Alloy Performance Optimization Enhancing Component Durability

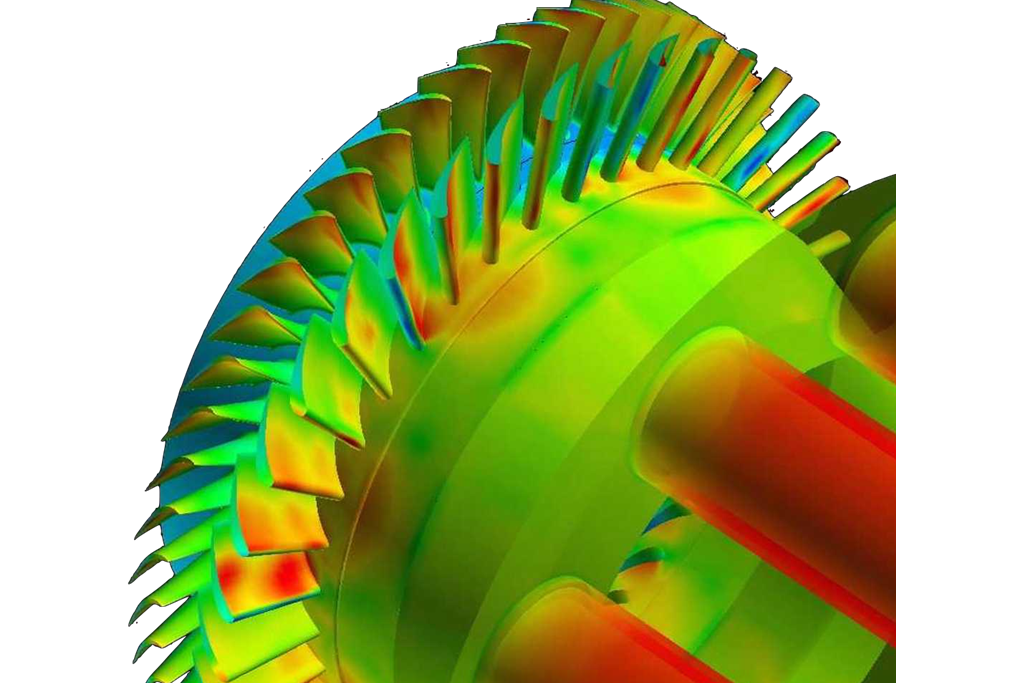

Superalloys are critical materials in high-performance applications, where extreme heat, stress, and corrosion conditions often prevail. These alloys, known for their remarkable strength and resistance to high temperatures, are integral to aerospace, power generation, and defense industries. Their exceptional durability ensures that components perform reliably under demanding conditions, including in environments where other materials would fail. As industries increasingly push the limits of performance and efficiency, optimizing superalloy components is essential to maintaining reliability, reducing maintenance costs, and extending the lifespan of critical parts.

Different Process Superalloy Parts

Superalloy components are produced using a variety of sophisticated manufacturing processes, each designed to achieve specific mechanical properties tailored to their intended application. Some of the most common processes include:

Vacuum investment casting: This process is often used to produce highly complex and precise parts, particularly for aerospace and turbine applications. Vacuum investment casting allows for the production of intricate geometries while ensuring minimal porosity and high surface finish. Components like turbine blades and nozzles are often manufactured using this method, as it can produce fine-grain structures that enhance mechanical properties.

Single crystal casting: This method is widely used to produce jet engine turbine blades. It involves the controlled solidification of the alloy, allowing the formation of a single crystal structure, which provides superior resistance to thermal fatigue and creep. This process is ideal for high-performance engine parts subjected to extreme heat and mechanical stresses.

Equiaxed crystal casting: The alloy solidifies in a random crystalline structure, resulting in equiaxed grains. This casting type is often used to produce parts that require good overall mechanical properties but do not need the high directional strength that single crystal casting provides. Equiaxed crystal casting is commonly used in manufacturing components such as gas turbines and engine casings.

Directional casting: This process involves the controlled solidification of the alloy in a specific direction, resulting in a grain structure that is oriented along the axis of the part. This helps improve mechanical strength and fatigue resistance in high-stress areas, such as turbine blades and rotors. Directional casting is essential for applications that require the part to endure significant cyclic stresses under high temperatures.

Powder metallurgy: A high-efficiency manufacturing process, powder metallurgy involves using metal powders that are compressed and sintered to form complex parts. This technique allows for creating parts with superior material properties, such as high strength and resistance to wear, often used in turbine discs, seals, and other components that require fine-tuned performance characteristics.

