Advanced Testing Equipments

Superalloy Parts Testing Equipments

Neway provides vacuum investment casting, single crystal and directional casting, powder metallurgy, precision forging, 3D printing, and CNC machining. They manufacture turbine blades, discs, combustion chambers, afterburners, nozzle rings, impellers, casings, and gas turbines for aerospace applications.

Glow Discharge Mass Spectrometer (GDMS)

The Glow Discharge Mass Spectrometer (GDMS) is an advanced analytical tool used primarily to determine solid samples' elemental composition, particularly metals, alloys, semiconductors, and ceramics.

Carbon Sulfur Analyzer

The Carbon Sulfur Analyzer measures superalloys' carbon and sulfur content, ensuring proper alloy composition and preventing defects like brittleness and cracking. It plays a crucial role in quality control by maintaining alloy purity and optimizing mechanical properties. This testing process ensures the production of reliable, high-performance superalloy parts, such as turbine blades, for aerospace and energy applications.

X-ray Inspection Workshop

The X-ray Inspection Workshop performs non-destructive testing to detect internal defects like cracks and porosity in superalloy castings. It ensures structural integrity, verifies dimensional accuracy, and supports quality control by examining parts without causing damage. This inspection process is essential for certifying the reliability and performance of high-precision components like turbine blades in aerospace and energy industries.

Metallographic Microscopy

Metallographic Microscopy examines the microstructure of superalloy casting parts, identifying defects like cracks and inclusions and assessing grain size and phase composition. It verifies the effectiveness of heat treatments and ensures the alloy’s mechanical properties meet design specifications. This detailed analysis is essential for producing high-performance, durable components in critical industries such as aerospace and energy.

