Custom Precision Vacuum Investment Casting Service

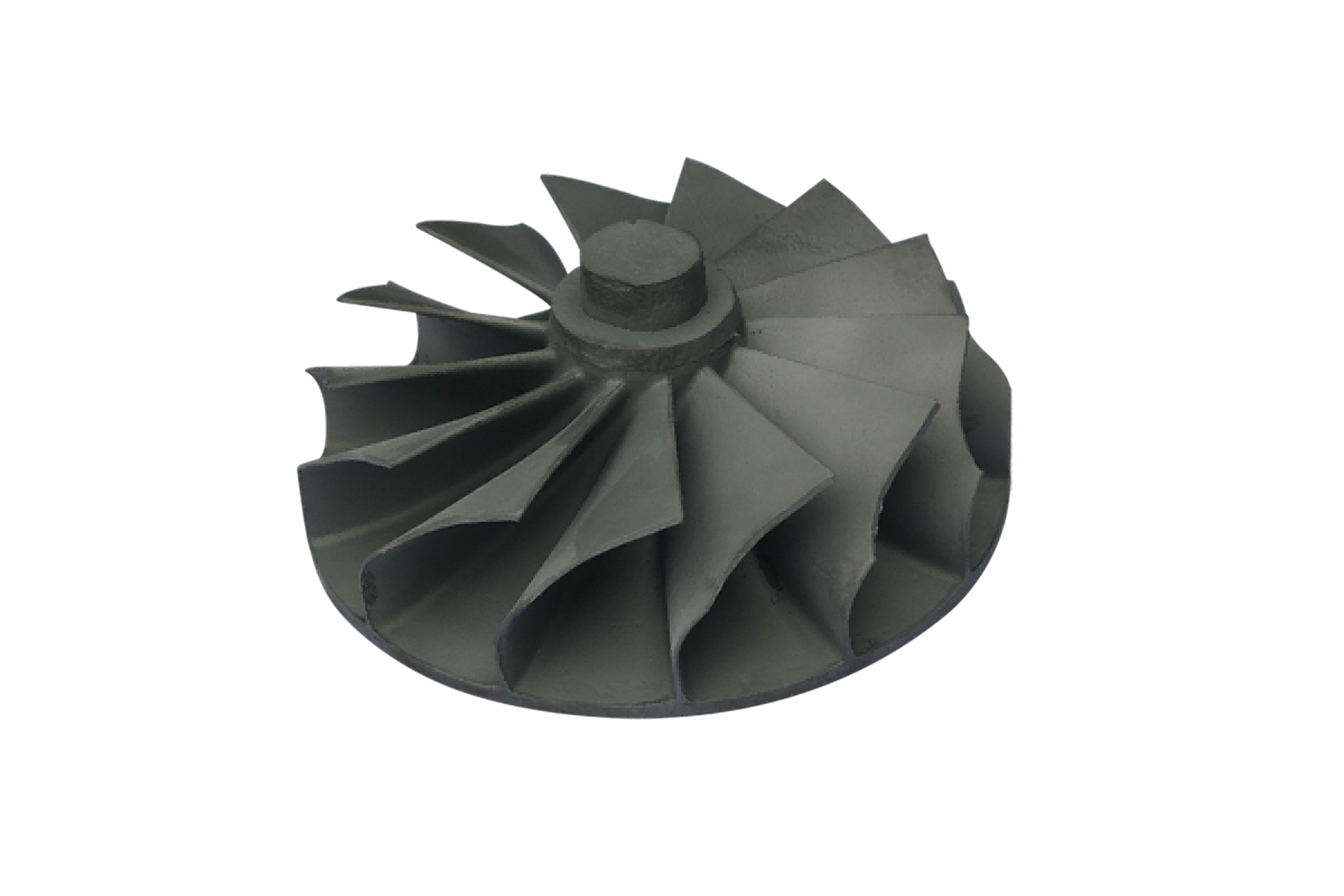

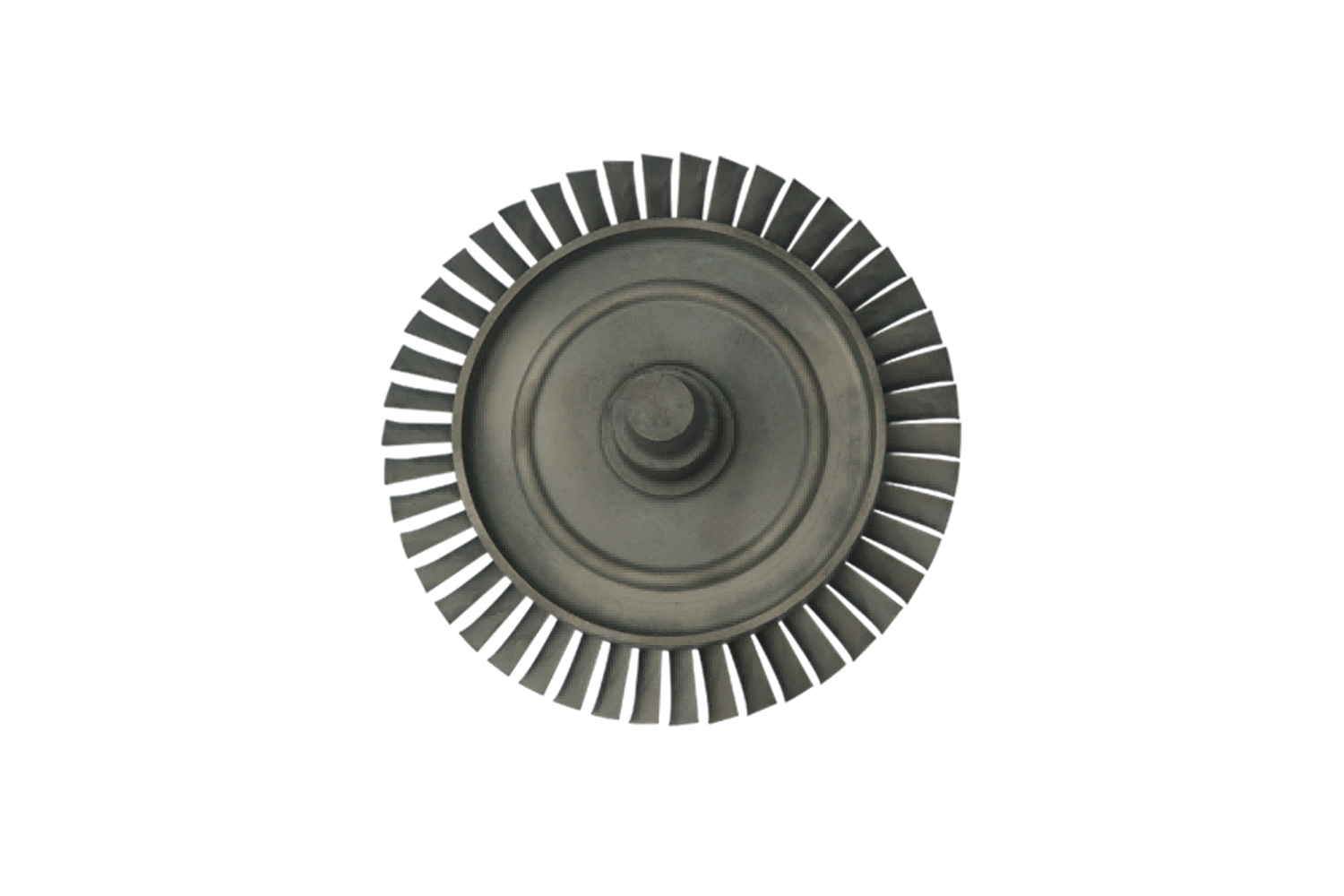

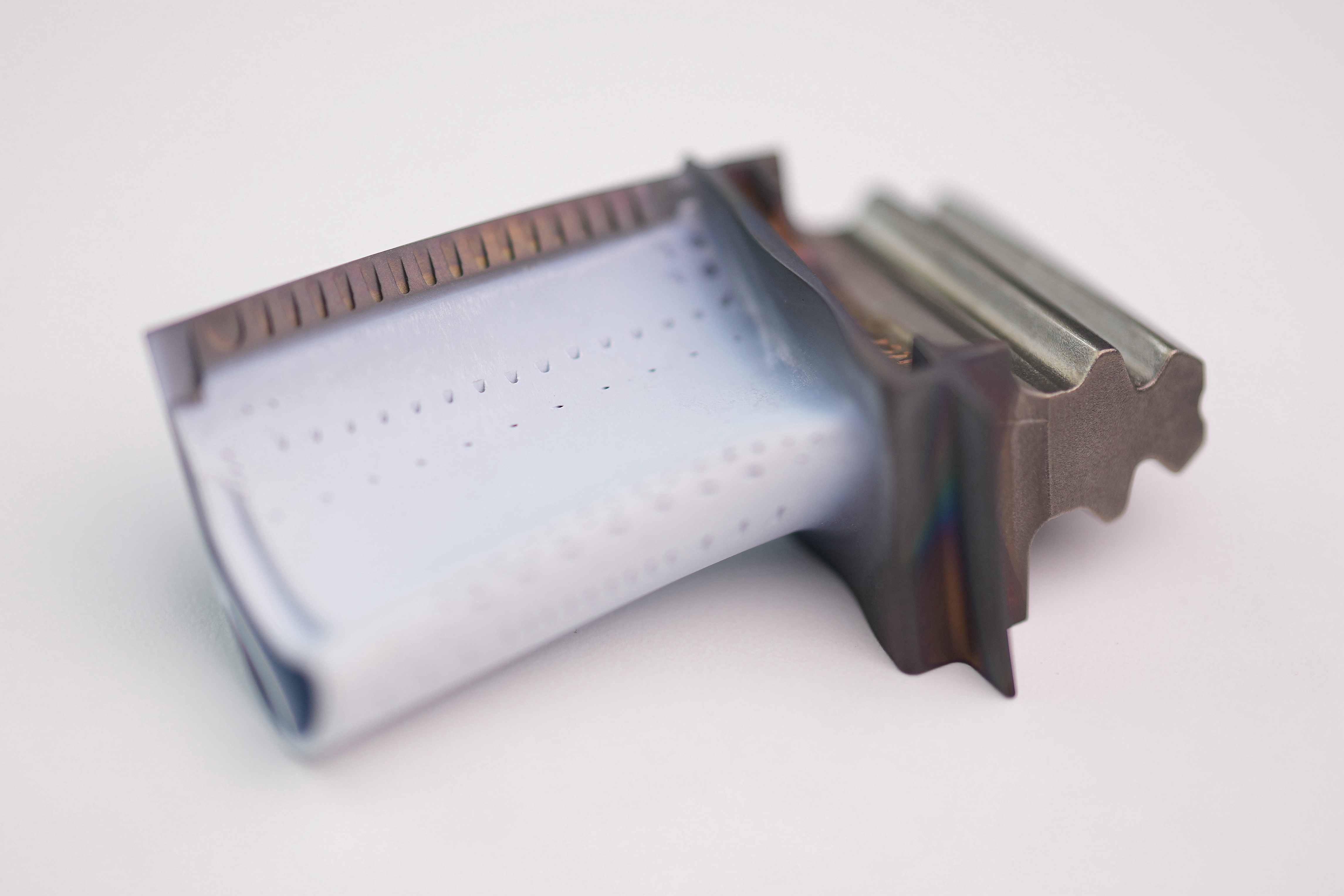

Discover expert Custom Precision Vacuum Investment Casting services for complex metal parts. Achieve tight tolerances, excellent surface finishes, and enhanced durability for aerospace, gas turbine, and petroleum applications, such as turbine blades, turbine disks, afterburners, and tail nozzles.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

