Stellite Alloy Components Manufacturing Service

Neway provides precision manufacturing of Stellite alloy parts using advanced techniques like vacuum investment casting and CNC machining. These high-performance parts offer exceptional wear, corrosion, and heat resistance, serving industries such as aerospace, oil, and chemical processing.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Stellite Alloy Components Manufacturing

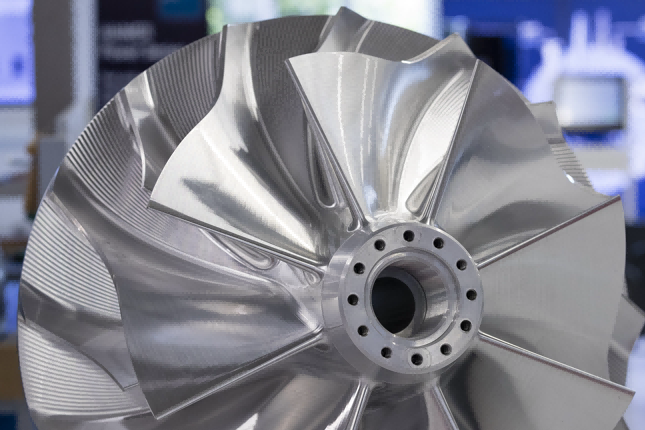

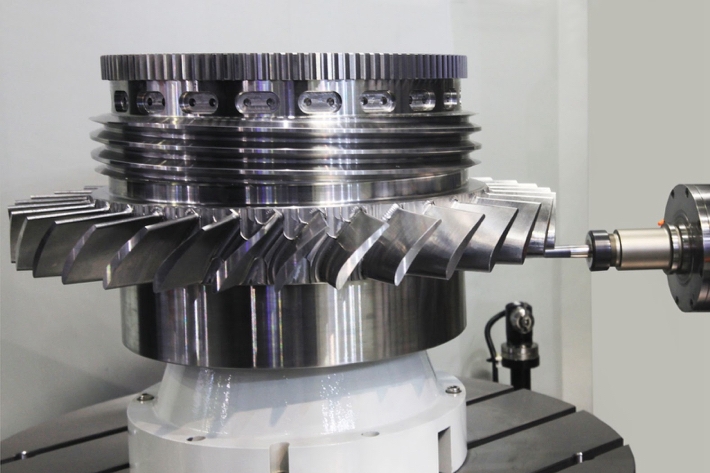

Neway's Stellite alloy components manufacturing process combines vacuum investment casting and precision CNC machining. We ensure high-temperature stability, wear resistance, and corrosion protection. Post-processing includes heat treatment, Hot Isostatic Pressing (HIP), and material testing, delivering components for demanding industries like aerospace, chemical, and oil processing with tight tolerances and high performance..

