Non-Destructive Elemental Analysis in Superalloy Castings: Preserving Sample Integrity with GDMS

In industries where performance, safety, and precision are paramount, superalloys are essential materials. These alloys are designed to withstand extreme conditions, such as high temperatures, pressure, and corrosive environments. Superalloy components are widely used in aerospace, energy, and defense industries, where failure is not an option. To ensure the reliability and performance of these materials, it is essential to perform thorough quality control tests. One of the most advanced methods for this purpose is Glow Discharge Mass Spectrometry (GDMS). This non-destructive elemental analysis technique preserves the integrity of superalloy castings and other components.

GDMS provides a precise, high-sensitivity analysis of the elemental composition of superalloy materials, ensuring that they meet stringent specifications. It is an indispensable tool in industries where even the slightest impurity or compositional variation can lead to failure. This is especially critical in applications such as high-temperature alloy engine components and superalloy turbine blades, where performance under extreme conditions is non-negotiable.

GDMS enables manufacturers to detect both bulk and trace elements in superalloys with high accuracy, helping to identify any impurities or variations in alloy composition that could affect the material's strength, durability, or resistance to corrosion. This non-destructive approach ensures that parts maintain their structural integrity throughout the testing process, unlike traditional methods that may require material removal or alteration.

This blog will explore the role of GDMS in non-destructive elemental analysis, the benefits of using this method, the superalloy parts that require this testing, and how GDMS compares with other analytical techniques, such as X-ray testing and metallographic microscopy.

What is GDMS and How Does it Work?

