How Water Immersion Ultrasonic Testing Helps Superalloy Parts Material Homogeneity

Water immersion ultrasonic testing (WIUT) is a highly effective non-destructive testing (NDT) method used to assess the material homogeneity of superalloy parts. This process is crucial in industries where material consistency directly impacts the final product's performance, reliability, and safety. Superalloys, known for their ability to withstand extreme temperatures, corrosion, and mechanical stresses, are used in critical applications such as aerospace, power generation, and military defense.

However, to meet these demanding requirements, the material’s internal structure must be uniform and free from defects like cracks, voids, or inconsistencies in grain structure. This is where water immersion ultrasonic testing plays a pivotal role in ensuring the integrity and reliability of these high-performance superalloy components. The technique utilizes ultrasonic waves transmitted through the material, allowing for the detection of internal defects that could compromise the strength and performance of parts used in critical systems like jet engines and turbine blades.

WIUT is particularly effective for evaluating superalloy parts in industries that demand high reliability, ensuring that internal flaws such as cracks, voids, or material inconsistencies are identified early in the production process. This non-destructive testing method supports the production of superalloy components that can endure the high stresses and temperatures encountered in aerospace and power generation applications, thereby increasing the lifespan and safety of critical equipment.

What is Water Immersion Ultrasonic Testing?

Water immersion ultrasonic testing involves using high-frequency sound waves to inspect the internal structure of superalloy parts. The principle is simple: ultrasonic waves are transmitted through the material, and the time it takes for the sound waves to reflect to the transducer is measured. These waves are introduced into the material with the help of water, which acts as a coupling medium. Water immersion ensures optimal transmission of sound waves, minimizing signal loss and providing high-resolution data, even in highly complex geometries.

In this process, a transducer emits sound waves that travel through the superalloy material. If the material is homogeneous, the waves travel consistently, returning to the transducer without significant variations. However, any irregularities in the material’s internal structure—such as voids, cracks, or differences in density—will cause these waves to scatter, reflect, or refract in abnormal ways. These changes in sound wave behavior are recorded and analyzed to detect any inconsistencies in the material's homogeneity.

This testing method is ideal for inspecting high-stress components such as superalloy turbine blades and other critical parts used in aerospace and power generation, where precision and defect detection are paramount.

The Function of Water Immersion Ultrasonic Testing in Material Homogeneity

The primary function of water immersion ultrasonic testing is to assess the uniformity of a superalloy's internal structure. Material homogeneity is essential for ensuring that the part will perform as expected under high-temperature, high-pressure, and corrosive conditions. For superalloy components, inconsistencies in the material’s internal structure can lead to premature failure, compromised strength, or other mechanical issues.

Water immersion enhances the efficiency of the process by creating a stable and consistent medium through which the ultrasonic waves can pass. This results in more accurate readings and better detection of material defects. The reflected sound waves are analyzed to identify variations in material properties, such as differing density levels, which could indicate porosity, delamination, or other structural anomalies.

By using this method, manufacturers can ensure that only the highest-quality, defect-free superalloy parts are used in critical applications, such as turbine discs or jet engine components. This precision and material integrity level is crucial for aerospace and power generation industries.

Superalloy Parts Requiring Water Immersion Ultrasonic Testing

Water immersion ultrasonic testing is a critical inspection method for superalloy components, particularly those used in high-performance applications like aerospace, power generation, and military systems. This testing ensures material consistency and identifies internal defects that could compromise the part's integrity. The following are key superalloy parts that benefit from water immersion ultrasonic testing:

