Titanium Alloy Printing Capabilities with WAAM Technology

Titanium Alloy Printing Capabilities with WAAM Technology

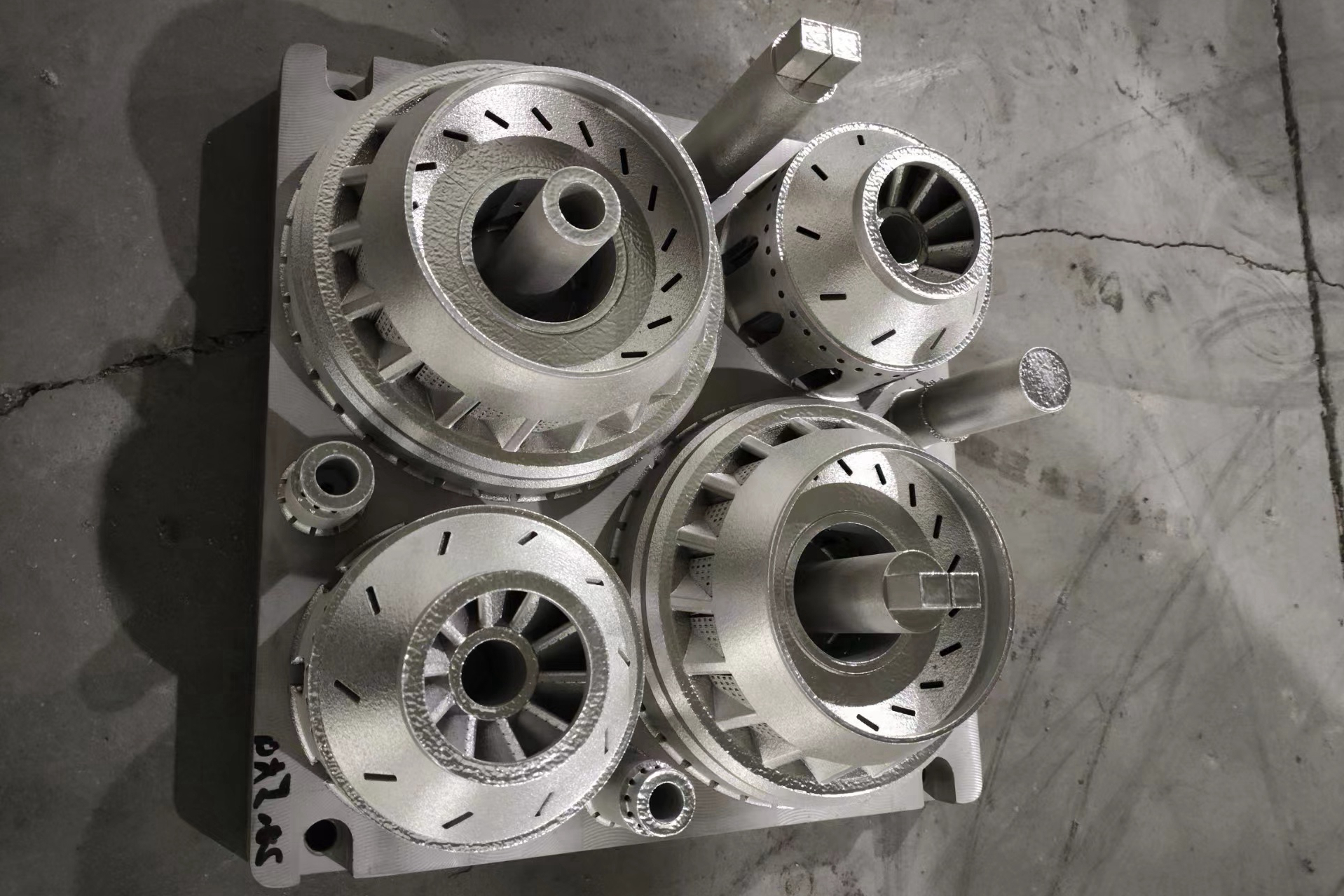

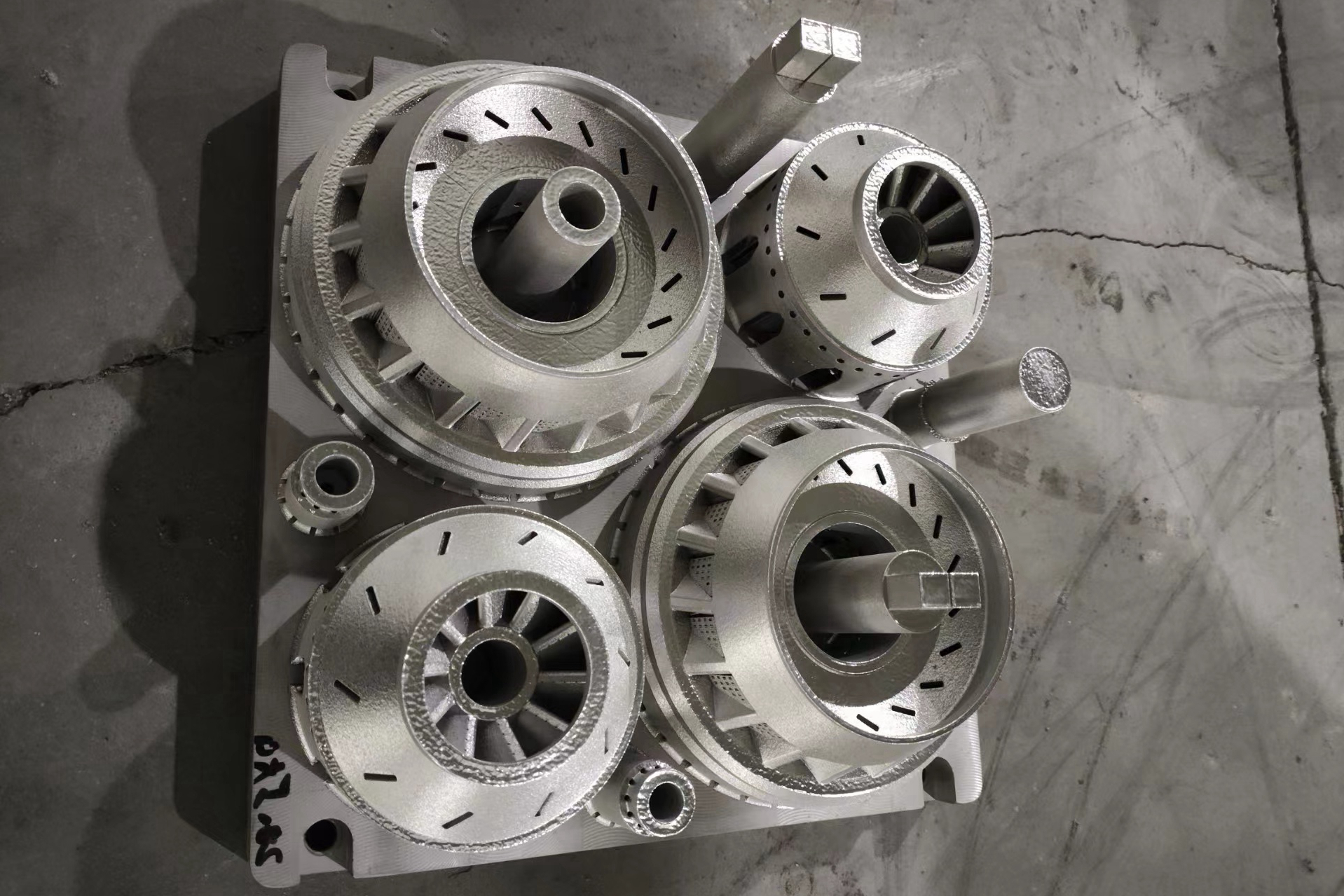

Wire and Arc Additive Manufacturing (WAAM) is a transformative technology in the manufacturing world, enabling the creation of complex and large-scale parts with exceptional precision and efficiency. As industries continue to demand high-performance components, the need for lightweight, strong, and corrosion-resistant materials like titanium alloys has never been greater. Titanium alloys, known for their high strength-to-weight ratio and excellent corrosion resistance, are well-suited to additive manufacturing, mainly through the WAAM process.