Stellite alloy Materials

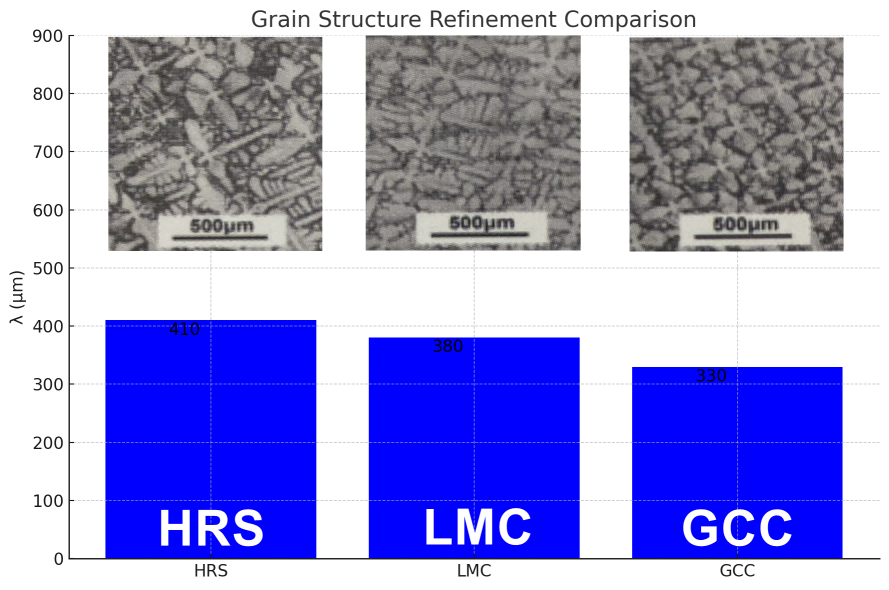

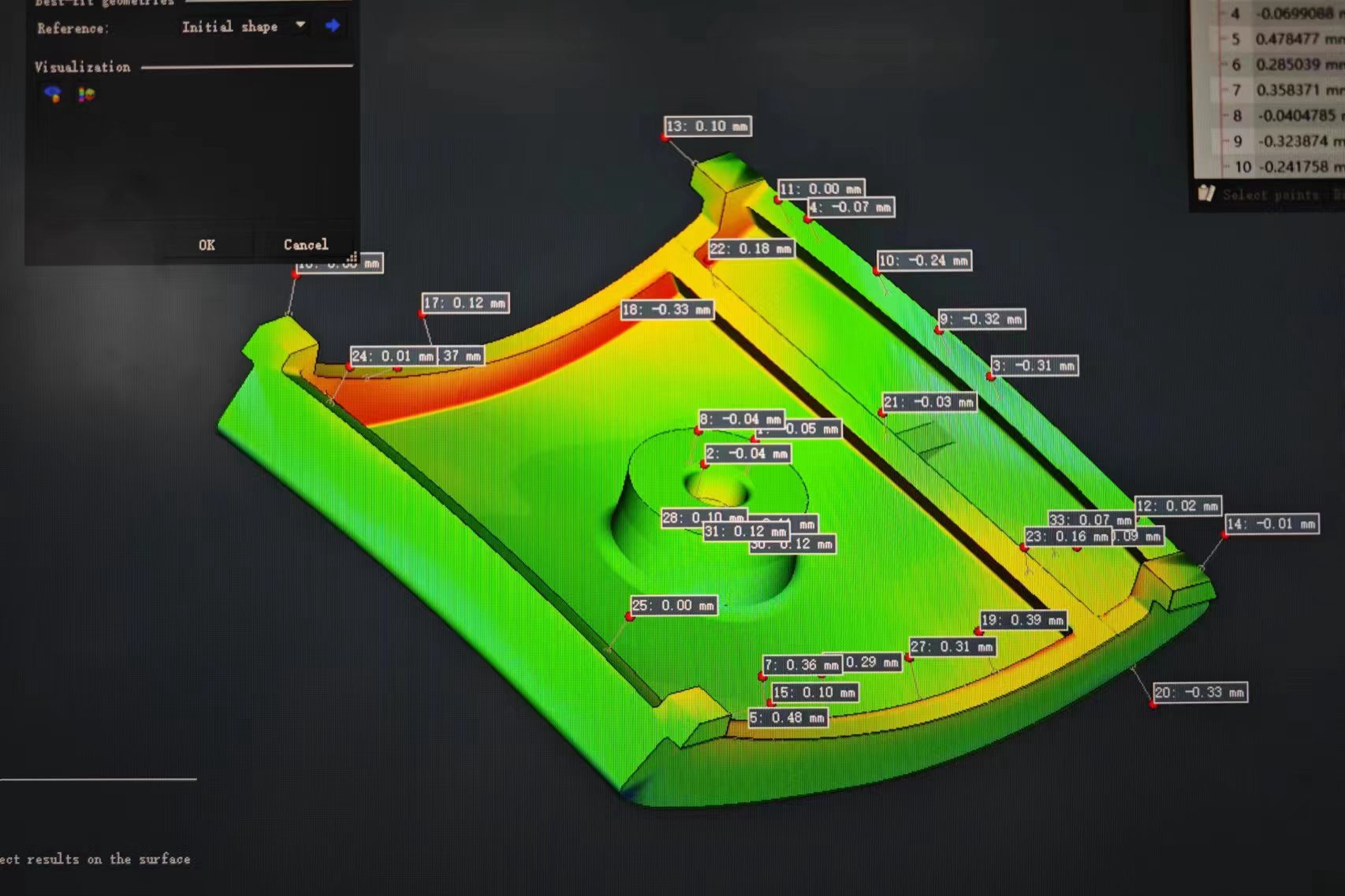

Post Process for Vacuum Investment Castings

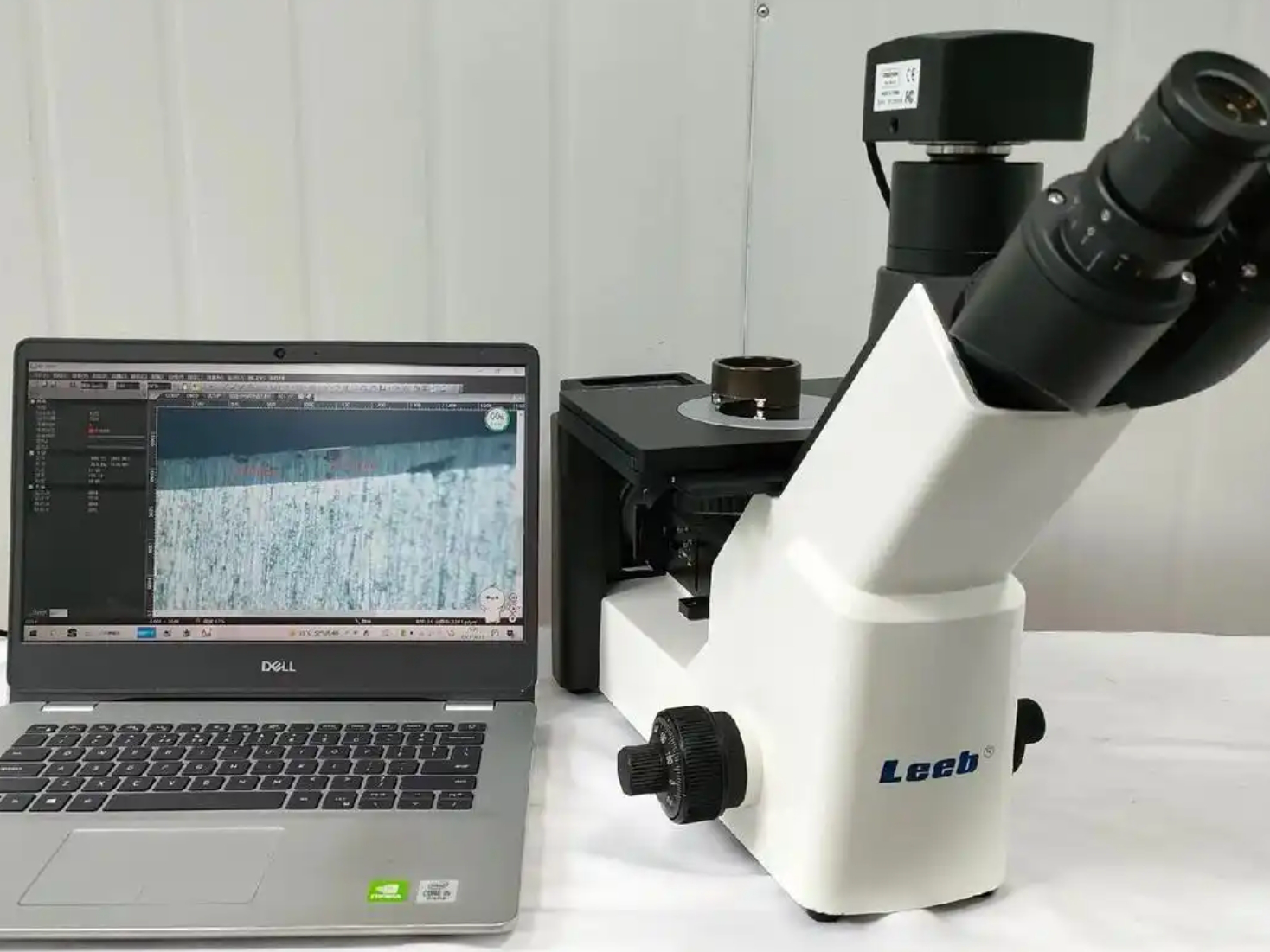

Post-processing for Stellite alloy casting components ensures enhanced performance and longevity. Techniques include Hot Isostatic Pressing (HIP) to eliminate porosity, heat treatment to optimize mechanical properties, superalloy welding for precise assembly, Thermal Barrier Coating (TBC) for heat resistance, and CNC machining for intricate detailing. Advanced