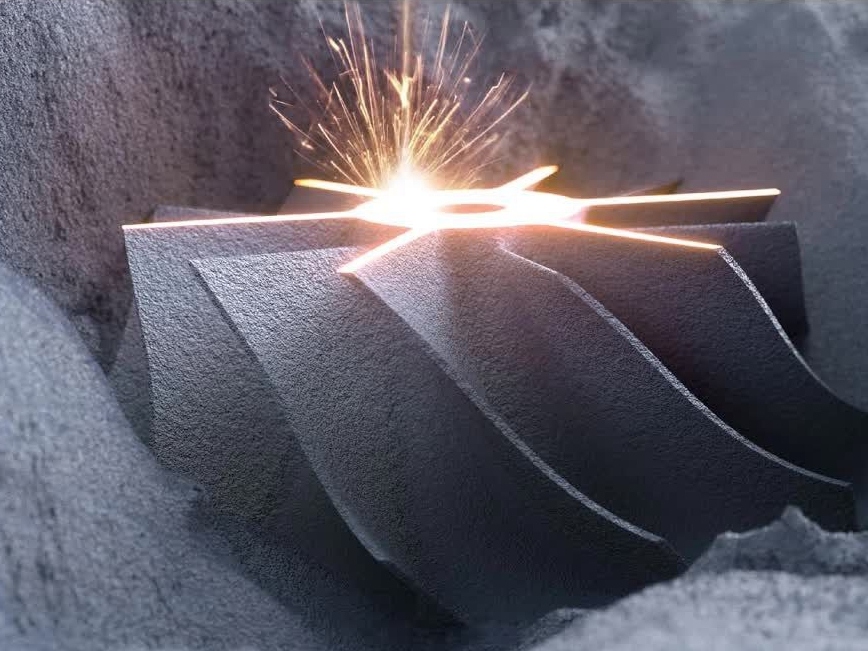

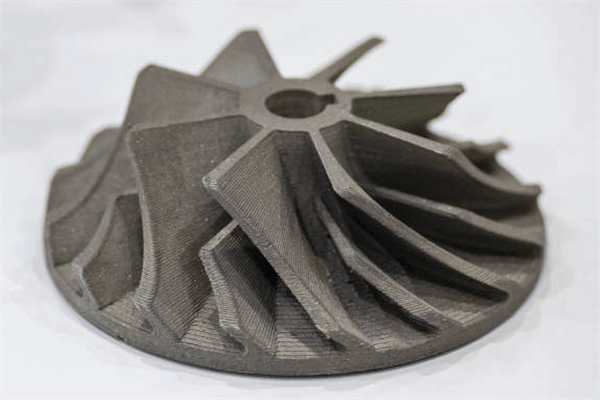

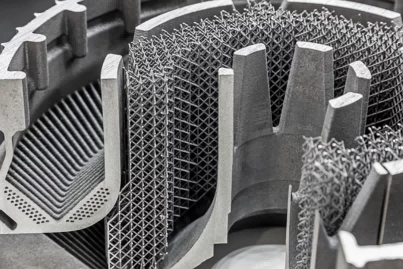

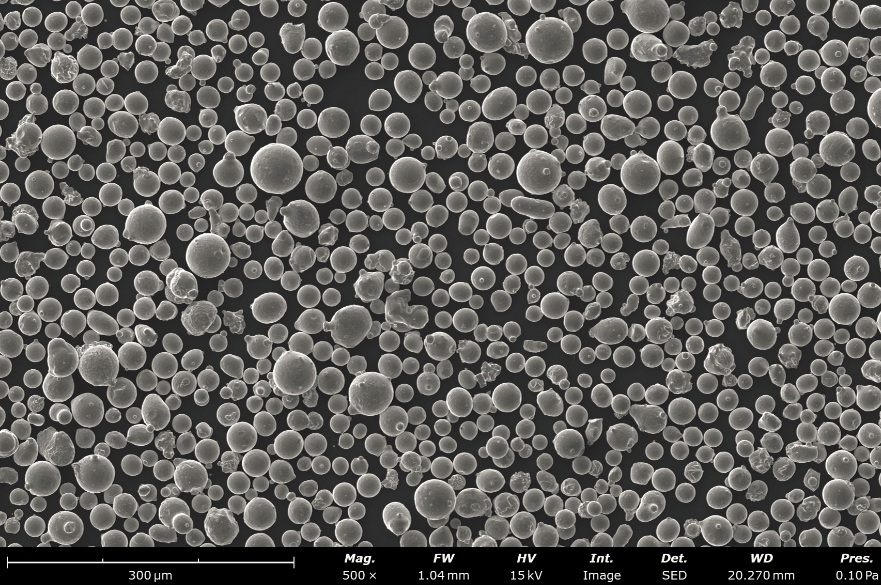

Selective Laser Melting (SLM) 3D Printing Service

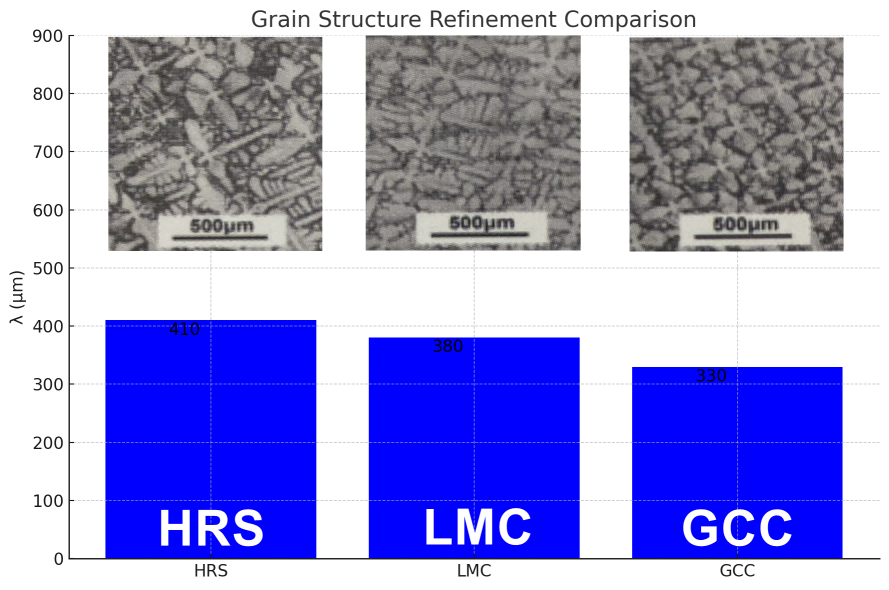

SLM laser selective melting technology is a significant technical approach in metal additive manufacturing. This technology uses the laser as the energy source and scans the metal powder bed layer by layer according to the path planning in the 3D CAD slice model. The scanned metal powder is melted and solidified to achieve the metallurgical bonding effect, and finally, the metal parts designed by the model are obtained.

LENS Laser Melting Deposition (LMD) 3D Printing Service

LENS laser near-net shaping technology is an organic combination of rapid prototyping technology and laser cladding technology. It uses metal powder as raw material and a high-energy laser beam as a heat source. According to the CAD model of the forming part, the supplied metal powder is melted, rapidly solidified, and deposited layer by layer, thereby realizing the direct manufacturing of the entire metal part.

WAAM (Wire and Arc Additive Manufacturing) 3D Printing Service

Arc additive manufacturing technology uses an arc/plasma arc as a heat source to scan the forming path obtained by part layering, forming a moving molten pool on the metal substrate. Metal droplets formed by melting the external metal wire are continuously fed into the molten pool, and the metal material is accumulated point by point, layer by layer, on the forming path to achieve part forming.

