Ensuring Optimal Phase Distribution in Superalloy Single Crystal Castings with EBSD

In manufacturing high-performance superalloys, particularly in aerospace, power generation, and defense, the material's microstructure is paramount. The phase distribution within superalloy single crystal castings significantly influences the material's mechanical properties, including its strength, thermal stability, and resistance to fatigue and creep. Ensuring optimal phase distribution in these materials is essential to achieving the desired performance in extreme operating conditions, such as those in superalloy jet engine components and high-temperature alloy pump components.

Electron Backscatter Diffraction (EBSD) is a powerful technique for analyzing and optimizing the phase distribution in superalloy single-crystal castings. By providing detailed insights into the material's crystallographic orientation and phase boundaries, EBSD enables manufacturers to detect and correct inconsistencies that could impact the alloy’s performance under high-stress conditions. This is particularly critical in industries where superalloy components, such as superalloy reactor vessel components, are exposed to extreme heat and pressure over prolonged periods.

With EBSD, the phase distribution can be precisely controlled to ensure that the material maintains its structural integrity and performance in demanding applications. This level of control is essential for ensuring the longevity and reliability of superalloy components used in industries like oil and gas and nuclear, where any failure could have catastrophic consequences.

What is Phase Distribution in Superalloy Single Crystal Castings?

Phase distribution in superalloy single crystal castings refers to how the different phases within the alloy are arranged and distributed throughout the material. Superalloys are designed with a complex microstructure that typically includes a primary solid solution phase (γ phase), a strengthening phase known as γ' (gamma prime), and other phases such as carbides or intermetallics. These phases are critical in the material's high-temperature performance, especially in superalloy turbine blade single-crystal casting applications.

The γ' phase is especially significant in superalloys because it contributes to the material’s strength and creep resistance at elevated temperatures. For example, in turbine blades used in jet engines, the γ' phase helps the alloy maintain its structural integrity under extremely high pressure and temperature conditions. Uneven or improper phase distribution can lead to localized weaknesses, which can cause premature failure of components. Thus, achieving a uniform and optimal phase distribution is crucial for ensuring the performance and longevity of superalloy components.

What is EBSD and How Does It Help Analyze Phase Distribution?

Electron Backscatter Diffraction (EBSD) is a powerful technique used to analyze the microstructure of materials by measuring the diffraction patterns generated when an electron beam interacts with the surface of a sample. This technique is typically employed in scanning electron microscopes (SEM) to map materials' crystallographic orientation and phase distribution, particularly in superalloy single-crystal casting, where precision is crucial.

EBSD works by directing an electron beam onto a polished sample's surface. The electrons scatter and produce diffraction patterns specific to the material's crystalline structure. These patterns can be analyzed to determine the crystallographic orientation of individual grains and phases. This allows manufacturers to assess the distribution of phases such as γ' and γ phases, critical to the material's performance in high-temperature applications like turbine blades and jet engine components.

This technique is particularly effective in superalloy casting, where the phase distribution can significantly affect material properties such as strength, fatigue resistance, and creep resistance. By analyzing the crystallographic orientation and phase distribution, EBSD allows manufacturers to refine casting processes and ensure that the alloys meet the stringent requirements of aerospace, energy, and defense industries.

The Function of EBSD in Ensuring Optimal Phase Distribution

EBSD plays a pivotal role in optimizing the phase distribution in superalloy casting. This technique helps identify issues such as phase segregation, irregular distribution of the γ' phase, or the presence of undesirable phases, which can adversely affect the material's mechanical performance. For example, improper phase boundaries, such as those between the γ' and γ phases, can lead to weak points in the material, making it more susceptible to failure under stress.

One of the key advantages of using EBSD is its ability to map phase boundaries with high precision. In superalloy parts, these boundaries are critical for ensuring material strength and durability. By ensuring that the boundaries between phases are correctly aligned, EBSD helps enhance the mechanical properties of the alloy, making it suitable for demanding applications like gas turbines and nuclear reactor components.

Moreover, EBSD is invaluable for monitoring the effects of heat treatments on phase distribution. During casting or forging processes, superalloys undergo thermal treatments to refine their microstructure and optimize performance. By assessing the phase distribution before and after heat treatments, EBSD ensures that the desired microstructure is achieved, which is essential for applications where material integrity is paramount.

Furthermore, EBSD can detect defects in superalloy materials that are not visible with conventional optical microscopy, such as secondary phases or precipitates. Identifying these defects early in manufacturing helps manufacturers avoid costly rework and guarantees that only the highest-quality materials are used in critical components, such as turbine discs or aerospace-grade engine components. This proactive approach to quality control is crucial for industries where safety and performance standards are non-negotiable.