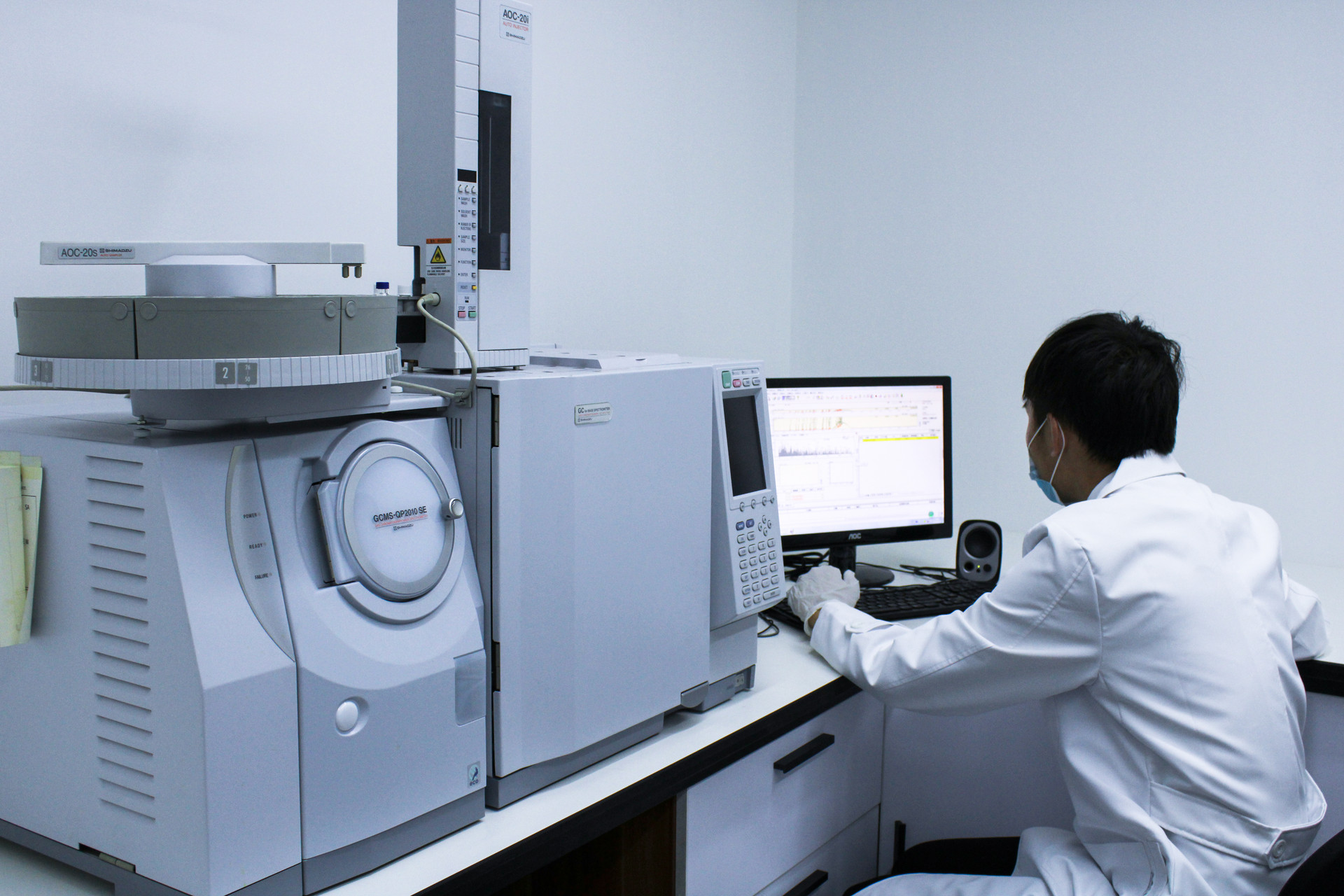

Glow Discharge Mass Spectrometry (GDMS) is an advanced analytical technique used to analyze the elemental composition of solid materials, especially metals and alloys like superalloys. GDMS creates a glow discharge between a solid sample and a low-pressure gas, typically argon. A high-voltage electric field ionizes the sample surface, and the resulting ions are then analyzed using a mass spectrometer. This allows for identifying and quantifying elements present in the sample, even at trace levels.

The non-destructive nature of GDMS lies in its ability to analyze the elemental composition of a sample without altering or damaging the sample's structure. The process is performed in a vacuum chamber, and the mass spectrometer directly analyzes the ions generated by the glow discharge. Because GDMS does not require sample preparation, such as dissolution or cutting, it preserves the integrity of the material and allows for further analysis or processing.

One of the key features of GDMS is its ability to analyze a wide range of elements in superalloy castings, including base metals like nickel, cobalt, and iron, as well as critical alloying elements like chromium, molybdenum, titanium, and aluminum. GDMS also allows for the detection of trace impurities such as sulfur, carbon, phosphorus, and boron, which can significantly affect the performance of superalloys in high-temperature and high-stress environments. This capability is significant for ensuring the durability and reliability of components in industries like aerospace and energy, where failure due to impurities could lead to catastrophic consequences.

GDMS is essential for quality control and optimization in superalloy production, ensuring that materials meet stringent specifications before they are used in critical applications like turbine blades, reactor vessel components, and engine parts. By providing detailed, accurate elemental analysis, GDMS helps manufacturers guarantee the performance and reliability of superalloy components across various industries.

Benefits of GDMS for Non-Destructive Elemental Analysis in Superalloy Production

Preservation of Sample Integrity

One of the key advantages of GDMS in superalloy testing is its non-destructive nature. GDMS allows manufacturers to perform elemental analysis without altering the sample, essential when testing high-value superalloy parts. This feature is particularly beneficial in industries like aerospace, where parts such as turbine blades or combustion chambers are expensive and critical to performance. By preserving the sample's integrity, GDMS enables further processing, testing, or reuse of the material, optimizing resource utilization without compromising the part's structure or properties.

High Sensitivity and Precision

GDMS is known for its exceptional sensitivity and precision, making it a powerful tool for superalloy testing. The technique can detect elements at concentrations as low as parts-per-million (ppm) or parts-per-billion (ppb) levels. This level of sensitivity is crucial for maintaining the strict compositional control required in high-performance applications, such as turbine discs used in power generation or aerospace. Even trace amounts of impurities can significantly affect the material’s mechanical properties, so GDMS ensures that the superalloy components meet the specifications for optimal performance, reducing the risk of material failure.

Quantitative and Qualitative Analysis

GDMS offers quantitative and qualitative analysis capabilities, providing comprehensive data for superalloy testing. In quantitative analysis, GDMS accurately measures the concentration of each element in the sample, ensuring that the alloy meets the exact compositional requirements for strength, heat resistance, and corrosion resistance. For example, ensuring precise levels of elements like nickel, chromium, and molybdenum is essential in Inconel alloys used in aerospace components. In qualitative analysis, GDMS identifies the presence of specific elements, even in trace amounts, without needing precise concentration data. This dual capability makes GDMS a versatile tool for ensuring the quality of complex superalloy components, from single crystal alloys to directional solidification castings.

