Titanium Alloy Components Manufacturing Service

Neway Precision Works provides advanced Titanium Alloy Parts Manufacturing services, utilizing precision technologies like vacuum casting, CNC machining, and 3D printing. Our process ensures high strength, corrosion resistance, and lightweight components, ideal for aerospace, chemical, and industrial applications.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Titanium Alloy Components Manufacturing

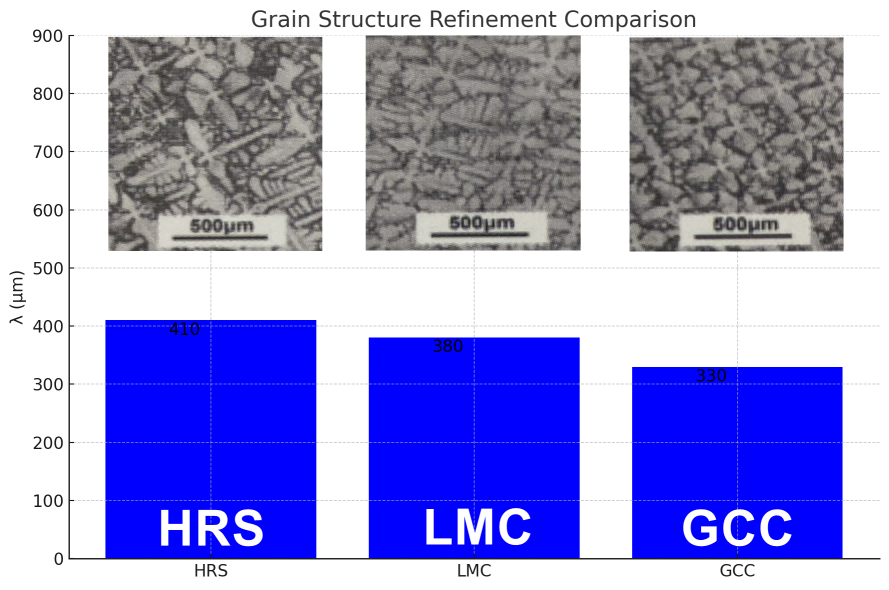