Which Superalloy Parts Benefit from EBSD in Phase Distribution Analysis?

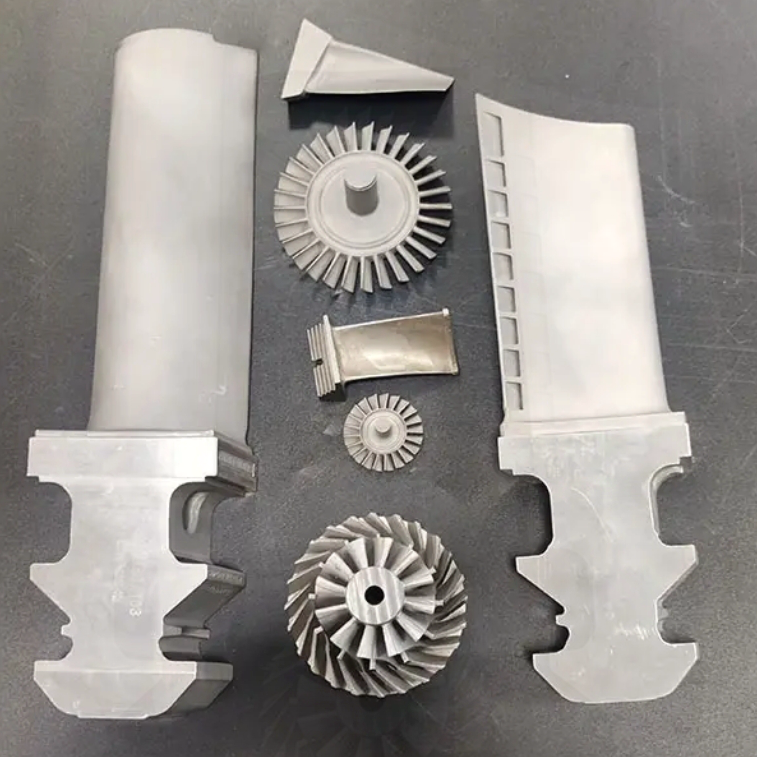

EBSD (Electron Backscatter Diffraction) ensures optimal phase distribution in various superalloy components, essential for their performance under extreme conditions. Superalloy single crystal castings, forged parts, CNC machined components, and 3D printed parts all benefit from this advanced technique to ensure that the phase distribution is precisely controlled, thereby enhancing material properties such as high-temperature strength, creep resistance, and fatigue resistance.

Superalloy Castings

In superalloy castings, phase distribution is critical for turbine blades, nozzle guide vanes, and combustion chambers. Gas turbines and jet engines expose These components to extremely high temperatures and pressures. EBSD is used to assess the distribution of the γ' phase, which plays a key role in enhancing the material’s high-temperature strength and creep resistance. Ensuring a uniform phase distribution is vital for the longevity and reliability of these parts in demanding applications such as aerospace and power generation.

Forged Superalloy Parts

Forged superalloy parts, including turbine discs, impellers, and other critical engine components, undergo high mechanical stresses during operation. The forging process can alter the microstructure and phase distribution of the alloy. EBSD helps verify that the phase structure remains balanced after forging, ensuring that the components exhibit optimal mechanical properties, such as strength, fatigue resistance, and durability. This analysis is essential for parts used in industries where performance under extreme conditions is non-negotiable, such as aerospace and power generation.

CNC Machined Superalloy Parts

After superalloy castings or forged parts are machined into their final form, it’s essential to ensure that the machining process does not disrupt the phase distribution. EBSD checks that machining does not cause phase segregation or degradation, particularly in parts with intricate geometries like turbine blades. By confirming that the phase distribution remains optimal after machining, EBSD ensures that the parts retain their required mechanical properties and high performance, particularly in demanding applications where precision is critical.

3D Printed Superalloy Parts

In the rapidly growing field of 3D printing, phase distribution analysis is critical due to the rapid cooling process involved in additive manufacturing. This cooling can cause variations in phase distribution, which may affect the material's strength and performance. EBSD analyzes the phase structure in 3D printed superalloy parts to ensure uniformity and that the material meets the performance standards required for critical components like turbine blades and other aerospace parts. This is crucial for ensuring that 3D printed parts perform reliably in high-stress, high-temperature environments.

