Cutting Edge Superalloy Technology

Superalloy R&D and Simulation

Neway's cutting-edge technology in high-temperature alloys encompasses material optimization, failure analysis, and life extension for components. Advanced methods like HIP diffusion welding and inertia friction welding ensure enhanced performance. Full-process simulation—including structural and fluid dynamics analysis—coupled with test verification drives innovation and precision in extending the life of single-crystal directional blades and alloy components.

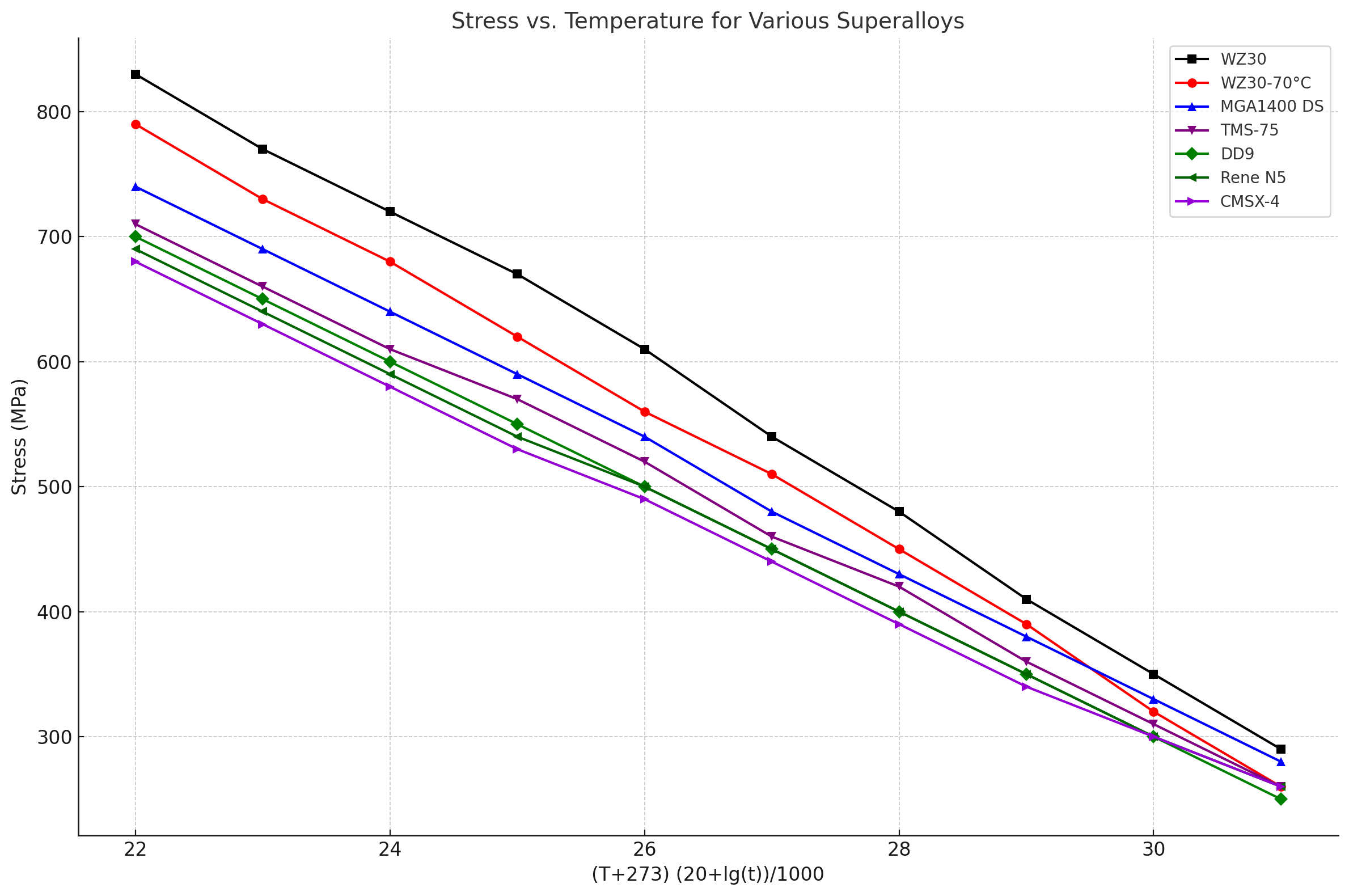

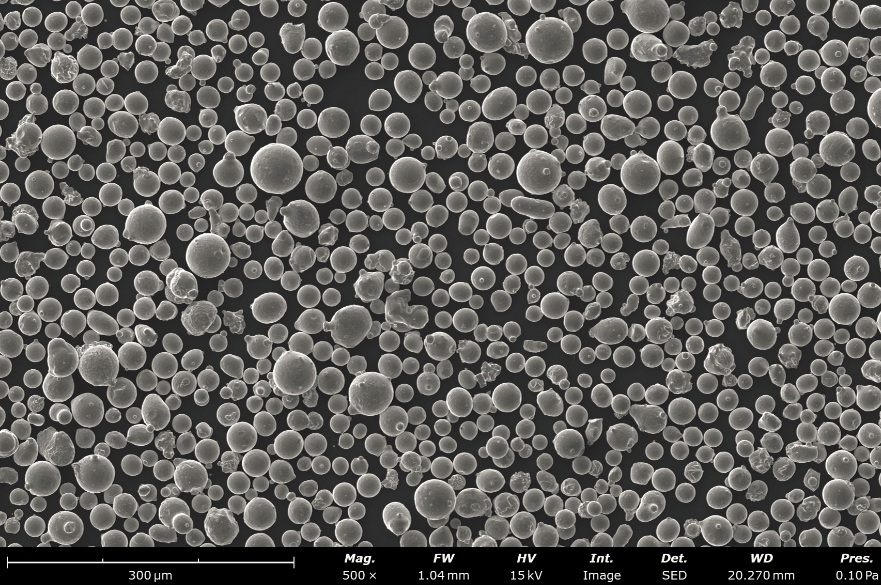

Material Design Optimization

At Neway Precision Works, our Material Design Optimization process leverages high-throughput calculation and advanced alloy characterization techniques. We develop high-performance superalloys with fully independent intellectual property rights through this integration of simulation and experimental methodologies. Our capabilities in this area are focused on optimizing alloy compositions and microstructures to enhance properties such as high-temperature strength, oxidation resistance, fatigue resistance, and corrosion resistance.

