Custom Superalloy Parts Factory and Supplier

Custom High Temperature Alloy Automotive Parts Manufacturing

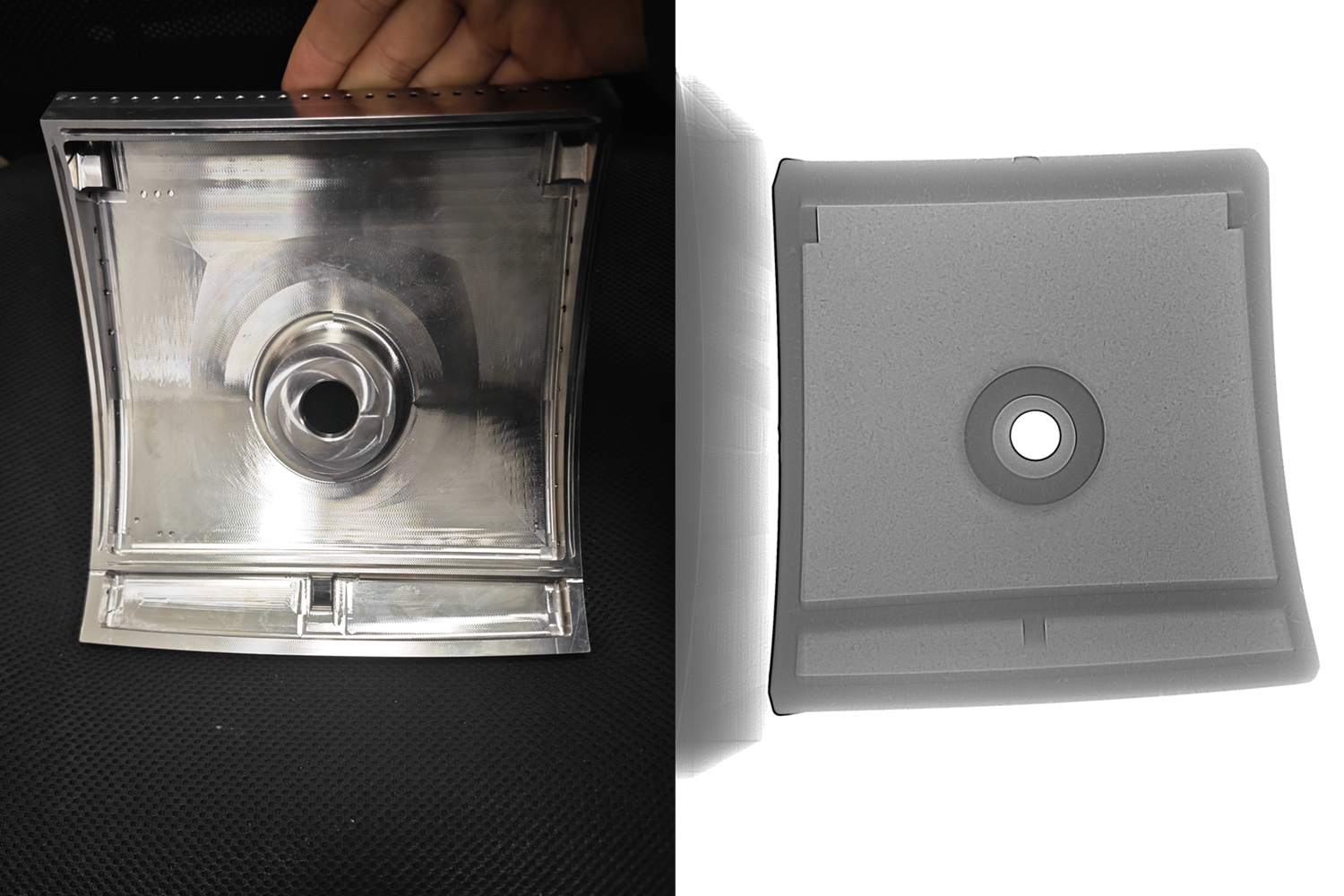

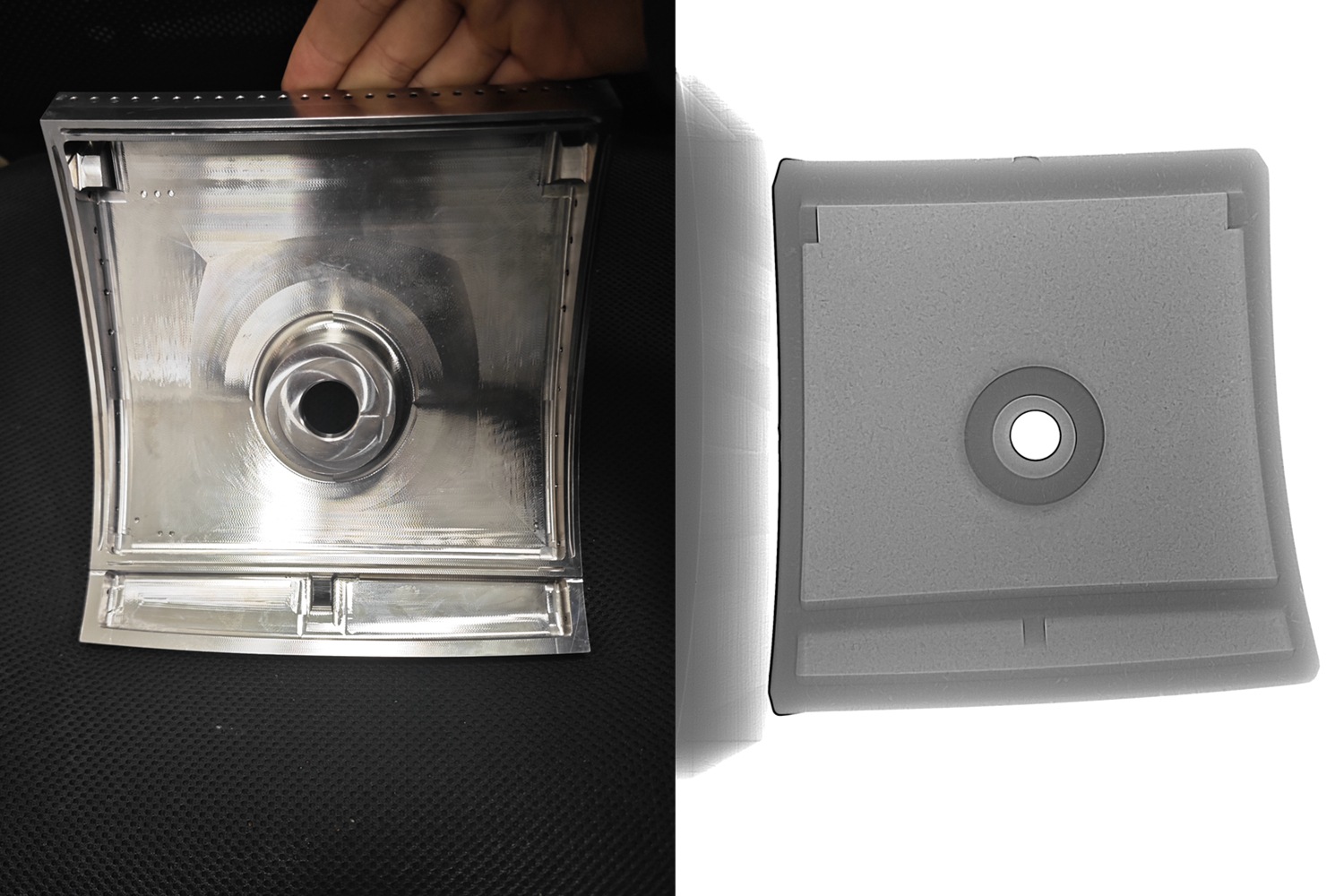

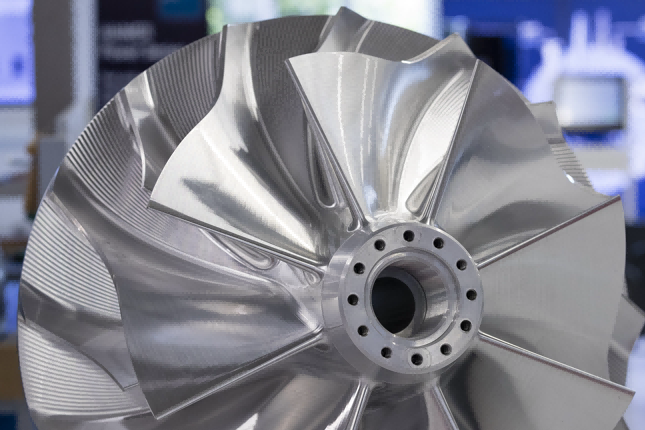

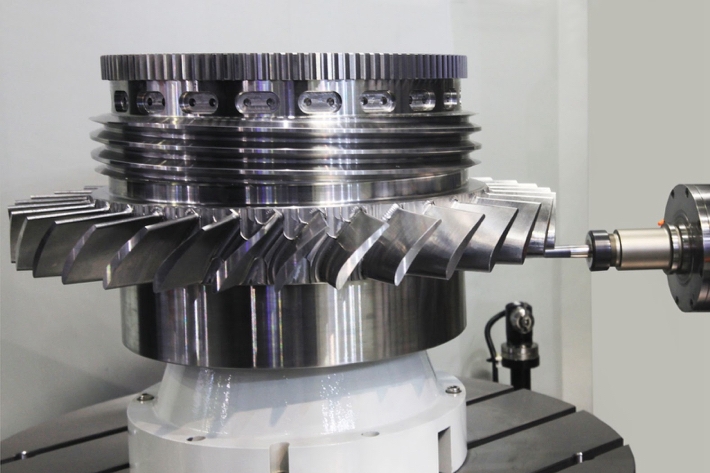

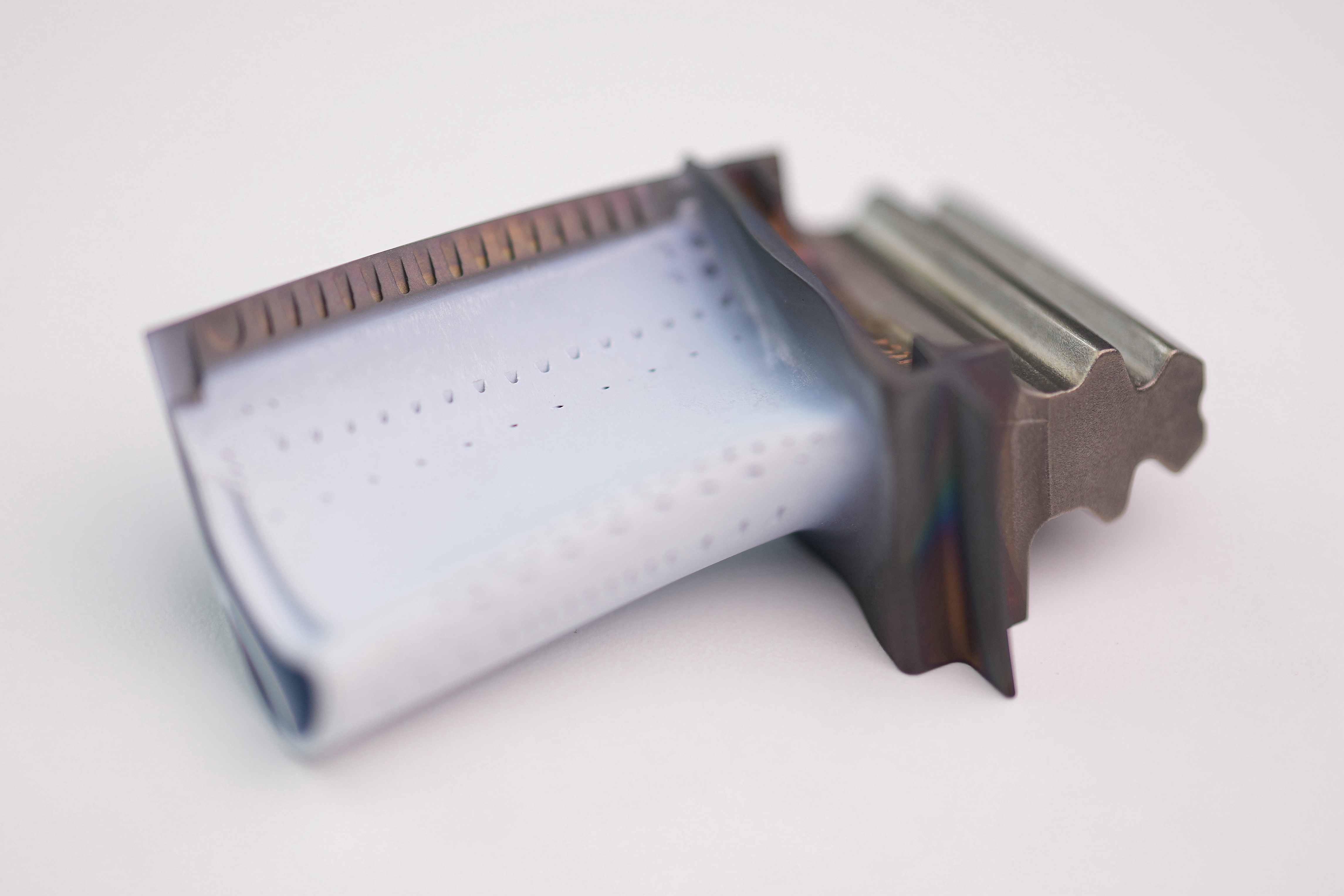

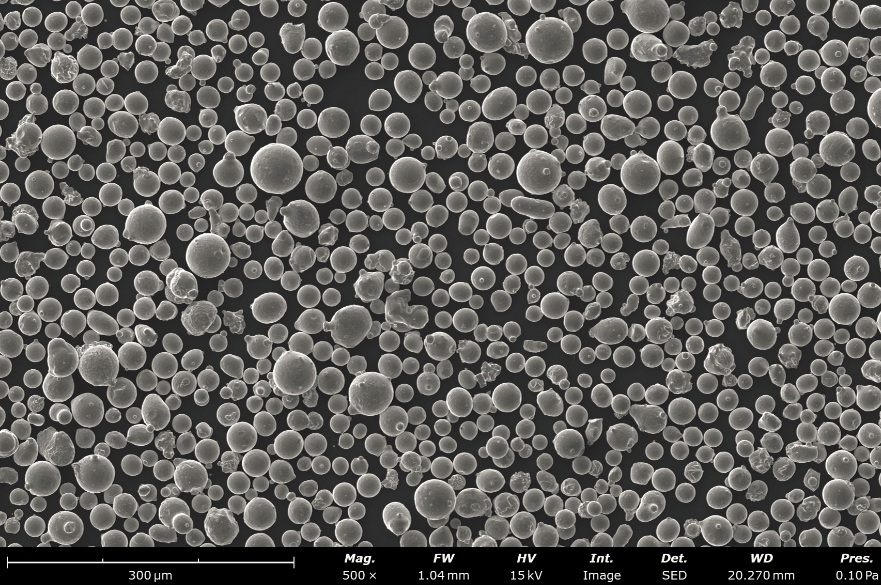

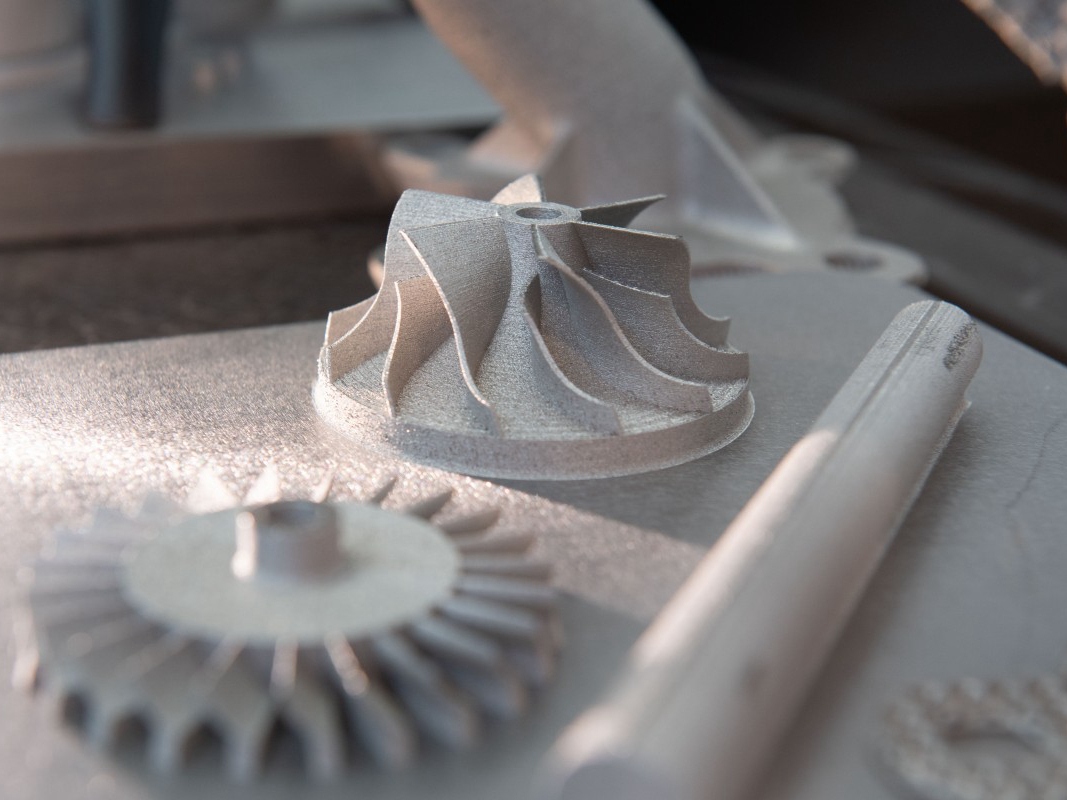

Neway offers processes like Vacuum Investment Casting, Superalloy 3D Printing, CNC Machining, and Hot Isostatic Pressing (HIP). Using high-temperature alloys, they can manufacture custom