Understanding Specific Heat Capacity for Superalloy Directional Casting

Specific heat capacity is a fundamental thermal property that measures the heat energy required to raise the temperature of a given amount of material by one degree Celsius (or Kelvin). For superalloys, high-performance materials used in extreme environments, specific heat capacity is crucial for determining how they behave when exposed to high temperatures. In the context of superalloy directional casting, understanding the material's specific heat capacity plays an essential role in the design and manufacturing of high-performance components, particularly in aerospace, power generation, and military defense.

Superalloy directional casting involves the controlled solidification of molten superalloys to form parts with specific microstructural properties, such as uniform grain structures. These properties are crucial to ensuring that the components can withstand high temperatures, thermal stresses, and mechanical loads without failing. The specific heat capacity influences how quickly or slowly the material can absorb and release heat during casting, ultimately affecting the solidification rate and microstructure.

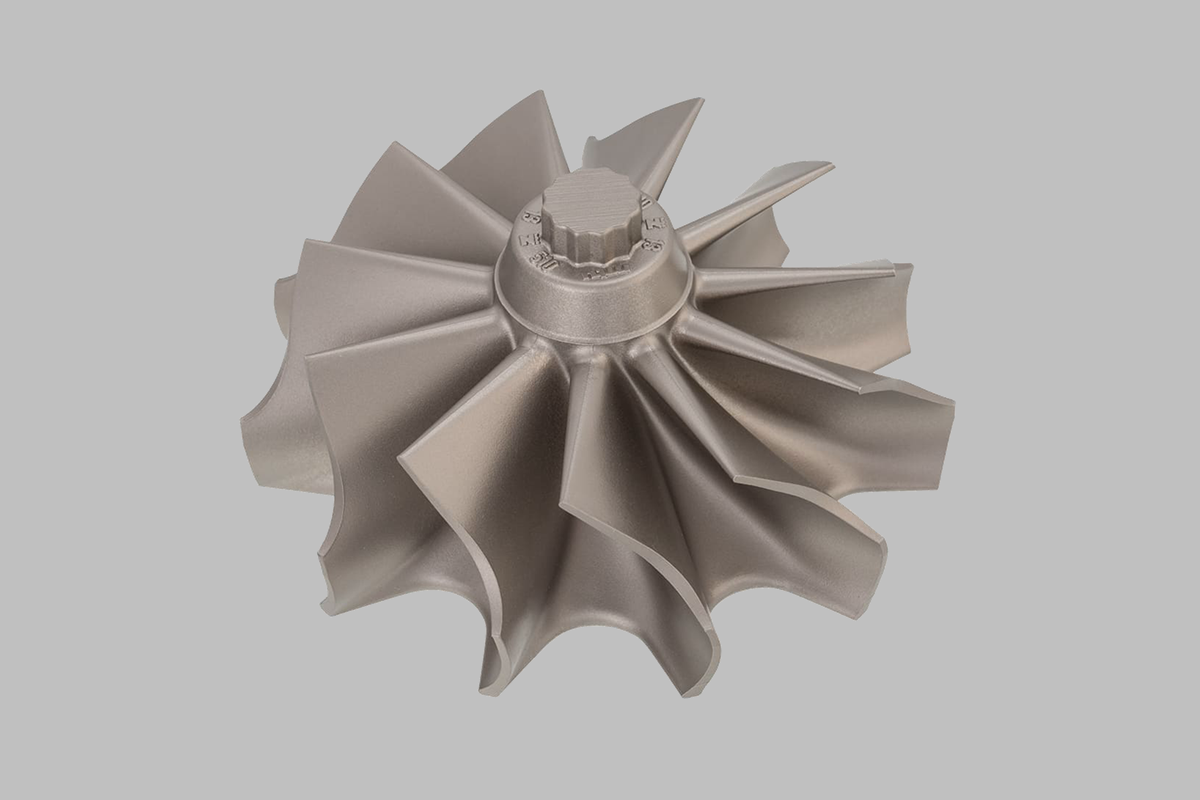

By controlling the cooling process through specific heat measurements, manufacturers can ensure that components are produced with the correct grain size, phase distribution, and minimal defects. Superalloys are specifically designed to retain their mechanical properties under high-temperature conditions, and understanding specific heat capacity helps optimize the casting process to achieve these goals, particularly for critical components such as turbine blades and engine components.

The Function of Specific Heat Capacity in Directional Casting

Specific heat capacity plays a vital role in the directional casting process by influencing molten superalloys' temperature and solidification behavior. Directional casting aims to control the cooling and solidification rates, ensuring that the material solidifies in a controlled manner that yields optimal microstructure and mechanical properties. The solidification process directly impacts the grain structure, influencing the alloy’s strength, fatigue resistance, and thermal stability.