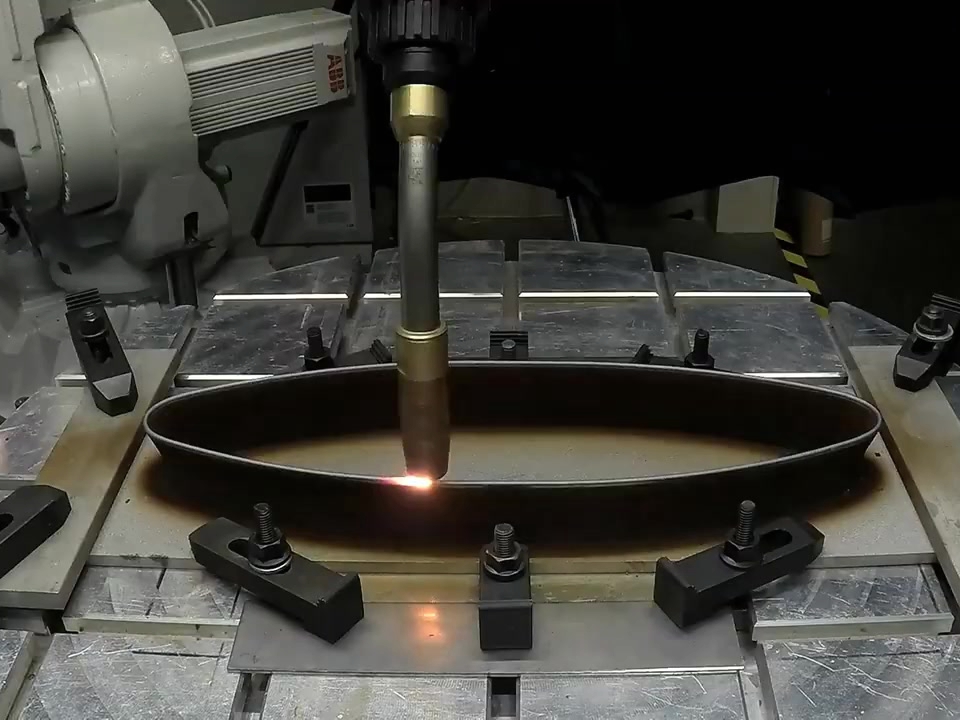

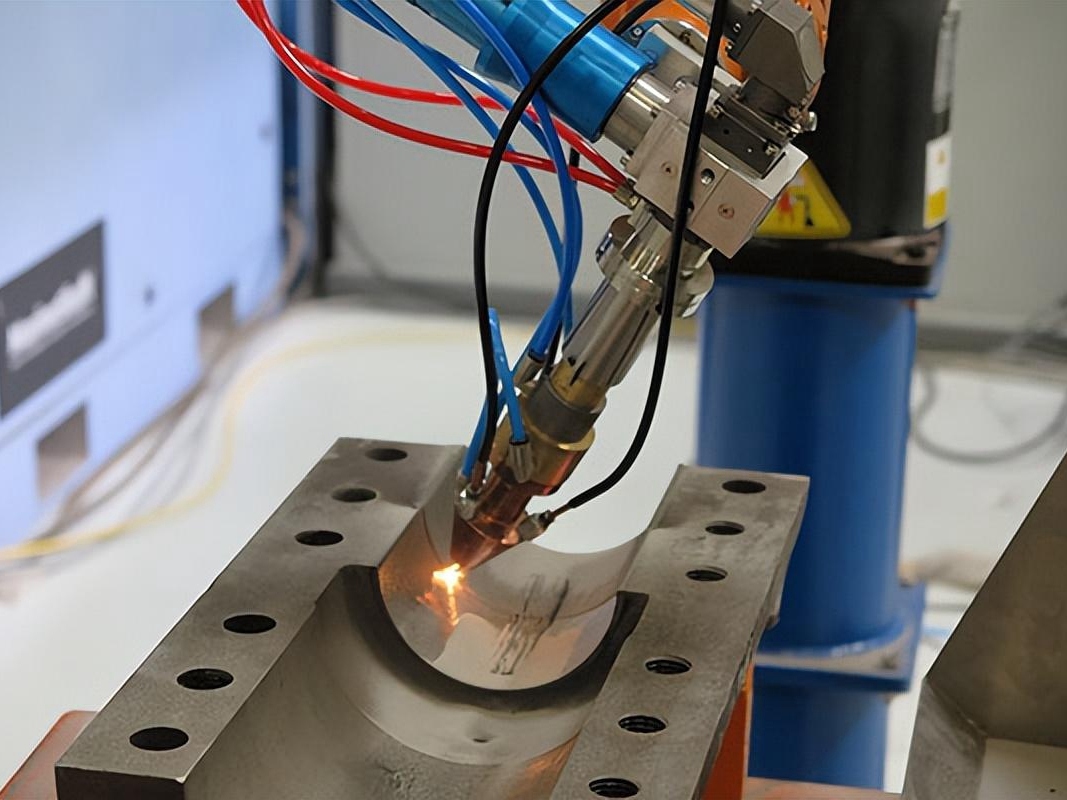

Laser Cladding (LC) 3D Printing Service

Laser cladding technology refers to placing selected coating materials on the surface of the coated substrate using different filler methods and melting them simultaneously with a thin layer on the substrate surface through laser irradiation. The dilution of the cladding layer is low. It has a strong bonding force and is metallurgically bonded with the matrix, which can significantly improve the wear resistance, corrosion resistance, heat resistance, oxidation resistance, or electrical properties of the surface of the matrix material, thereby achieving the purpose of surface modification or repair, and satisfies. It can save a lot of material costs while meeting specific performance requirements on the material surface.