Speed and Efficiency

In addition to its precision, GDMS is a rapid and efficient testing method. It can analyze multiple elements simultaneously, significantly reducing testing time compared to traditional methods. This is particularly advantageous in large-scale production environments, where fast and reliable analysis is critical to maintaining tight production schedules and quality control standards. For instance, in industries like aerospace and energy, where the demand for high-performance components is high, GDMS allows manufacturers to quickly verify the material composition of superalloy parts and continue production without delay.

Minimal Material Waste

GDMS does not require sample preparation or dissolution, which minimizes material waste—a crucial benefit when working with expensive, high-performance materials. Testing without sacrificing material is a significant cost-saving advantage in applications where every gram of material counts, such as in producing superalloy turbine discs or stainless steel castings. This reduces waste while ensuring that each part meets the highest quality standards.

Reproducibility and Reliability

GDMS is highly reproducible, ensuring that the results of each test are consistent and reliable. This is particularly important in quality control processes, where manufacturers must ensure that each batch of superalloy components meets the required strength, durability, and performance standards. With GDMS, consistently producing accurate results is crucial for industries like aerospace, where component integrity is vital to safety and performance. By providing reliable data, GDMS supports manufacturers in maintaining stringent quality assurance standards and meeting industry certifications.

Superalloy Parts Requiring GDMS Testing

GDMS (Glow Discharge Mass Spectrometry) is a powerful technique used for elemental analysis of superalloy components, such as castings, CNC machined parts, and 3D printed parts. Each component demands a precise balance of elements to ensure optimal performance in extreme conditions, making GDMS an essential tool for quality control and material verification.

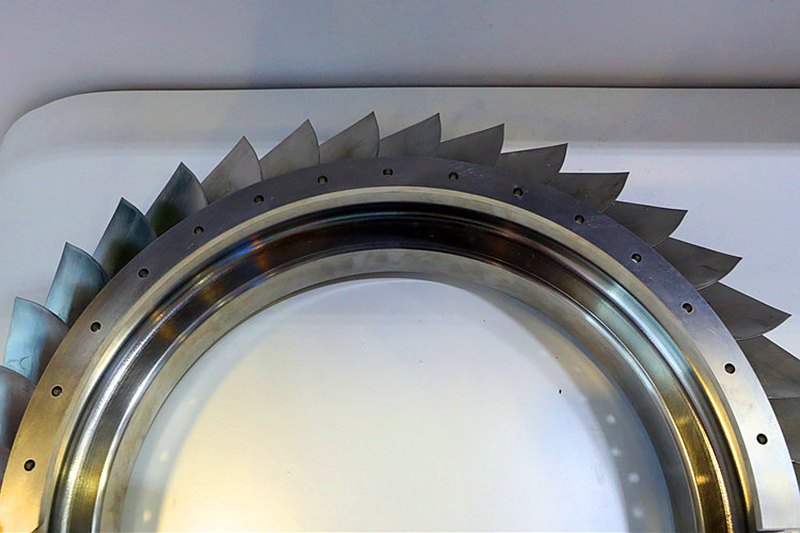

Superalloy Castings

Superalloy castings, including turbine blades, combustion chambers, and nozzle rings, are subjected to severe thermal and mechanical stresses in environments like jet engines and gas turbines. GDMS ensures that the casting process results in materials with the correct elemental composition, which is critical for performance under these extreme conditions. By verifying the alloy's composition, GDMS helps prevent premature failure due to thermal creep or oxidation, ensuring long-term reliability and efficiency.