automotive parts such as turbocharger components, exhaust manifolds, and high-performance engine parts.

High Temperature Alloy Automotive Parts Manufacturing Solutions

Neway uses several processes for high-temperature alloy automotive parts, including Vacuum Investment Casting, Superalloy 3D Printing, and CNC Machining for precise shaping. Post-processing, like Heat Treatment and Hot Isostatic Pressing (HIP), ensures durability and strength. These processes are ideal for producing turbochargers, exhaust manifolds, engine components, and other parts that endure extreme temperatures in automotive applications.

Automotive Industry Superalloy Selection

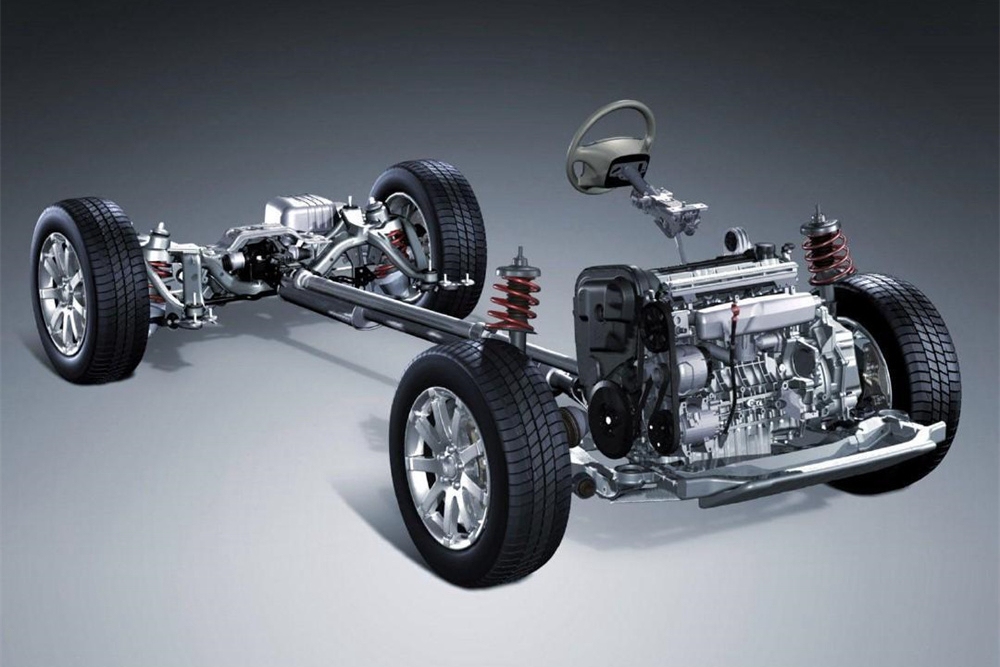

The automotive industry utilizes superalloys like Inconel, Nimonic, Hastelloy, Stellite, and Titanium for their strength, heat resistance, and durability. These materials are essential in turbochargers, exhaust systems, valves, and catalytic converters, where they withstand extreme temperatures and corrosive gases. Their reliability improves engine performance, fuel efficiency, and emissions control, ensuring long-lasting, high-performance components in modern vehicles.

