Non-Destructive Testing for Superalloy Components: Preserving Quality and Integrity

Non-destructive testing (NDT) is an essential process in manufacturing and maintaining superalloy components, offering a reliable way to evaluate the quality and integrity of parts without damaging them. Superalloys, especially those used in critical applications like aerospace, power generation, and defense, must meet extremely high performance, durability, and safety standards. NDT allows manufacturers to ensure these standards are met while maintaining the integrity of the parts for their intended use.

In industries such as aerospace, where components like turbine blades and jet engine components are subjected to extreme temperatures and mechanical stresses, NDT methods, such as ultrasonic testing and water immersion ultrasonic testing (WIUT), play a critical role in identifying internal defects like cracks and voids that could compromise the part's structural integrity. Similarly, for power generation applications, NDT helps detect potential issues in high-temperature alloy parts such as heat exchangers and reactor vessel components, ensuring their long-term reliability.

What is Non-Destructive Testing (NDT) for Superalloy Components?

Non-destructive testing refers to a group of techniques used to evaluate the properties of a material, component, or system without causing any damage. In superalloys, NDT methods are crucial for identifying defects, ensuring uniformity, and confirming the mechanical properties of components subject to extreme conditions, such as high temperatures and pressures. The goal is to detect flaws that could lead to failure, such as cracks, porosity, or inclusions, without compromising the part's functionality.

Standard NDT methods used for superalloy components include:

Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal defects. It can measure thickness, detect cracks or voids, and assess material properties.

X-ray or Computed Tomography (CT) Scanning: These techniques offer detailed imaging of internal structures and are used to identify internal flaws and porosity. Industrial CT can also be employed for a more comprehensive analysis of internal structures.

Eddy Current Testing: Electromagnetic induction is used to detect surface and near-surface defects, especially in conductive materials.

Dye Penetrant Testing (DPT): A surface inspection method that uses a liquid dye to reveal surface cracks and discontinuities.

Magnetic Particle Testing (MPT): Primarily used for ferromagnetic materials, it detects surface and near-surface flaws by applying a magnetic field.

These techniques ensure that superalloy parts meet the rigorous requirements for high-temperature applications and maintain their strength, toughness, and resistance to corrosion and fatigue.

The Function of Non-Destructive Testing in Superalloy Components

The primary function of non-destructive testing (NDT) is to ensure the quality and safety of superalloy components before they are put into service. Superalloys are often used in extreme environments, such as gas turbines, jet engines, and nuclear reactors, where even minor defects can lead to catastrophic failure. NDT plays a critical role in detecting defects that may not be visible to the naked eye and can help prevent costly repairs, downtime, and safety hazards.

Some of the key functions of NDT in superalloy components include:

Detection of Internal Defects

NDT methods, such as ultrasonic testing and X-ray scanning, can reveal cracks, voids, and porosity within the material that would otherwise be invisible. These defects can compromise the mechanical properties of the alloy, leading to premature failure. For example, ultrasonic testing is precious in detecting internal flaws in superalloy castings or precision parts, ensuring the structural integrity of critical components like turbine blades.

Assessment of Material Homogeneity

Non-destructive testing can also assess the uniformity of the material. For example, in superalloy castings or 3D printed components, the distribution of alloying elements needs to be homogeneous to ensure optimal performance. NDT can detect areas of material segregation or inconsistent microstructures, helping to optimize the manufacturing process for parts like turbine discs or jet engine components.

Surface Integrity Evaluation

Surface defects such as cracks or pits can be detected using dye penetrant or eddy current testing. These surface-level issues are critical in parts subjected to high stresses or corrosive environments. For example, precision casting in aerospace applications demands high surface integrity to ensure part durability.

Verification of Heat Treatment Effects

NDT can be used to verify whether the heat treatment processes applied to superalloy components have achieved the desired material properties, such as hardness, toughness, and oxidation resistance. This is crucial for ensuring that parts like gas turbine components meet performance standards.

Using NDT, manufacturers can verify that the components meet stringent performance standards, ensuring safety, reliability, and longevity in their applications, particularly in critical sectors such as aerospace, power generation, and automotive industries.

Which Superalloy Parts Require Non-Destructive Testing?

Various superalloy components, particularly those used in aerospace, power generation, automotive, and defense industries, undergo rigorous non-destructive testing (NDT) to ensure their structural integrity and performance. Common parts that benefit from NDT include:

Superalloy Castings

Superalloy castings, such as turbine blades, combustion chambers, and nozzle rings, are often subjected to complex casting processes like vacuum investment casting. NDT methods like ultrasonic testing or X-ray scanning can identify internal defects such as porosity, shrinkage, and voids. These defects could weaken the part under stress, potentially leading to premature failure in high-performance applications like gas turbines or jet engines.

Forged Superalloy Parts

Forged superalloy parts, including turbine discs, shafts, and compressor blades, are essential for heavy-duty industrial applications. Forging can introduce internal stresses or defects, and NDT is used to detect micro-cracks or voids that could compromise the part’s integrity. This is particularly important for components that experience extreme stress, such as those found in superalloy isothermal forging and aerospace applications, where material failures can have catastrophic consequences.