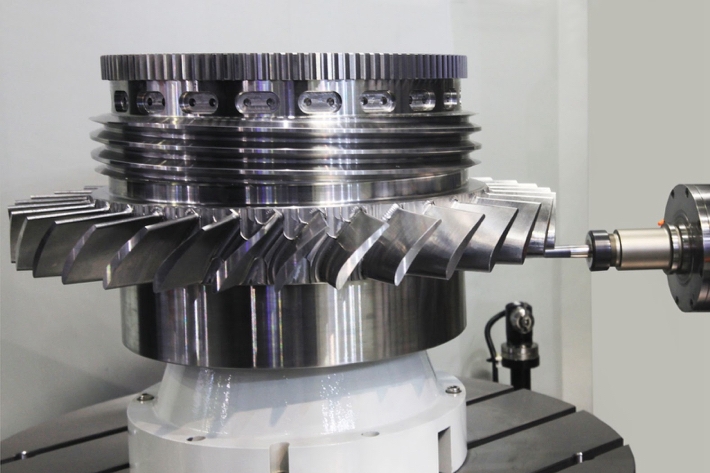

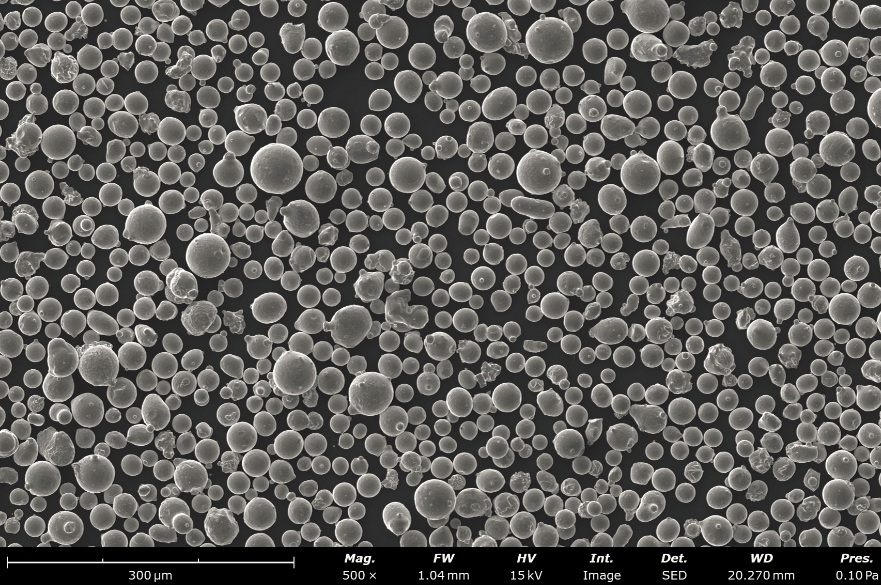

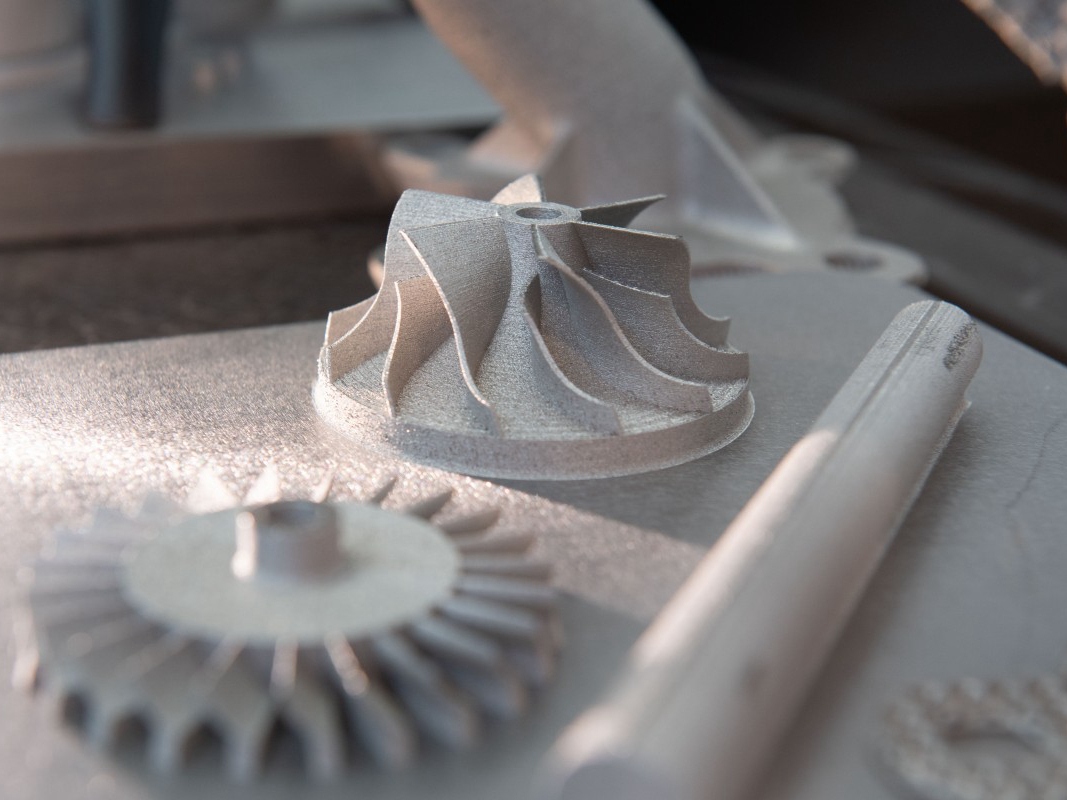

Neway's Titanium Alloy Components Manufacturing Process combines vacuum casting, CNC machining, and 3D printing to create high-performance parts. We use advanced techniques like heat treatment, precision forging, and HIP to enhance strength, durability, and corrosion resistance, ensuring reliable components for aerospace, chemical, and industrial sectors.