testing methods validate component quality, ensuring reliability for aerospace, energy, and industrial applications.

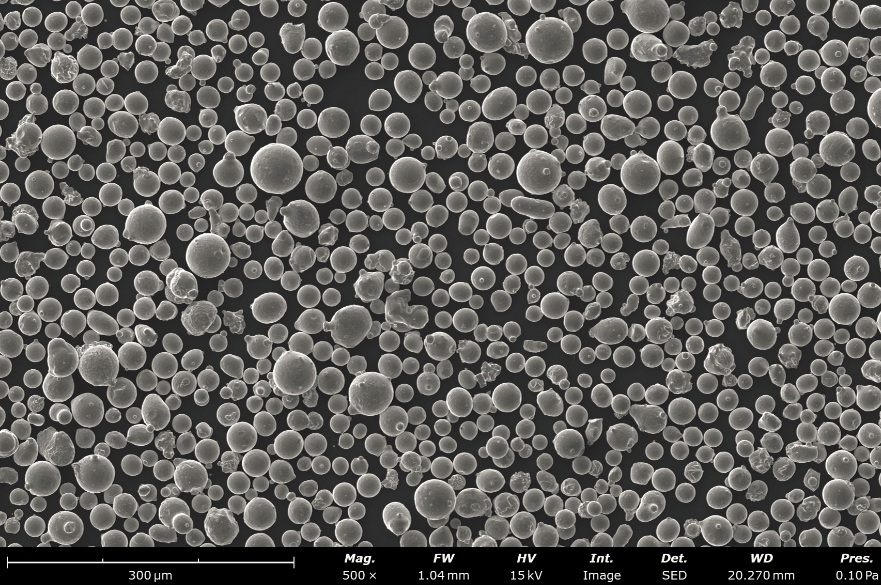

Stellite Alloy Available In Neway

Stellite alloys are known for exceptional wear, corrosion, and heat resistance. Key grades include Stellite 6, for general wear; Stellite 21, offering higher impact resistance; and Stellite 12, excelling in abrasion. These alloys maintain hardness at elevated temperatures, ideal for extreme industrial environments and high-performance components.