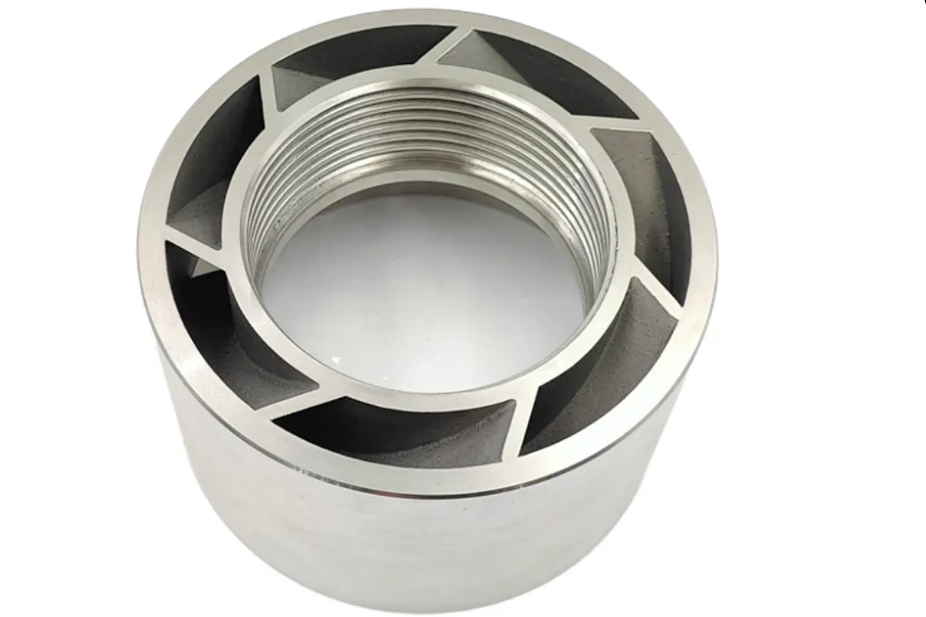

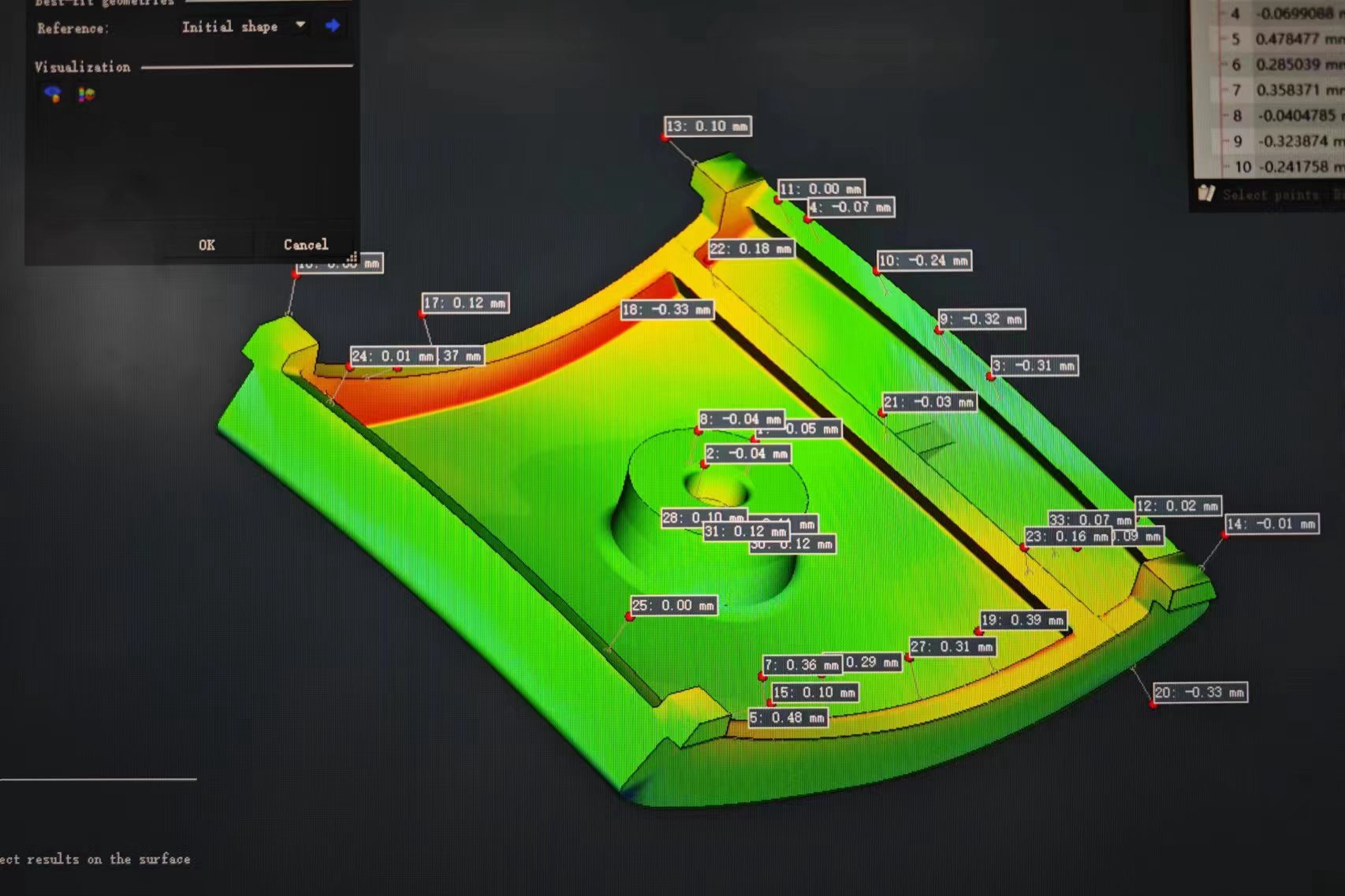

3D Scanning Measuring Instrument

The 3D Scanning Measuring Instrument ensures dimensional accuracy and surface quality of superalloy parts by creating precise 3D models. It detects defects, performs quality control, and compares scanned parts to CAD designs for consistency. Additionally, it supports reverse engineering by generating detailed models, making it essential for producing high-precision components in industries like aerospace and energy.

