Innovations in 3D Printing Inconel 625 with SLM Technology

Inconel 625 is a superalloy celebrated for its remarkable properties, making it an essential material in high-stress, high-temperature environments. Known for its excellent corrosion resistance, tensile strength, and fatigue endurance, Inconel 625 is widely used across aerospace, marine, chemical processing, and power generation industries.

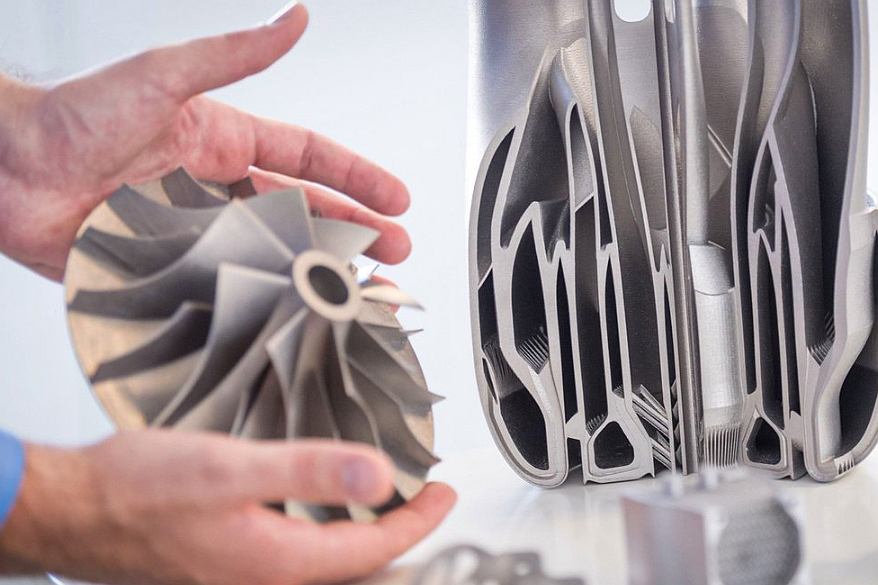

Selective Laser Melting (SLM) technology has expanded the material’s potential, allowing for intricate, high-performance components that were once impossible to manufacture using traditional methods. This blog explores the interplay between Inconel 625 and SLM technology, covering everything from suitable materials to post-processing, testing, industry applications, and innovations driving future use.

Overview of Inconel 625: Properties and Advantages

Inconel 625 is a nickel-based superalloy composed primarily of nickel, chromium, and molybdenum. This composition provides exceptional resistance to high-temperature oxidation, corrosion, and stability in various severe environments. These qualities make Inconel 625 highly valuable for manufacturing parts in extreme conditions, such as jet engines, nuclear reactors, and deep-sea applications. Its high tensile strength and weldability allow components to endure mechanical stresses and environmental challenges without degradation.

When used in 3D printing, Inconel 625’s stability is retained while opening new possibilities in design and manufacturing. The precision of additive manufacturing enables engineers to create complex geometries with high customization, achieving both solid and lightweight parts and durability and corrosion resistance.

3D Printing Inconel 625 with SLM Technology

Selective Laser Melting (SLM) is an advanced form of additive manufacturing that uses a high-powered laser to selectively fuse metal powder into a solid structure layer by layer. SLM is particularly suited for Inconel 625 because it allows precise control over the melting and solidification process, ensuring a consistent microstructure and minimizing residual stresses.

SLM technology offers several advantages in manufacturing Inconel 625 parts. Its high-energy laser enables the formation of dense, vital components with minimal porosity, resulting in parts with optimal mechanical properties. Additionally, SLM’s layer-by-layer approach supports intricate geometries, allowing engineers to optimize part designs for strength, heat transfer, and weight, which is essential for high-performance applications in

Materials Used in 3D Printing: Inconel 625 Powder Specifications

In 3D printing with SLM, material quality is paramount. For Inconel 625, the quality of the metal powder directly impacts the final part's strength, consistency, and overall success. Inconel 625 powder must meet stringent criteria, including particle size distribution, morphology, and purity. Particles are typically spherical with a narrow size range (between 10–50 microns), which ensures a uniform layer during printing and a consistent melt pool.

To achieve reliable results, manufacturers must use high-quality powder certified by industry standards, such as ASTM or ISO, and undergo rigorous quality control processes. The presence of impurities or irregular particle shapes can lead to inconsistent melting, reducing the part's structural integrity. As the demand for 3D-printed superalloy components grows, powder suppliers consistently improve their processes to meet these quality requirements.

Manufacturing Considerations for SLM with Inconel 625

When designing components for Selective Laser Melting (SLM) with Inconel 625, several vital considerations are essential to achieve optimal results. Inconel 625’s properties make it ideal for applications demanding strength, thermal performance, and durability, but careful attention to printing parameters is required to leverage these benefits fully.