Stellite Alloy Parts Applications and Industries

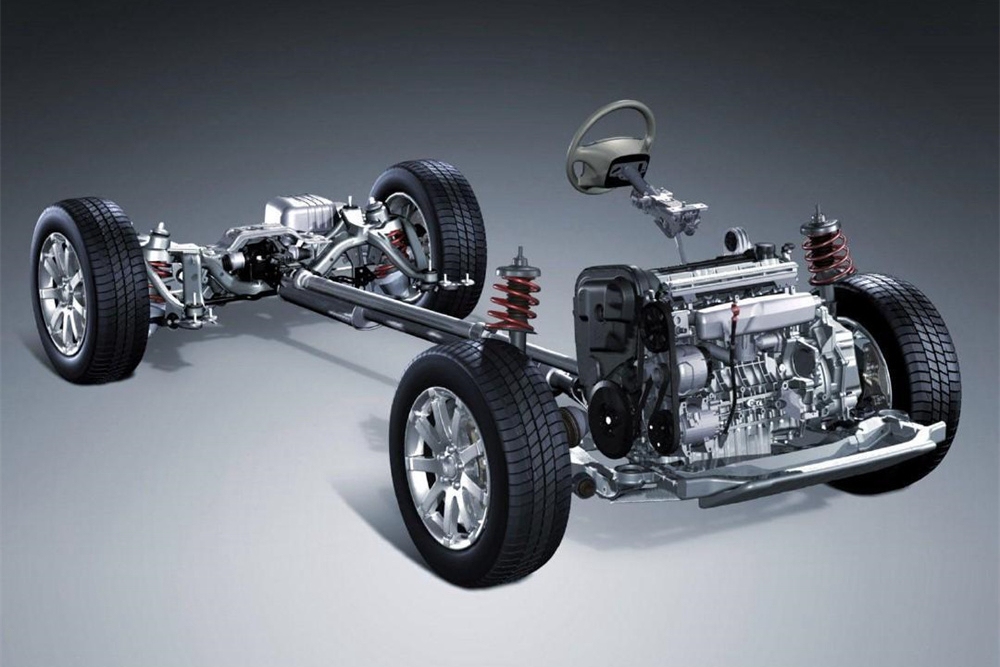

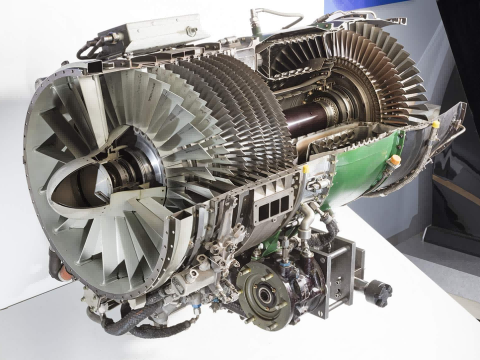

Stellite alloy parts are renowned for their exceptional wear resistance, corrosion resistance, and high-temperature strength. These components are widely used in aerospace, power generation, oil and gas, marine, and energy industries. Typical applications include turbine blades, nozzle rings, valve seats, and cutting tools, where durability and performance in harsh environments are critical, ensuring long service life and reduced maintenance.