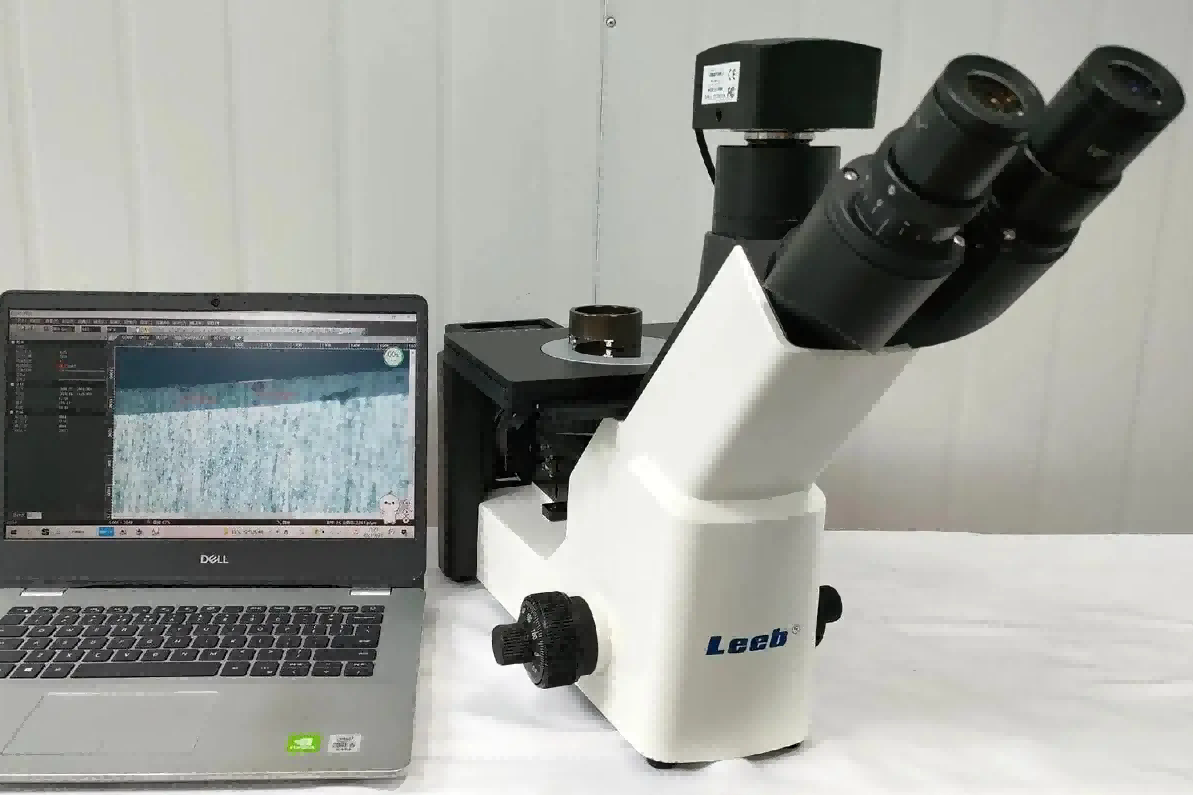

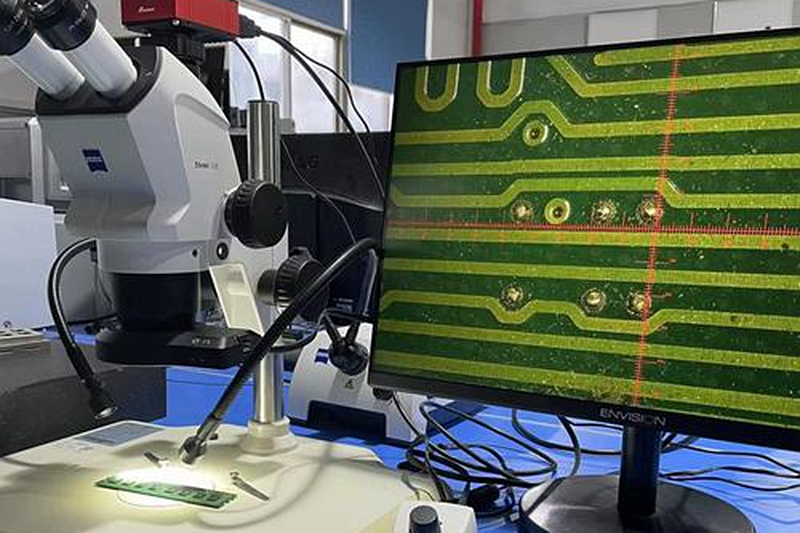

Stereo Microscope

The Stereo Microscope enables detailed inspection of superalloy parts by detecting surface defects, examining intricate features, and visualizing grain structures. It allows for non-destructive testing and precise dimensional measurements, ensuring parts meet high-quality standards. This tool is crucial for verifying the reliability and performance of superalloy components used in demanding industries like aerospace and energy.