Forging: Forging, including precision and free forging, is a standard method for manufacturing high-strength superalloy components. The process involves shaping the material using compressive forces, which leads to improved mechanical properties due to the alignment of the grain structure. Forging produces critical parts such as turbine rotors, shafts, and engine components.

CNC machining: Many superalloy components require precise machining to achieve the desired dimensions and tolerances after casting or forging. CNC machining allows for the accurate and efficient production of complex geometries, making it an essential post-processing technique for superalloy parts used in aerospace and defense industries.

3D printing: As an advanced additive manufacturing technique, 3D printing has gained popularity for producing complex superalloy components, especially for low-volume production and prototyping. This method allows for greater design freedom and reduced material waste compared to traditional manufacturing processes. In superalloy manufacturing, 3D printing is beneficial for creating intricate parts like turbine blades and structural components that would be difficult to produce using conventional methods.

Benefits to Different Superalloys

Each superalloy is designed with specific performance characteristics to suit its intended application. Manufacturers can enhance the properties required for different environments by tailoring the alloy composition and microstructure.

Inconel Alloys

Known for their excellent high-temperature strength, oxidation resistance, and overall durability, Inconel alloys are widely used in aerospace and power generation applications. Inconel 718, for example, is often used in gas turbines and jet engine components because it can withstand extreme temperatures while maintaining its strength.

CMSX Series

These single-crystal superalloys are designed to perform under extreme conditions, offering superior creep resistance and thermal fatigue strength. CMSX-10, a popular choice, is used in advanced turbine blades and other components exposed to high temperatures and mechanical stress.

Monel and Hastelloy Alloys

These alloys are prized for their excellent corrosion resistance, making them ideal for use in harsh chemical environments. Monel 400, for example, is used in marine applications where resistance to seawater corrosion is critical. Similarly, Hastelloy C-276 is commonly used in chemical processing industries due to its resistance to a wide range of corrosive substances.

Stellite Alloys

These cobalt-based alloys are known for their hardness, wear, and corrosion resistance. Stellite alloys are commonly used in valves, pumps, and other components exposed to abrasion and wear in industrial applications.

Titanium Alloys

Known for their lightweight and high-strength properties, titanium alloys like Ti-6Al-4V are widely used in aerospace applications, including airframes and turbine engines, where the strength-to-weight ratio is critical.

Rene Alloys

Offering excellent high-temperature strength and resistance to thermal creep, Rene alloys are often used in turbine engines and other aerospace applications that demand superior performance under extreme heat and mechanical stress.

Post-Processes Comparison

After the initial manufacturing of superalloy components, several post-processing techniques are often employed to improve their mechanical properties and ensure that they meet the stringent requirements of their respective applications. These processes can enhance material performance, eliminate defects, and optimize the microstructure for increased durability.

Hot Isostatic Pressing (HIP): This post-processing technique involves subjecting the material to high temperature and pressure in a controlled environment to eliminate porosity and improve the material’s density and mechanical properties. HIP is particularly beneficial for parts produced by powder metallurgy and casting, as it can significantly reduce internal defects and increase the overall integrity of the component. It is critical in improving fatigue resistance and strength, which is essential for aerospace and energy applications.

Heat treatment: Heat treatment processes, such as solution treatment and aging, are essential for optimizing the mechanical properties of superalloys. This process helps to refine the microstructure, increase hardness, and improve strength, which is critical for components that operate in high-temperature environments. Heat treatment increases fatigue resistance and creep strength in high-stress applications, such as turbine blades and engine components.

Superalloy welding: Many components require welding to join different parts or repair damaged components. Superalloy welding techniques are highly specialized, requiring precise control of heat and filler materials to prevent the formation of defects such as cracks or weakening of the joint. Precision in welding ensures the structural integrity and reliability of complex assemblies in gas turbines and aerospace structures.

Thermal Barrier Coating (TBC): TBCs are applied to high-temperature components to provide additional protection against heat and thermal cycling. Thermal Barrier Coating (TBCs) are commonly used in gas turbines and jet engines, where they help to protect the underlying superalloy parts from the extreme temperatures encountered during operation. These coatings also reduce oxidation and material degradation, extending the lifespan of critical components.

CNC machining and deep hole drilling: CNC machining is used for post-processing to achieve tight tolerances and complex geometries, essential for parts used in critical applications. Deep hole drilling is often required for components like turbine blades, which have intricate cooling passages that must be precisely manufactured to ensure optimal performance. Deep hole drilling techniques allow for the creation of cooling channels that significantly improve the heat dissipation of high-performance turbine components.

