Quantitative and Qualitative Analysis of Superalloy Elements: How GDMS Enhances Performance

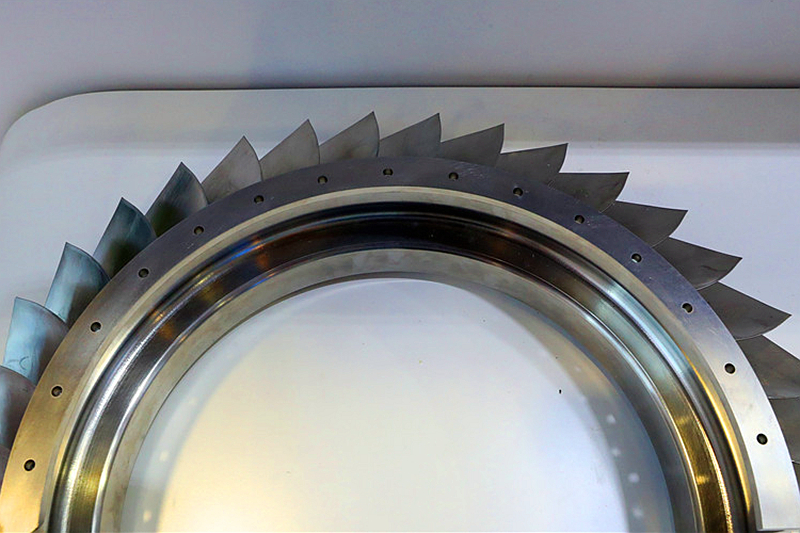

Superalloys are high-performance materials that withstand extreme environments, such as high temperatures, high pressures, and corrosive conditions. These alloys are critical in aerospace, power generation, oil and gas, and defense, where failure could lead to catastrophic consequences. To meet the demanding specifications of these applications, it is crucial to ensure that the superalloy components are manufactured with precise elemental compositions, free of impurities that could affect their performance.

Glow Discharge Mass Spectrometry (GDMS) is an advanced analytical technique used to achieve just that. It plays a vital role in both quantitative and qualitative analysis of superalloy elements, providing manufacturers with the data they need to optimize the alloy’s properties. GDMS is particularly useful for detecting trace elements in superalloy casting, where precise control over elemental composition is essential to maintaining the material’s integrity under extreme conditions.

In this blog, we will explore how GDMS enhances the performance of superalloy components by providing accurate elemental analysis, its application in both quantitative and qualitative testing, and its importance in ensuring the reliability of superalloy parts across various industries, such as power generation and defense.

What is GDMS and How Does it Work?

Glow Discharge Mass Spectrometry (GDMS) is a cutting-edge technique used for elemental analysis of solid materials, particularly metals and alloys. GDMS works by ionizing the surface of a solid sample using a glow discharge and then analyzing the ions produced in a mass spectrometer to identify and measure the elemental composition.

The process begins with a sample in a vacuum chamber exposed to a low-pressure gas (typically argon). A high-voltage electric field is applied, causing the gas to ionize and create a glow discharge on the sample surface. The ions generated from this discharge are then accelerated and passed through a mass spectrometer, which sorts and measures the ions based on their mass-to-charge ratio. This allows for precisely identifying the elements present in the material and quantifying their concentrations.

The versatility of GDMS lies in its ability to perform quantitative and qualitative analysis. Quantitative analysis involves measuring the exact concentration of elements in the alloy. In contrast, qualitative analysis is concerned with identifying the presence and types of elements, even if their concentrations are not precisely measured. This capability is critical in aerospace and power generation industries, where the precise elemental composition is crucial for the performance of superalloy components.

GDMS is particularly useful in analyzing superalloy castings, where detecting even trace impurities or variations in alloying elements can significantly impact the reliability and longevity of the final product. The ability to accurately assess these materials ensures that components will perform optimally in their demanding applications, from nuclear reactors to aerospace engines.

Quantitative and Qualitative Analysis in Superalloy Production with GDMS

Quantitative Analysis: Accurate Measurement of Elemental Concentrations

Quantitative analysis is at the core of GDMS’s utility in superalloy production. In the context of superalloys, achieving accurate elemental concentrations is critical for ensuring that the material performs optimally under extreme conditions. Superalloys are composed of base metals (such as nickel, cobalt, or iron) and alloying elements (such as chromium, molybdenum, titanium, and aluminum) that impart specific properties, including high-temperature strength, oxidation resistance, and thermal stability.