Why Titanium Alloys Are Ideal for WAAM

Titanium alloys are highly sought after in engineering and manufacturing due to their remarkable combination of properties. These include a high strength-to-weight ratio, excellent corrosion resistance, biocompatibility, and exceptional performance in extreme environments, such as high temperatures and high-stress applications. As a result, they are commonly used in industries like aerospace, automotive, medical implants, and defense, where lightweight yet durable materials are critical.

Properties of Titanium Alloys

Titanium alloys are divided into several categories, each offering unique properties that suit different applications. The most commonly used titanium alloys in WAAM are:

Grade 5 (Ti-6Al-4V): This is the most widely used titanium alloy, known for its high strength, lightweight properties, and excellent corrosion resistance. It is commonly used in aerospace and automotive applications.

Grade 2 (Commercially Pure Titanium): Known for its excellent corrosion resistance and high flexibility, it is used in chemical processing and marine applications.

Grade 23 (Ti-6Al-4V ELI): This alloy is used for medical implants due to its enhanced flexibility and lower interstitial content, which minimizes the risk of rejection in the body.

Benefits of Using Titanium Alloys in WAAM

WAAM is particularly well-suited to the characteristics of titanium alloys. The high strength-to-weight ratio of titanium makes it ideal for aerospace and automotive components, where minimizing weight while maximizing strength is paramount. Additionally, titanium alloys possess superior thermal stability, which allows them to retain their structural integrity even in high-temperature environments. This makes them essential for applications like turbine blades, engine components, and exhaust systems.

Titanium alloys are also corrosion-resistant, which benefits parts exposed to harsh environments such as chemical processing, marine, and offshore industries. By leveraging WAAM's ability to print large parts with high precision, manufacturers can create intricate titanium components that would be difficult or impossible to produce using traditional machining methods. WAAM is ideal for superalloy parts manufacturing that require precision in harsh environments.

Moreover, WAAM offers the advantage of producing parts with minimal material waste. Unlike subtractive manufacturing processes, which involve cutting away material from a larger piece, WAAM builds parts layer by layer, using only the amount of material required for the part itself. It makes it an environmentally friendly option, as less material is wasted in the production process. WAAM's precision aligns well with the goals of superalloy precision forging, minimizing waste while ensuring part integrity.

Post-Processing for WAAM-Printed Titanium Alloys

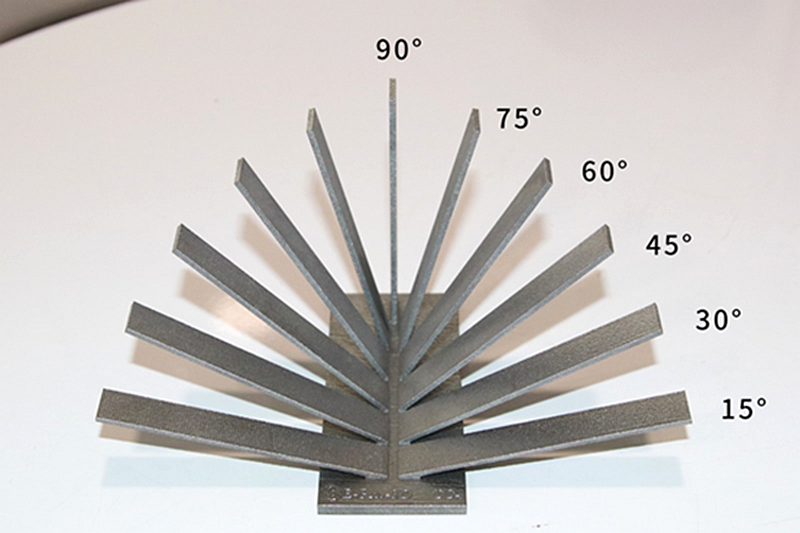

While WAAM technology offers a fast and efficient way to produce titanium alloy parts, the printed components often require post-processing to achieve the final properties and surface finish required for their intended application. Post-processing steps can include:

Heat Treatment

Heat treatment: Titanium alloys, especially Ti-6Al-4V, benefit from heat treatments that improve their mechanical properties. Heat treatment processes such as annealing, aging, or solutionizing can enhance the material's strength, hardness, and ductility.