High Temperature Alloy Parts Manufacturing Service

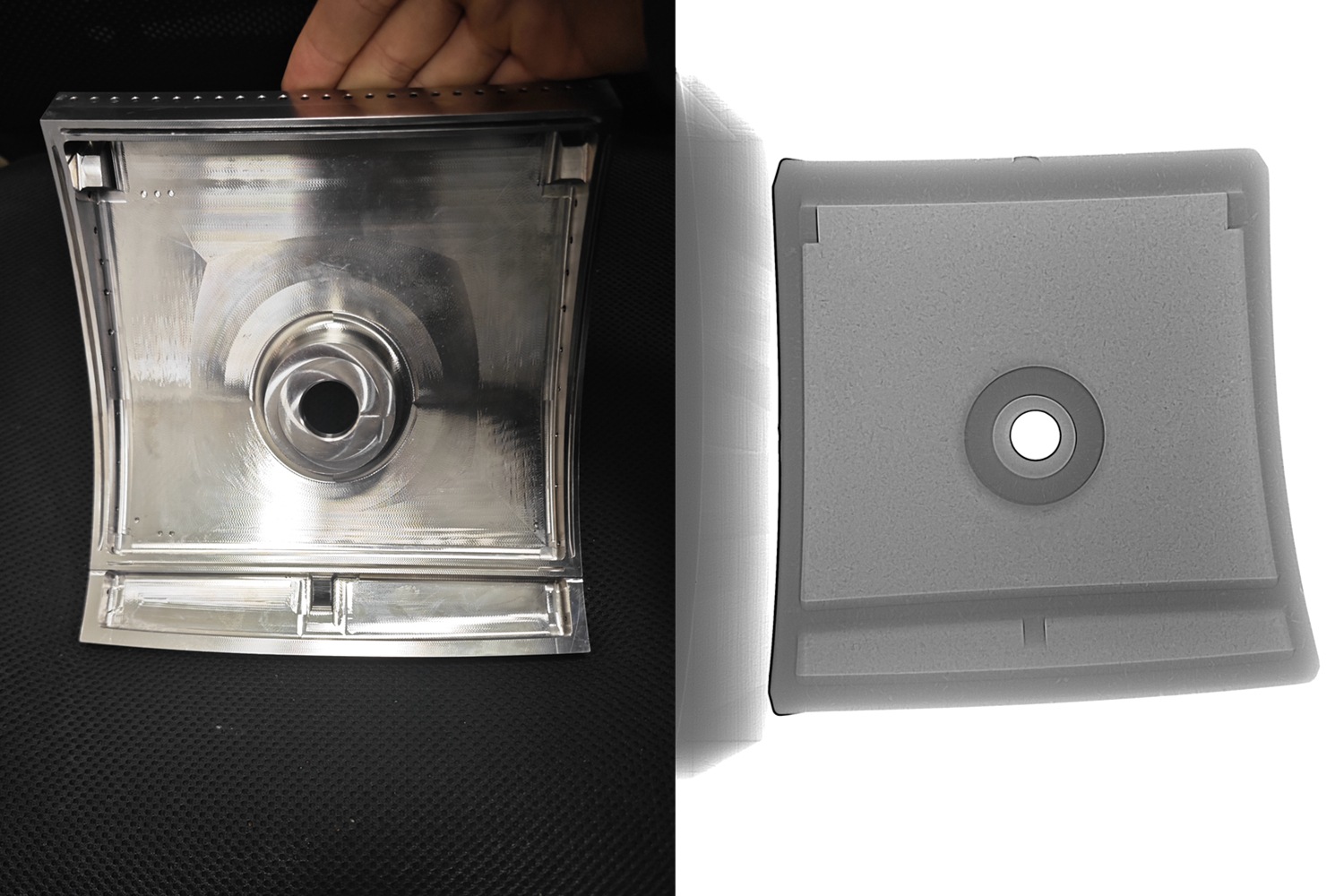

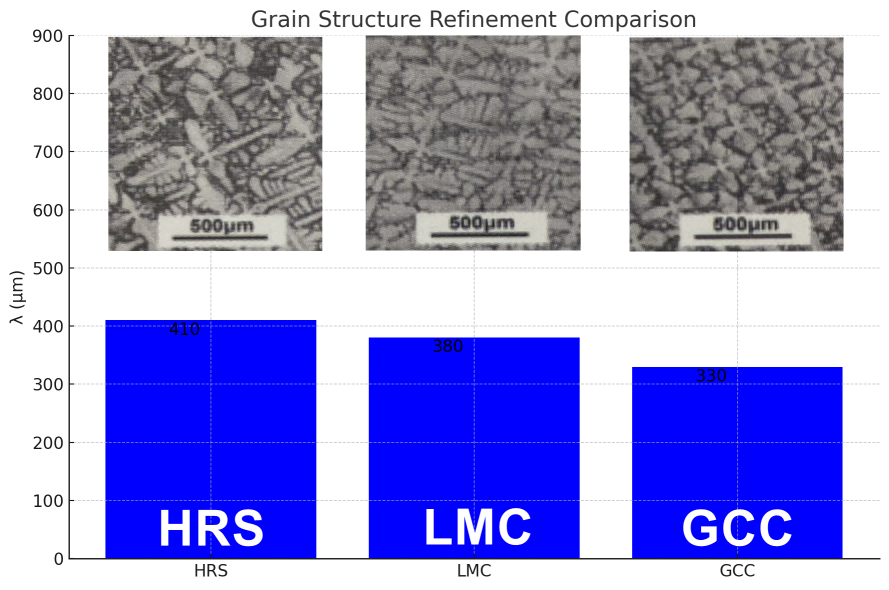

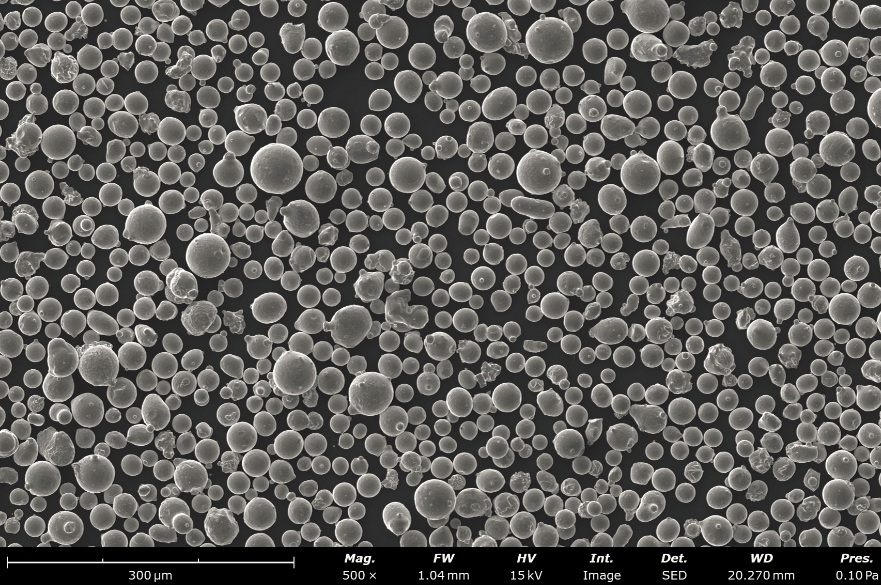

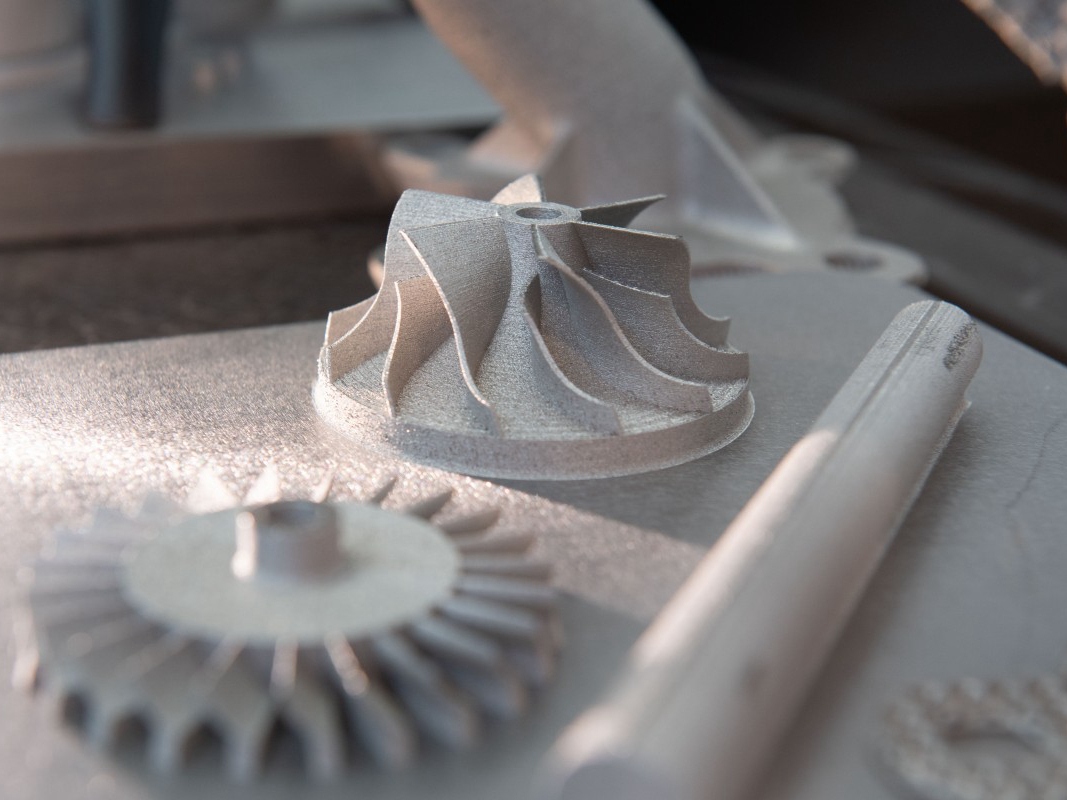

Neway specializes in vacuum casting and forging of high-temperature alloys, including single crystal casting, directional casting, powder metallurgy and equiaxed crystal casting of high-temperature alloys. At the same time, it provides CNC machining, 3D printing rapid proofing services for high-temperature alloys, as well as post-processing processes such as deep hole drilling, EDM, thermal barrier coating, hot isostatic pressing, etc., to provide you with one-stop service.

Post Process for Vacuum Investment Castings

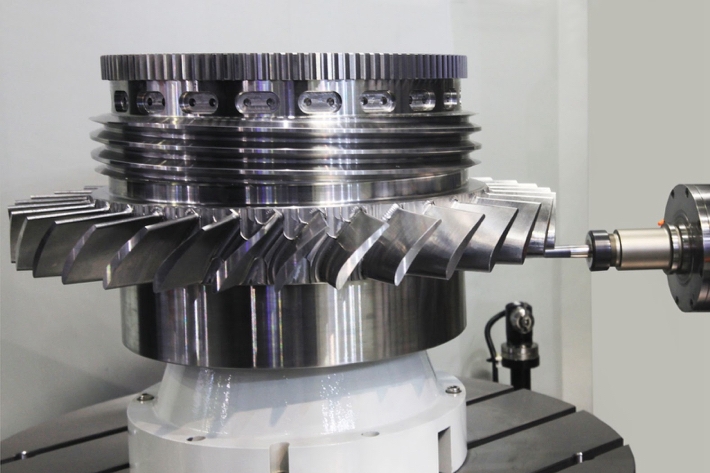

Post-processing for vacuum investment castings enhances performance and precision. HIP removes porosity and improves fatigue resistance. Heat treatment optimizes mechanical properties like hardness and strength. CNC machining ensures dimensional accuracy, while EDM enables intricate geometries. TBC protects components from high temperatures, and material testing validates quality. These processes ensure reliability for aerospace, energy, and industrial applications.

Our Strength In Manufacturing Superalloy Components

We provide high-temperature alloy casting, forging, powder metallurgy, CNC machining, and 3D printing services. We have advanced manufacturing equipment, testing equipment, and strong R&D capabilities. We provide one-stop manufacturing services for your high-temperature alloy parts.

Precision Vacuum Investment Castings in Different Industries

Precision vacuum investment casting is widely used across industries. In aerospace and aviation, it produces turbine blades and combustion chambers. Power generation utilizes it for turbine discs. Oil and gas rely on it for impellers and subsea components. It makes propellers for marine, drill bits for mining, turbochargers for automotive, heat exchangers for chemical processing, sanitary valves for pharmaceuticals, and reactor parts for nuclear.

Superalloy Part R&D and Testing

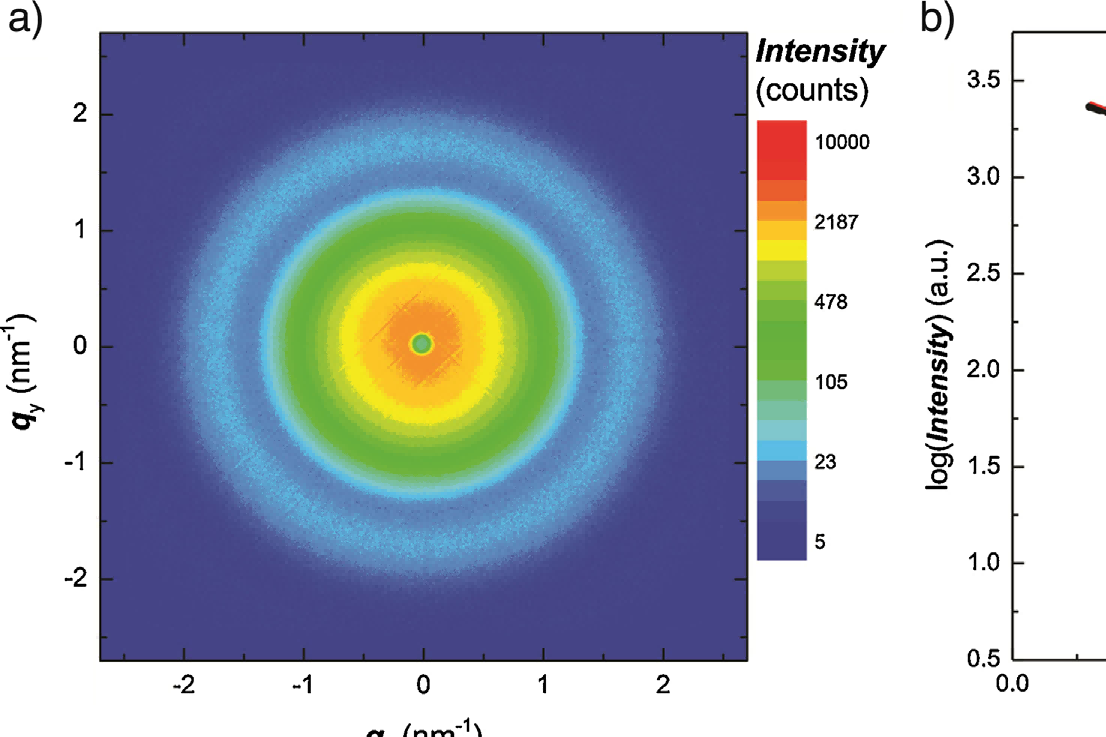

We offer the manufacturing and testing services of superalloy components that are vital in aerospace for jet engine turbine blades and exhaust systems, power generation for gas turbines, chemical processing in reactors, automotive for high-performance engine parts, and medical devices requiring high strength and corrosion resistance.