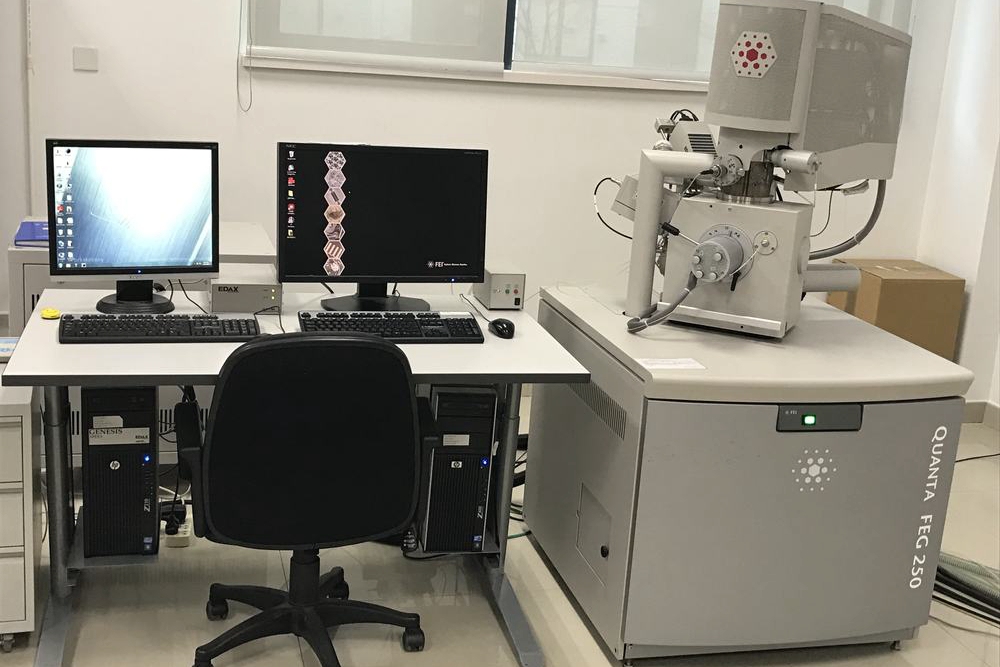

Scanning Electron Microscope (SEM)

The Scanning Electron Microscope (SEM) provides high-resolution imaging and chemical composition analysis of superalloy parts. It detects surface defects, analyzes microstructures, and investigates fracture surfaces to identify failure mechanisms. SEM ensures the quality, integrity, and performance of superalloy components, making it essential for industries like aerospace and energy, where precision and reliability are critical.