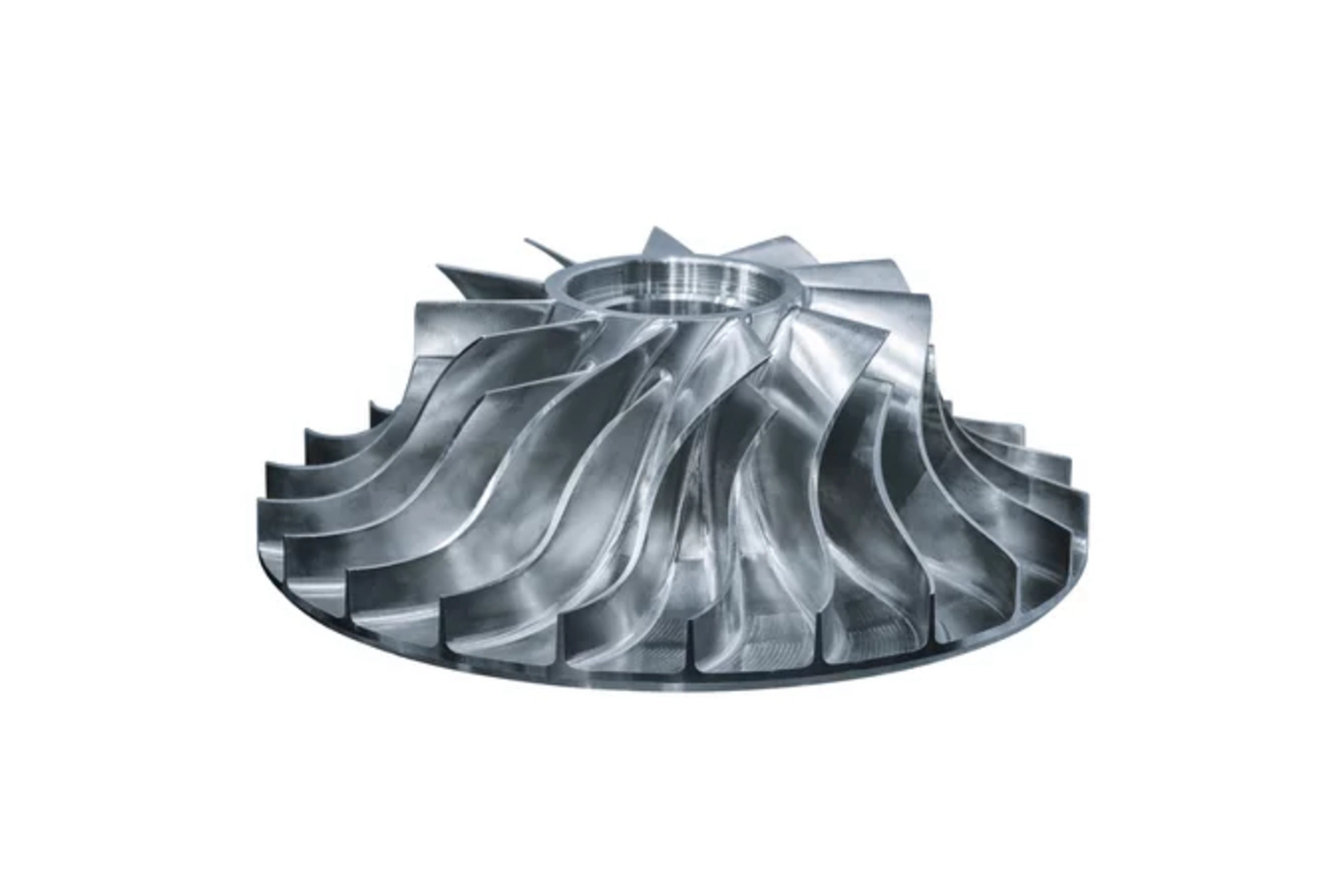

Superalloy Castings

Superalloy castings, such as turbine blades, impellers, and combustion chambers, often face high thermal and mechanical stresses during operation. To ensure reliable performance, these parts must exhibit uniform material properties across all sections. Water immersion ultrasonic testing helps detect internal defects like voids, cracks, or inconsistencies in the grain structure, which can weaken the component and lead to premature failure. For example, in aerospace applications, turbine blades and combustion chambers are particularly susceptible to such defects, making this testing method crucial for quality assurance.

Forging Parts

Forged superalloy components, such as turbine discs, shafts, and compressor blades, are subjected to intense mechanical stresses during the forging process and operational use. Water immersion ultrasonic testing is essential for evaluating the material consistency of these forged parts. It ensures that no internal defects, such as cracks or voids, are present, which could compromise their strength under high-stress conditions. By detecting these issues early, manufacturers can prevent costly failures and enhance the safety of critical components used in gas turbines and other high-performance engines.

