Stainless Steel 316L in SLM 3D Printing: Benefits and Challenges

Stainless Steel 316L is one of the most versatile materials used in various industries thanks to its remarkable properties, such as high corrosion resistance, excellent strength, and exceptional performance in high-temperature environments. When combined with Selective Laser Melting (SLM), Stainless Steel 316L becomes even more attractive as a material for complex, high-performance components. This combination of advanced material properties and cutting-edge manufacturing technology is revolutionizing industries ranging from aerospace and aviation to energy.

Selective Laser Melting (SLM), a form of additive manufacturing, uses a high-powered laser to selectively melt and fuse powdered material to create three-dimensional objects layer by layer. This method offers unparalleled design freedom, making it an ideal process for producing intricate and highly customized parts. In particular, Stainless Steel 316L has emerged as a preferred material for SLM due to its balance of mechanical properties, ease of processing, and versatility. This innovative combination of 3D printing and high-performance alloys transforms how industries approach component design and production.

Suitable Materials for SLM 3D Printing

The choice of material is one of the most critical factors in any additive manufacturing process. 316L is particularly well-suited for SLM 3D printing due to several vital properties that enhance the quality and functionality of the printed parts. Here's why:

Material Properties

Stainless Steel 316L is known for its excellent corrosion resistance, particularly against chloride environments, making it a go-to material for marine, chemical processing, and medical applications. It also exhibits high tensile strength, weldability, and fatigue resistance. These properties make it ideal for producing functional parts that withstand extreme conditions, such as high temperatures and harsh chemical exposure.

Ease of Processing

Stainless Steel 316L has a relatively low carbon content compared to other stainless steel alloys, reducing the risk of carbide formation during printing. This characteristic improves the material's resistance to stress corrosion cracking, making it more durable and reliable.

Versatility in Applications

The material's properties suit various industries, including aerospace, automotive, medical, and energy sectors.