Electronic Universal Room Temperature Tensile Testing Machine

The Electronic Universal Room Temperature Tensile Testing Machine measures superalloy parts' tensile strength, yield strength, elongation, and elastic modulus. It evaluates their mechanical properties and resistance to stress, providing critical data on material stiffness, ductility, and fracture behavior. This testing ensures that superalloy components meet performance standards for high-stress applications in the aerospace and energy industries.

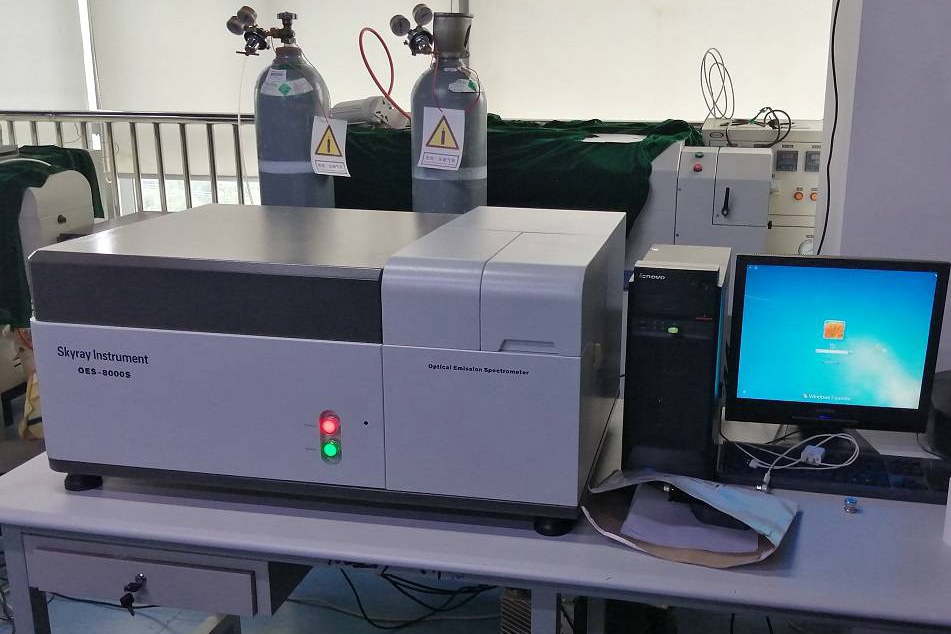

Direct Reading Spectrometer

The Direct Reading Spectrometer performs rapid, non-destructive analysis of superalloy parts, identifying and quantifying their elemental composition. It verifies alloy grades, detects impurities, and ensures chemical consistency for quality control. This device is essential for maintaining the integrity and performance of superalloy components used in high-stress applications like aerospace and energy industries.