Superalloys are often used in components subjected to high thermal gradients—such as turbine blades in jet engines or gas turbines. Controlling the heat flow through the material during casting is crucial for achieving mechanical properties like resistance to creep (slow, permanent deformation under stress at high temperatures) and thermal fatigue.

During the casting process, the specific heat capacity of the superalloy governs how the molten material absorbs and releases heat as it solidifies. Materials with a high specific heat capacity require more energy to heat up, cooling more slowly and resulting in coarser grains. Conversely, materials with a lower specific heat capacity heat up and cool more quickly, forming finer grains. This behavior is critical in directional casting, as it determines the cooling rate at various points in the casting, which impacts the material's microstructure.

Understanding the specific heat capacity of the alloy allows manufacturers to fine-tune the casting process by adjusting parameters such as cooling rates and mold designs. This ensures the formation of a fine, uniform grain structure, which is critical for achieving optimal mechanical properties, such as high strength, resistance to thermal stress, and low crack propensity.

In addition to its impact on grain structure, specific heat capacity also affects the solidification time of the material. The longer the solidification time, the more time the crystals have to form, leading to a more homogeneous microstructure. This is particularly advantageous for components performing under high mechanical and thermal stresses, such as turbine blades or critical aerospace parts. By leveraging the insights gained from specific heat capacity measurements, manufacturers can achieve superalloys with enhanced durability and performance in demanding environments.

Superalloy Parts That Require Specific Heat Capacity Considerations

Certain superalloy parts produced through directional casting and other advanced manufacturing processes require precise control over specific heat capacity to ensure optimal thermal performance. Parts such as turbine blades, forging components, CNC machined parts, and 3D printed superalloy components all benefit from careful management of thermal properties during production. Specific heat capacity is crucial in controlling how the material absorbs and dissipates heat, ultimately influencing the part's structural integrity, performance, and quality.

Superalloy Castings

Superalloy castings, including critical components like turbine blades, combustion chambers, and nozzle rings, operate under extreme thermal conditions, making specific heat capacity a key factor during production. For turbine blades used in jet engines, controlling the cooling rate through precise thermal management ensures that the superalloy maintains its strength and structural integrity at high temperatures. Specific heat capacity helps optimize the solidification process, achieving the desired grain structure and mechanical properties necessary for the part to withstand intense heat and rotational forces.