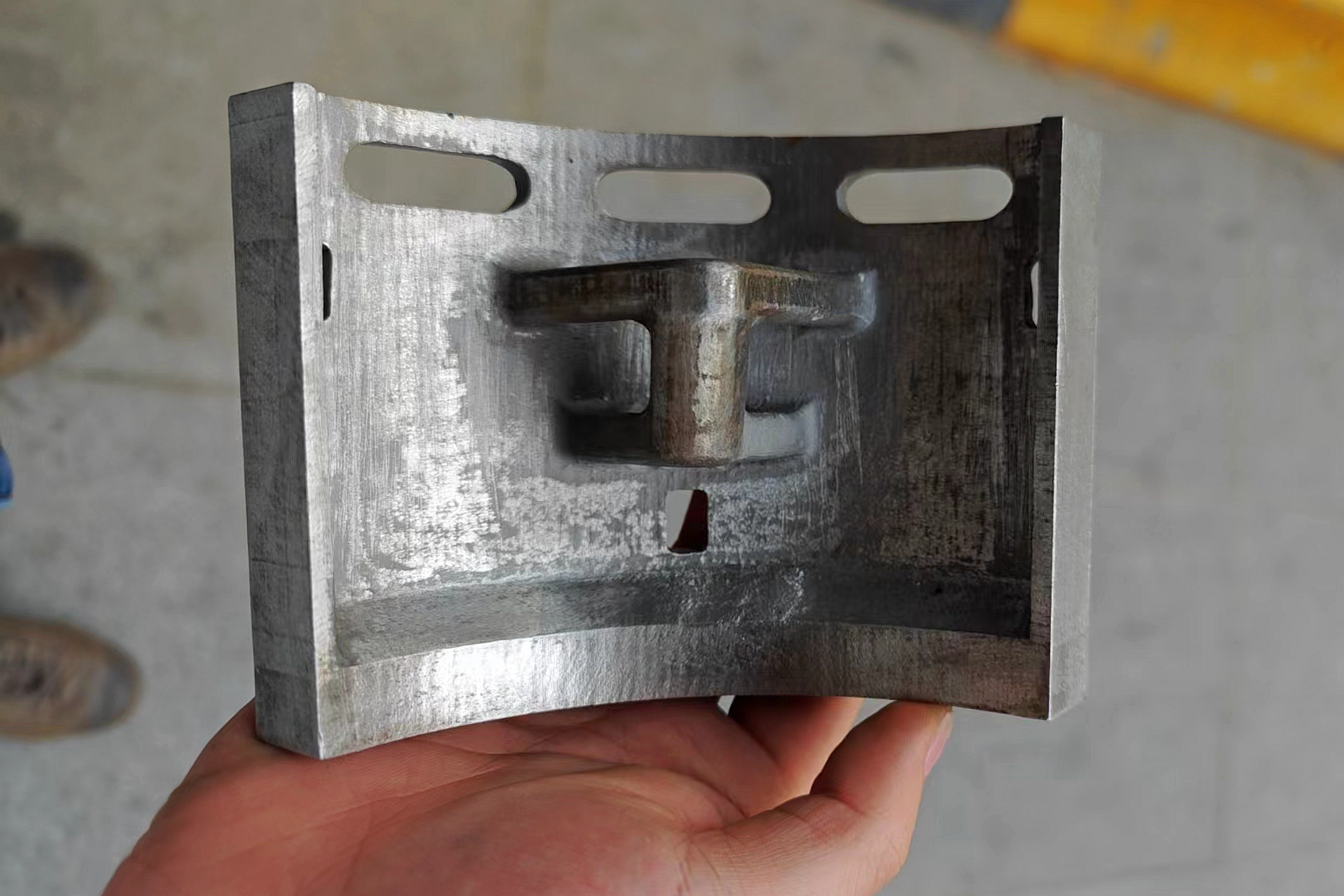

SLM 3D Printing Process for Stainless Steel 316L

The SLM 3D printing process for Stainless Steel 316L follows well-established steps, each crucial to achieving high-quality parts. These steps involve carefully selecting parameters such as laser power, scan speed, and layer thickness to achieve optimal results.

Powder Bed Preparation

In SLM, the process begins with depositing a thin layer of stainless steel 316L powder onto a build platform. This powder must meet specific particle size and flowability requirements to ensure uniform deposition during printing. The quality of the powder is critical, as any inconsistency can lead to defects in the final part. Powder metallurgy processes are integral to ensuring the consistency of the materials used in the build.

Laser Melting and Fusing

A high-powered laser is directed onto the powder bed, selectively melting the stainless steel particles according to the part's 3D design. The laser fuses the particles, creating a solid layer. Once a layer is complete, the build platform lowers, and a new layer of powder is applied on top. This layer-by-layer process continues until the final part is formed. The precision achieved in this step is crucial for applications requiring high-performance parts similar to those produced using precision casting.

Controlled Atmosphere

The SLM process is typically performed in a controlled atmosphere to prevent oxidation and contamination, often using an inert gas such as argon. It ensures the stainless steel parts maintain their high-quality finish and mechanical properties throughout the build.

Post-Build Cooling

After printing, the printed part must undergo post-processing to cool at a controlled rate. This cooling phase helps to relieve stresses introduced during printing, ensuring dimensional accuracy and preserving the mechanical integrity of the final component.

Post-processing of Stainless Steel 316L Parts

Post-processing is essential in ensuring the final part meets the required specifications and performance standards. Several post-processing techniques are employed for Stainless Steel 316L parts produced via SLM 3D printing to improve surface finish, mechanical properties, and overall quality.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) often eliminates residual porosity and enhances the material's density. The process involves subjecting the part to high pressure and temperature in a controlled environment, which helps to close any voids and improve the overall mechanical properties of the part.

Heat Treatment

Heat treatment processes, such as solution annealing, relieve internal stresses and improve the material's hardness and strength. These treatments can also improve the material's corrosion resistance, which is particularly important in applications where parts are exposed to aggressive environments.

Superalloy Welding

Welding may be necessary for some complex assemblies. Stainless Steel 316L is well-suited for welding, though careful attention is required to ensure that the heat-affected zones do not degrade the material's properties. Specialized welding techniques are used to maintain the integrity of the alloy.

Surface Finish and Coating

The surface finish of 3D printed parts can sometimes be rough, requiring additional post-processing steps such as machining, polishing, or applying thermal barrier coatings (TBC). Thermal barrier coatings, in particular...

Testing and Quality Assurance

Once the post-processing is complete, Stainless Steel 316L parts undergo rigorous testing to meet the desired performance, strength, and durability standards. Several testing methods are used to evaluate the mechanical properties and integrity of the parts.