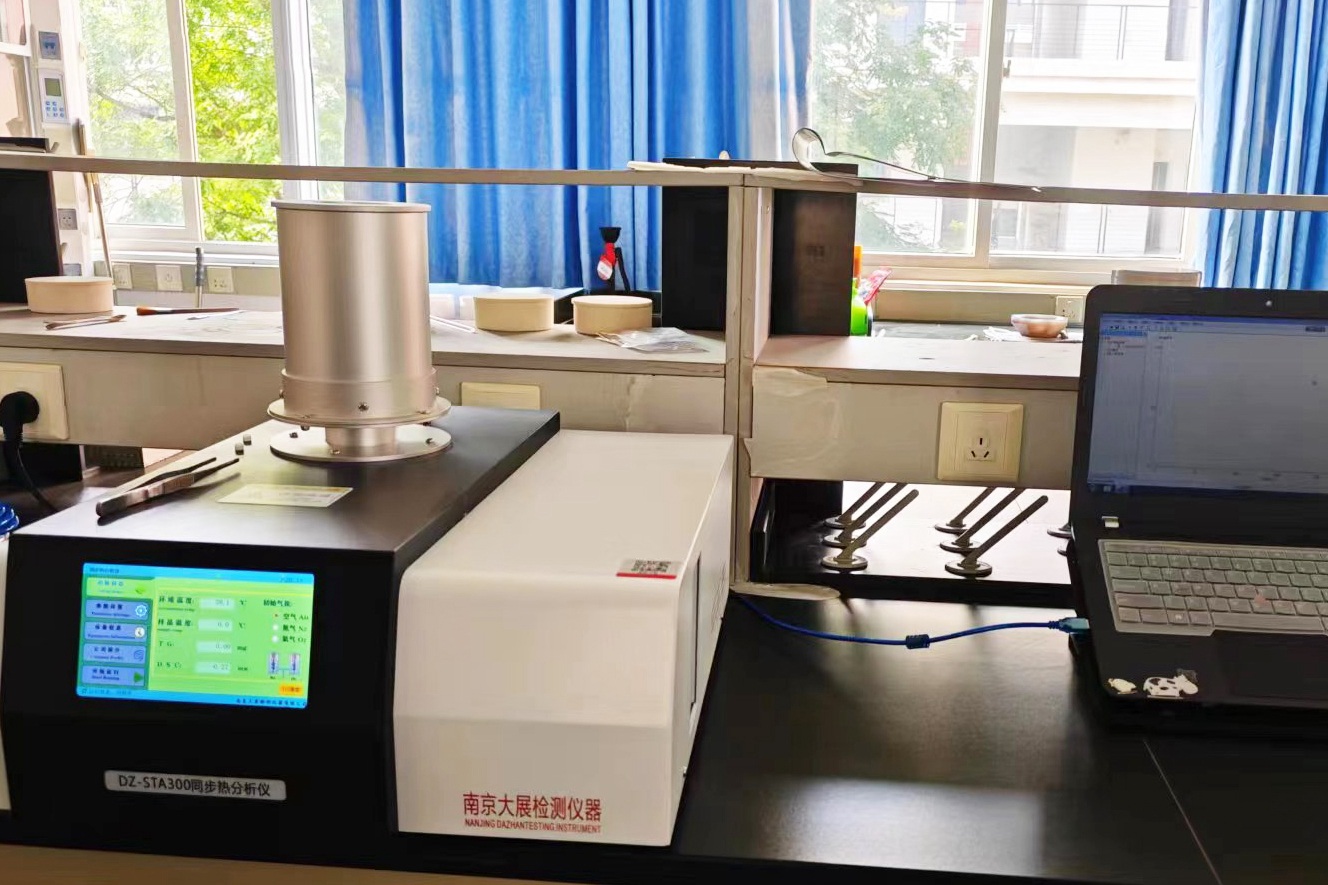

Simultaneous Thermal Analyzer (STA)

The Simultaneous Thermal Analyzer (STA) evaluates the thermal properties of superalloy parts by measuring thermal stability, phase transitions, heat capacity, decomposition, and oxidation behavior. It provides critical insights into how superalloys perform under high temperatures, ensuring their reliability and efficiency in demanding applications like aerospace and power generation, where thermal resistance is essential.

Dynamic and Static Fatigue Tester

The Dynamic and Static Fatigue Tester evaluates the durability of superalloy parts by measuring their performance under cyclic and constant loads. It analyzes crack propagation and stress resistance and predicts the life cycle of components. This testing ensures that superalloy parts, like turbine blades, can withstand the demands of high-stress environments in aerospace and energy industries.

450KV Line Array Industrial CT(GE)

The Line Array Industrial CT provides high-resolution 3D imaging for non-destructive testing of superalloy parts. It detects internal defects, verifies dimensional accuracy, analyzes material density, and inspects complex geometries. This ensures components' quality, precision, and reliability, making it essential for industries like aerospace and energy, where high-performance superalloy parts are critical.