GDMS excels at providing highly accurate measurements of the concentration of each element in a superalloy, often down to parts-per-million (ppm) or even parts-per-billion (ppb) levels. This level of precision is essential when working with high-performance materials, as even slight variations in the concentration of key alloying elements can significantly impact the material’s properties. For example, in nickel-based superalloys, such as Inconel 718 or Inconel 625, the precise levels of chromium, aluminum, and niobium are essential for achieving the desired balance between strength, corrosion resistance, and resistance to thermal creep. GDMS can verify that these elements are within the specified ranges, ensuring that the superalloy will meet the requirements for demanding applications, such as turbine blades in jet engines or combustion chambers in aerospace.

Similarly, the concentration of trace elements, such as sulfur, phosphorus, and boron, must be carefully controlled. GDMS can accurately quantify these trace elements, which can weaken the material or reduce its resistance to corrosion and thermal fatigue if present in excessive amounts. These tests are critical in manufacturing processes such as superalloy precision forging, where material integrity and alloy composition directly influence the strength and durability of aerospace components.

Qualitative Analysis: Identifying Impurities and Trace Elements

While quantitative analysis focuses on measuring the exact concentration of elements, qualitative analysis plays an equally important role in superalloy production. This type of analysis is used to identify the presence and types of elements, particularly trace impurities that may not be quantifiable but can still substantially impact the alloy's performance.

GDMS is particularly effective at detecting low levels of impurities, such as carbon, sulfur, oxygen, hydrogen, and nitrogen, which can be detrimental to the properties of superalloys. For example, even small amounts of sulfur or carbon can lead to embrittlement or weaken the material's high-temperature fatigue resistance, which is unacceptable in critical applications like aerospace or power generation. GDMS can identify these impurities, ensuring that single crystal alloys and directional solidification castings, used for high-stress components like turbine blades, maintain their structural integrity.

In addition to detecting impurities, GDMS can identify microstructural anomalies, such as unwanted phases or secondary elements, that may not be evident from a simple inspection of the material’s surface. For example, when manufacturing superalloy turbine discs, GDMS helps identify anomalies that could lead to premature failure. By detecting these contaminants early in manufacturing, GDMS ensures that the superalloy components meet the strict quality standards required for high-performance applications in aerospace, defense, and energy sectors.

How GDMS Enhances Superalloy Performance

GDMS (Glow Discharge Mass Spectrometry) plays a crucial role in optimizing the performance of superalloy components by ensuring they meet strict purity standards. Through quantitative and qualitative analysis, GDMS helps manufacturers achieve the perfect balance of alloy composition, enhancing the desired properties of superalloys, including strength, heat, fatigue, and corrosion resistance. This is essential for high-performance applications in aerospace, power generation, and automotive industries.

For instance, turbine blades used in jet engines or gas turbines must withstand temperatures exceeding 1,000°C while maintaining their mechanical strength. Even slight variations in the alloy composition can lead to failures due to mechanisms like thermal creep or oxidation. GDMS ensures that critical elements, such as chromium, aluminum, and tantalum, are in the precise amounts required for optimal strength and protection. This precision in material composition is fundamental for superalloy castings, such as turbine blades and combustion chambers, which must perform reliably in extreme conditions.

GDMS also enhances material consistency across large production batches of superalloy components, reducing the risk of defects that could lead to performance failures. In industries like aerospace, where parts such as jet engine components and combustion chambers are subjected to extreme stresses, ensuring consistent material composition is critical for both safety and performance. GDMS’s ability to accurately measure elemental concentrations guarantees that every part, whether cast, forged, or 3D printed, meets the exact material specifications required for its intended application.

Additionally, GDMS supports robust quality control by verifying that materials remain consistent throughout the production cycle. By identifying any variations in elemental composition, GDMS ensures that only superalloy components with the correct material properties proceed to the next stage. This allows manufacturers to detect and address issues early in the production process, ensuring that the final product meets the highest performance and reliability standards.

Comparison to Other Analytical Methods

While GDMS is a powerful tool for elemental analysis, other analytical methods are also commonly used in superalloy production. These methods have their strengths and weaknesses, and choosing the right one depends on the specific requirements of the material being tested.

GDMS vs. Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES)

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES) is another commonly used technique, but it is typically more suited for analyzing liquids rather than solid materials. While ICP-OES is highly effective for elemental analysis, GDMS can analyze solid samples directly without the need for sample preparation or dissolution. This makes GDMS ideal for superalloy testing where maintaining the integrity of the material is essential.