Titanium alloy Materials

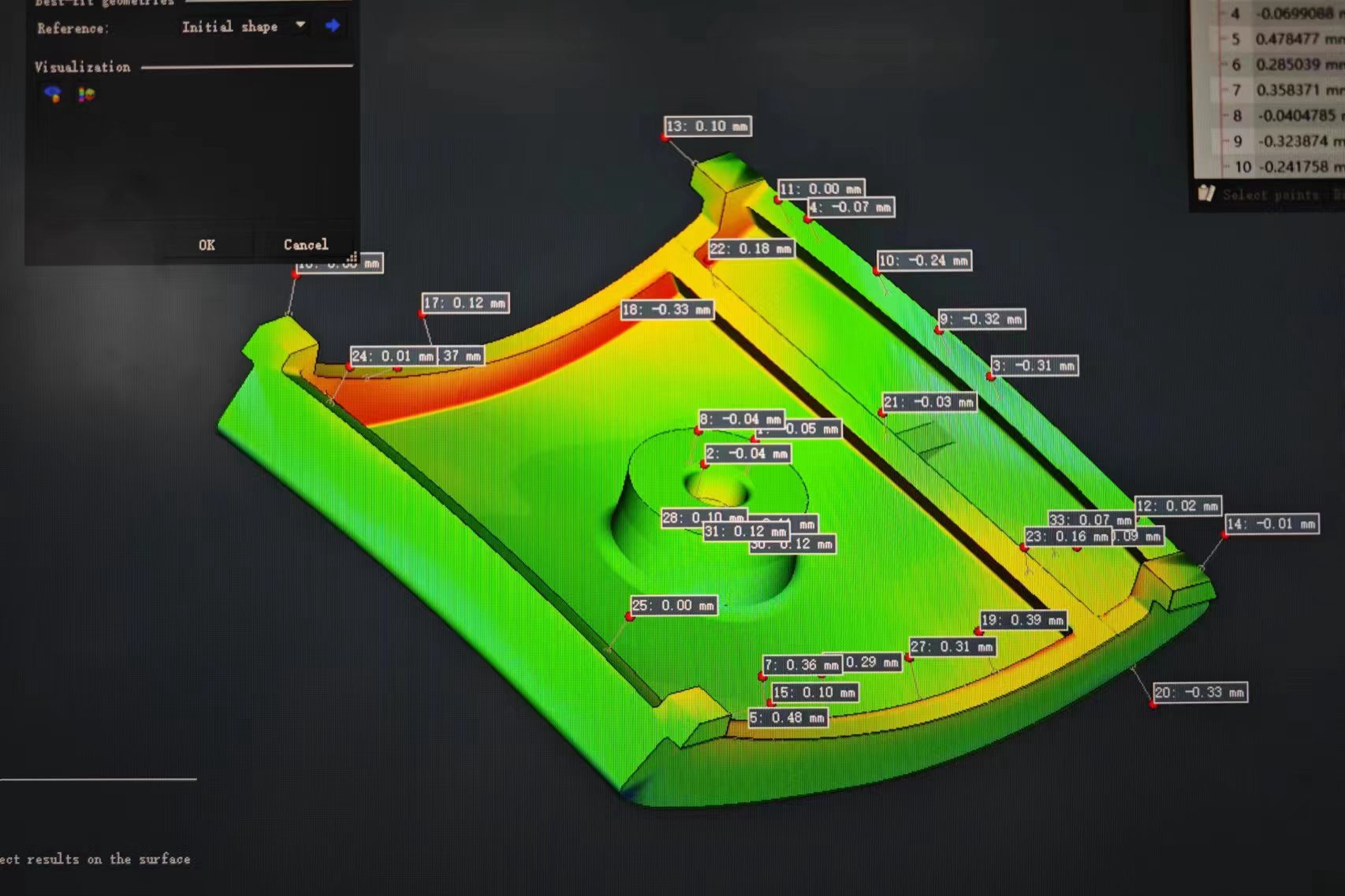

Custom Titanium Alloy Components Post-Process Service

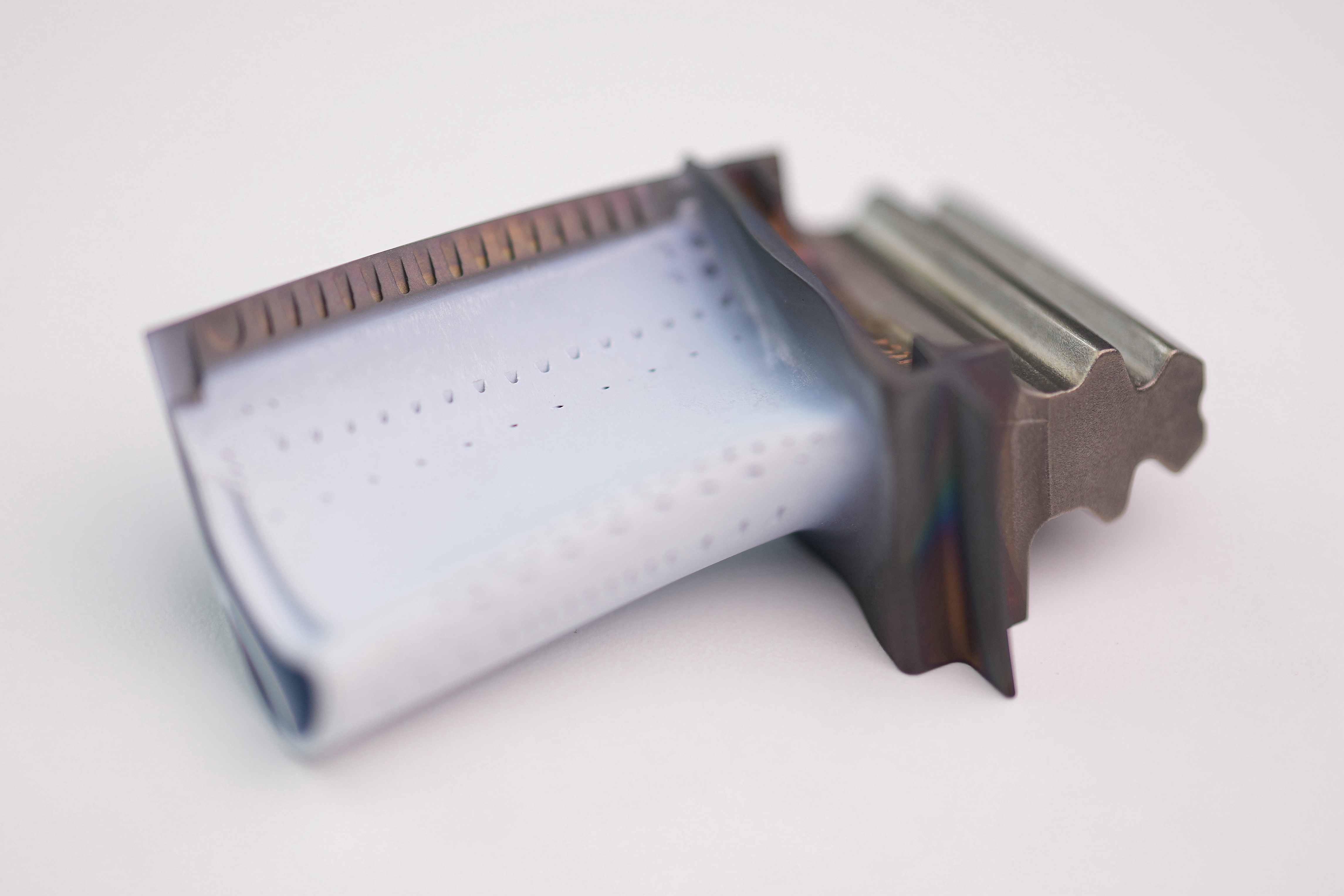

Our Custom Titanium Alloy Components Post-Process Service ensures high-performance finishing through advanced techniques. We offer Hot Isostatic Pressing (HIP) for defect elimination, Heat Treatment to enhance mechanical properties, CNC Machining for precision shaping, Welding for seamless integration, and Thermal Barrier Coating (TBC) for superior heat resistance. Our meticulous Material Testing and Analysis guarantees durability and compliance across aerospace, energy, and automotive industries.

Titanium Alloy Available In Neway

Neway utilizes Titanium alloys like Ti-6Al-4V (Grade 5) and Ti-6Al-2Sn-4Zr-6Mo for their high strength, corrosion resistance, and lightweight properties. These alloys are ideal for aerospace and chemical applications, offering excellent temperature resistance, durability, and weldability in demanding environments.