High Temperature Alloy Components In Automotive Industry

Neway has produced high-temperature alloy components like turbocharger wheels, exhaust manifolds, and engine valves for the automotive industry. We use processes such as Vacuum Investment Casting, Precision Forging, and Superalloy 3D Printing. Post-processes like Hot Isostatic Pressing (HIP), Heat Treatment, CNC Machining, and Thermal Barrier Coating (TBC) ensure superior strength, heat resistance, and durability in these parts.

learn more

Direct Reading Spectrometer

learn more

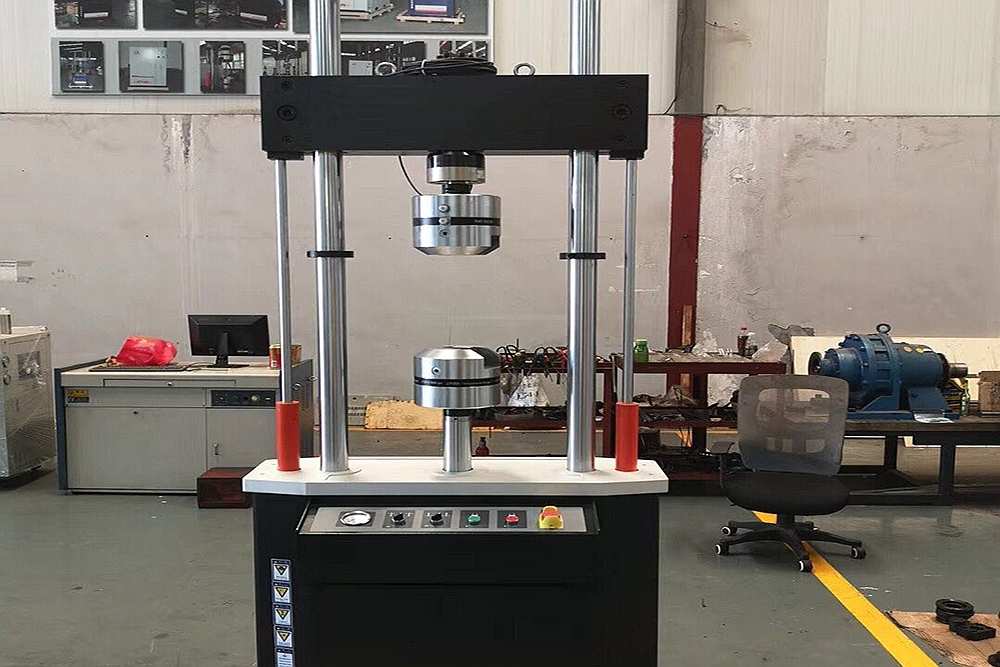

Tensile Testing Machine Checking

learn more

X-ray Checking

learn more

Thermal Physical Properties Test Platform

learn more

Corrosion Production Line

learn more

Dynamic and Static Fatigue Tester

learn more

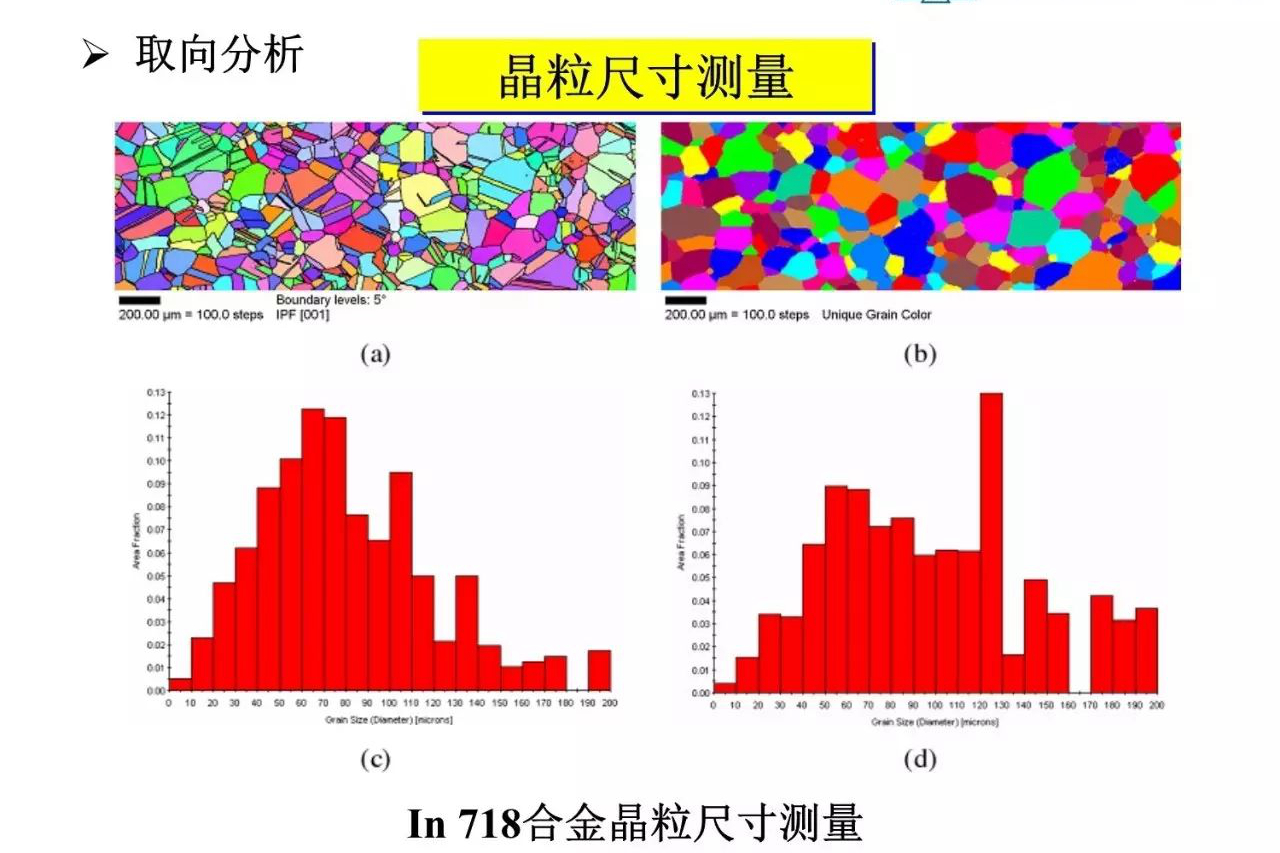

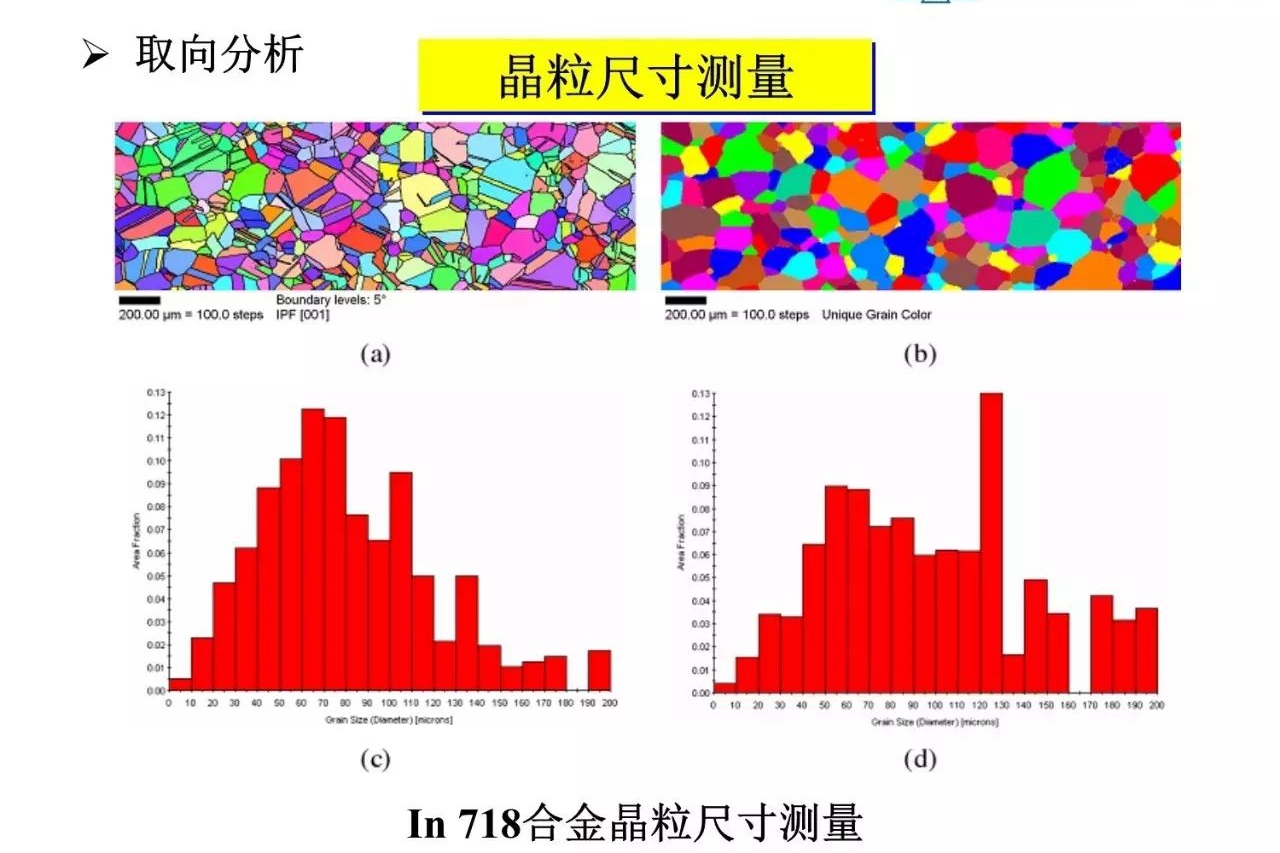

Electron Backscattering Diffractometer (EBSD)

learn more

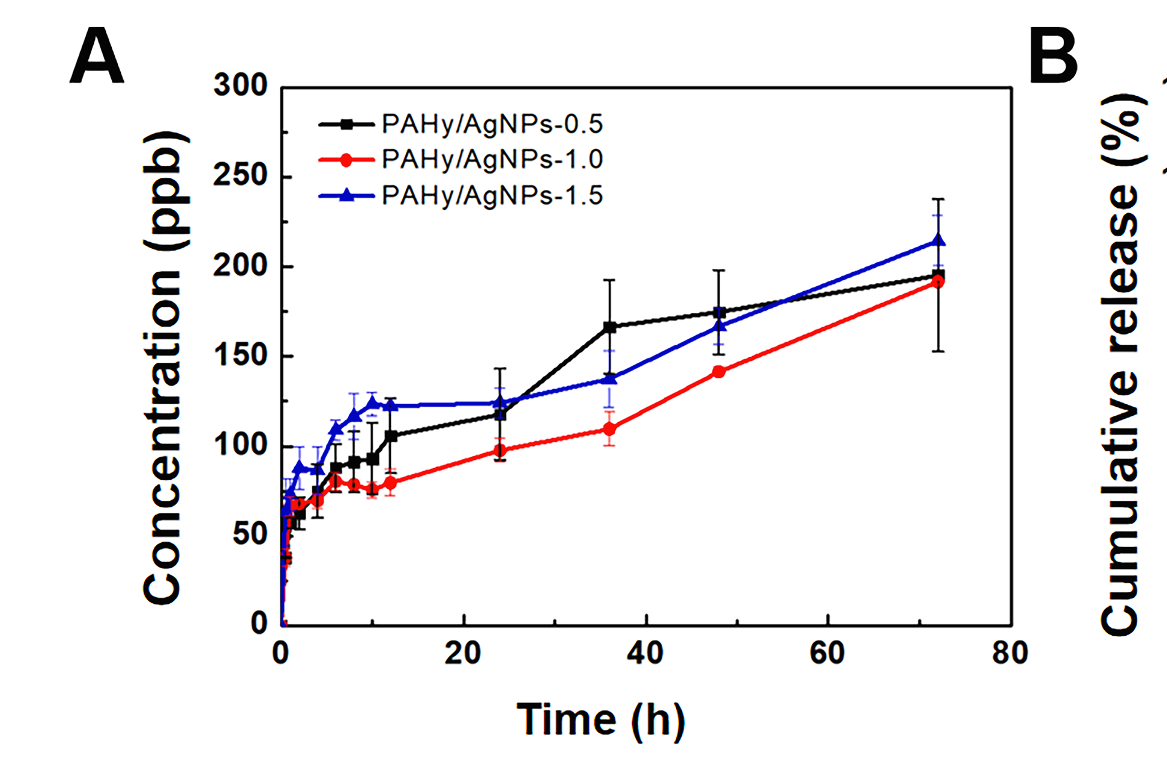

Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES)