learn more

Direct Reading Spectrometer

learn more

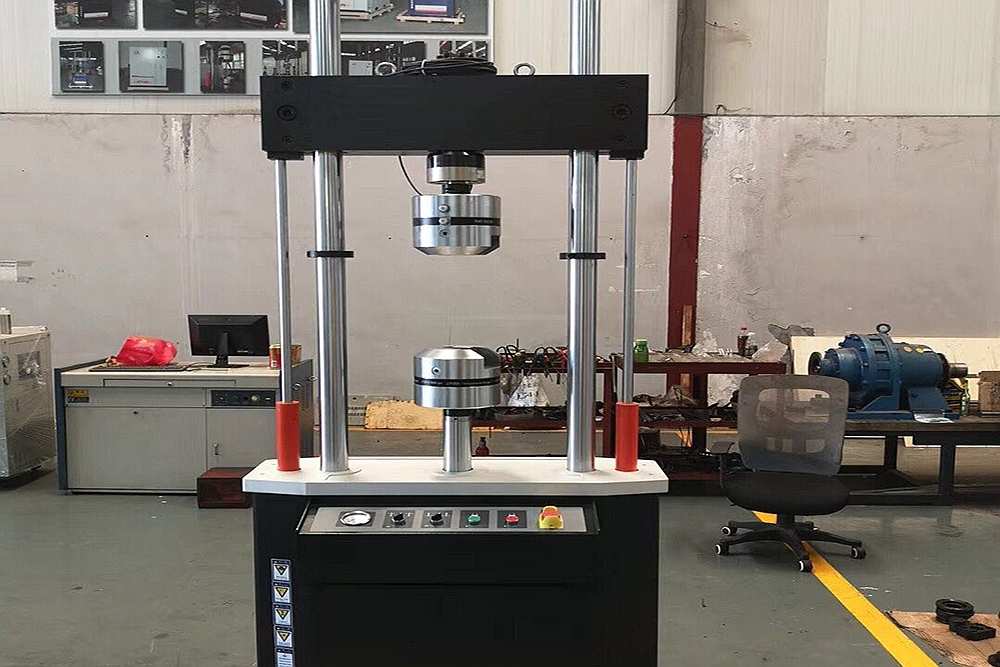

Tensile Testing Machine Checking

learn more

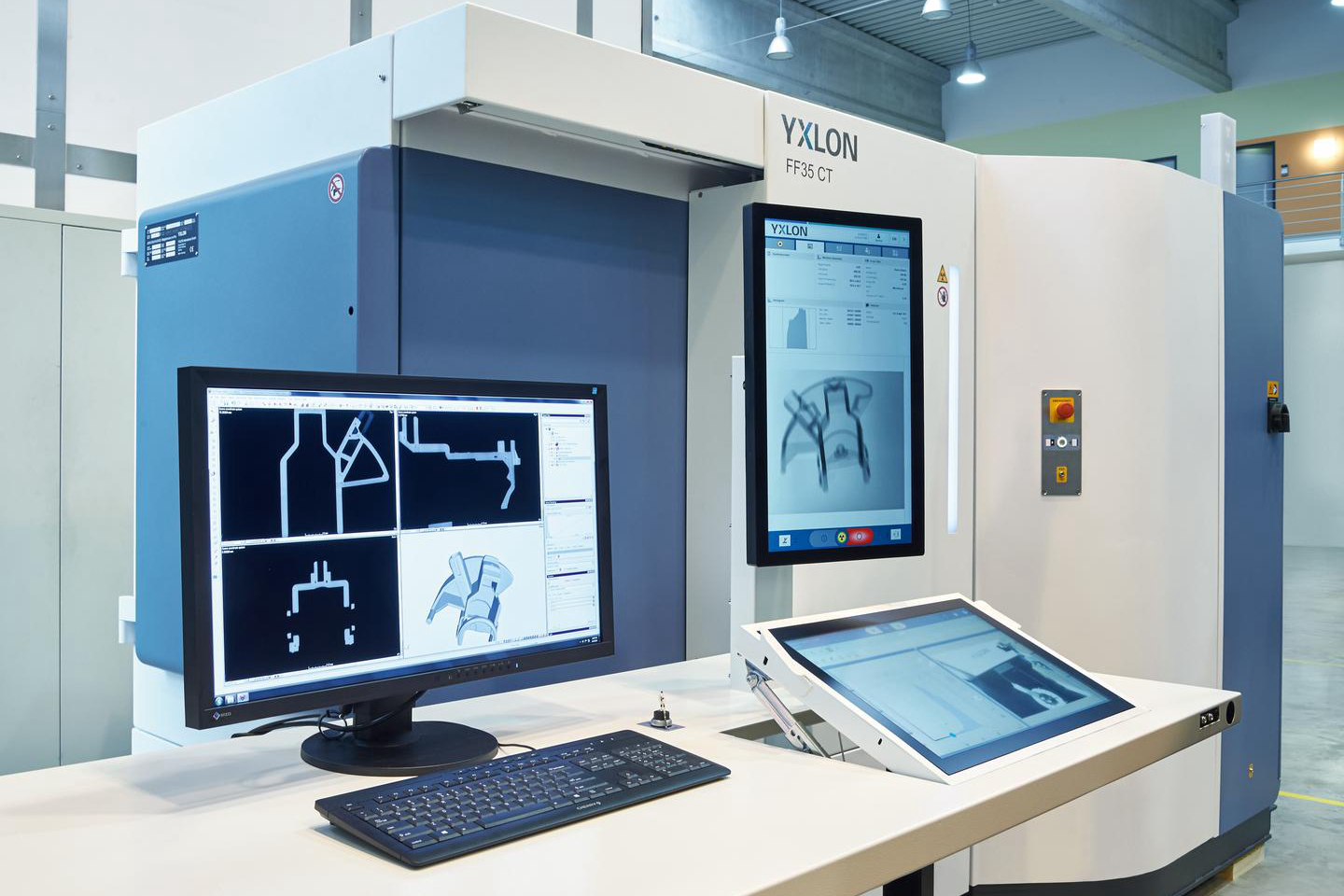

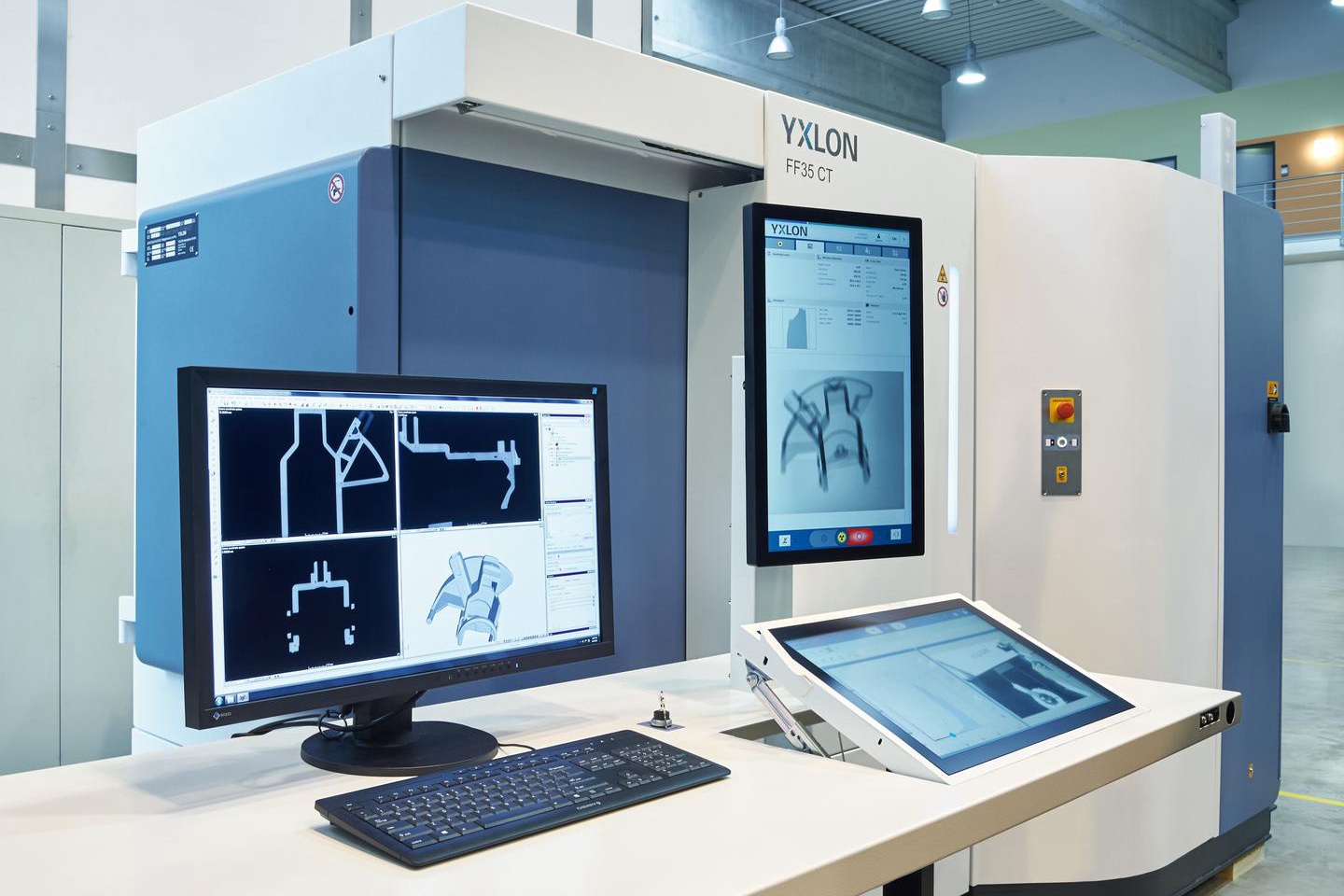

X-ray Checking

learn more

Thermal Physical Properties Test Platform