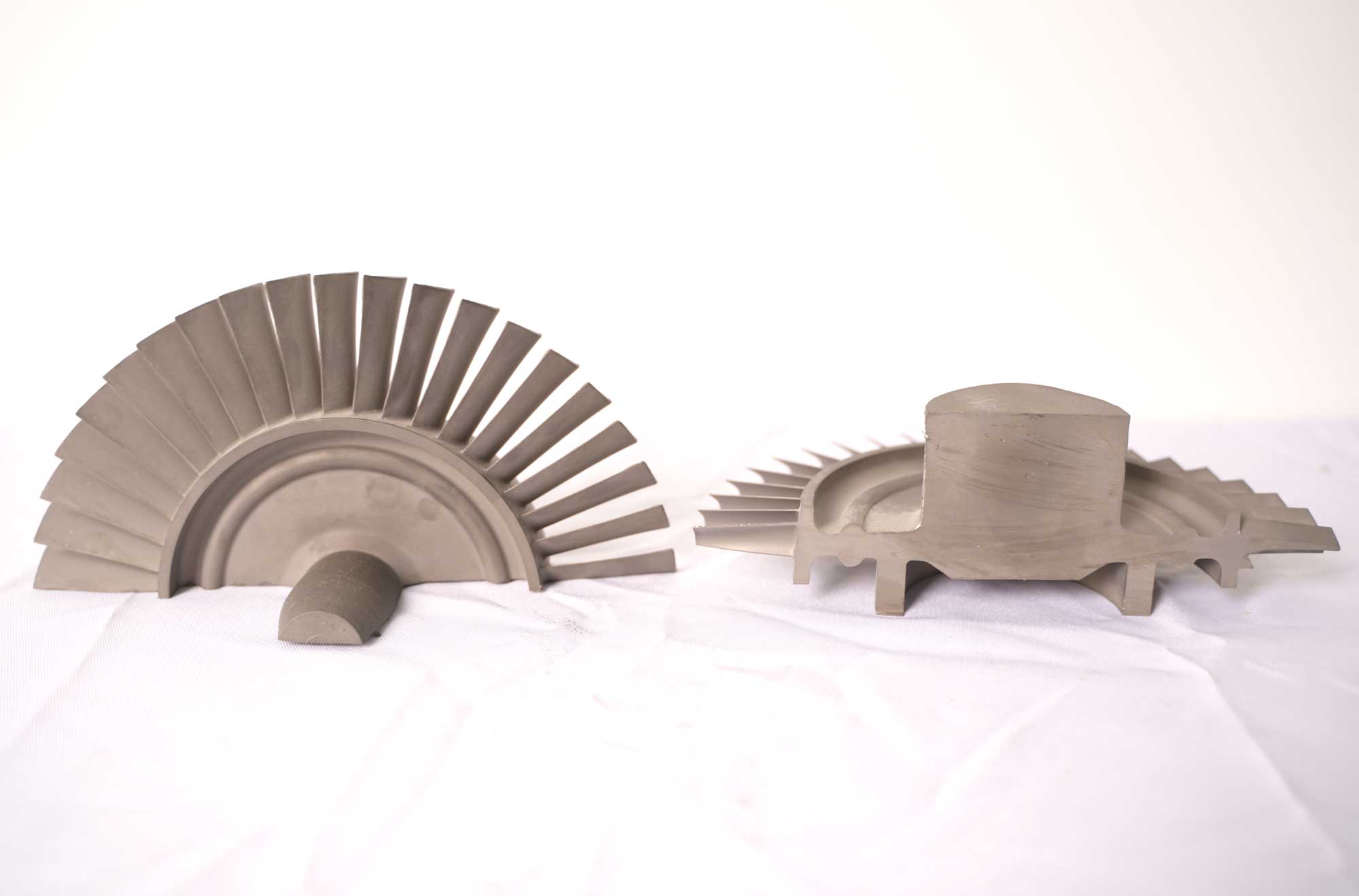

Forging Parts

Superalloy forgings, such as turbine discs, impellers, and compressor blades, require specific heat capacity considerations to maintain thermal properties during the forging process. Forging involves shaping the material under high pressure, and the thermal properties of the superalloy influence how the material responds to heat. By controlling specific heat capacity, manufacturers can ensure that the material cools at the correct rate, minimizing thermal stresses and preventing defects like cracking or warping. This is critical for parts that must maintain their integrity and performance under high temperatures, such as those used in aerospace or power generation.

CNC Machined Superalloy Parts

After casting or forging, many superalloy parts undergo CNC machining to achieve precise final dimensions and surface finishes. During machining, the material's thermal properties can influence the part’s stability, particularly if it is exposed to high temperatures during processing. Specific heat capacity ensures that the part retains its structural integrity throughout machining by preventing thermal distortion or warping issues. Accurate thermal management is essential for parts that must meet rigorous performance standards, such as those used in high-performance engines or turbines.

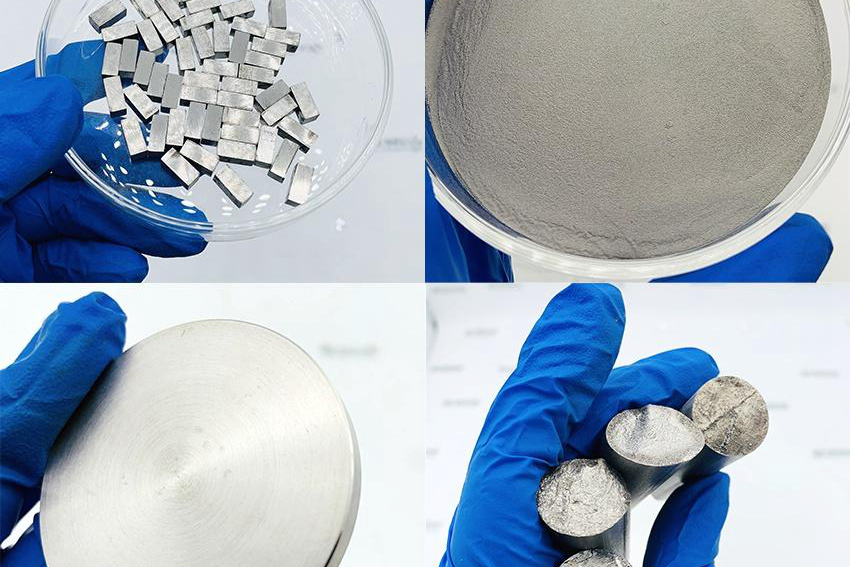

3D Printed Superalloy Parts

With the rise of 3D printing for creating complex superalloy components, controlling the material's thermal properties is vital for ensuring a high-quality print. During the additive manufacturing process, heat is applied layer by layer, and understanding the material's specific heat capacity helps manage how the superalloy absorbs and dissipates heat. This is particularly important for 3D printed superalloy parts, as it ensures that each layer bonds correctly and that the part maintains its thermal stability throughout the build process. Controlling specific heat capacity helps prevent defects such as warping, delamination, or thermal gradients that could compromise the part’s performance in critical applications like aerospace or turbine systems.