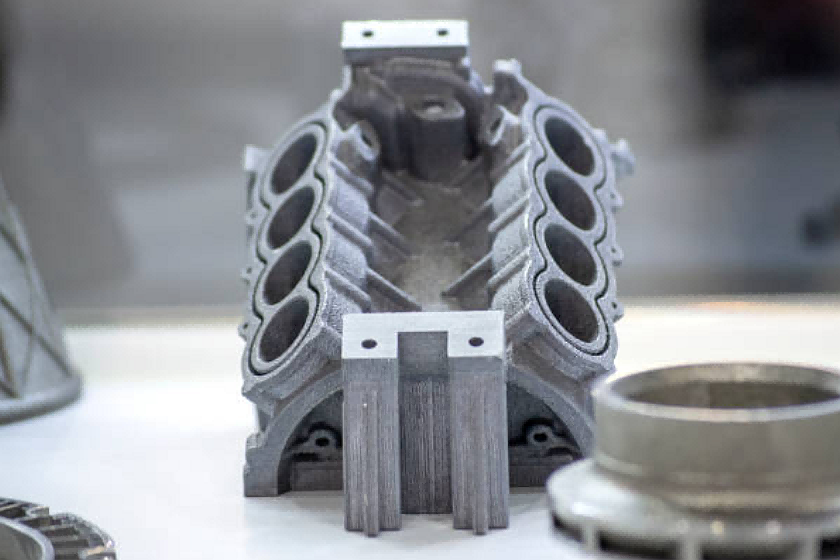

3D Printed Parts Applications

We provide superalloy, stainless steel, aluminum, and plastic rapid 3D printing prototyping services for industries such as Aerospace and Aviation, Power Generation, and Automotive. We also provide post-processing and inspection services for 3D-printed parts.

