Failure Analysis in Superalloy Single Crystals: How EBSD Improves Component Reliability

Failure analysis is crucial in ensuring the reliability and longevity of superalloy single-crystal components, which are essential in high-performance industries like aerospace, power generation, and defense. Superalloy single crystal components, such as turbine blades, combustion chambers, and nozzle guide vanes, are exposed to extreme temperatures, high mechanical stress, and harsh environments. These demanding conditions require precise analysis to prevent premature failure and ensure the components perform reliably over their service life.

One of the most advanced techniques used in failure analysis today is Electron Backscatter Diffraction (EBSD). This method offers unparalleled insights into the microstructural features of superalloy materials, allowing engineers to identify failure mechanisms and improve the overall reliability of critical components. By examining the crystallographic structure, grain boundaries, and phase distribution, EBSD can detect misorientations, phase transformations, and deformation patterns, often precursors to failure.

EBSD's ability to analyze the microstructure at a high resolution makes it invaluable for industries where failure can lead to catastrophic results, such as aerospace-grade metal fuel system modules or high-temperature alloy reactor vessel components. By providing detailed maps of grain orientation and defect locations, EBSD allows manufacturers to pinpoint the root cause of failure, be it due to fatigue, creep, or thermal stresses. This detailed insight helps optimize the material properties and refine the manufacturing processes for superalloy components.

In addition to identifying failure mechanisms, EBSD aids in the design of superalloy parts with enhanced mechanical properties. For example, EBSD can guide the optimization of the grain structure in high-temperature alloy engine components, improving their resistance to mechanical fatigue and creep under extreme conditions. The data derived from EBSD analysis is instrumental in making material and design adjustments that enhance performance, ultimately increasing the lifespan and reliability of components across multiple industries.

What is this process?

Failure analysis in superalloy single crystal components involves identifying and understanding the root causes of material failures, which can result from fatigue, thermal gradients, mechanical stress, or phase instability. In superalloys, mainly single crystal alloys, these failures can manifest in complex ways due to the unique properties and behavior of the materials under extreme conditions, such as in superalloy turbine blade single crystal casting applications.

Electron Backscatter Diffraction (EBSD) is a powerful characterization technique used to analyze the crystallographic orientation of materials at the microstructural level. The process involves scanning a material surface with an electron beam and collecting diffracted electron patterns produced when the beam interacts with the material's crystalline structure. These patterns can be analyzed to determine the crystallographic orientation, grain boundaries, phase changes, and other microstructural features responsible for material failure.

In the context of superalloy single crystals, EBSD is particularly valuable as it can provide insights into the alignment of the crystal structure, which is critical for understanding the material's mechanical properties and behavior under stress. This process can reveal hidden microstructural defects such as dislocations, misalignments, or phase changes that could be precursors to failure, helping to optimize superalloy single crystal casting quality and performance.

The Function of EBSD in Analyzing Superalloy Components

Electron Backscatter Diffraction (EBSD) is a diagnostic tool to assess the microstructural integrity of superalloy single crystal castings. It enables engineers to visualize and analyze the material’s crystallographic structure, comprehensively understanding how it behaves under various mechanical and thermal stresses.

One of the main benefits of EBSD is its ability to identify defects within the superalloy, such as dislocations, grain boundaries, and phase instability. These defects often lead to potential failure modes in superalloy components, especially under extreme conditions in industries like aerospace or power generation. Through EBSD, engineers can detect the root causes of failure, including:

Strain Localization: EBSD can pinpoint areas within the material that experience high strain and are prone to developing cracks or fractures under operational loads. This helps identify critical weak points in parts like turbine blades and combustion chambers undergoing repeated high-stress cycles.

Phase Transitions: Superalloys experience phase transformations due to temperature and mechanical stress fluctuations. EBSD is key in tracking phase transitions, significantly affecting material strength, toughness, and performance in high-temperature environments like gas turbines and reactor components.

Grain Boundary Characterization: Grain boundaries significantly influence the material’s performance in single-crystal superalloys. EBSD can detect misorientations or abnormal grain boundary structures that may lead to issues such as brittle fracture or creep deformation, particularly in critical parts like turbine blades.