learn more

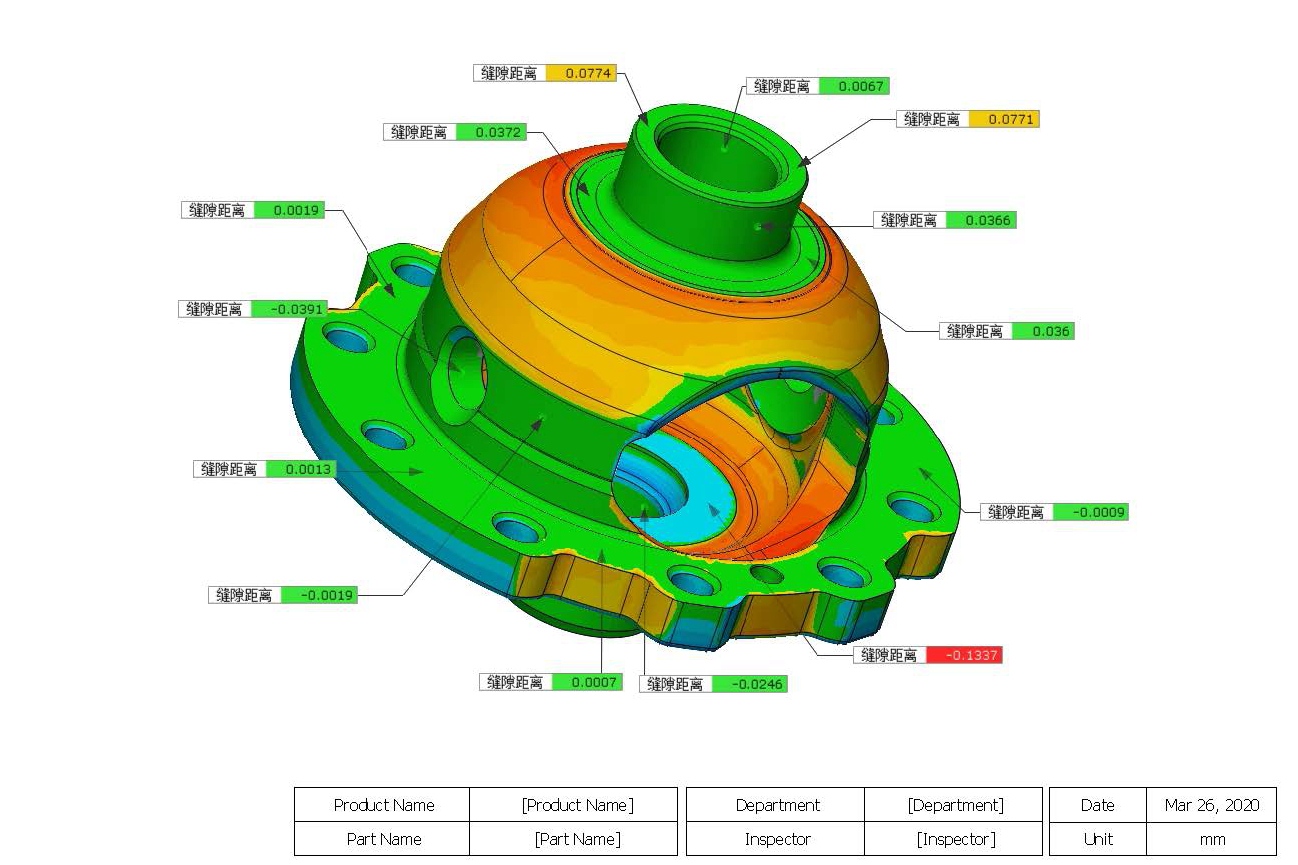

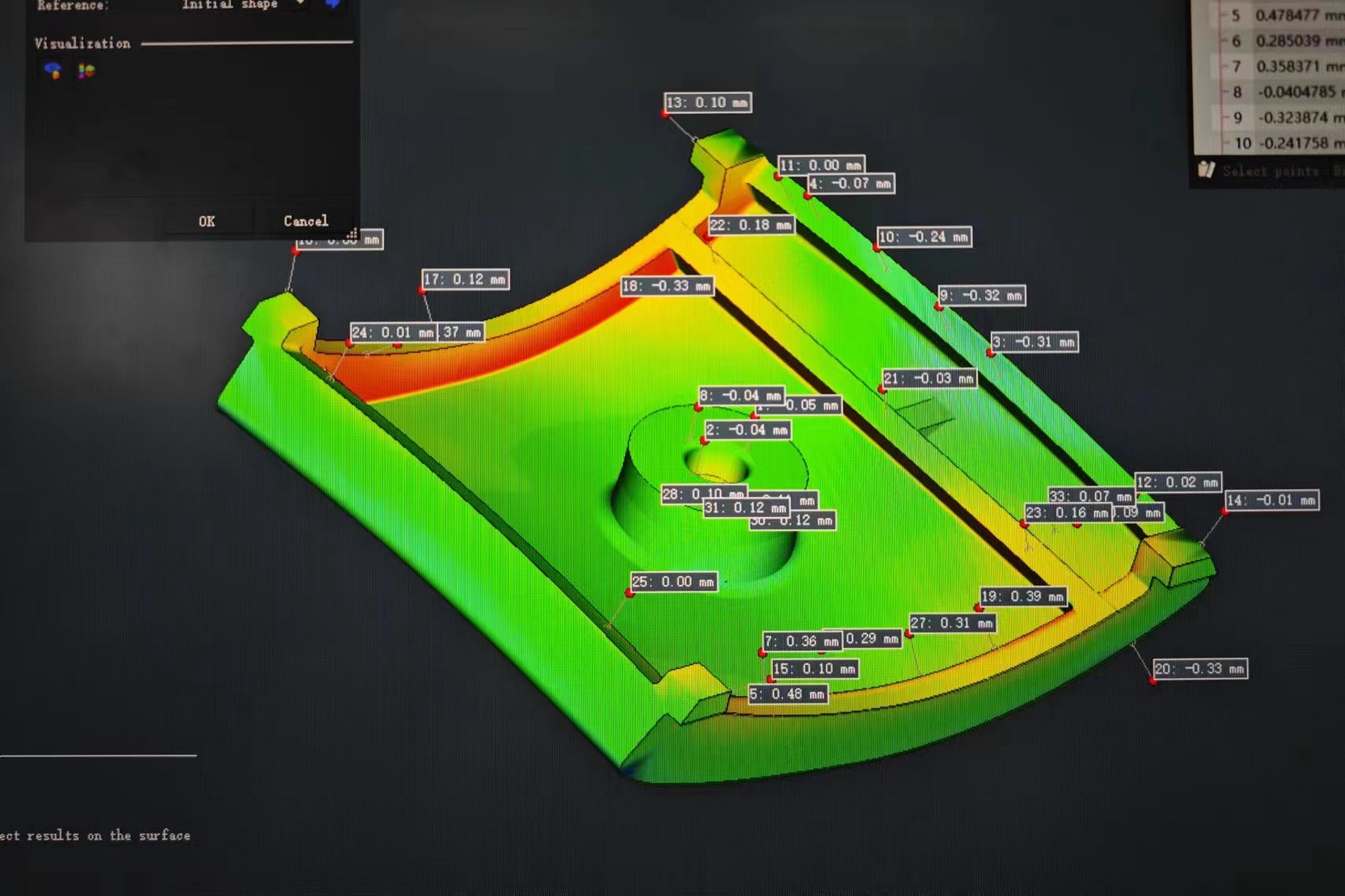

3D Scanning Measuring Instrument Checking

learn more

Coordinate Measuring Machine (CMM)

learn more

Glow Discharge Mass Spectrometer (GDMS)