learn more

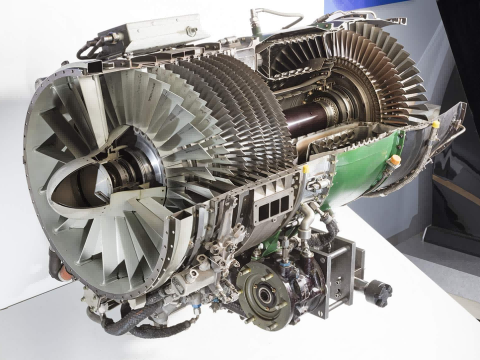

Aerospace and Aviation

learn more

Power Generation

learn more

Oil and Gas

learn more

Energy

learn more

Marine

learn more

Mining

learn more

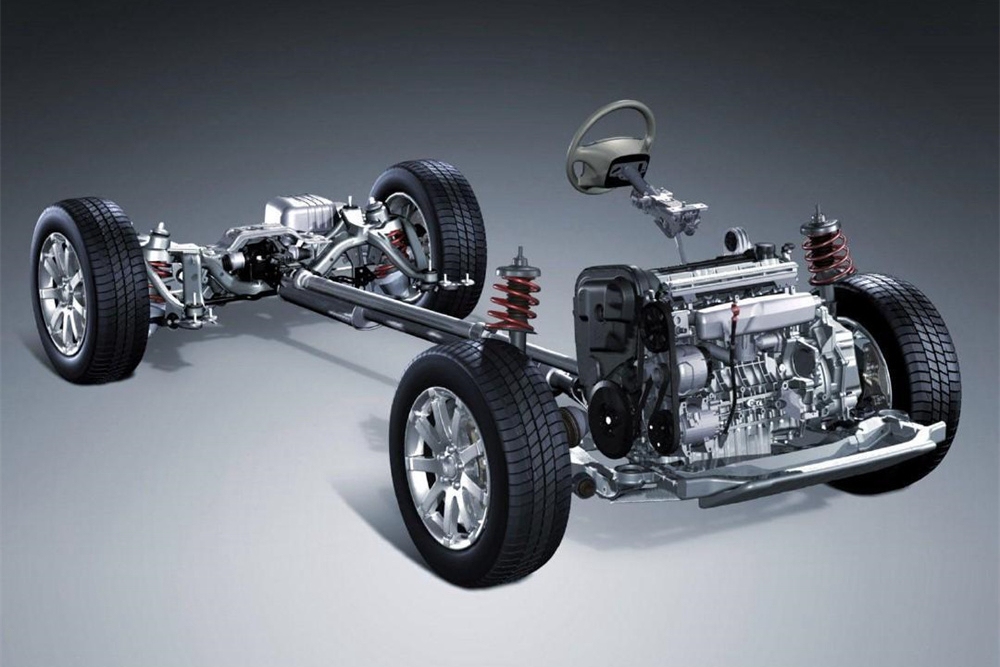

Automotive

learn more

Chemical Processing

learn more

Pharmaceutical and Food

learn more