Design Considerations

Design elements such as support structures, wall thickness, and overhangs must be strategically planned to reduce internal stresses and minimize post-processing. It helps maintain the structural integrity and dimensional accuracy of complex geometries, especially for parts with intricate features.

Printing Parameters

SLM for Inconel 625 involves specific laser parameters, including power, speed, and layer thickness. The typical layer thickness ranges from 20 to 60 microns, adjusted based on the desired balance between part accuracy and production speed. For Inconel 625, a high-power laser combined with a slower scan speed ensures complete fusion, maximizing density and minimizing potential defects, which is critical for high-stress applications.

Process Monitoring

Process monitoring is a crucial aspect of SLM for quality assurance. Advanced SLM systems use sensors and imaging to track real-time parameters like temperature, laser stability, and layer consistency. This monitoring capability allows manufacturers to detect and correct potential flaws during production, reducing waste, improving quality, and enhancing production efficiency.

By considering these factors, SLM technology optimizes the performance and reliability of Inconel 625 components, making them suitable for demanding environments in aerospace, energy, and high-performance industries.

Post-Processing Techniques for Inconel 625 Parts

Post-processing is a critical phase that enhances the performance and reliability of Inconel 625 components. Since 3D-printed parts often contain residual stresses, treatments like Hot Isostatic Pressing (HIP) relieve internal stresses and remove porosity, improving the material’s mechanical properties. HIP subjects the part to high temperature and pressure in an inert environment, resulting in a uniform, dense structure ideal for demanding applications, particularly in the aerospace and energy sectors.

Heat Treatment

Heat treatment is another post-processing method to refine the material’s microstructure further. Inconel 625 components undergo heat treatment at high temperatures, which improves tensile strength and fatigue resistance by promoting an even grain structure. This step is essential for parts that face high mechanical stress or temperature variations, making them more resilient in extreme conditions.

Surface Finishing

Surface finishing is essential to meet specific application requirements. Techniques such as polishing, shot peening, and sandblasting enhance surface quality, while coatings like Thermal Barrier Coating (TBC) provide additional thermal insulation. TBC is invaluable for parts exposed to extreme heat, adding another layer of durability to components like turbine blades and exhaust nozzles, where thermal protection is critical to performance.

Testing and Quality Assurance of 3D-Printed Inconel 625 Parts

The rigorous demands on Inconel 625 parts mean that quality assurance is vital. Non-destructive testing (NDT) methods, such as X-ray and ultrasonic testing, detect internal defects without compromising the part’s integrity. 3D scanning is also commonly used to ensure dimensional accuracy and to verify the part’s geometry against its design specifications.

Mechanical Testing

Mechanical testing assesses tensile strength, fatigue resistance, and impact resilience. These tests confirm that the part can withstand the expected stresses in its intended application, whether in high-pressure, high-temperature, or corrosive environments. For a detailed breakdown of mechanical testing procedures, check out Tensile Testing in Superalloy Parts.

Dimensional and Surface Accuracy

Dimensional and surface accuracy is verified using Coordinate Measuring Machines (CMM) and Scanning Electron Microscopes (SEM). These methods ensure that the component meets all tolerance requirements for its physical dimensions and surface integrity, essential for high-performance applications.

Critical Industry Applications for SLM-Printed Inconel 625 Components

The combination of SLM and Inconel 625 is transformative in industries where high-performance, durable components are essential. Below are some critical applications:

Aerospace and Aviation

SLM-printed Inconel 625 parts are used for turbine blades, exhaust systems, and fuel nozzles due to their ability to withstand extreme heat and mechanical loads. The alloy’s excellent fatigue and thermal-fatigue strength make it a top choice for aerospace components that operate under high-stress conditions in jet engines and other aerospace systems.

Oil and Gas

In the oil and gas sector, Inconel 625 is commonly applied to valves, seals, and other components exposed to corrosive substances and high pressures. Its corrosion resistance and mechanical strength make it ideal for offshore and deep-sea environments, where equipment must remain reliable under severe conditions. The alloy’s resilience ensures that components such as superalloy valve systems perform under the most challenging conditions.

Power Generation

Power generation applications also benefit from SLM-printed Inconel 625 components. Heat exchangers, pump systems, and other parts exposed to high temperatures require the strength and thermal resilience that Inconel 625 provides. This alloy is widely used in turbines and other critical systems that demand performance in harsh, high-temperature environments.

Marine

The alloy’s corrosion resistance in the marine industry makes it suitable for exhaust systems, propulsion units, and other parts subject to saltwater exposure. Inconel 625’s durability ensures long-term reliability and performance in marine applications, including superalloy marine components.

FAQs

What are the primary benefits of using Inconel 625 in 3D printing with SLM technology?

How does powder quality impact the final results of Inconel 625 parts produced with SLM?

What are the most common post-processing techniques for 3D-printed Inconel 625 parts, and why are they necessary?

Which industries benefit the most from SLM-printed Inconel 625 components?

What advancements in SLM technology are expected to enhance the use of Inconel 625 in additive manufacturing?