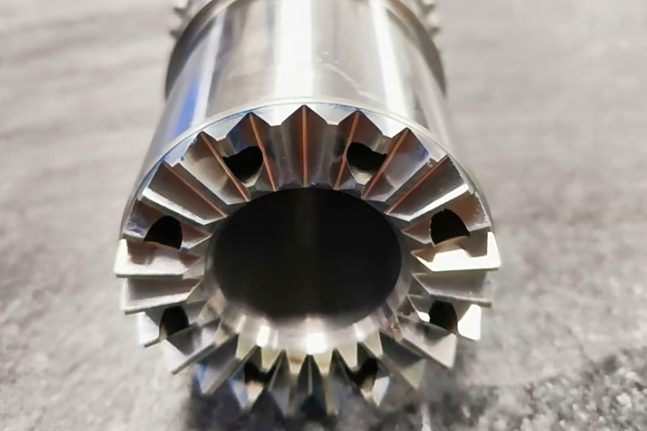

CNC Machined Superalloy Parts

Precision-machined superalloy parts, such as engine components, seals, and structural elements, must meet extremely tight tolerances. NDT ensures that these machined parts are free from defects that could affect their performance, such as surface cracks or dimensional inaccuracies. This is crucial for high-performance parts used in superalloy turbine discs and other demanding applications in industries like aerospace and energy generation.

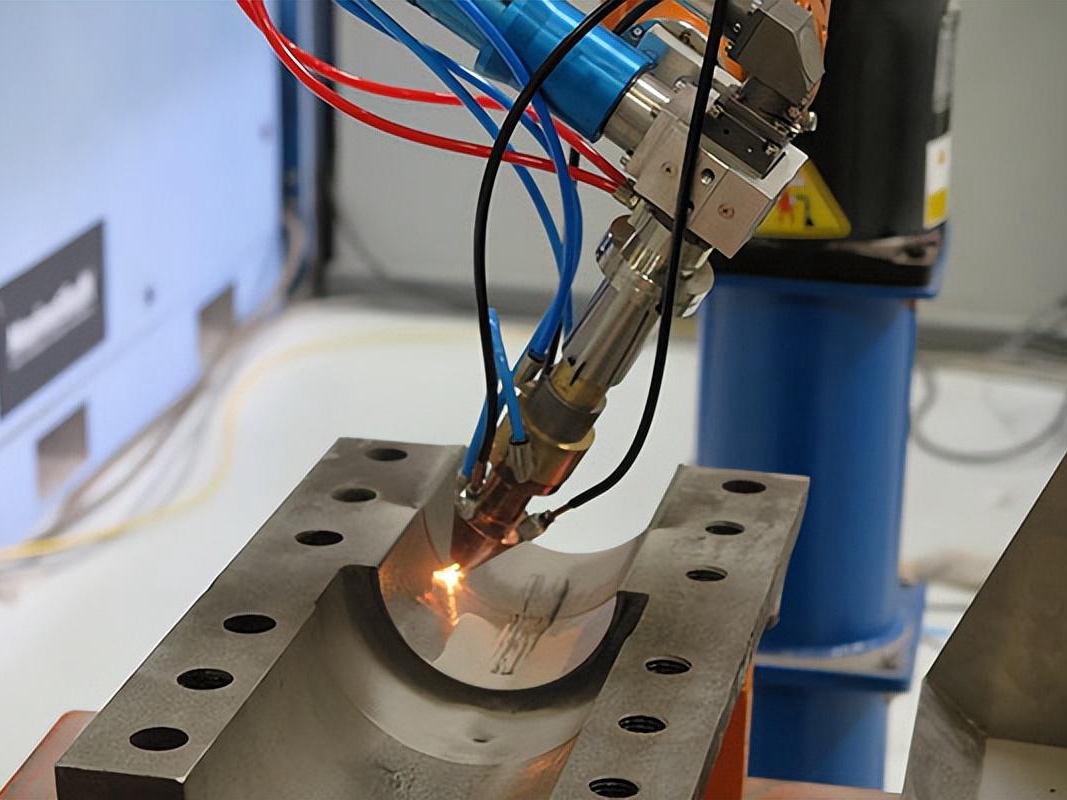

3D Printed Superalloy Parts

Additive manufacturing, or 3D printing, allows for creating intricate superalloy components with complex geometries. However, the process can lead to defects like porosity or incomplete bonding between layers. NDT methods such as X-ray or ultrasonic testing are critical to ensuring the quality of 3D printed superalloy parts and meet the required standards for aerospace, power generation, and other high-performance applications.

Powder Metallurgy Parts

Powder metallurgy components, such as turbine discs, are made from metal powders fused during manufacturing. These parts require a thorough inspection to ensure adequate bonding between particles and that no defects remain in manufacturing. NDT is essential to verify the integrity of these complex components, often used in high-temperature turbine discs for aerospace and power generation applications.