Military and Defense

learn more

Nuclear

learn more

More Cases

learn more

New Technology

learn more

Products Gallery

learn more

Various Industries

learn more

Surface Finishings

learn more

Post-Process

learn more

Manufacturing Technology

learn more

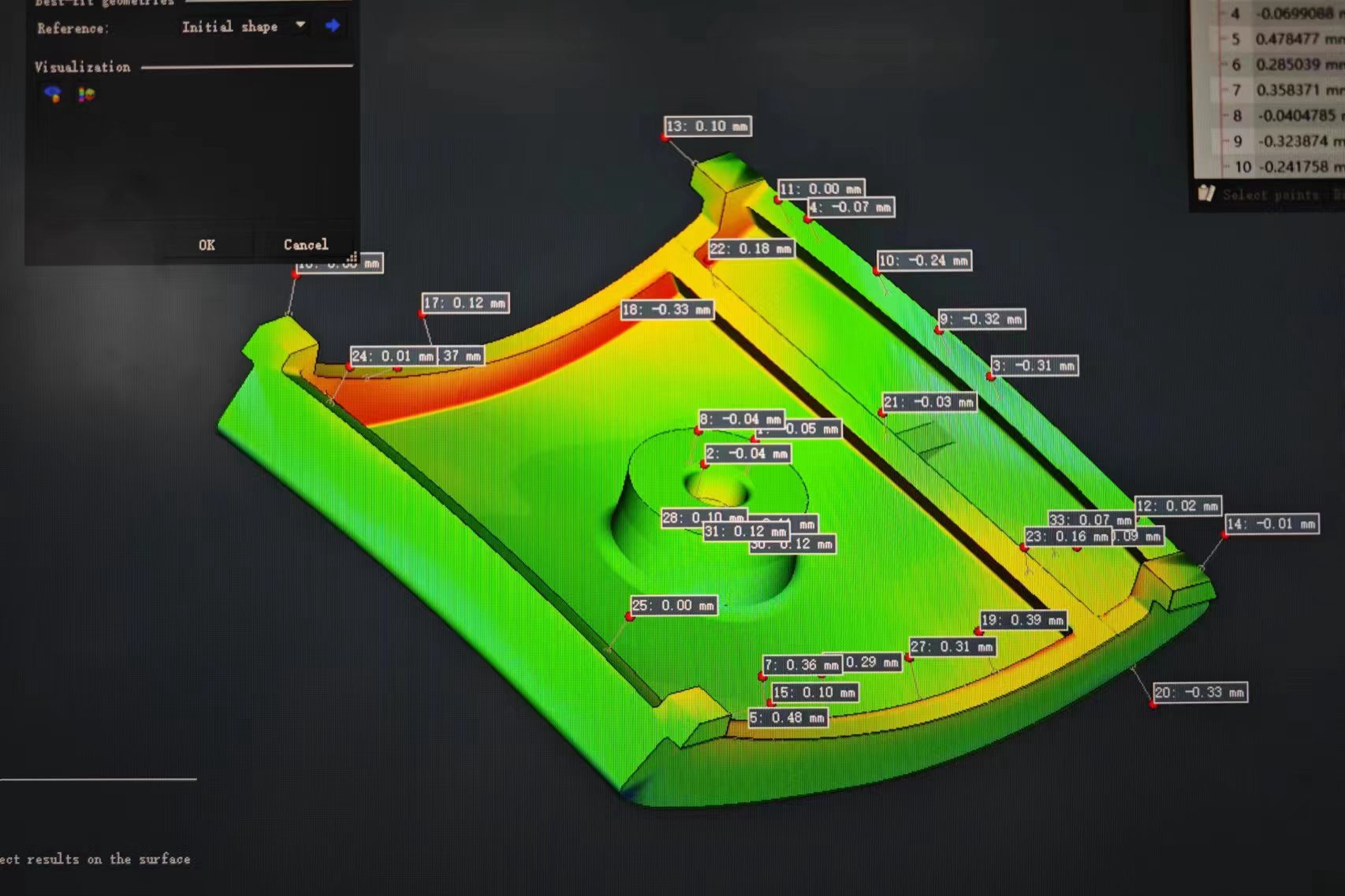

R&D and Simulation

learn more