learn more

Corrosion Production Line

learn more

Dynamic and Static Fatigue Tester

learn more

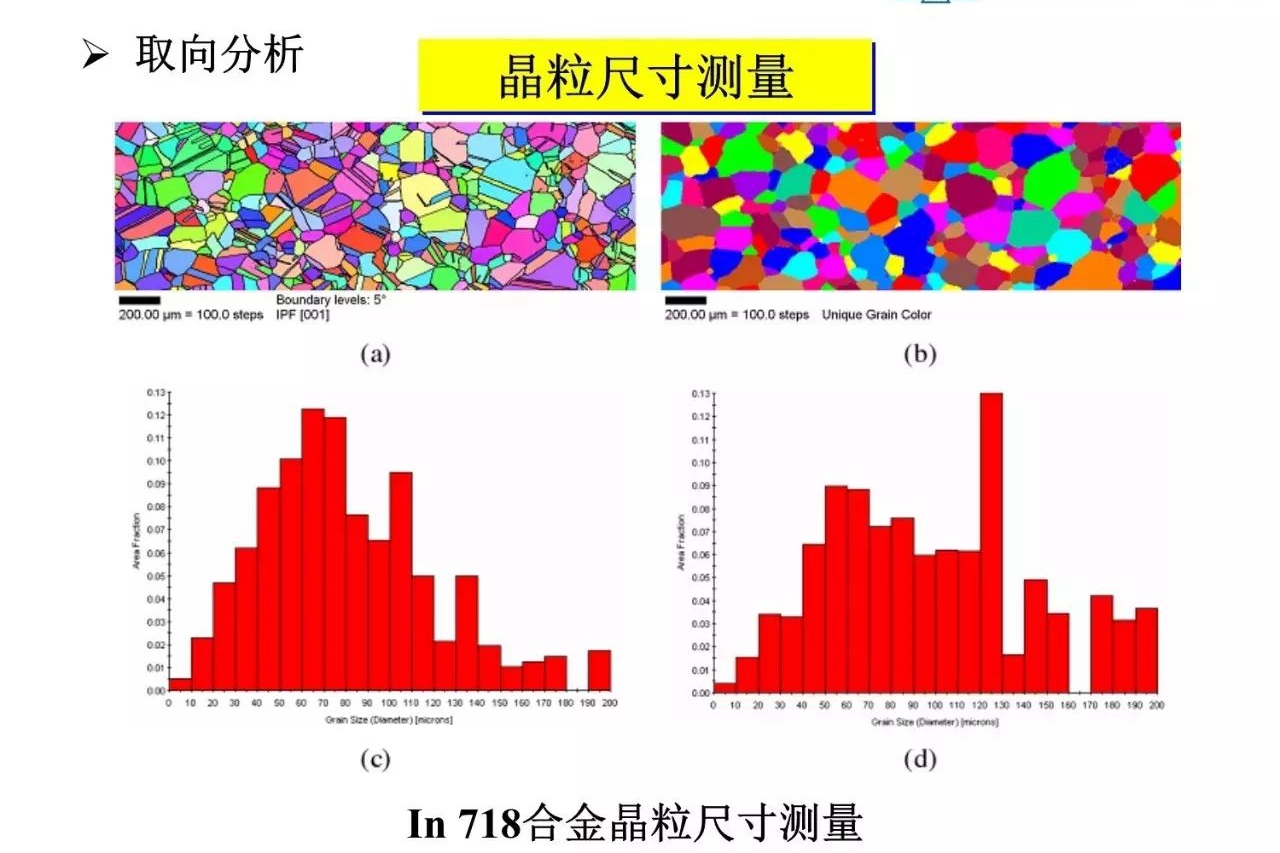

Electron Backscattering Diffractometer (EBSD)

learn more

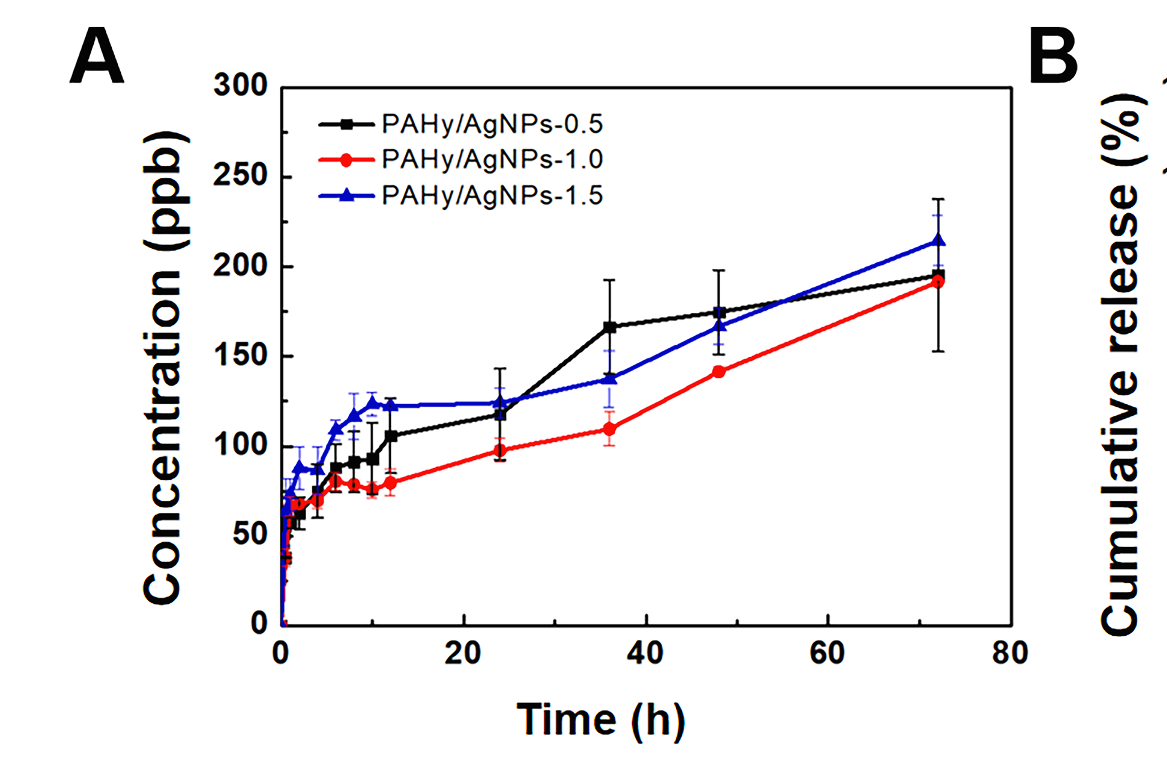

Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES)