In addition to these functions, EBSD also helps measure crystallographic orientation in multi-grain superalloys, offering insights into how the material will perform under high-temperature and high-stress conditions. By identifying weak spots or microstructural abnormalities, EBSD empowers engineers to make more accurate predictions about material behavior, allowing for better design decisions and timely corrective actions in processes such as superalloy precision forging and superalloy CNC machining.

Which Superalloy Parts Are Needed?

Superalloy parts are essential in industries where materials must perform under extreme conditions, such as aerospace, power generation, and defense. These components are often subjected to high temperatures, mechanical stresses, and thermal cycling, requiring superior material properties for optimal performance and longevity. Below are essential superalloy parts that are indispensable in these industries:

Superalloy Castings

Superalloy castings, particularly turbine blades, nozzle guide vanes, and combustion chambers, are critical for aerospace and power generation applications. These components operate at extremely high temperatures and are subject to complex thermal and mechanical loading. Superalloy castings are vital for ensuring the reliability and performance of gas turbines and jet engines. EBSD analysis is invaluable in identifying defects such as misaligned crystals or imperfections during the casting process, helping optimize strength and resistance to fatigue.

Forging Parts

Forged superalloy components, such as turbine discs, impellers, and compressor blades, are fundamental in aerospace and energy production. These parts experience high mechanical loads and must retain exceptional strength and fatigue resistance under extreme conditions. EBSD strain and phase distribution analysis can detect issues like grain misalignment or internal stress, which negatively affect performance and component integrity during operation. This makes forged superalloy parts essential for engines' and turbines' safe and efficient functioning.

CNC Machined Superalloy Parts

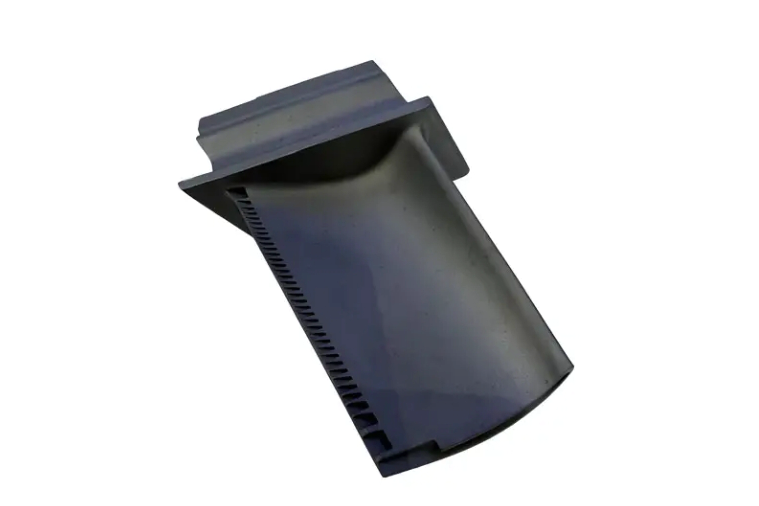

Superalloy components like brackets, housings, and precision machined parts are often used in aerospace, power generation, and defense sectors. After casting or forging, these components undergo CNC machining to achieve precise shapes and tolerances. EBSD analysis ensures that machining does not introduce residual stresses or crystallographic misalignment, which could weaken the material and cause premature failure. This is particularly important for parts exposed to dynamic stresses, where reliability is critical.

3D Printed Superalloy Parts

Additive manufacturing, or 3D printing, is increasingly used for producing complex geometries in aerospace and defense applications, including turbine blades and heat exchanger components. However, the additive manufacturing process can result in non-uniform cooling rates, potentially leading to phase segregation or strain issues. EBSD helps optimize the crystallographic orientation and phase distribution in 3D printed superalloy parts, ensuring that the components meet the stringent performance requirements for high-stress applications.

In each of these categories, superalloy parts are essential for maintaining the reliability and safety of critical systems, and advanced analysis techniques like EBSD ensure that these parts are manufactured to meet the rigorous standards of high-temperature, high-stress environments.

Compared with Other Processes

EBSD stands out for its ability to provide high-resolution, spatially resolved crystallographic information compared to other failure analysis methods. Traditional failure analysis techniques, such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and microhardness testing, offer valuable insights but may not provide the level of detail needed to understand the intricate microstructural features of superalloy materials.