Applications and Industries of Custom Titanium Alloy Parts

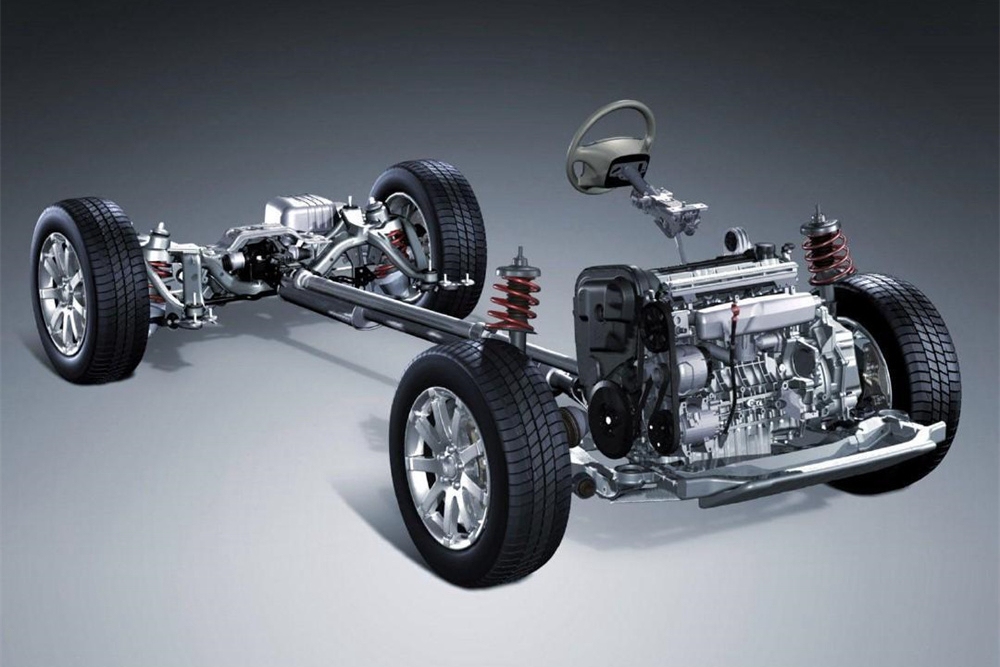

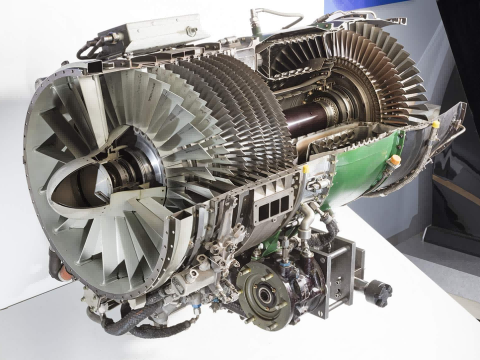

Custom titanium alloy parts find applications across various industries due to their exceptional strength, corrosion resistance, and lightweight properties. They are widely used in aerospace and aviation for structural components, power generation, and energy systems, oil and gas pipelines, marine vessels, automotive parts, chemical processing equipment, medical devices in pharmaceutical and food industries, as well as defense, nuclear, and mining sectors for demanding environments.