learn more

Aerospace and Aviation

learn more

Power Generation

learn more

Oil and Gas

learn more

Energy

learn more

Marine

learn more

Mining

learn more

Automotive

learn more

Chemical Processing

learn more

Pharmaceutical and Food

learn more

Military and Defense

learn more

Nuclear

learn more

More Cases

learn more

New Technology

learn more

Products Gallery

learn more

Various Industries

learn more

Surface Finishings

learn more

Post-Process

learn more

Manufacturing Technology

learn more

R&D and Simulation

learn more

Manufacturing Equipments

learn more

Testing Equipments

learn more

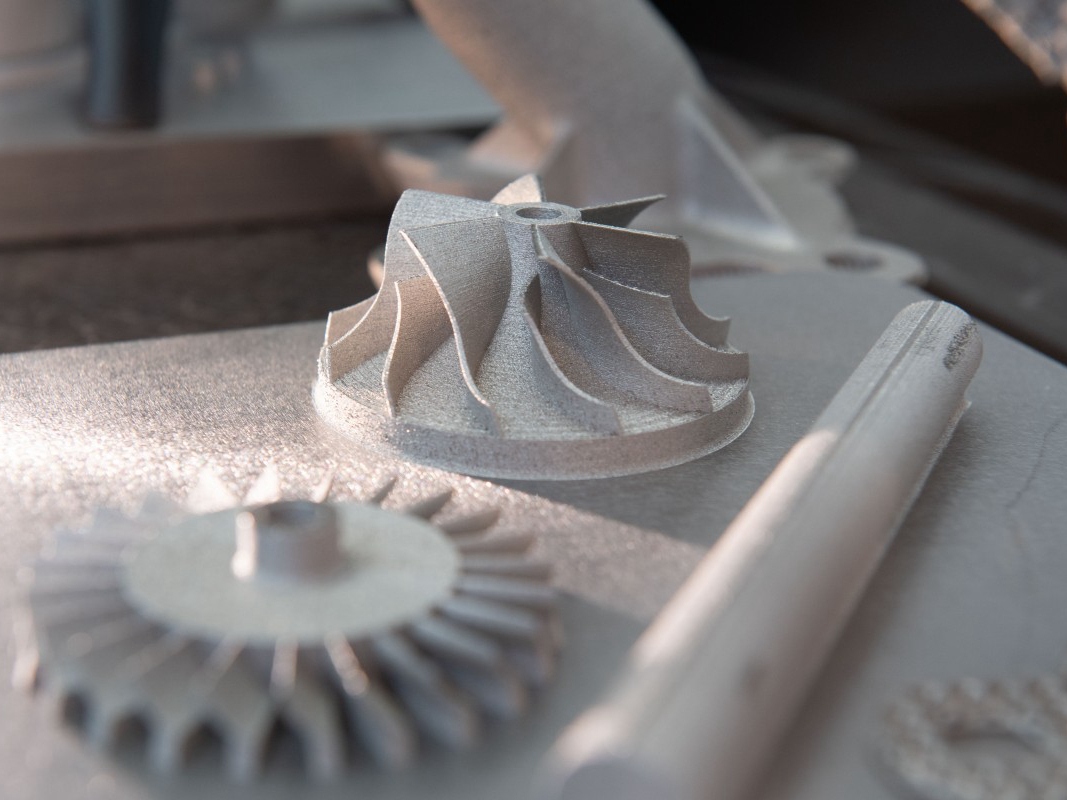

3D Printing Prototyping

learn more

FAQs

learn more

Contact