Hot Isostatic Pressing (HIP)

HIP: This post-processing technique involves subjecting the printed part to high pressure and temperature in an inert gas environment. HIP helps to reduce porosity, improve mechanical properties, and refine the microstructure of the titanium alloy.

Machining

While WAAM can produce parts with relatively high dimensional accuracy, some components may require secondary machining to achieve tolerances or surface finishes. CNC machining is commonly used to finalize features such as holes, threads, or tight tolerances.

Surface Finishing

The surface finish of WAAM parts can be rough compared to traditional machining methods, so additional steps like grinding, polishing, or bead blasting may be required to achieve the desired surface texture or smoothness.

Testing and Quality Control for Titanium Alloy Parts

Given the critical nature of parts made from titanium alloys, particularly in aerospace, automotive, and medical applications, rigorous testing and quality control are essential to ensure that parts meet the necessary standards.

Tensile Testing

Tensile Testing measures the material’s ability to withstand tension and determines its ultimate tensile strength, yield strength, and elongation. This test is essential for evaluating the mechanical properties of titanium parts to ensure they can withstand the stresses they will encounter in high-performance applications.

Microstructural Analysis

Manufacturers can use techniques such as scanning electron microscopy (SEM) or metallographic microscopy to examine the grain structure and identify any defects, such as porosity or cracks. These methods are crucial for assessing the quality of the material and ensuring that the part will perform as intended.

Hardness Testing

To ensure the part has the required hardness, especially for aerospace or medical applications, hardness testing using Rockwell or Vickers scales is essential. It ensures that the part has the right balance of strength and durability for its specific application.

X-ray and Ultrasonic Testing

X-ray and Ultrasonic Testing are non-destructive testing methods used to detect internal defects, such as voids or cracks that might not be visible on the surface. These tests ensure the structural integrity of the titanium alloy parts, confirming their suitability for high-stress environments.

Applications of WAAM-Printed Titanium Alloy Parts

WAAM technology has unlocked the possibility of producing titanium alloy components across various industries. Some of the critical applications include:

Aerospace

In Aerospace and Aviation, WAAM produces turbine blades, structural components, and engine parts where lightweight and strength are critical. Titanium alloys, such as Ti-6Al-4V, are commonly used in these applications due to their excellent high-temperature strength and resistance to oxidation. These alloys are essential in reducing the weight of aircraft components while maintaining their performance under extreme conditions.

Automotive

The Automotive industry uses WAAM to produce lightweight titanium components for exhaust systems, suspension parts, and engine components. These parts benefit from titanium’s high strength-to-weight ratio and corrosion resistance, improving fuel efficiency and overall vehicle performance. WAAM technology ensures precise control over part dimensions, critical in automotive manufacturing.

Medical

Titanium is widely used in the medical field for implants, such as hip replacements, bone plates, and dental implants. WAAM allows for custom-shaped implants that match the patient’s anatomy, providing better fit and performance. Titanium alloys are known for their biocompatibility, making them ideal for medical applications where both strength and a high level of safety are required.

Energy

In the energy sector, WAAM technology produces parts that must withstand high pressures and temperatures, such as components for gas turbines and heat exchangers. These parts must be manufactured from materials that can endure extreme conditions without compromising performance, and titanium alloys provide the necessary combination of strength, durability, and corrosion resistance.

FAQs

What are the key advantages of using titanium alloys in WAAM for aerospace applications?

How does the WAAM process compare to traditional titanium alloy manufacturing methods?

What are the standard post-processing techniques used for WAAM-printed titanium parts?

How is the surface finish of WAAM-printed titanium parts improved after printing?

What testing methods ensure the quality and performance of WAAM-printed titanium alloy parts?