Water Immersion Ultrasonic Inspection Equipment

The Water Immersion Ultrasonic Inspection Equipment detects internal defects, measures thickness, evaluates bond quality, and checks material homogeneity in superalloy parts. It provides non-destructive testing using ultrasonic waves, ensuring structural integrity and compliance with design specifications. This technology is crucial for verifying the quality and reliability of components in high-performance industries like aerospace and energy.

Surface Corrosion Production Line

The Surface Corrosion Production Line tests and enhances the corrosion resistance of superalloy parts by simulating harsh environments, applying protective treatments, and revealing surface defects. It ensures parts meet quality standards for corrosion resistance and adjusts surface roughness for optimal performance. This process is vital for superalloy components in extreme conditions, such as aerospace and energy applications.

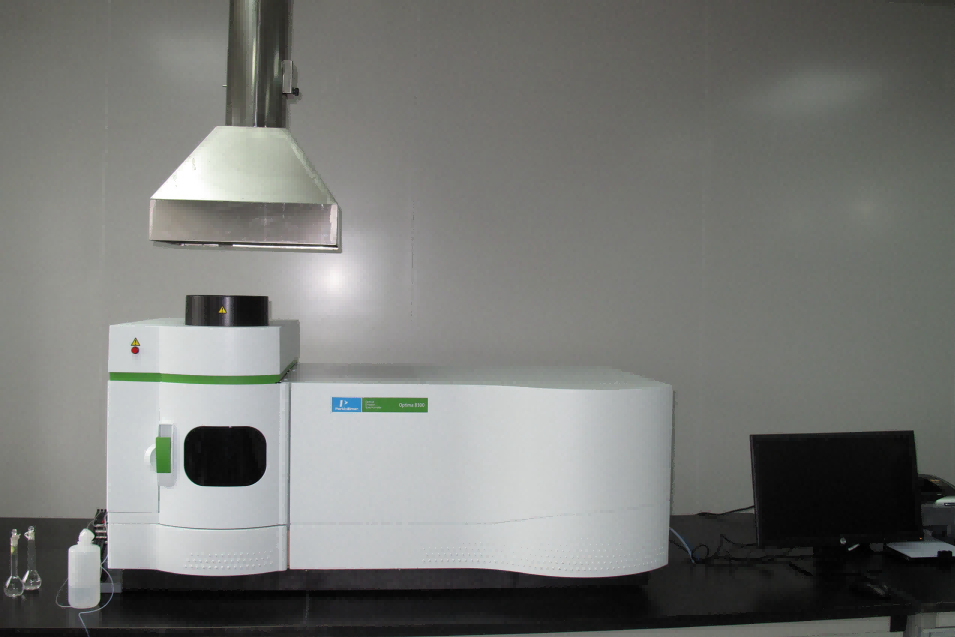

Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES)

The Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES) analyzes the elemental composition of superalloy parts, detecting trace elements and impurities. It ensures alloy grade verification, quality control, and compliance with industry standards. This non-destructive testing method is crucial for maintaining superalloy components' chemical integrity and performance in high-stress environments like aerospace and energy.

Electron Backscattering Diffractometer (EBSD)

The Electron Backscattering Diffractometer (EBSD) analyzes the microstructure of superalloy parts by mapping crystallographic orientation, characterizing grain boundaries, identifying phases, and evaluating strain and deformation. It also aids in failure analysis. This detailed microstructural insight ensures optimal mechanical performance and reliability of superalloy components in high-stress environments like aerospace and energy industries.

Thermal Physical Properties Test Platform

The Thermal Physical Properties Test Platform measures key thermal characteristics of superalloy parts, including thermal conductivity, specific heat capacity, thermal expansion, and thermal diffusivity. It also evaluates high-temperature stability, ensuring that superalloy components maintain performance and dimensional stability under extreme heat. These tests are critical for validating the durability and reliability of superalloys in aerospace and energy applications.

Let's Start A New Project Today