learn more

Aerospace and Aviation

learn more

Power Generation

learn more

Oil and Gas

learn more

Energy

learn more

Marine

learn more

Mining

learn more

Automotive

learn more

Chemical Processing

learn more

Pharmaceutical and Food

learn more

Military and Defense

learn more

Nuclear

learn more

More Cases

learn more

New Technology

learn more

Products Gallery

learn more

Various Industries

learn more

Surface Finishings

learn more

Post-Process

learn more

Manufacturing Technology

learn more

R&D and Simulation

learn more

Manufacturing Equipments

learn more

Testing Equipments

learn more

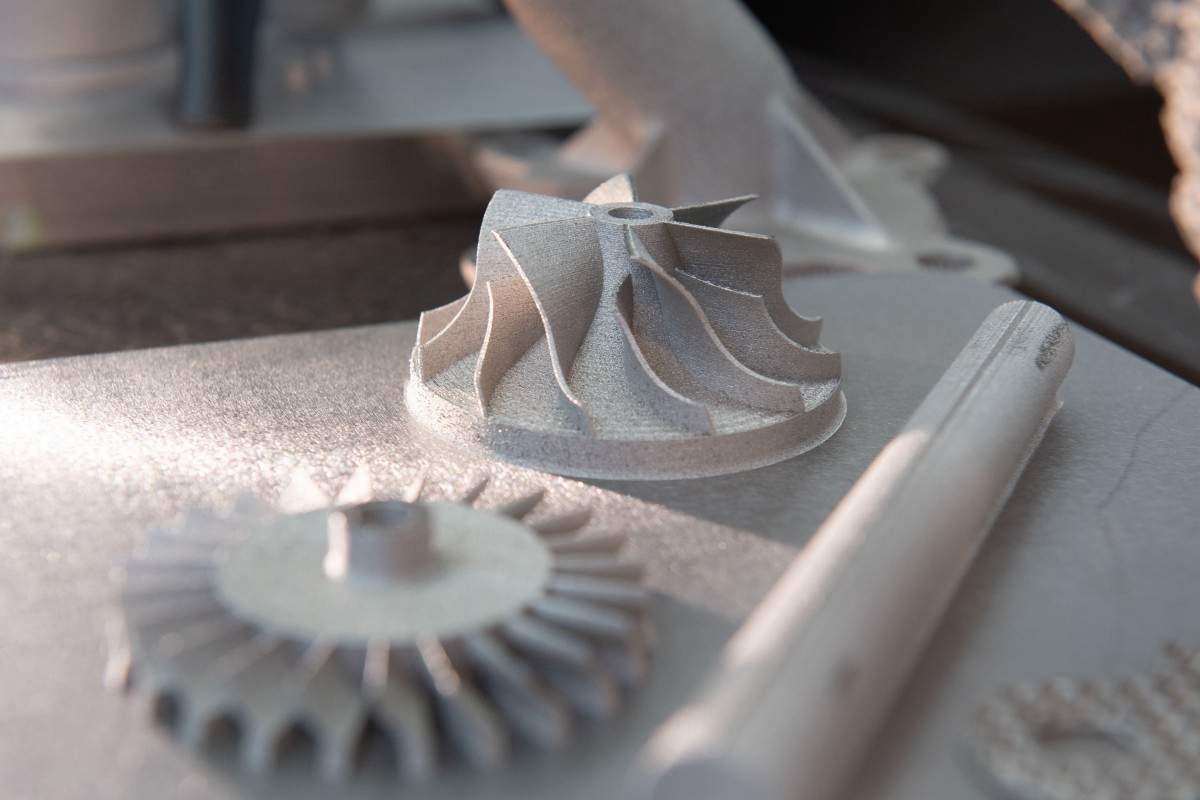

3D Printing Prototyping

learn more

FAQs

learn more

Contact

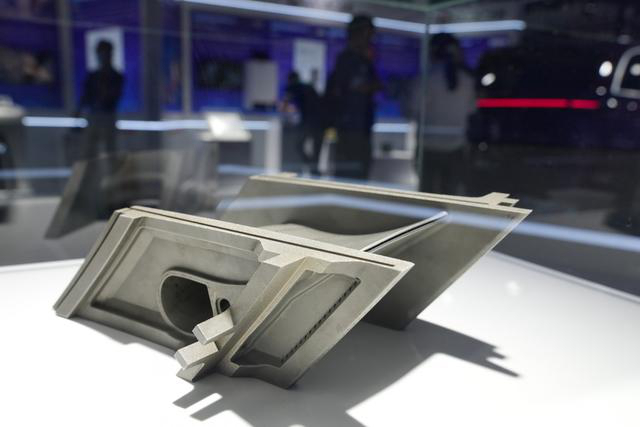

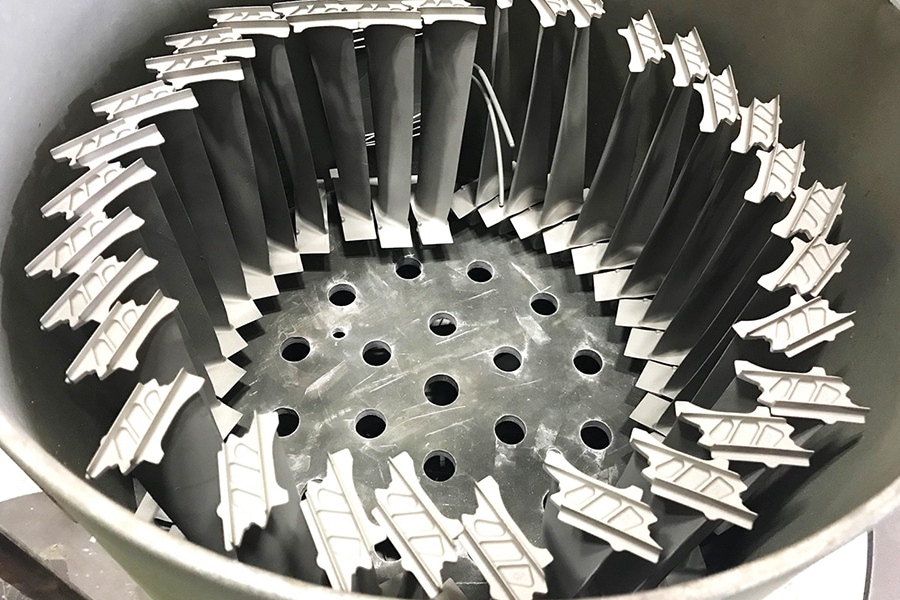

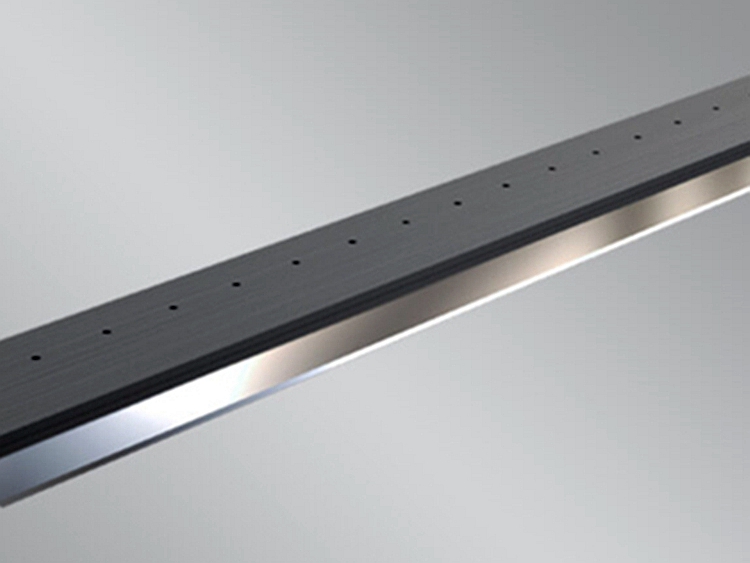

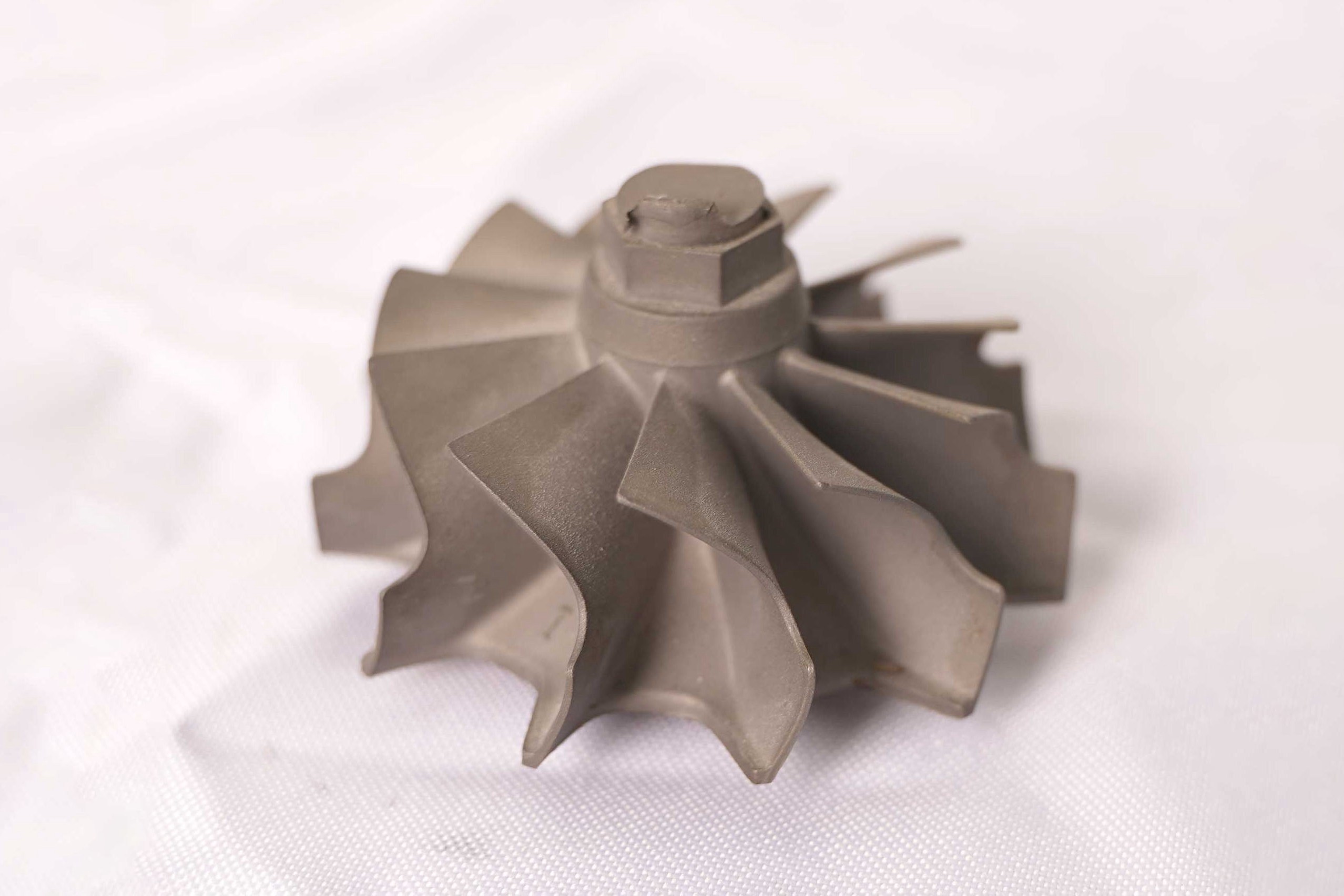

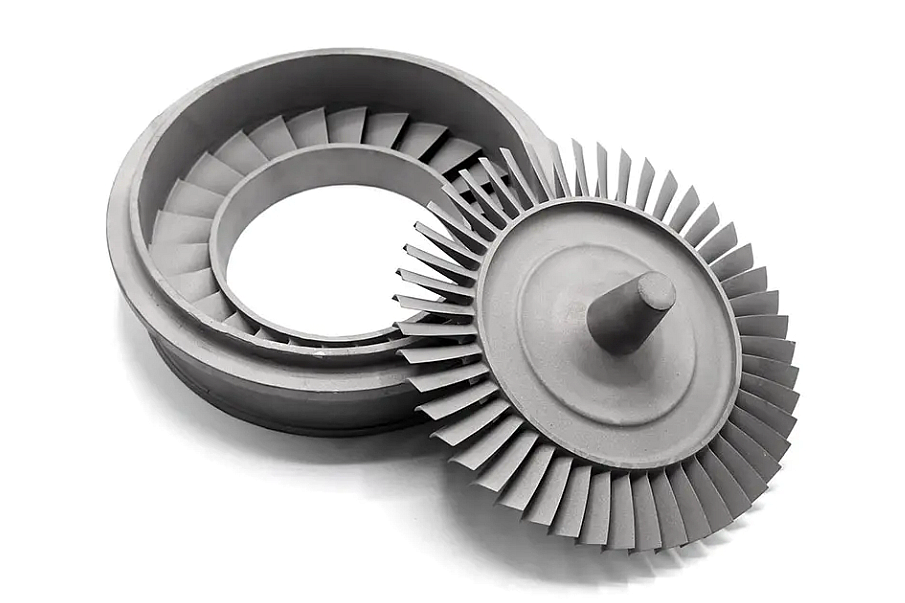

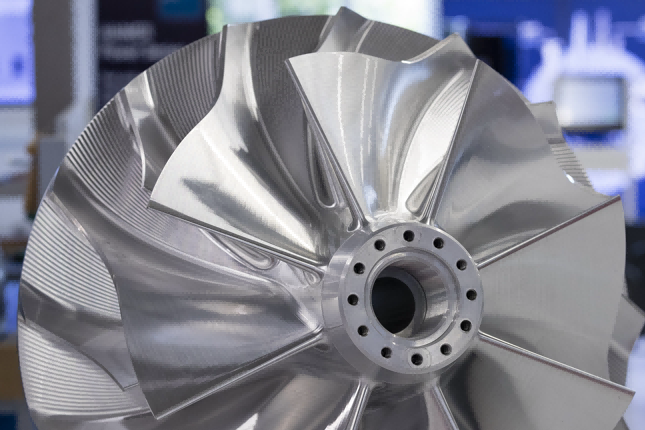

Custom Titanium Alloy Components Gallery

Neway has produced custom titanium alloy components such as precision turbine blades for aerospace engines, high-performance chemical reactor parts, and corrosion-resistant heat exchanger components. We've also created custom medical implants, including joint replacements, and marine-grade propellers, all tailored to specific industry requirements for strength, durability, and performance.

Let's Start A New Project Today