Electrical Discharge Machining (EDM): EDM is commonly used to machine complex or delicate features in superalloy components, particularly for parts with intricate geometries or those made from tough materials. This method uses high-precision electrical discharges to remove the material, making it ideal for producing small, detailed features in components used in gas turbines and other high-stress applications. EDM allows for the creation of fine features in hard-to-machine alloys, ensuring optimal functionality.

Testing

Testing is an essential aspect of ensuring the performance and durability of superalloy components. Several testing methods are employed to verify that parts meet the required specifications and can perform reliably under extreme conditions.

Tensile Testing determines superalloy materials' strength, elasticity, and elongation properties. This test is crucial for assessing how well a material can withstand tensile stresses without failing, making it an essential method for evaluating components like turbine blades and shafts.

Fatigue Testing assesses superalloy parts' resistance to crack initiation and propagation under cyclic loading. Fatigue testing is critical for parts used in jet engines, turbines, and other high-stress environments, ensuring that components can withstand repeated stress without failure.

X-ray and Metallographic Analysis are used to assess the internal structure of superalloy components, detecting defects such as voids, cracks, or inclusions that could compromise the part’s integrity. These methods ensure that parts meet the rigorous standards of aerospace and other critical industries.

CMM (Coordinate Measuring Machine) Inspection ensures that the dimensions and tolerances of a superalloy part are within the required specifications. CMM is often used in high-precision applications, such as aerospace components, where even minor dimensional discrepancies can lead to catastrophic failures.

SEM (Scanning Electron Microscope) provides high-resolution imaging of superalloy parts' microstructure and surface features. This method is valuable for identifying issues like crack propagation, wear patterns, and the effects of high-temperature exposure on material performance.

Industry and Application of Superalloys

Superalloys are crucial in several industries where high performance and reliability are paramount. Their ability to withstand extreme environments makes them indispensable for various applications, from aerospace to power generation.

Aerospace and Aviation

Superalloy components like turbine blades, combustion chambers, and heat shields are vital for the performance and safety of jet engines. These components are exposed to extreme temperatures, stresses, and environmental conditions, and superalloys ensure that they can withstand these demands without failure. Precision heat treatment further enhances the performance of these components, improving their longevity and efficiency.

Power Generation

Superalloys are used to produce turbine blades, rotors, and nozzles for power plants. These components operate under high heat and mechanical stress, and the superior properties of superalloys ensure they can function reliably over long periods, minimizing downtime and maintenance costs. For instance, superalloy heat exchanger parts are commonly used in high-temperature environments to maintain efficiency in heat transfer systems.

Oil and Gas

In the oil and gas industry, superalloy components are used in drilling equipment, valves, and offshore platforms, where resistance to corrosion and high temperatures is essential. The harsh operating conditions make superalloys the material of choice for ensuring long-term performance and reliability. High-temperature alloy pump components are an excellent example of superalloy applications in oil and gas, offering durability and strength in challenging environments.

Marine

Superalloys are employed in naval ship components, including propellers, heat exchangers, and other critical systems exposed to saltwater and harsh marine environments. The corrosion resistance and strength of superalloys make them ideal for these applications. For example, superalloy naval ship modules are essential in ensuring naval vessels' longevity and operational reliability in demanding conditions.

Chemical Processing

Superalloys are used in chemical processing plants' reactors, heat exchangers, valves, and other components. Their resistance to chemical corrosion ensures that they can perform reliably in aggressive environments, extending the lifespan of critical equipment. Superalloy materials are essential for superalloy heat exchanger parts, where corrosion resistance is critical in maintaining operational efficiency.

Military and Defense

In military and defense applications, superalloys are used in engine components for aircraft, missiles, and naval systems, where durability and strength are vital. Superalloys ensure these parts can operate in extreme environments without failure, improving mission success rates and reducing maintenance costs. For example, superalloy armor system parts are designed to meet the rigorous demands of military standards, offering protection and reliability in critical defense systems.

Superalloys are essential across these industries, ensuring that high-performance components can withstand extreme conditions and contribute to the reliability and efficiency of critical systems.

FAQs

What are the key properties that make superalloys ideal for high-temperature applications?

How does Single Crystal Casting improve the performance of turbine blades?

What are the advantages of Powder Metallurgy in the production of superalloy components?

How does Hot Isostatic Pressing (HIP) affect the mechanical properties of superalloy parts?

What testing methods are crucial for evaluating the performance and durability of superalloy components in aerospace applications?