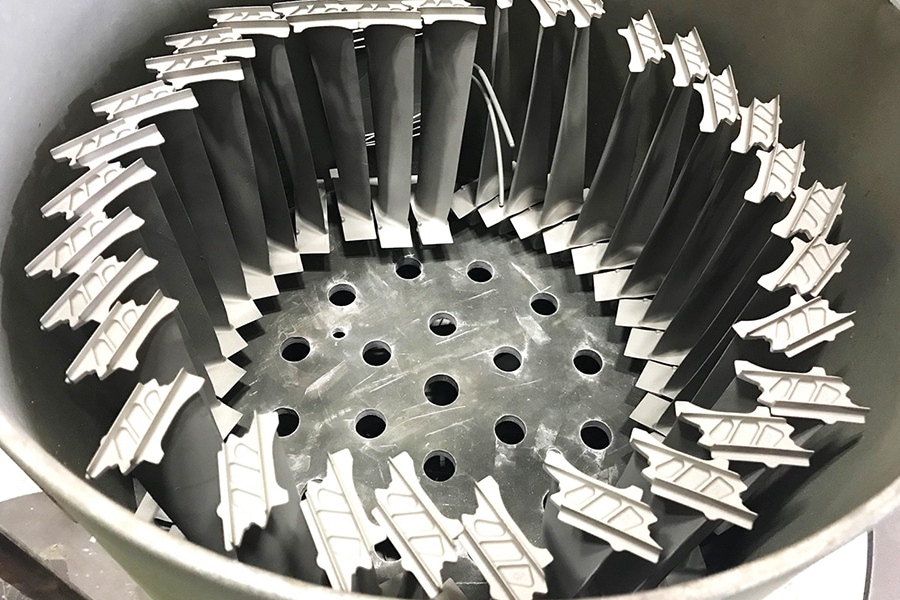

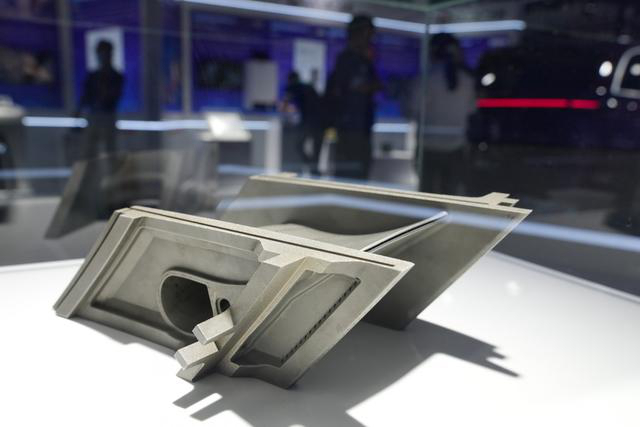

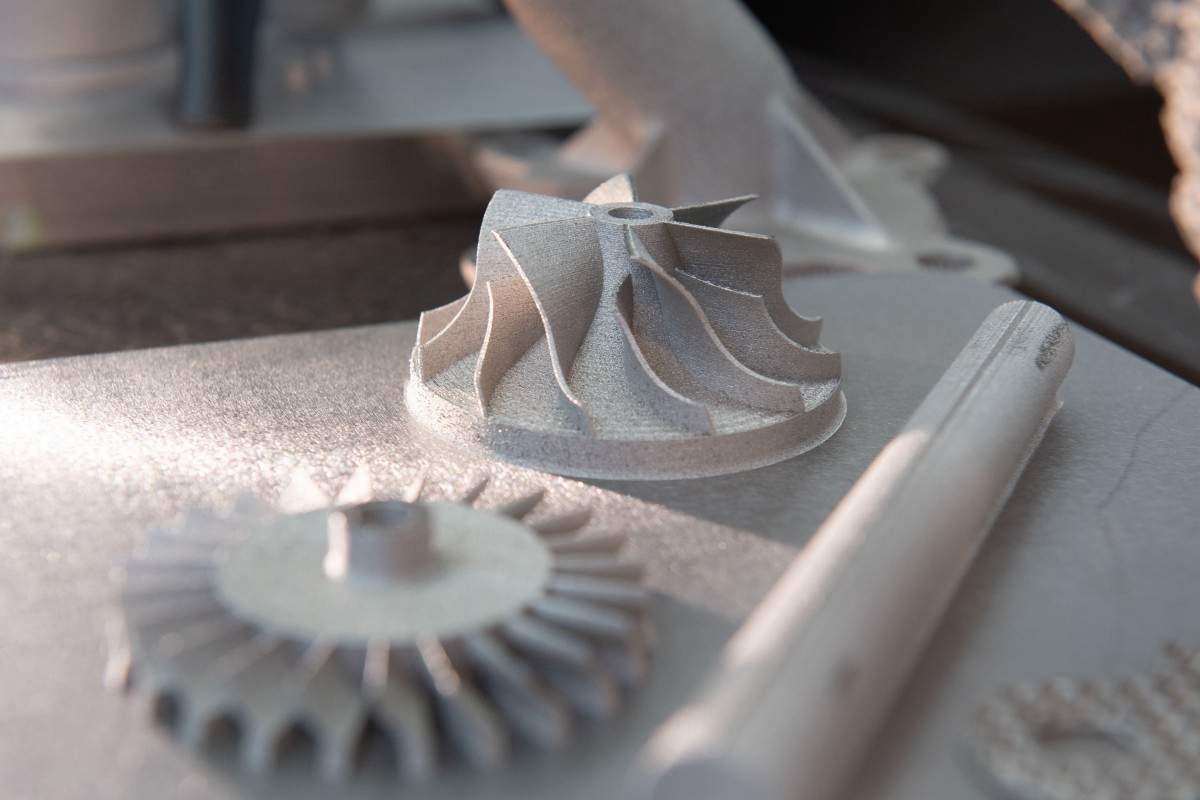

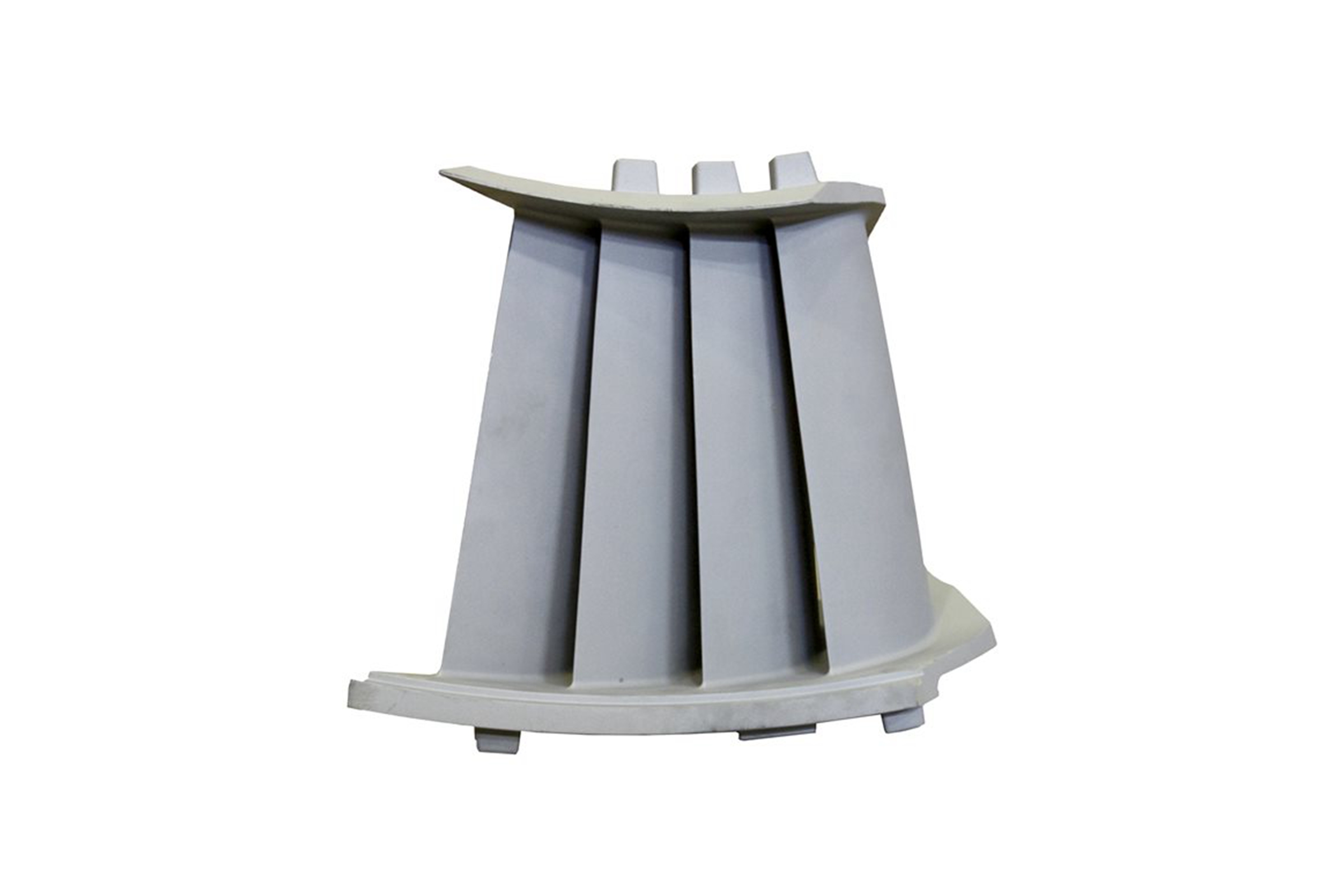

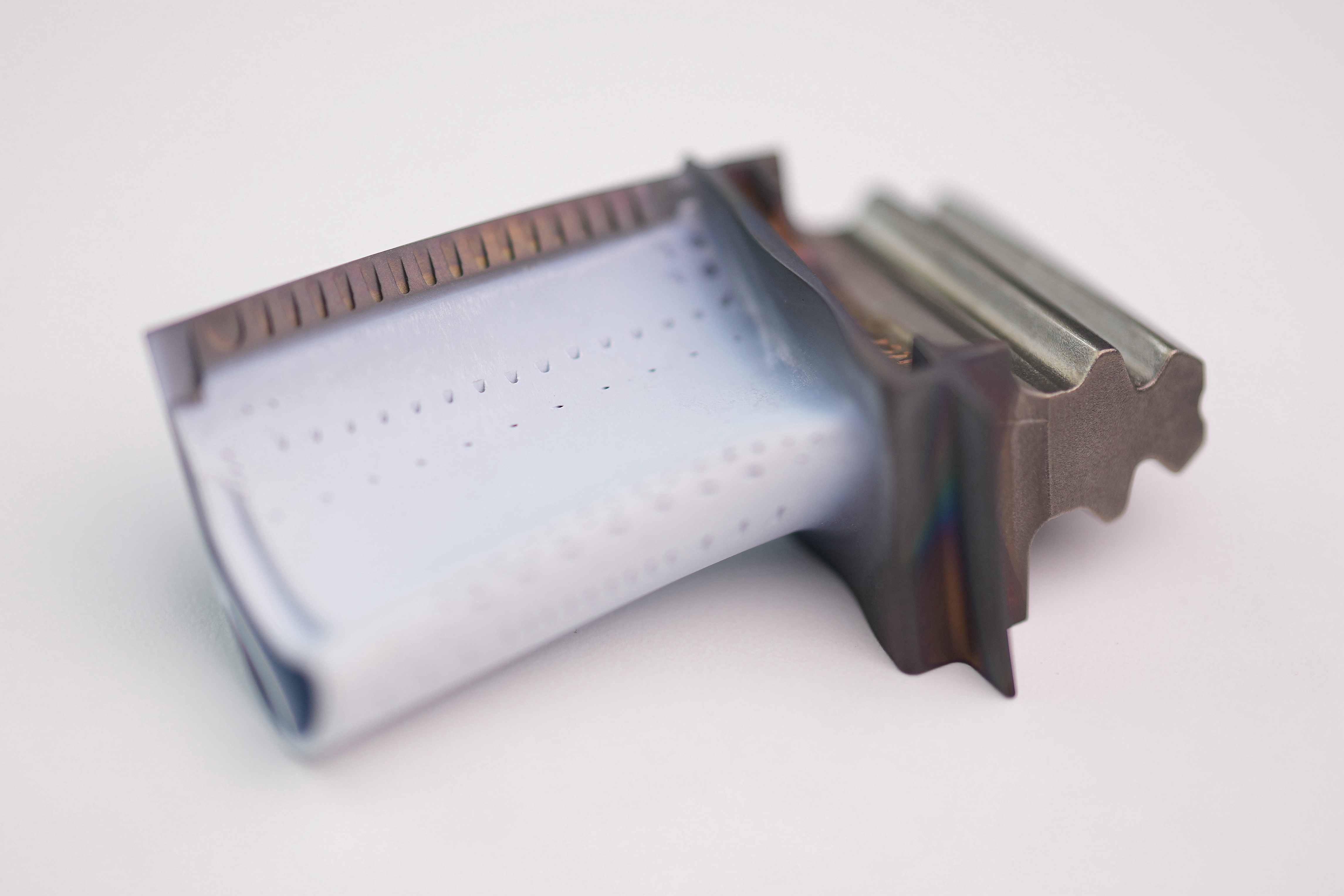

Custom Stellite Alloy Components Gallery

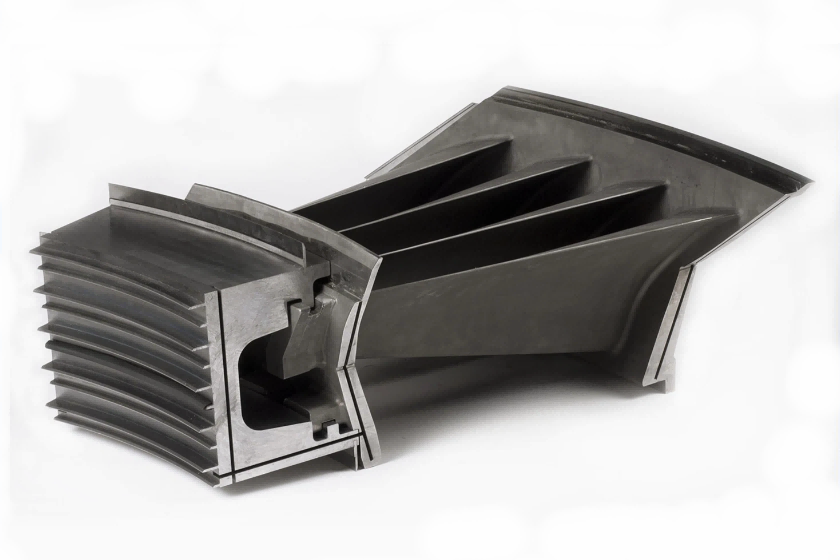

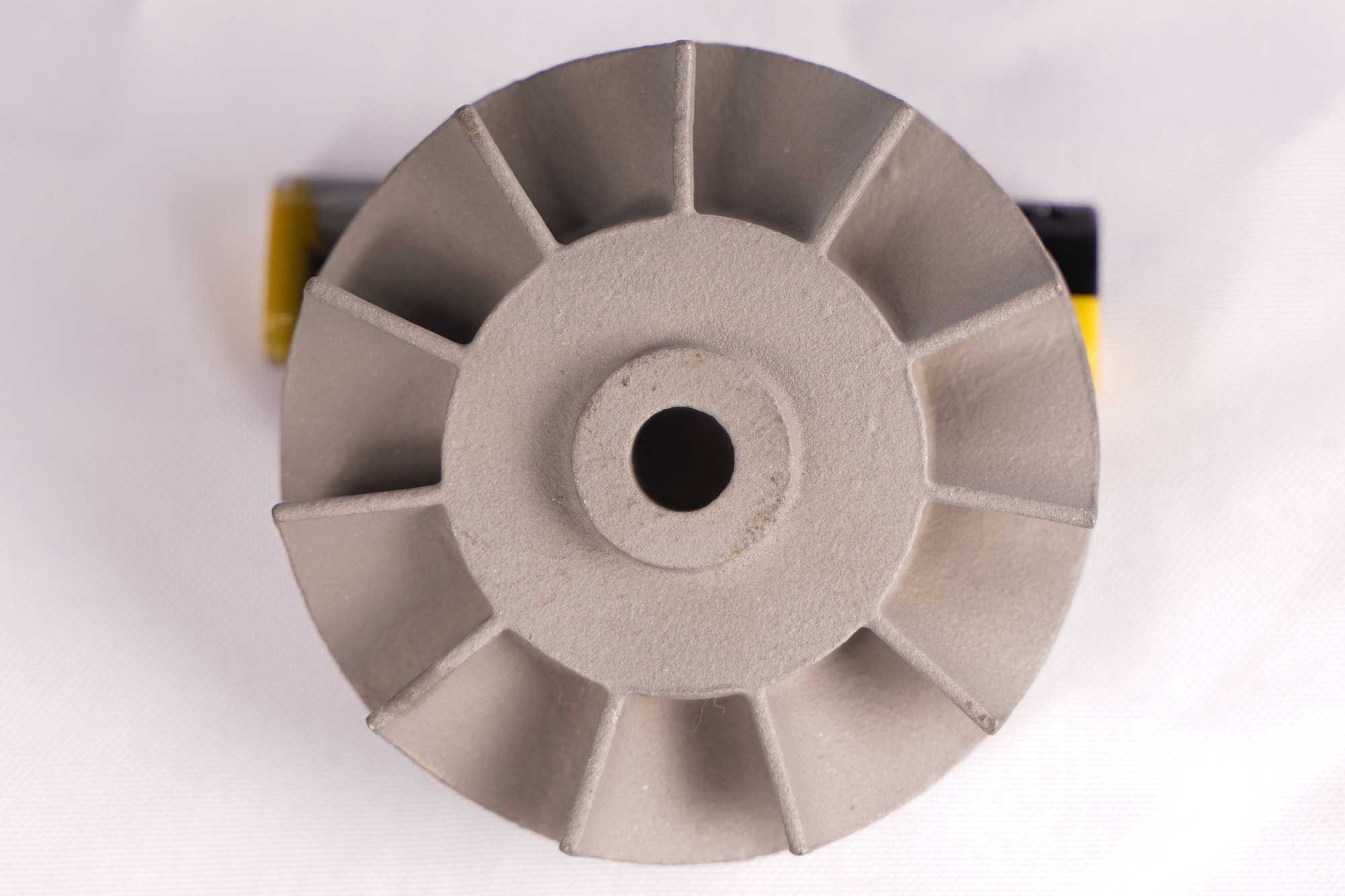

Neway has produced custom Stellite alloy components such as precision turbine blades for aerospace engines, corrosion-resistant valve seats for chemical processing, and durable pump impellers for the oil and gas industry. Each component is tailored to meet specific wear, heat, and corrosion resistance requirements for demanding operational environments.

Let's Start A New Project Today