learn more

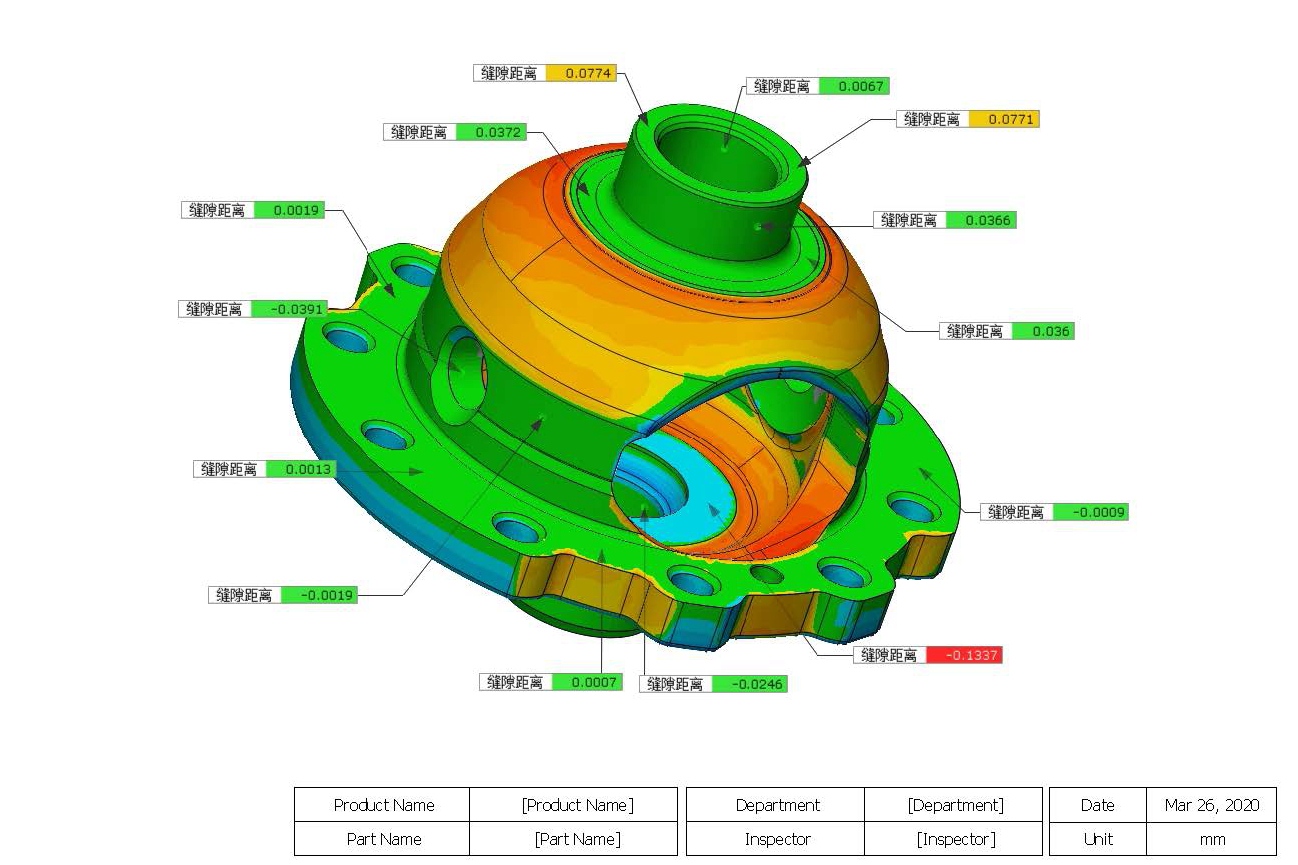

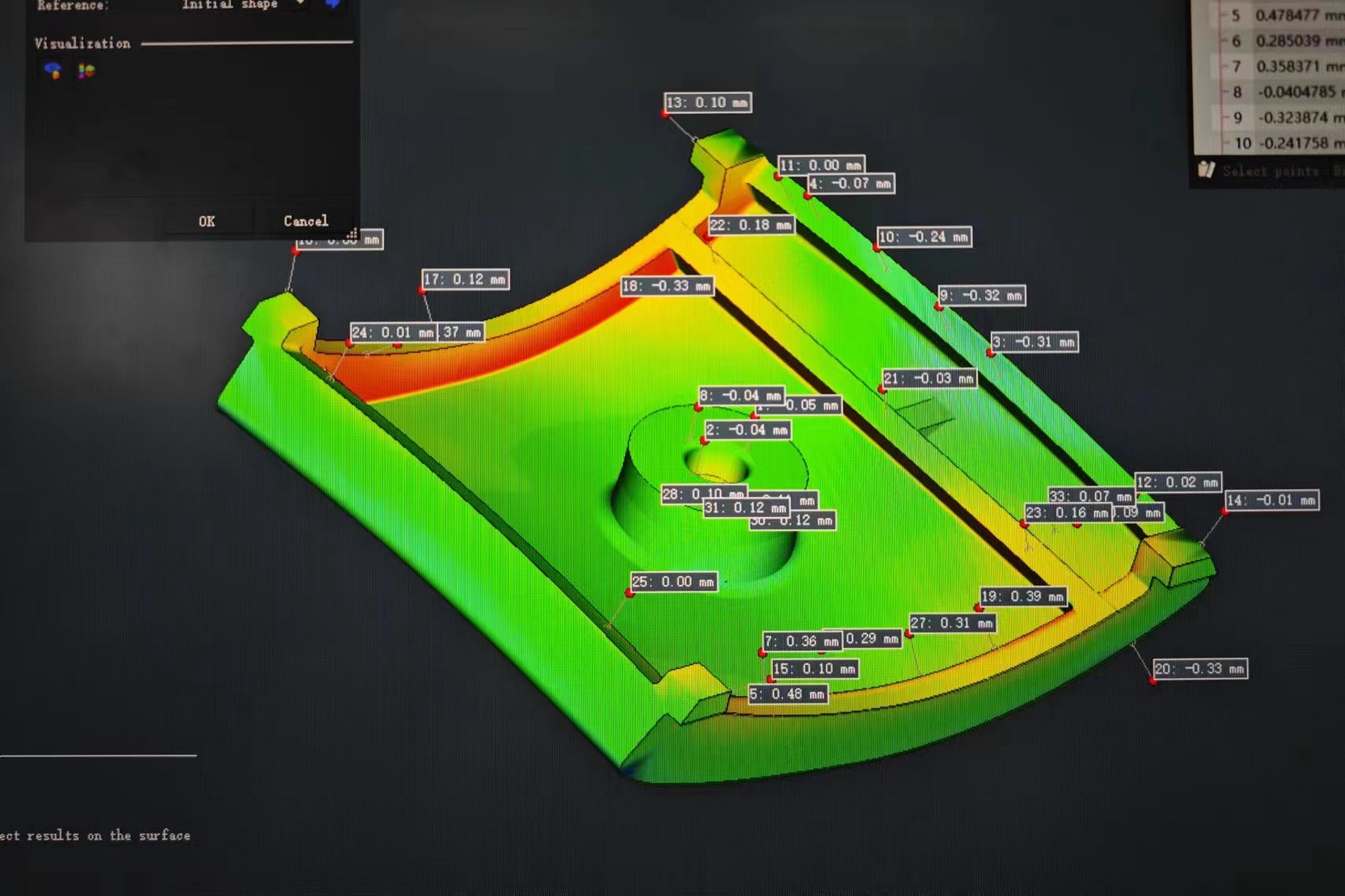

3D Scanning Measuring Instrument Checking

learn more

Coordinate Measuring Machine (CMM)

learn more

Glow Discharge Mass Spectrometer (GDMS)