GDMS vs. X-ray Fluorescence (XRF)

X-ray Fluorescence (XRF) is a non-destructive technique used for elemental analysis, but it is less sensitive when compared to GDMS. XRF can effectively measure higher concentrations of elements but struggles with detecting trace impurities, which is where GDMS excels. In high-performance applications, such as in aerospace or turbine blades, even minute variations in material composition can impact performance, making GDMS the preferred choice.

GDMS vs. Atomic Absorption Spectroscopy (AAS)

Atomic Absorption Spectroscopy (AAS) is suitable for measuring specific elements in a sample but is less versatile and often requires sample preparation. Unlike GDMS, AAS is unsuited for the precise and broad elemental analysis required in superalloy production. GDMS can analyze multiple elements simultaneously with high sensitivity, making it a more efficient solution for materials that contain a complex mix of metals.

GDMS vs. Optical Emission Spectroscopy (OES)

Optical Emission Spectroscopy (OES), similar to GDMS, is used for elemental analysis but typically requires the sample to be prepared as a solution. GDMS, by contrast, can work directly with solid samples, making it a more efficient tool in many applications, particularly in superalloy manufacturing. OES often struggles with detecting trace elements and may require additional sample handling. In contrast, GDMS provides more detailed, direct analysis, which is crucial for high-performance components such as turbine blades or aerospace engines.

Industries and Applications Relying on GDMS for Superalloy Quality

GDMS (Glow Discharge Mass Spectrometry) is essential in industries that depend on superalloys for critical applications where performance, reliability, and safety are paramount. GDMS ensures that superalloy components meet the highest material standards, enabling them to perform effectively under extreme operating conditions. Below are some key industries where GDMS is extensively used.

Aerospace and Aviation

In the aerospace and aviation, superalloy components such as turbine blades, combustion chambers, and heat exchangers must withstand extreme thermal and mechanical stresses. GDMS ensures these parts have the right alloy composition, ensuring reliability at high altitudes and in challenging flight environments. For instance, superalloy jet engine components are thoroughly analyzed to verify material purity and avoid defects that could compromise performance under high temperatures.

Power Generation

In the power generation, turbine discs, blades, and other high-temperature components are exposed to high stresses and thermal extremes. GDMS testing plays a crucial role in ensuring that these superalloy parts meet strict material specifications required for optimal performance and longevity. Components like superalloy heat exchanger parts are tested to maintain their strength, thermal stability, and resistance to corrosion over time, improving the reliability and efficiency of power plants.

Oil and Gas

The oil and gas industry relies heavily on superalloy components like pump casings, valves, and heat exchangers, which must endure extreme pressure, temperature, and corrosive environments. GDMS ensures that these critical components are contaminant-free and meet material standards to prevent premature failure. For example, high-temperature alloy pump components undergo GDMS analysis to verify their resistance to wear and corrosion, ensuring operational safety and longevity in challenging field environments.

Military and Defense

In the military and defense sectors, superalloys are used in applications such as missile components, armor systems, and high-performance firearms, where performance and safety are critical. GDMS ensures that these parts are impure-free and possess the necessary strength, heat, and corrosion resistance. For instance, superalloy armor system parts are tested to guarantee their ability to withstand extreme combat conditions, offering the protection and durability needed in defense applications.

Nuclear

In the nuclear industry, superalloy components like reactor vessel parts, control rods, and other critical components must meet stringent purity and composition requirements to ensure safe and efficient operation. GDMS is crucial in verifying that these parts are made from high-quality alloys that can withstand extreme radiation and temperature conditions. For example, nickel-based alloy control rod modules are analyzed to ensure they maintain structural integrity and resist corrosion in the highly demanding environment of a nuclear reactor.

GDMS is indispensable for ensuring the quality and integrity of superalloy components across these industries. By detecting impurities at extremely low levels, GDMS helps manufacturers maintain the reliability and performance of parts used in aerospace, power generation, oil and gas, military, and nuclear applications.

FAQs

How does GDMS compare to other elemental analysis techniques like ICP-OES or XRF?

What are the key advantages of using GDMS for superalloy testing in aerospace applications?

How does GDMS detect impurities in superalloys, and why is this important?

What types of superalloy components benefit the most from GDMS analysis?

How does GDMS ensure the quality and consistency of materials in high-performance industries like power generation and defense?