learn more

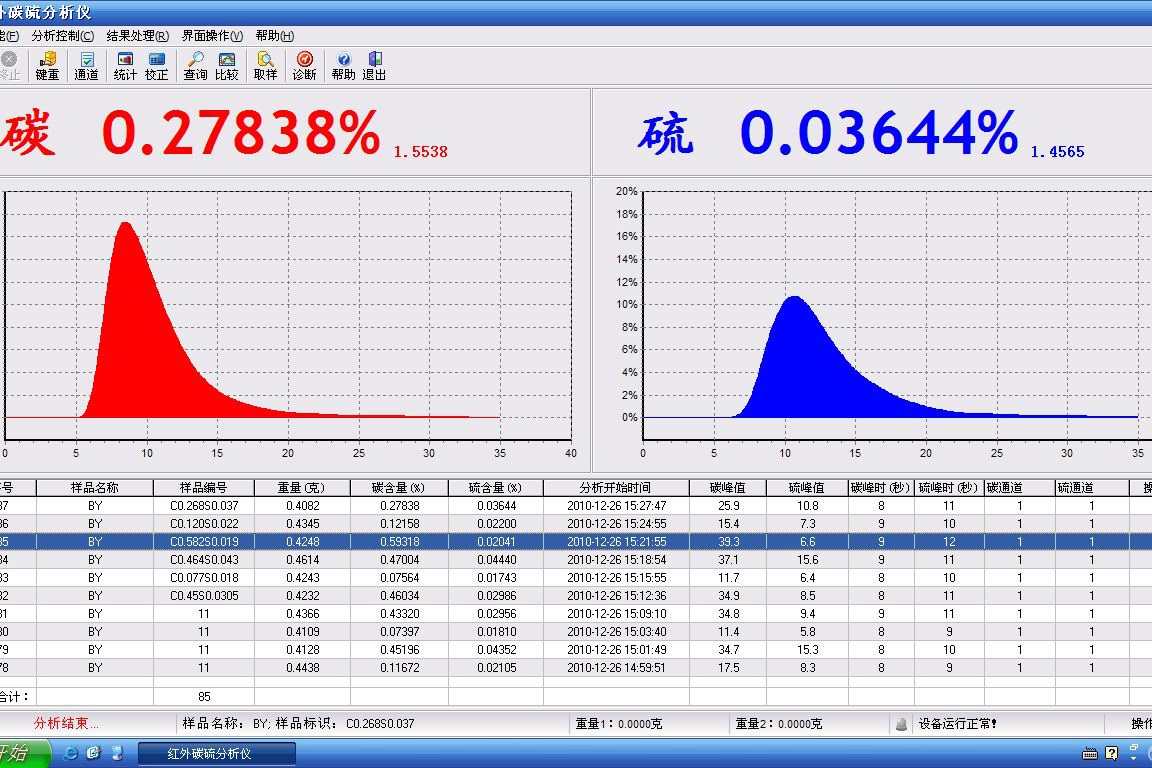

Carbon Sulfur Analyzer Checking

learn more

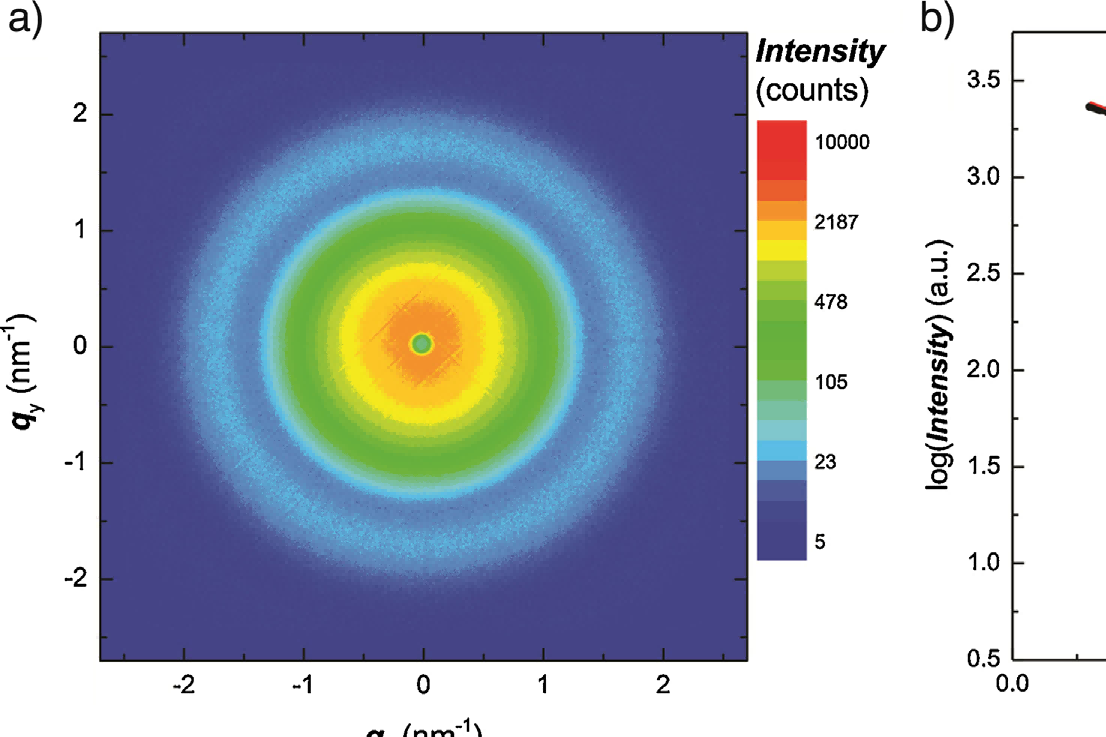

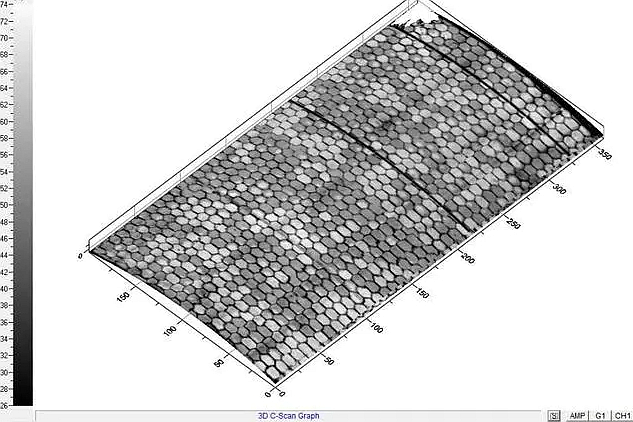

Water Immersion Ultrasonic Inspection

learn more

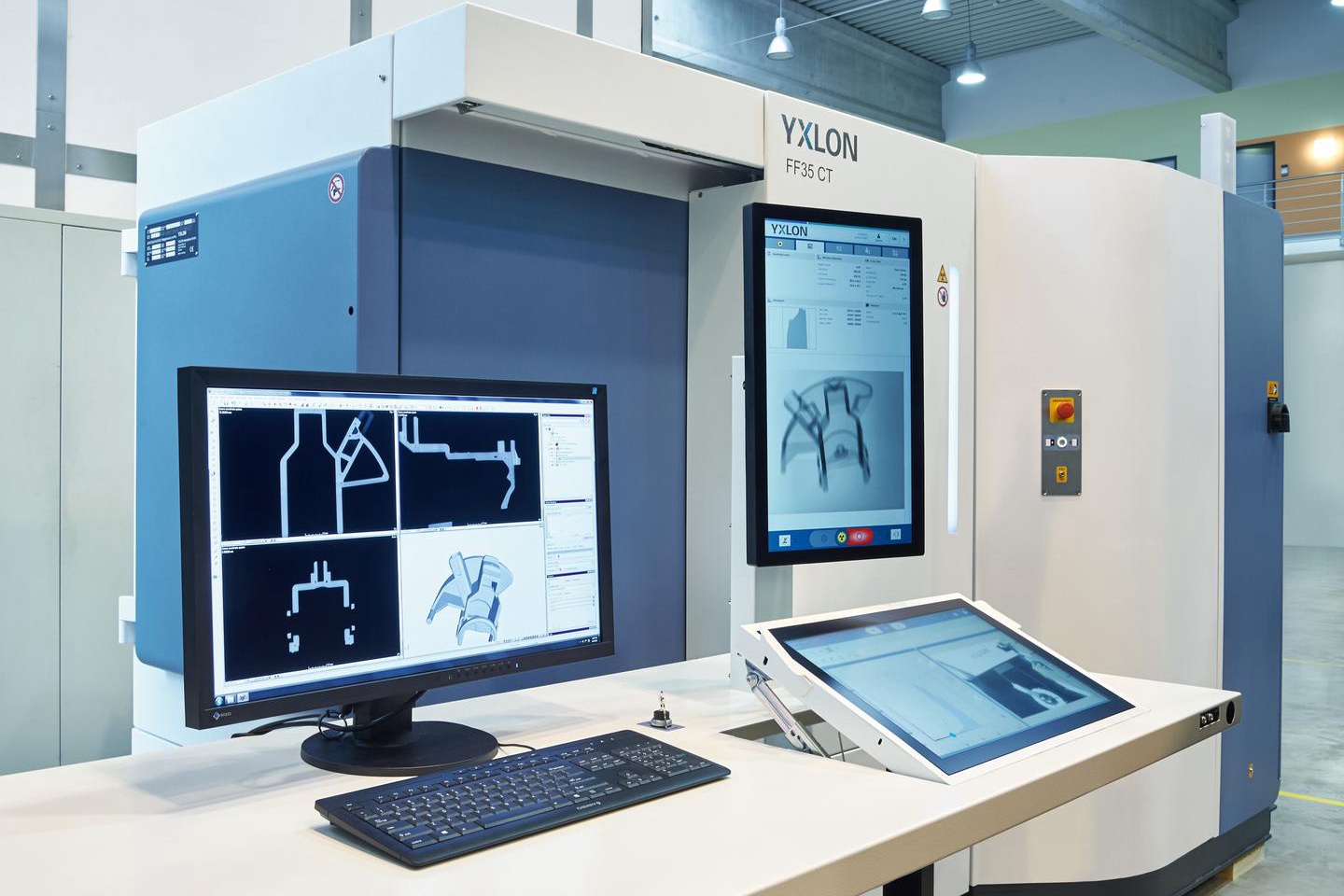

Line Array Industrial CT(GE)