Each of these superalloy parts faces unique challenges during the manufacturing process. Non-destructive testing ensures these components are safe, reliable, and meet the stringent requirements for high-performance applications.

Comparison of NDT Methods with Other Testing Processes

While NDT is preferred for inspecting superalloy parts, comparing it with other testing processes, particularly destructive testing methods, is essential. In destructive testing, parts are subjected to conditions that intentionally cause failure, allowing engineers to analyze their behavior under stress. Although this provides valuable data on the material’s performance, it also destroys the component, making it unsuitable.

NDT, by contrast, enables manufacturers to preserve the parts for further use, reducing costs and increasing efficiency. It provides the same level of defect detection and material assessment without the need to sacrifice the part. In addition, NDT methods such as ultrasonic testing, eddy current testing, and X-ray scanning can detect flaws at various depths and locations within the material that destructive methods cannot assess.

For example, while visual inspection might identify surface cracks or damage, it cannot reveal subsurface defects like voids or inclusions that might be critical in high-temperature applications. In comparison, ultrasonic testing can reveal these issues by sending sound waves through the material, allowing for a thorough examination of the surface and interior without causing any harm to the component. X-ray inspection, though helpful in detecting significant internal flaws, cannot detect the material homogeneity or subtle variations that ultrasonic testing excels at uncovering.

Another advantage of NDT over destructive testing is its ability to inspect large quantities of parts quickly and cost-effectively. In industries such as aerospace, where thousands of components are produced, NDT can perform high-throughput inspections without compromising the part’s usability. With methods like water immersion ultrasonic testing and X-ray, manufacturers can inspect components' surface and internal integrity, which is crucial for ensuring the reliability and safety of parts used in high-performance applications like gas turbines and jet engines.

In contrast, destructive testing often requires significant time and resources to recreate failure conditions and analyze the results. This makes it less practical for large-scale production than NDT, which provides real-time, actionable data without sacrificing valuable components. Therefore, NDT methods are increasingly preferred for quality control and material analysis in critical industries where component reliability is paramount.

Industry and Application of Non-Destructive Testing in Superalloy Components

Non-destructive testing (NDT) is essential across several industries, where superalloy components play a vital role in ensuring critical systems' safety, performance, and longevity. Some of the key industries and applications include:

Aerospace and Aviation

NDT is crucial in aerospace and aviation to ensure the integrity of turbine blades, compressor blades, and other engine components. These parts must withstand extreme temperatures, pressure, and mechanical stress without failure. Regular NDT inspections are performed to detect any signs of fatigue or damage, ensuring the safety of aircraft and passengers. For example, components like superalloy turbine engine parts undergo NDT to identify any potential structural issues that could compromise performance during flight.

Power Generation

In power generation, gas turbines, steam turbines, and other high-performance components in power plants rely heavily on superalloys for their strength and resistance to heat. NDT is used to inspect turbine blades, heat exchangers, and reactor components to detect potential defects that could compromise the system’s efficiency or safety. For example, superalloy heat exchanger parts are regularly tested for material consistency to ensure they can withstand extreme thermal cycling conditions without degradation or failure.

Oil and Gas

In the oil and gas industry, superalloy parts are used in harsh environments like deep-sea drilling and pipeline systems. NDT methods check for surface cracks, corrosion, and other defects in critical components like drilling equipment, pressure vessels, and pumps. For example, high-temperature alloy pump components are subjected to NDT to verify their structural integrity and ensure they can handle extreme pressure and temperature conditions in deep-sea operations.

Automotive

Automotive applications, such as turbochargers and exhaust systems, require superalloys that withstand high temperatures and mechanical stress. NDT ensures that these parts are free from defects that could compromise their operation under these extreme conditions. For example, superalloy exhaust system parts undergo NDT to detect surface imperfections that could lead to early failure or performance issues in high-performance vehicles.

Marine and Military

Superalloys are used in naval propulsion systems, missile components, and other defense applications. NDT methods ensure that these parts can withstand extreme pressures and operating conditions without failure. Components such as superalloy naval ship modules are subjected to NDT to ensure their reliability and safety in harsh marine environments, including exposure to corrosive seawater and high mechanical loads.

Nuclear

Superalloy components used in nuclear reactors must meet stringent safety standards to prevent catastrophic failures. NDT ensures that reactor vessel components, fuel systems, and heat exchangers are free from internal defects that could lead to failure under high radiation and temperature conditions. For example, superalloy reactor vessel components are regularly inspected using NDT to verify their integrity and to ensure safe operation in the high-stress environment of a nuclear reactor.

Non-destructive testing is vital to quality assurance in industries that rely on superalloy components. By detecting defects early, NDT helps ensure critical systems' safety, performance, and reliability, from aerospace engines to nuclear reactors.

FAQs

What is the most common NDT method used for superalloy components?

How does ultrasonic testing help detect defects in superalloy parts?

What are the benefits of using NDT over destructive testing for superalloys?

Which industries benefit most from NDT in superalloy parts?

How can NDT improve the longevity of superalloy components in aerospace applications?