For example, while XRD can reveal information about phase composition and crystallinity, it cannot provide the precise orientation of individual crystals. Similarly, SEM is effective for surface morphology analysis and detecting large-scale fractures. Still, it does not offer high-resolution crystallographic data to assess smaller-scale defects such as grain boundary misorientations or dislocation patterns. Microhardness testing can measure material hardness but does not provide the detailed crystallographic information necessary for a full failure analysis.

Other non-destructive testing (NDT) methods, such as ultrasonic testing or eddy current inspection, are also widely used for detecting cracks and defects. Still, they typically provide less detailed information about the material's microstructure. These methods often rely on detecting macroscopic features such as cracks or voids, whereas EBSD allows for identifying microstructural features that could indicate a developing failure. This makes EBSD particularly valuable for aerospace and energy industries where failure prevention and early detection of material degradation are critical.

Industry and Application

EBSD's role in failure analysis is particularly critical in industries where superalloy components are used in high-stress, high-temperature environments. These industries demand the highest levels of component reliability to ensure safe and efficient operation. Key sectors benefiting from EBSD-based failure analysis include:

Aerospace and Aviation

In aerospace and aviation, turbine blades, engine casings, and nozzle guide vanes are made from superalloy single crystals. These components must withstand extreme thermal and mechanical stress, making failure analysis essential. EBSD helps ensure that these parts maintain structural integrity throughout their service life by identifying potential points of failure before they occur. For example, superalloy turbine blades are critical in jet engine operation. EBSD analysis helps detect any microstructural anomalies that could lead to premature failure, ensuring the safety and reliability of aircraft engines.

Power Generation

In the power generation sector, superalloy components like turbine blades, nozzles, and heat exchangers are subjected to high-pressure steam and thermal cycling. EBSD can detect phase transformations and crystallographic misalignments that could affect the performance and reliability of these components, helping to prevent costly failures in power plants. For instance, superalloy heat exchangers experience extreme thermal stress during operation. EBSD analysis identifies and addresses any weak spots before they result in critical failure, ensuring efficient and continuous energy production.

Oil and Gas

The oil and gas industry relies on superalloy components for equipment such as pressure vessels, pumps, and heat exchangers, all of which must endure extreme pressures and temperatures. EBSD helps in failure analysis by ensuring these components can operate safely under challenging conditions. For example, superalloy corrosion-resistant piping is used in offshore drilling operations where high pressures and corrosive environments are shared. EBSD is employed to detect microstructural defects that could lead to failure, improving the lifespan and reliability of critical infrastructure.

Defense and Military

In the defense and military sector, high-performance components such as missile parts, control rods, and propulsion system components are fabricated from superalloy materials. The reliability of these parts is crucial for mission success, and EBSD helps identify potential failure modes that could compromise performance. For example, components like superalloy missile segment parts benefit from EBSD failure analysis to withstand extreme impact, heat, and mechanical stresses during defense operations, ensuring mission-critical functionality.

Nuclear

Nuclear power plants use superalloy components like reactor vessel parts, control rods, and fuel system modules. These components are exposed to high radiation levels, extreme temperatures, and mechanical stresses, making failure analysis critical for maintaining the safety and reliability of nuclear reactors. Superalloy reactor vessel components undergo EBSD analysis to assess their ability to withstand the harsh conditions inside nuclear reactors over time. EBSD is used to evaluate any potential structural weaknesses or phase transformations that could lead to failure, ensuring the safe operation of nuclear plants.

By leveraging EBSD for failure analysis, industries can detect and address potential issues in superalloy components before they lead to catastrophic failures. This helps ensure the safety, efficiency, and longevity of critical components used in aerospace, power generation, oil and gas, defense, and nuclear industries.

FAQs:

What is EBSD and how does it work in failure analysis of superalloy single crystals?

How does EBSD improve the reliability of superalloy components used in turbine engines?

What are the main benefits of using EBSD for failure analysis compared to traditional techniques?

How does EBSD detect microstructural defects that can lead to component failure?

In which industries is EBSD most commonly used for failure analysis of superalloy materials?