learn more

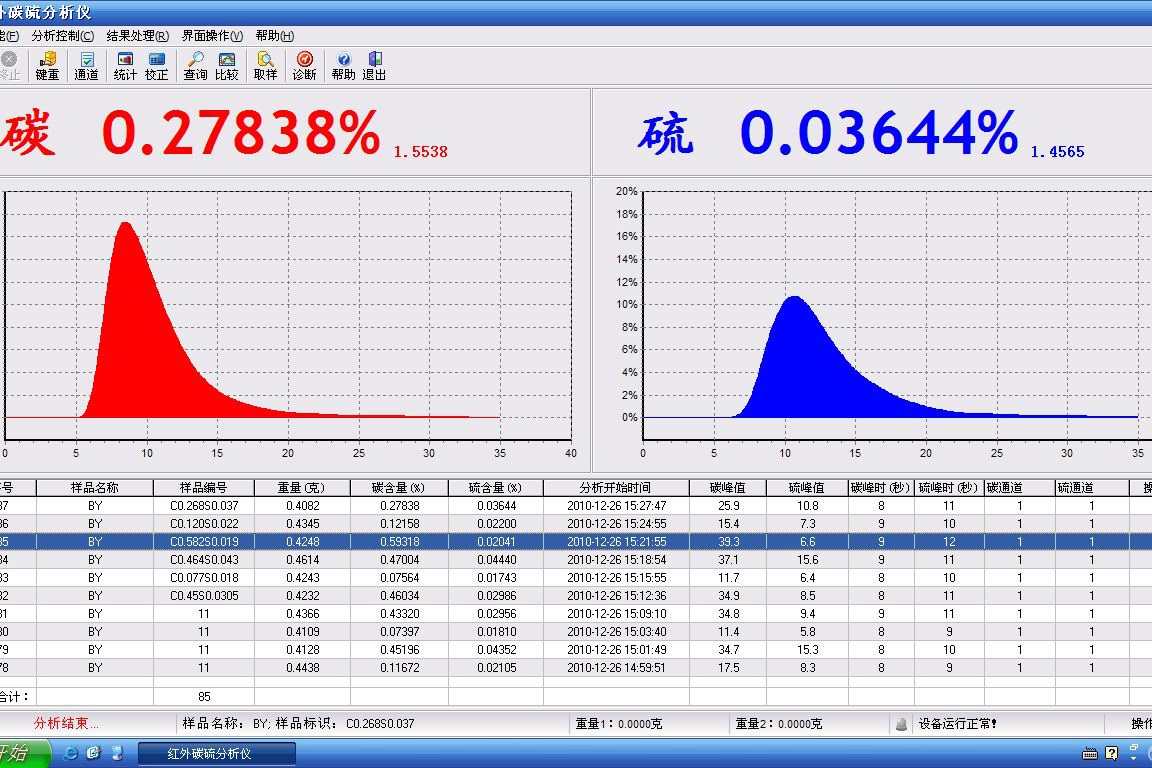

Carbon Sulfur Analyzer Checking

learn more

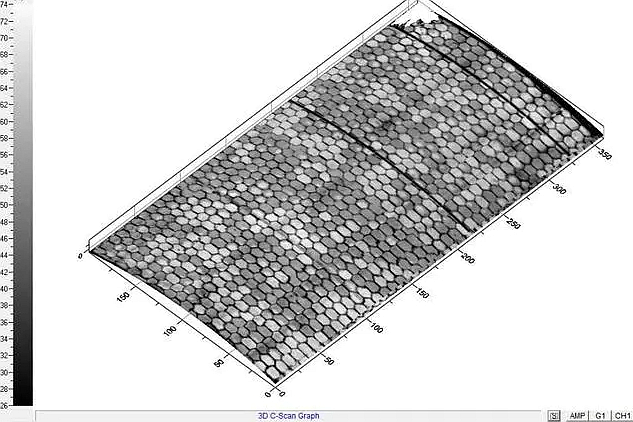

Water Immersion Ultrasonic Inspection

learn more

Line Array Industrial CT(GE)