Material Testing

Tests such as tensile testing, hardness testing, and fatigue testing are performed to evaluate the material's strength and resistance to wear and tear. These tests provide valuable data to determine whether the part can withstand the operating conditions it will face in its specific application.

Non-Destructive Testing (NDT)

Non-destructive testing methods like X-ray, ultrasonic, and eddy current testing are often used to detect internal defects or cracks in the parts without causing any damage. These methods ensure that the parts are free of imperfections that could compromise their functionality.

Surface and Dimensional Inspections

Coordinate Measuring Machines (CMM) and 3D scanning are often used to verify that the part's dimensions match the design specifications. Surface quality inspections are also performed to ensure the part has a smooth finish and meets aesthetic and functional requirements.

Industry Applications of Stainless Steel 316L in SLM 3D Printing

The versatility of Stainless Steel 316L in SLM 3D printing opens up a wide range of applications across industries that demand high-performance parts. Here are some key sectors where this material is making an impact:

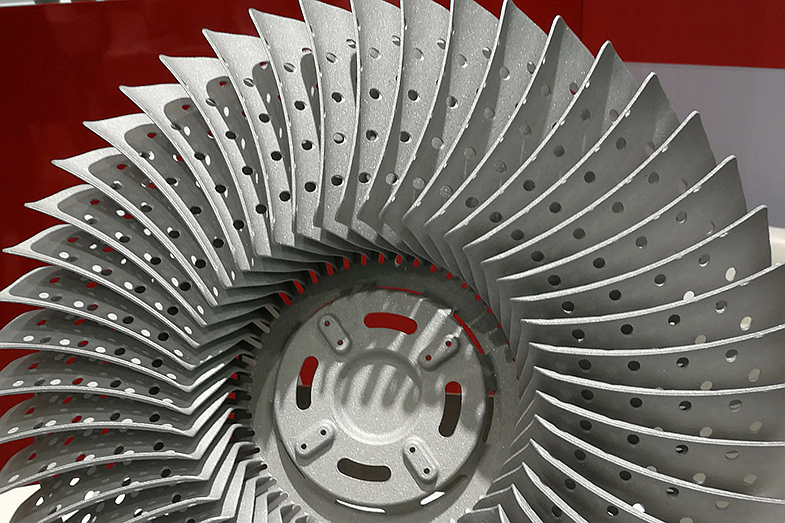

Aerospace and Aviation

Parts for jet engines, exhaust systems, and turbine blades are commonly manufactured using Stainless Steel 316L. The material's resistance to high temperatures and corrosion makes it ideal for components exposed to extreme conditions in the aerospace industry. Stainless Steel 316L helps ensure the durability and performance of high-stress components, contributing to reliable jet engine components.

Automotive

The automotive industry uses Stainless Steel 316L in applications like exhaust systems, fuel system components, and transmission parts. Its durability and high-temperature resistance make it suitable for critical automotive systems. This alloy's ability to resist wear, corrosion, and heat is essential for optimizing vehicle performance in demanding automotive environments.

Energy and Power Generation

In power plants, Stainless Steel 316L is used for manufacturing heat exchangers, turbines, and reactor components, where high performance and resistance to extreme conditions are essential. The alloy's excellent resistance to corrosion and high temperatures makes it invaluable in applications like superalloy heat exchangers.

Medical and Healthcare

Stainless Steel 316L is commonly used in the medical field to produce surgical instruments, implants, and other high-precision medical components. Its biocompatibility and resistance to corrosion in the human body make it an ideal material for medical devices, ensuring long-term durability and reliability in critical healthcare applications.

Chemical Processing

Due to its excellent resistance to aggressive chemicals, Stainless Steel 316L is often used in the chemical industry for pump components, mixers, and valves. Its corrosion resistance ensures reliable performance in harsh chemical environments, making it a go-to material for industrial applications requiring strength and durability under demanding conditions.

FAQs

What are the advantages of using Stainless Steel 316L in SLM 3D printing compared to other materials?

How does Hot Isostatic Pressing (HIP) improve the mechanical properties of 316L 3D printed parts?

What common post-processing steps are required for Stainless Steel 316L parts after SLM 3D printing?

How does the 3D printing process control thermal stresses in Stainless Steel 316L parts?

What industries benefit the most from using Stainless Steel 316L in SLM 3D printing?