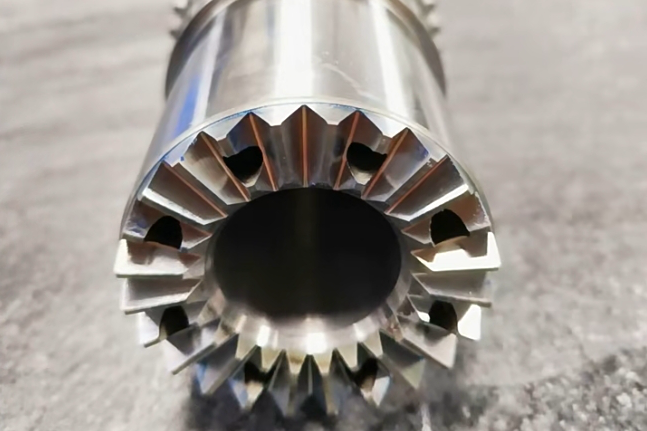

CNC Machined Superalloy Parts

Many superalloy components, such as turbine discs, impellers, and structural parts, are created from pre-cast superalloy ingots or billets and then subjected to CNC machining for precise shaping. GDMS testing is used to verify the material composition of these machined parts, ensuring they meet strict material specifications. This is especially important for aerospace or power generation components, where parts must maintain integrity under high stresses. GDMS confirms that the machining process has not altered the material properties and that the component will perform as required in demanding applications.

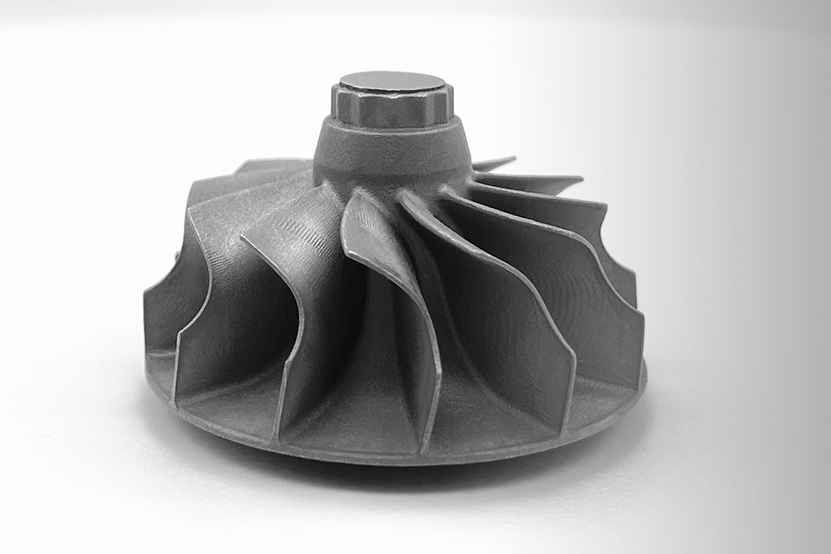

3D Printed Superalloy Parts

Additive manufacturing, or 3D printing, is increasingly used to produce complex superalloy components, particularly in the aerospace and defense sectors. GDMS plays a crucial role in ensuring the material properties of 3D printed superalloy parts are consistent with the required specifications. Given the complexities of the additive manufacturing process, GDMS provides an effective means of verifying the composition of the printed material. It ensures that the alloy used in 3D printing meets the necessary strength, corrosion resistance, and thermal stability requirements, even in parts with intricate geometries.

GDMS for Quality Control

GDMS is particularly valuable because it allows for direct material composition analysis without altering the sample. This makes it an ideal tool for industries like aerospace, where the reliability and performance of each superalloy part are critical. By providing accurate and non-destructive analysis, GDMS helps manufacturers ensure that each component—cast, machined, or 3D printed—meets the exact material specifications, ensuring safety and performance under extreme conditions.

GDMS Compared with Other Elemental Analysis Methods

While GDMS is a powerful and versatile technique for non-destructive elemental analysis, other analytical methods are also commonly used in superalloy testing. These methods each have their strengths and limitations, and the choice of method depends on the specific requirements of the material and the application.

GDMS vs. X-ray Fluorescence (XRF)

X-ray Fluorescence (XRF) is a non-destructive method that can quickly identify the elemental composition of a material. However, XRF is less sensitive than GDMS for detecting trace elements. GDMS offers much higher precision and sensitivity, especially for low-concentration elements, making it a better choice for superalloy testing where impurities or minute variations in composition can significantly impact the final product's performance.

GDMS vs. Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) is a susceptible technique used for elemental analysis, but it requires the sample to be dissolved in a liquid form. ICP-MS is unsuitable for solid materials like superalloys without prior preparation. In contrast, GDMS can analyze solid samples directly without altering their structure, making it a more efficient and less intrusive method for testing high-performance materials.