Comparison with Other Methods for Phase Distribution Analysis

While EBSD is a powerful tool for analyzing phase distribution in superalloy single crystal castings, it is often used with other techniques to analyze the material’s microstructure comprehensively. Other methods of analyzing phase distribution include X-ray diffraction (XRD), optical microscopy, and transmission electron microscopy (TEM). Each of these methods has its advantages and limitations.

X-ray Diffraction (XRD):

XRD is another widely used technique for identifying phases in a material. It provides information about the overall phase composition of a material but does not offer the high spatial resolution that EBSD provides. XRD is useful for bulk phase identification but cannot map phase distribution at a fine scale. EBSD, on the other hand, provides detailed spatial mapping and orientation information, which is crucial for understanding the distribution of phases within the material.

Optical Microscopy:

Optical microscopy is often used for routine inspection of materials. However, its resolution is limited compared to EBSD, and it is unsuitable for analyzing individual grains' crystallographic orientation or phases. While optical microscopy can detect macroscopic defects and grain boundaries, it cannot provide the level of detail required for phase distribution analysis at the scale needed for superalloy optimization.

Transmission Electron Microscopy (TEM):

TEM is a highly advanced technique that provides atomic-level resolution of the material’s structure. While TEM can offer even finer detail than EBSD, it is more complex and time-consuming. It is typically not practical for routine phase distribution analysis of large samples. EBSD strikes a balance by offering high resolution with more efficient analysis.

Overall, EBSD is an excellent tool for phase distribution analysis in superalloy single crystal castings, and when used alongside other methods, it provides a comprehensive understanding of the material’s microstructure. Combining EBSD with techniques like X-ray diffraction and optical microscopy can enhance the reliability and precision of superalloy component production, especially in high-performance applications such as aerospace and power generation.

Industry and Application of Superalloy Parts with Optimal Phase Distribution

Optimal phase distribution is crucial for the performance of superalloy components in several key industries, particularly those that operate in high-temperature and high-stress environments.

Aerospace and Aviation

In the aerospace and aviation industry, superalloy parts such as turbine blades, nozzle guide vanes, and combustion chambers are subjected to extreme temperatures and pressures. EBSD helps ensure that these critical components have a uniform distribution of the γ' phase, which improves their high-temperature strength and resistance to creep. Components like superalloy turbine blades benefit from optimized phase distribution, enabling them to endure the extreme thermal and mechanical stresses found in jet engines, enhancing both safety and efficiency.

Power Generation

Superalloy parts used in power generation, such as turbine discs and heat exchangers, must withstand prolonged exposure to high temperatures. The optimal phase distribution in these parts, ensured by EBSD, helps maintain their mechanical integrity and efficiency over time. This is particularly important for superalloy heat exchanger parts, where efficient thermal management and resistance to high-pressure environments are crucial for long-term operational stability.

Oil and Gas

Superalloy components used in oil and gas applications, such as drill bits and heat exchangers, require optimal phase distribution to ensure corrosion resistance and durability under harsh conditions. EBSD helps optimize phase distribution for these components, ensuring reliable performance in the field. For example, superalloy corrosion-resistant piping is engineered with precise phase distribution to withstand extreme pressure and corrosive environments encountered in deep-sea drilling and high-pressure gas extraction operations.

Military and Defense

The military and defense sectors rely on superalloy parts for missile components, armor systems, and propulsion systems. The ability to control phase distribution using EBSD ensures that these parts maintain their strength and resilience under extreme conditions, including high-impact forces and high temperatures. For example, components like superalloy armor system parts benefit from optimized phase distribution to provide superior protection against thermal and mechanical stresses in combat environments.

Nuclear

In nuclear power plants, components such as reactor vessel parts and control rods must maintain structural integrity in the face of high radiation and temperature. EBSD ensures that the phase distribution in these components is optimized for long-term performance and safety. For instance, superalloy reactor vessel components rely on optimized phase distribution to maintain their strength and resistance to radiation-induced damage, ensuring the safe operation of nuclear reactors over extended periods.

By ensuring optimal phase distribution through EBSD, industries can enhance superalloy components' performance, durability, and safety, ensuring they meet the rigorous demands of aerospace, power generation, oil and gas, military defense, and nuclear sectors. This optimization is key to ensuring critical components' long-term reliability and efficiency in extreme operating environments.

FAQs:

What is the role of phase distribution in the performance of superalloy single crystal castings?

How does EBSD help in ensuring optimal phase distribution in superalloy parts?

What are the advantages of using EBSD over other methods like X-ray diffraction or optical microscopy for phase analysis?

Which superalloy parts most benefit from EBSD phase distribution analysis?

How does EBSD enhance the mechanical properties of superalloy components in high-temperature applications?