learn more

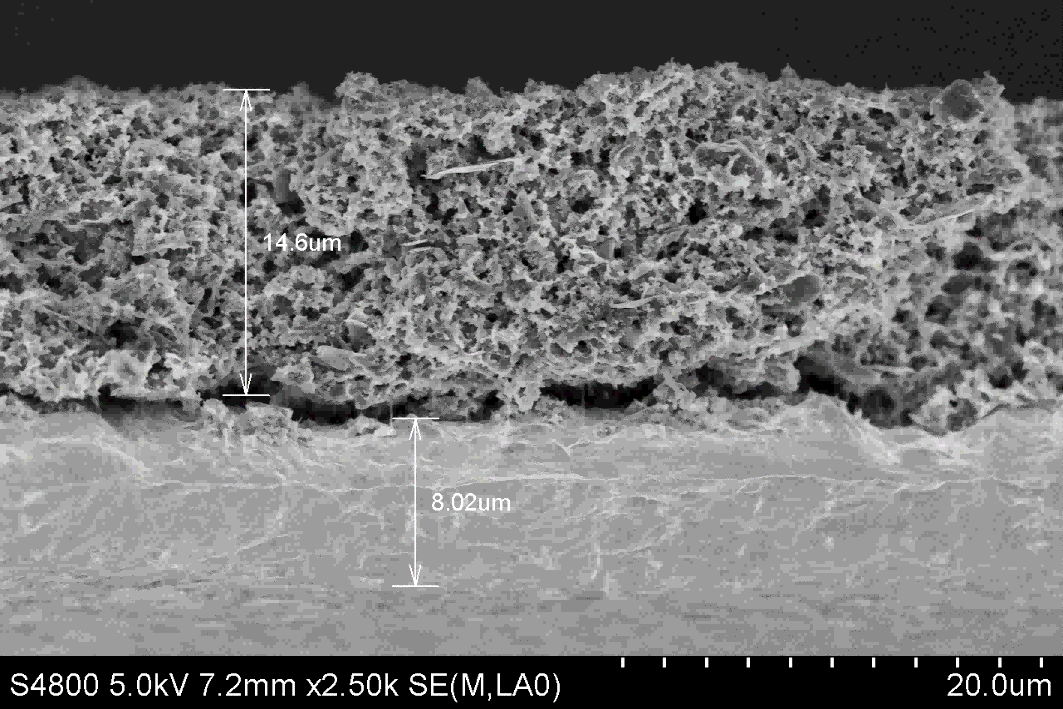

Scanning Electron Microscope (SEM) Checking

learn more

Simultaneous Thermal Analyzer (STA) Checking

learn more

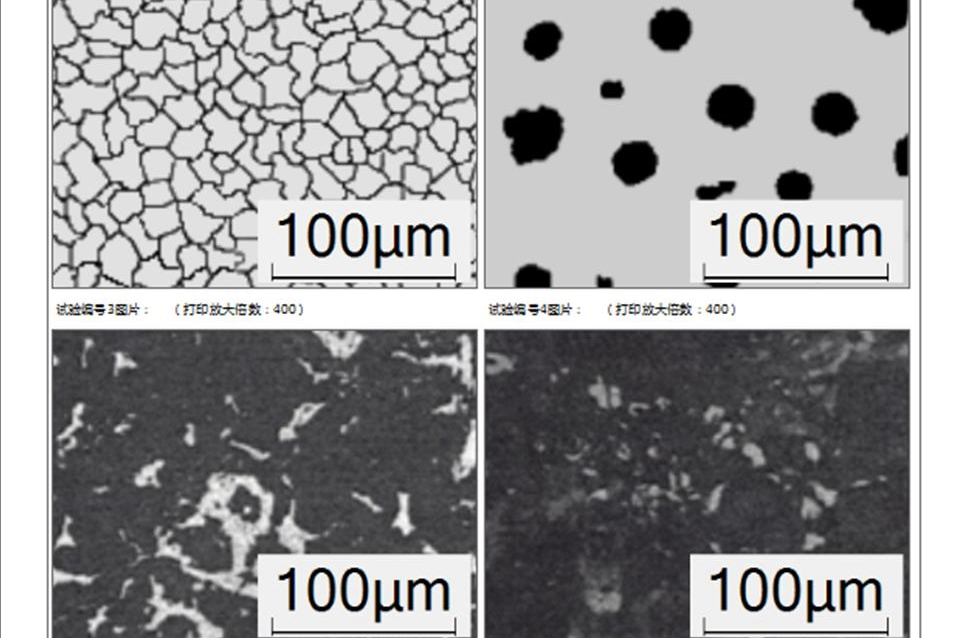

Metallographic Microscopy Checking

learn more

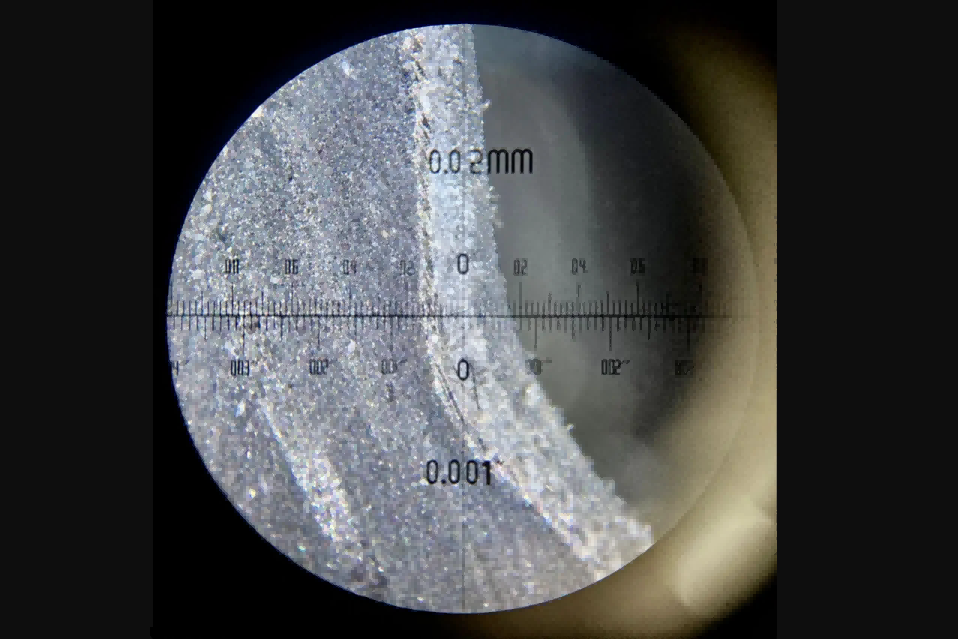

Stereo Microscope Checking

learn more

New Technology

learn more

Products Gallery

learn more

Various Industries

learn more

Surface Finishings

learn more

Post-Process

learn more

Manufacturing Technology

learn more

R&D and Simulation

learn more

Manufacturing Equipments

learn more