learn more

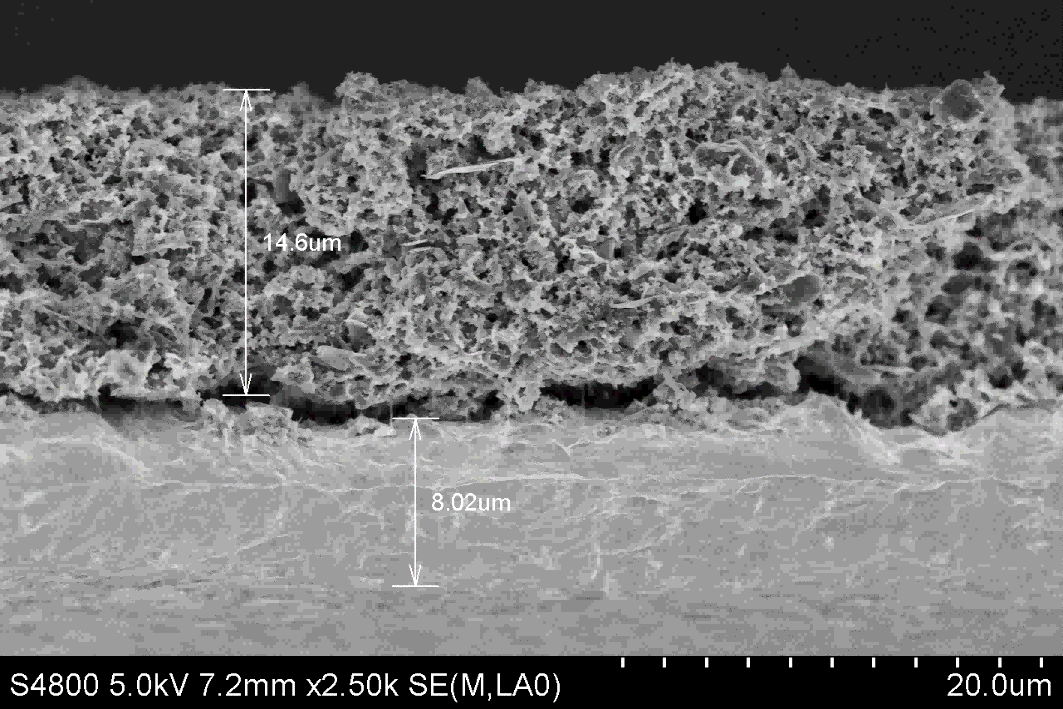

Scanning Electron Microscope (SEM) Checking

learn more

Simultaneous Thermal Analyzer (STA) Checking

learn more

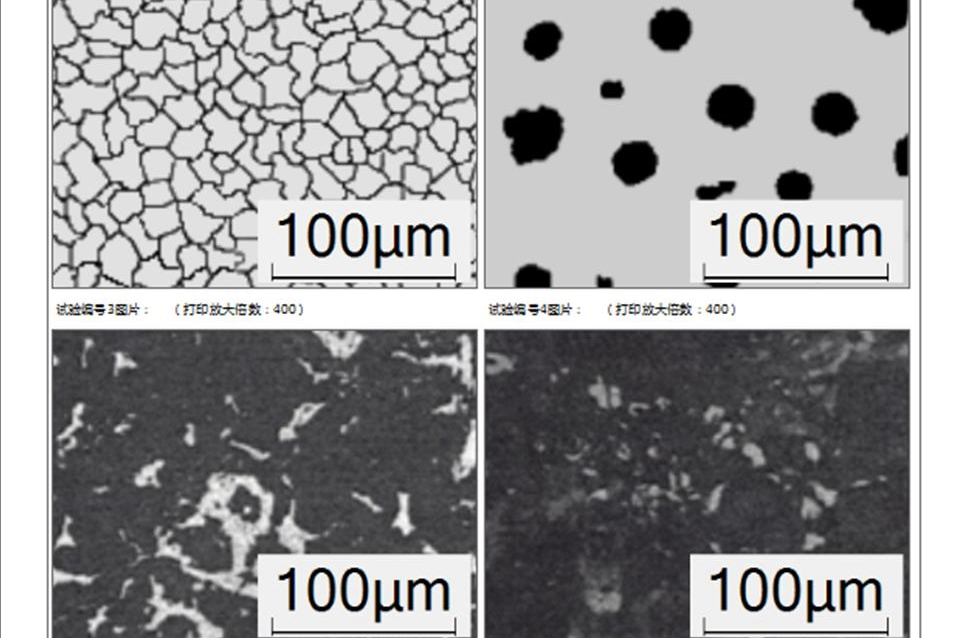

Metallographic Microscopy Checking

learn more

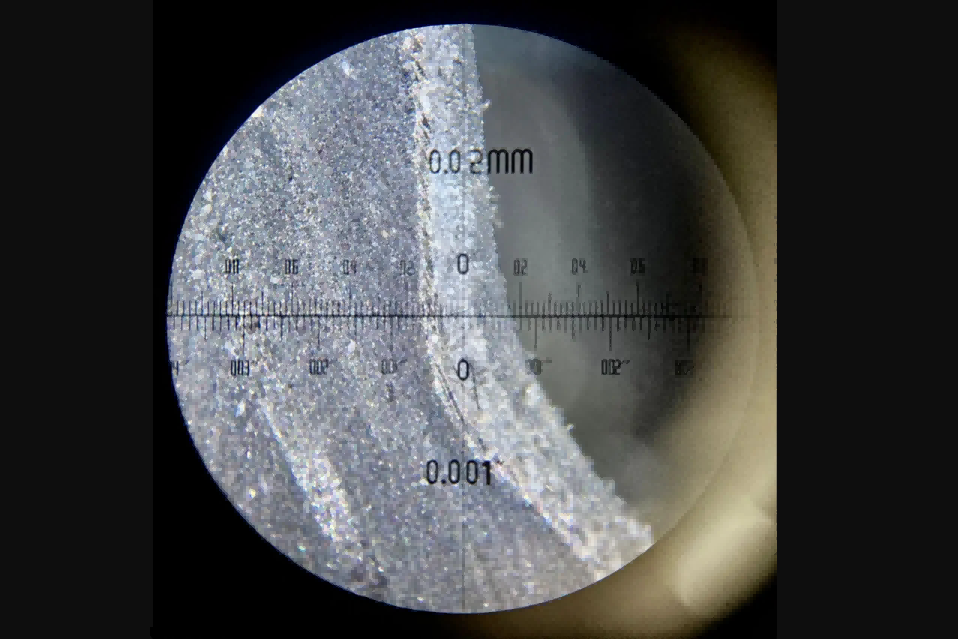

Stereo Microscope Checking

learn more

New Technology

learn more

Products Gallery

learn more

Various Industries

learn more

Surface Finishings

learn more

Post-Process

learn more

Manufacturing Technology

learn more

R&D and Simulation

learn more

Manufacturing Equipments

learn more

Testing Equipments

learn more

3D Printing Prototyping

learn more

FAQs

learn more

Contact

Let's Start A New Project Today