Manufacturing Equipments

learn more

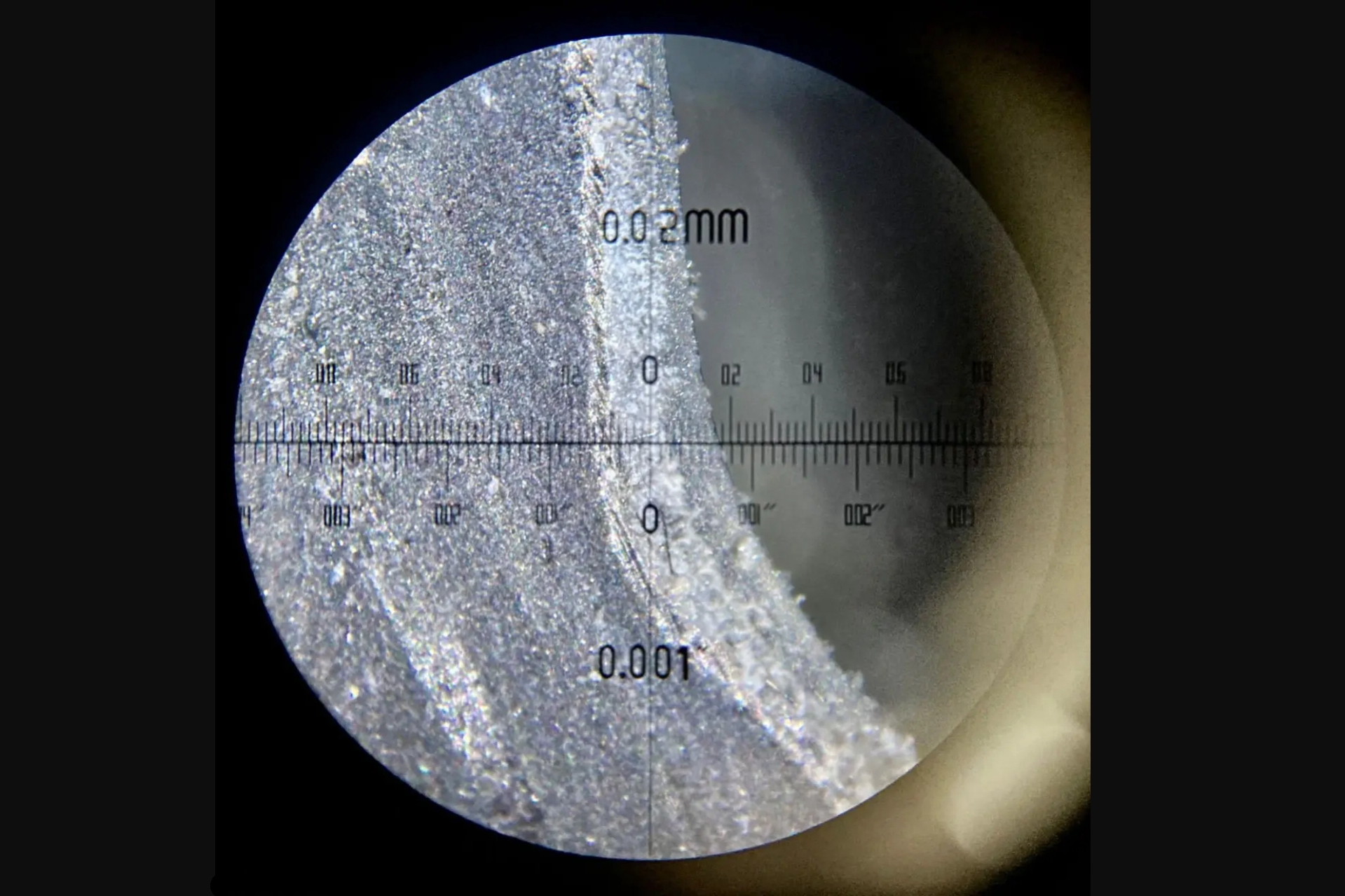

Testing Equipments

learn more

BLOGS

learn more

FAQs

learn more

Contact

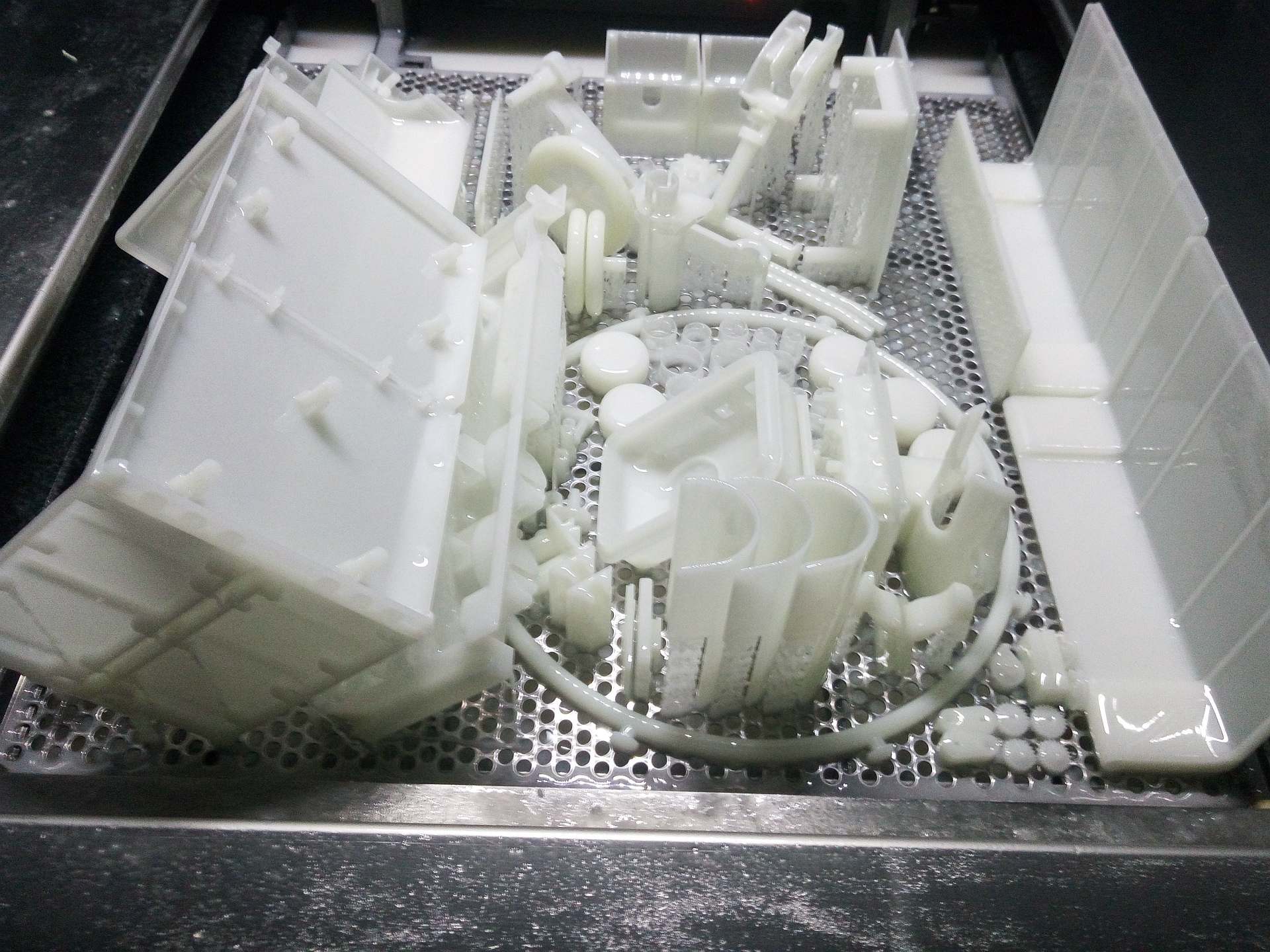

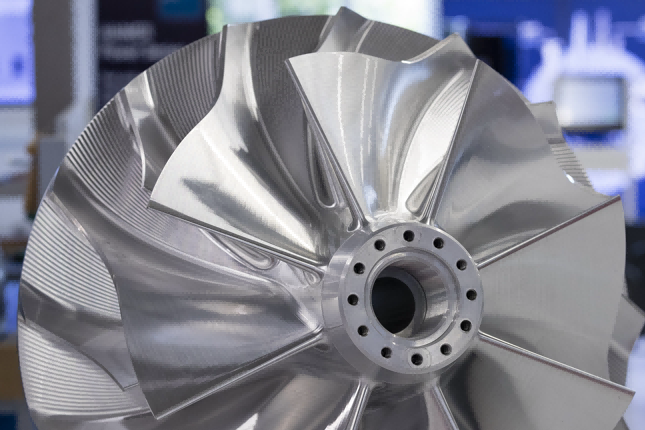

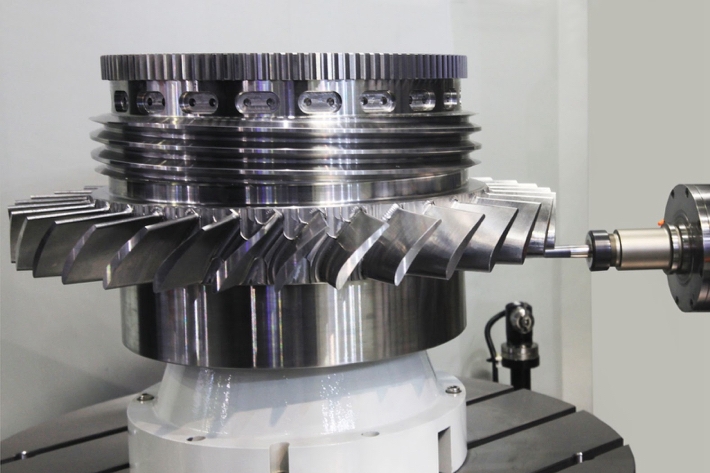

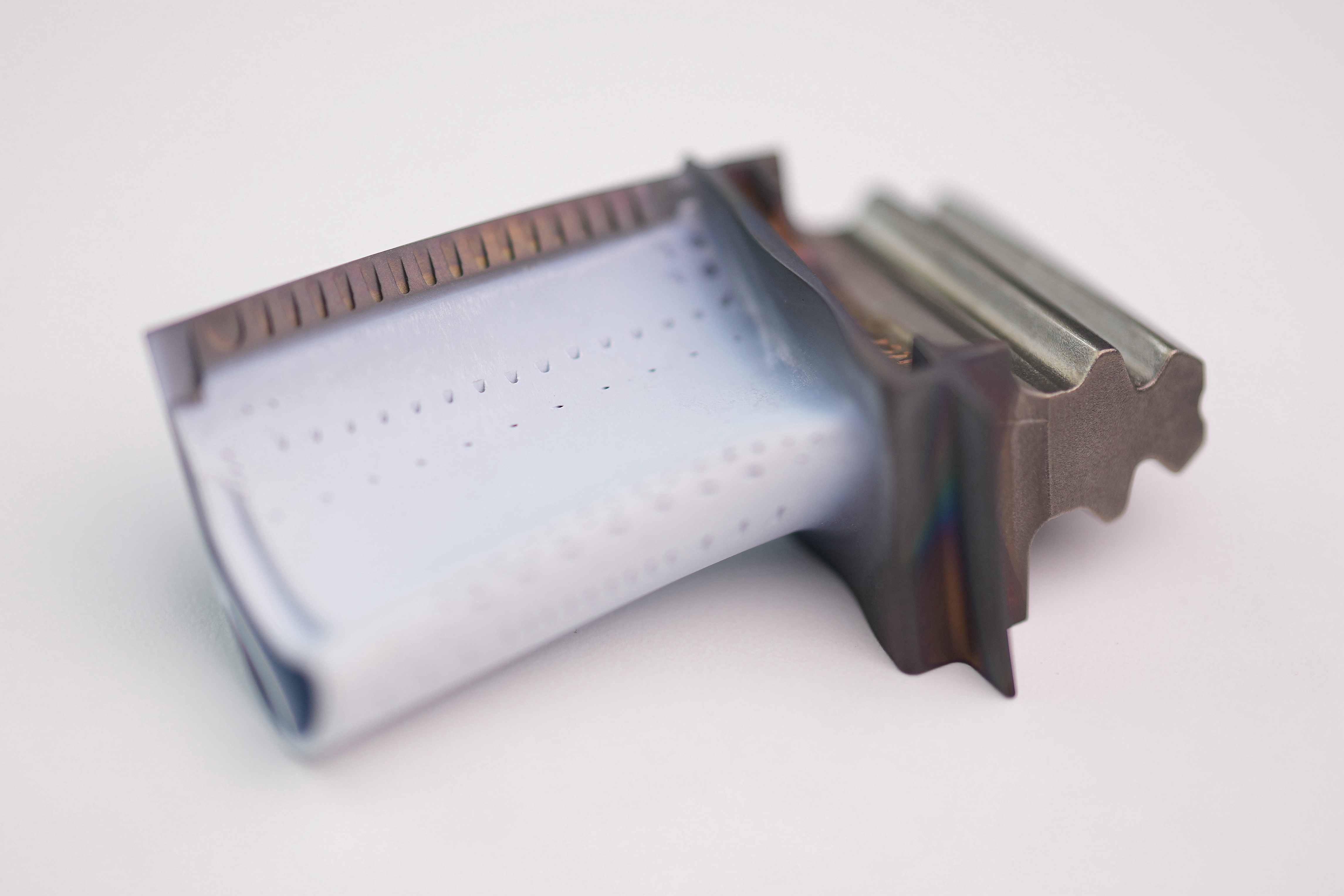

Custom Parts Gallery

At our custom parts gallery, we understand that every project is unique. That's why we work closely with our customers to ensure that their custom parts are designed to meet their exact specifications. With our attention to detail and commitment to quality, you can trust that your custom parts will exceed your expectations.

Let's Start A New Project Today