Testing Equipments

learn more

3D Printing Prototyping

learn more

FAQs

learn more

Contact

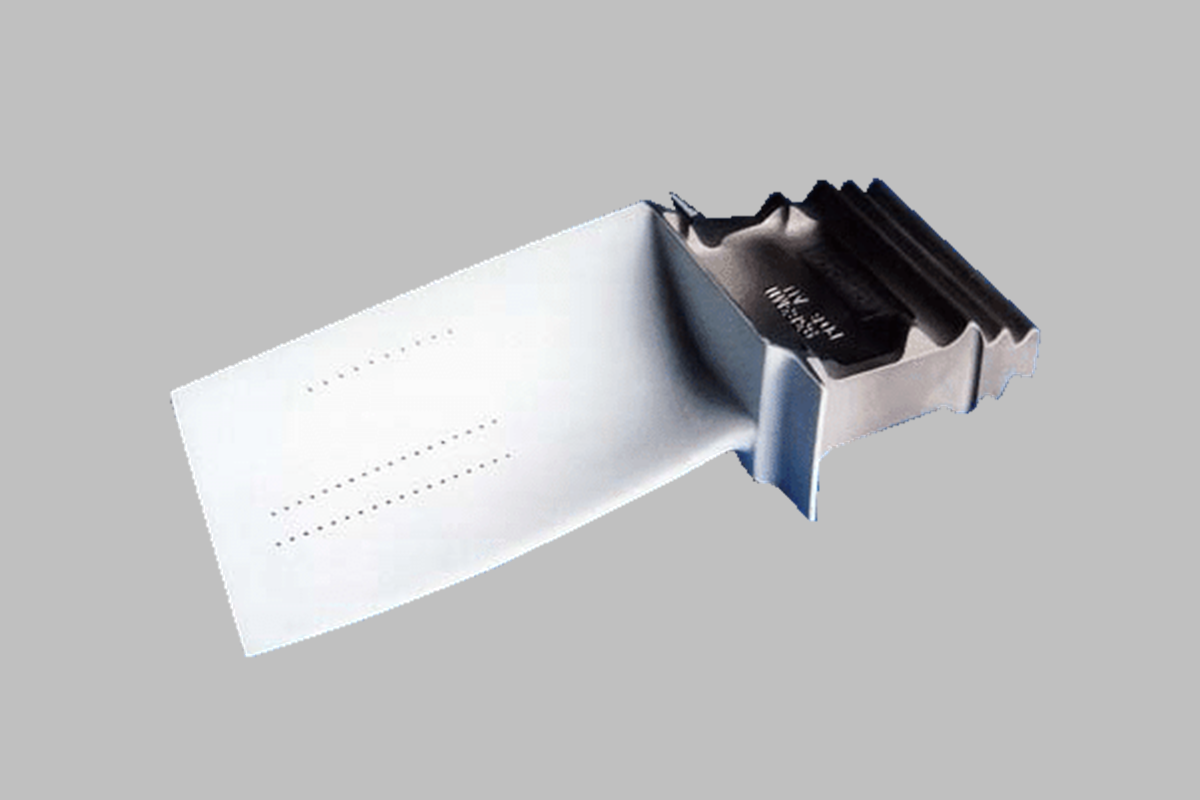

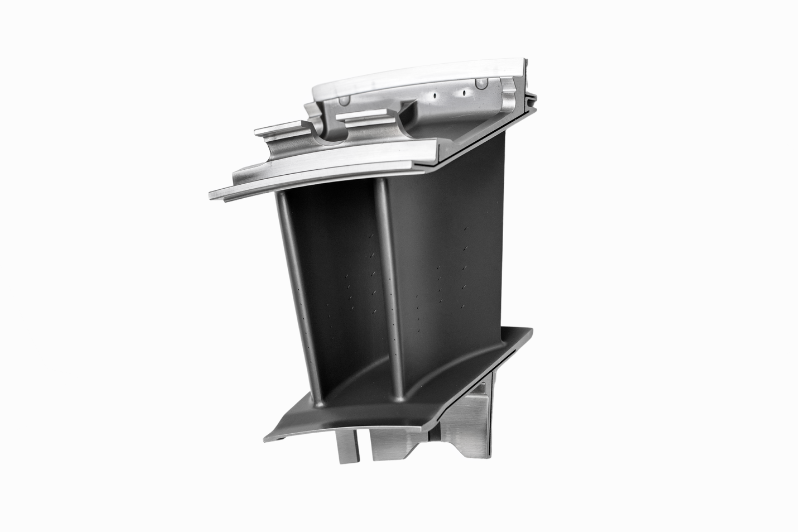

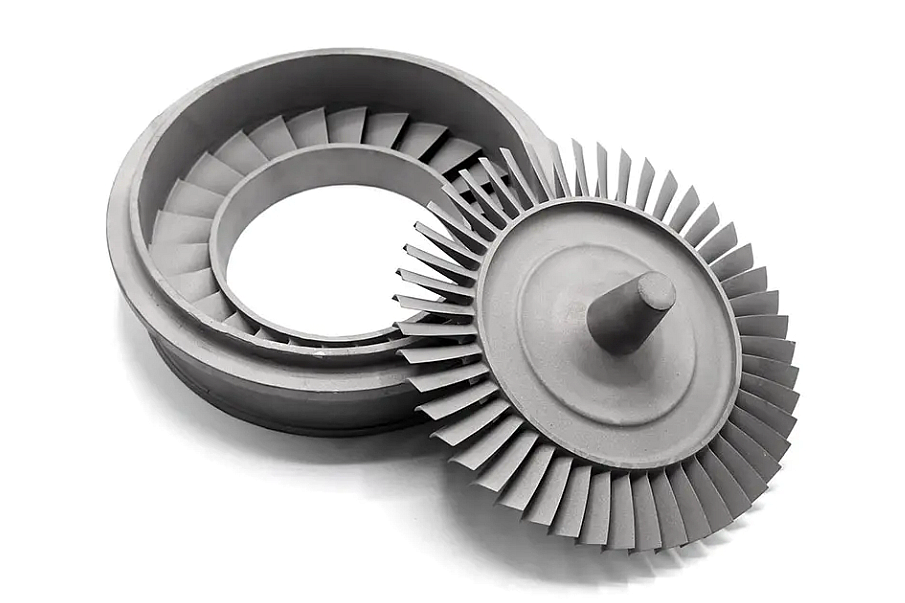

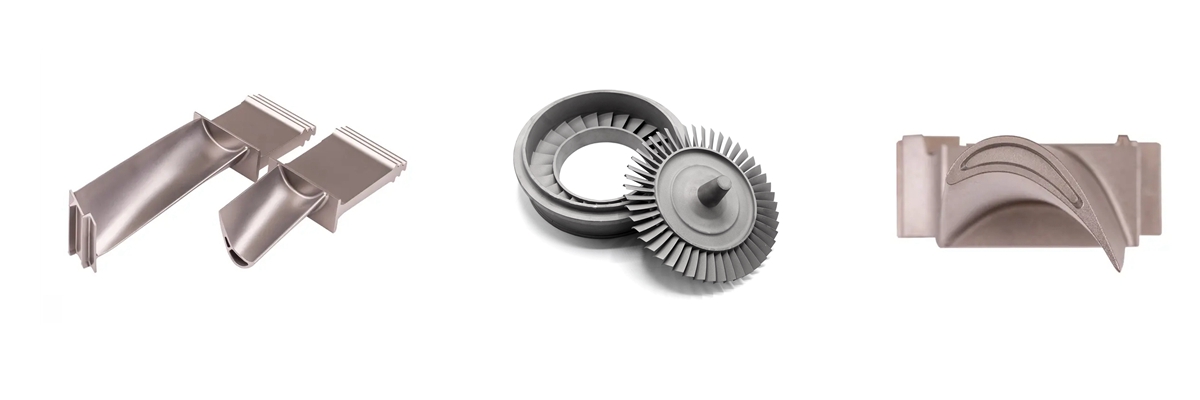

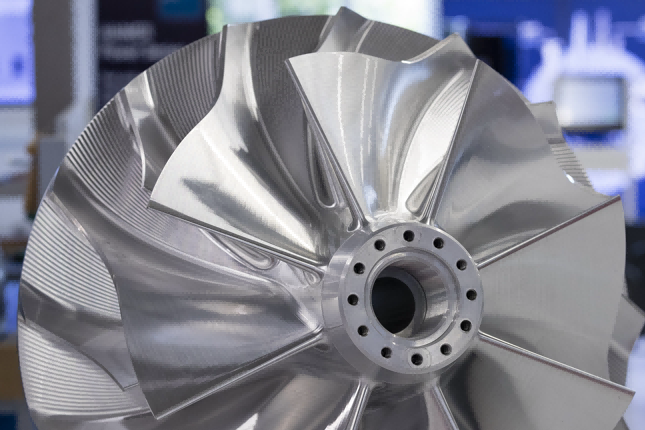

Superalloy Vacuum Cast Parts Gallery

We have practical manufacturing experience in single crystal and equiaxed crystal vacuum casting of Gas turbine parts, Turbine disks, Turbine wheels, Guide chambers, Engine combustion chambers, Tail nozzles, and Afterburners.

Let's Start A New Project Today