GDMS vs. Optical Emission Spectroscopy (OES)

Optical Emission Spectroscopy (OES) is commonly used to analyze metals and alloys. It is effective for detecting a wide range of elements, but it requires the sample to be prepared as a solution, which can be time-consuming and may not be ideal for solid superalloy parts. GDMS, on the other hand, can directly analyze solid superalloy samples, saving time and preserving material integrity while offering superior sensitivity, particularly for trace impurities in complex alloy compositions.

GDMS vs. Atomic Absorption Spectroscopy (AAS)

Atomic Absorption Spectroscopy (AAS) is used to analyze specific elements in a sample, but it is typically unsuitable for analyzing complex alloys like superalloys, especially in solid form. AAS often requires the sample to be dissolved and analyzed in solution. GDMS, on the other hand, can analyze multiple elements simultaneously in solid form without the need for sample preparation, making it more effective for analyzing high-temperature alloys used in aerospace, energy, and other critical industries.

Conclusion

Each method has its place in elemental analysis, but GDMS stands out for its ability to perform non-destructive analysis on solid superalloy samples with high sensitivity and accuracy, making it the preferred choice for applications where purity and material performance are critical.

Industries and Applications Relying on GDMS for Non-Destructive Testing

GDMS (Glow Discharge Mass Spectrometry) is an indispensable technique for performing non-destructive elemental analysis of superalloy components across various industries. By ensuring the integrity of materials without altering their structure, GDMS helps verify that components meet the rigorous standards required for high-performance applications. Below are some key industries where GDMS plays a critical role in quality control and material verification.

Aerospace and Aviation

In the aerospace and aviation industry, superalloy components such as turbine blades, engine parts, and combustion chambers must endure extreme mechanical stresses and high temperatures. GDMS is essential for confirming the precise elemental composition of these components, ensuring they meet safety and performance standards required for operation at high altitudes and in extreme flight environments. For example, superalloy jet engine components are rigorously tested with GDMS to detect even the smallest impurities that could compromise their reliability.

Power Generation

The power generation sector uses superalloy components like turbine discs, blades, and heat exchangers in high-temperature, high-pressure environments. GDMS testing ensures these critical parts maintain their strength and thermal stability, minimizing the risk of failure and downtime in power plants. GDMS helps verify that turbine components, such as those in superalloy heat exchangers, meet the stringent material standards for optimal performance, safety, and longevity.

Oil and Gas

Superalloy materials are essential in the oil and gas industry, where components like valves, pumps, and heat exchangers must withstand high pressures, corrosive environments, and extreme temperatures. GDMS ensures these components are free from impurities and possess the correct material composition to perform reliably in challenging field conditions. For example, GDMS testing of high-temperature alloy pump components helps verify their resistance to wear, corrosion, and high-pressure degradation, contributing to oil and gas operations' overall efficiency and safety.

Defense and Military

The military and defense industries use superalloy materials in missile components, armor systems, and jet engines, where failure can have critical consequences. GDMS is essential for ensuring that these components meet the stringent requirements for strength, heat resistance, and corrosion resistance. For instance, superalloy armor system parts undergo non-destructive testing to confirm they can withstand the extreme conditions encountered in combat, ensuring durability and safety.

Nuclear

In the nuclear industry, superalloy components such as reactor vessels, control rods, and heat exchangers are subject to extreme radiation, high pressures, and high temperatures. GDMS is critical in verifying that these components meet the highest purity standards. By detecting impurities and ensuring that the alloys meet the necessary composition requirements, GDMS helps prevent material failures that could compromise the safety and performance of nuclear reactors. For example, nickel-based alloy control rod modules are rigorously tested with GDMS to ensure they can withstand harsh conditions inside a nuclear reactor.

FAQs

How does GDMS preserve the integrity of superalloy samples during testing?

What are the primary benefits of using GDMS for elemental analysis in superalloy testing?

How does GDMS compare to other testing methods like XRF and ICP-MS in terms of sensitivity and precision?

Which industries rely most on GDMS for quality control of superalloy components?

What types of superalloy parts are best suited for GDMS testing?