Comparison with Other Processes

While specific heat capacity is a crucial factor in directional casting, it must be considered alongside other material properties and manufacturing processes to ensure the success of superalloy part production. Here’s how specific heat capacity compares to other key processes and material properties:

Specific Heat Capacity vs. Thermal Conductivity

While specific heat capacity and thermal conductivity relate to a material's ability to manage heat, they measure different properties. Thermal conductivity refers to how well a material can transfer heat, whereas specific heat capacity measures how much heat energy is required to change the material’s temperature. In directional casting, controlling the rate at which heat is absorbed (specific heat capacity) and transferred (thermal conductivity) is critical for ensuring the material solidifies properly and develops the desired microstructure. For instance, thermal testing helps fine-tune this balance, ensuring the casting process achieves the target mechanical properties.

Specific Heat Capacity vs. Thermal Expansion

Thermal expansion refers to how a material changes its size in response to changes in temperature. Superalloys used in directional casting often need to resist thermal expansion and contraction to maintain dimensional accuracy. While specific heat capacity influences the cooling rate, thermal expansion directly impacts how much a material expands or contracts during temperature changes. Both properties must be carefully controlled to avoid defects such as warping, cracking, or distortion during casting and subsequent cooling. X-ray checking and CMM checking are often used after casting to detect any dimensional inaccuracies that could result from poor thermal control.

Specific Heat Capacity vs. Other Casting Methods

Compared to other casting methods like sand casting, investment casting, and die casting, directional casting is specifically focused on controlling the cooling and solidification of the material to produce parts with uniform grain structures. While other casting methods may not require as much precise control over thermal properties, directional casting is more sensitive to these properties because it aims to control the solidification process to create components with a high degree of mechanical integrity. In these cases, specific heat capacity is essential in controlling the cooling rate and, ultimately, the material’s mechanical properties. Metallographic microscopy and thermal conductivity testing work with specific heat capacity to optimize part quality in high-performance applications.

Industry Applications and Benefits of Specific Heat Capacity Measurement

Understanding and controlling specific heat capacity is crucial in industries that rely on superalloy parts to perform under extreme conditions. These industries include:

Aerospace and Aviation

Superalloy components like turbine blades, nozzle rings, and combustion chambers are used in jet engines and turbines, where high thermal loads are expected. Specific heat capacity measurement ensures that these parts can handle the heat generated during flight without experiencing excessive thermal stresses or material degradation. For example, turbine blades in jet engines must maintain stable thermal properties to ensure reliability in high-temperature environments. By optimizing specific heat capacity, manufacturers can enhance the performance and longevity of critical components like superalloy jet engine components.

Power Generation

Superalloy castings used in power generation, particularly in gas turbines and heat exchangers, must withstand high temperatures and thermal cycling. Specific heat capacity measurement helps optimize the casting process to produce parts with the proper thermal stability, ensuring they can operate efficiently and reliably in power generation applications. For example, components such as superalloy heat exchanger parts rely on specific heat control to manage the intense thermal cycling that occurs during energy production, maintaining both efficiency and durability over time.

Oil and Gas

The oil and gas industry relies on superalloy components for high-temperature and high-pressure applications, such as downhole tools, pumps, and valves. Controlling specific heat capacity ensures that these parts can operate under extreme conditions without failing due to thermal stresses. For instance, superalloy pump components must manage rapid temperature fluctuations while maintaining structural integrity, ensuring reliable operation during drilling and extraction operations.

Military and Defense

In military and defense applications, such as missile systems and armor-piercing projectiles, superalloy parts must maintain their strength and stability under intense thermal and mechanical loads. Specific heat capacity measurement ensures these components perform reliably in high-stress, high-temperature environments. For example, superalloy armor system parts are designed to withstand extreme heat and mechanical forces, where precise control over specific heat capacity ensures maximum protection and performance under battlefield conditions.

Nuclear

Superalloy components used in nuclear reactors, such as pressure vessels and heat exchangers, must maintain thermal stability and structural integrity over long periods under extreme conditions. Understanding the specific heat capacity of these materials is key to ensuring safe and reliable operation. For instance, superalloy reactor vessel components require precise thermal management to prevent failures due to thermal cycling and radiation exposure, ensuring the safety of nuclear power plants and reactors.

By measuring and optimizing specific heat capacity, industries can ensure that their superalloy components meet their demanding thermal conditions, improving performance, reliability, and safety across critical applications.

FAQs

How is specific heat capacity measured in superalloy materials during directional casting?

Why is specific heat capacity important for controlling the cooling rate in directional casting?

How does specific heat capacity influence the grain structure of superalloy castings?

What superalloy parts are most sensitive to changes in specific heat capacity during the manufacturing process?

How does specific heat capacity compare to other thermal properties, such as thermal conductivity, in superalloy directional casting?