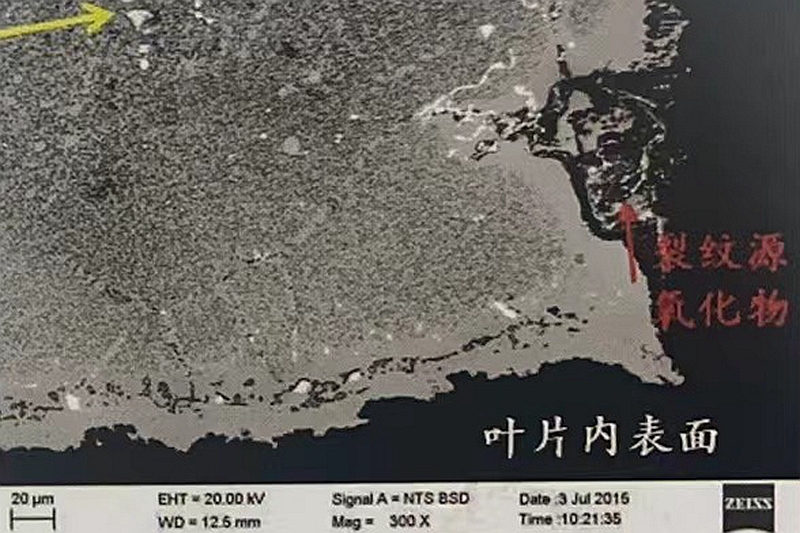

Failure Analysis

Failure Analysis involves fracture, metallographic, and SEM analysis to identify materials' failure modes and root causes. Examining crack morphology and microstructure helps determine stress points, fatigue, or material degradation. This technology is crucial in aerospace, energy, and manufacturing, enabling design optimization, improved material performance, and enhancing safety in high-stress components like turbine blades.

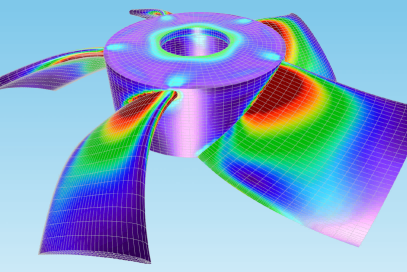

Structural Analysis

Structural Analysis uses finite element software to evaluate components' static, dynamic, and thermal behavior under different conditions. It includes stress, fatigue, and heat conduction analysis, ensuring safety and durability. Applications range from medical implants to aerospace and automotive industries, optimizing designs for performance, weight reduction, and reliability under real-world operating stresses and environmental conditions.

Let's Start A New Project Today