CNC Machined Superalloy Parts

CNC-machined superalloy parts, including valve bodies, engine blocks, and precision components, require strict adherence to material properties due to their use in high-performance systems. Even after machining, these parts must be verified for uniformity and free from internal defects that could affect their functionality. Water immersion ultrasonic testing ensures that the material used in the machining process maintains consistency and integrity, confirming that the final part meets the required standards for demanding applications like engine systems and turbine assemblies.

3D Printed Superalloy Parts

The use of 3D printed superalloy parts is increasing in industries like aerospace, where complex geometries and customized designs are often required. However, additive manufacturing introduces unique challenges, including material inconsistencies and internal defects like porosity or layer bonding issues. Water immersion ultrasonic testing is ideal for inspecting these parts, ensuring that each printed layer has consistent material properties and that internal flaws are detected before the part is used in critical applications. This is especially important for components subjected to high mechanical and thermal loads, such as turbine blades in jet engines.

Powder Metallurgy Parts

Superalloy components made through powder metallurgy, like turbine discs, rely on uniformity between layers to maintain mechanical strength and performance. Material inconsistencies or poor bonding between layers can weaken the part during the sintering process. Water immersion ultrasonic testing effectively detect issues like uneven powder compaction or incomplete bonding, ensuring that the final product meets the required strength and homogeneity. For example, turbine discs created through powder metallurgy need to be free from defects to ensure safe and reliable operation in jet engines or gas turbines.

By utilizing water immersion ultrasonic testing across these various superalloy parts, manufacturers can identify internal defects early in production, ensuring that only parts with optimal integrity are used in high-performance applications.

Comparison with Other Testing Methods for Material Homogeneity

While water immersion ultrasonic testing is highly effective for detecting internal defects and assessing material homogeneity, other testing methods are commonly used in the manufacturing industry. Below is a comparison of water immersion ultrasonic testing with other methods:

Conventional Ultrasonic Testing:

Traditional ultrasonic testing also uses high-frequency sound waves to inspect materials, but it lacks the benefits of water immersion. Without the coupling medium, the accuracy and penetration depth of the sound waves may be limited. Water immersion, on the other hand, ensures a more uniform transmission of sound waves, making it especially useful for inspecting complex superalloy parts with intricate geometries. The improved sound wave transmission in water immersion ultrasonic testing enhances the detection of material heterogeneity, particularly for parts that undergo high-stress applications, such as gas turbines.

X-ray and CT Scanning:

X-ray inspection and computed tomography (CT) scanning are both highly effective for detecting internal defects, such as cracks, voids, or inclusions. However, they do not provide the same level of material homogeneity information as ultrasonic testing. While X-ray inspection and CT scanning are practical for locating defects, they may not be able to identify subtle variations in material density or structure, which water immersion ultrasonic testing can detect with greater sensitivity. In high-performance parts like turbine blades, uniform material properties are critical for ensuring long-term reliability, and ultrasonic testing excels in assessing this aspect.

Eddy Current Testing:

Eddy current testing is often used for surface inspection and can detect cracks or other anomalies near the material's surface. However, it cannot provide insight into the internal homogeneity of the material. In contrast, water immersion ultrasonic testing penetrates deep into the material, allowing for a more thorough evaluation of the entire component. This is particularly valuable in superalloy applications, where internal structural integrity is key to preventing failure due to fatigue or creep.

Magnetic Particle Testing:

Magnetic particle testing is commonly used for ferromagnetic materials, but it is not suitable for non-ferromagnetic superalloys. Since superalloys are often non-magnetic, this method cannot effectively detect material homogeneity in many superalloy parts. Ultrasonic testing, on the other hand, is versatile and can be used on both ferromagnetic and non-ferromagnetic materials, making it a more suitable option for superalloy components. Its ability to detect internal flaws and evaluate material uniformity makes it ideal for high-performance alloy components in aerospace and power generation industries.

Conclusion:

Water immersion ultrasonic testing provides a comprehensive and detailed analysis of material homogeneity, offering advantages over many other testing methods. Its ability to assess internal structures and detect material variations makes it the preferred choice for inspecting superalloy turbine components, aerospace engine parts, and other mission-critical components, ensuring their performance and reliability under extreme conditions.

Industry and Application of Water Immersion Ultrasonic Testing for Superalloy Parts

Water immersion ultrasonic testing is critical in various industries where superalloy components are essential for high-performance applications. Some of the primary sectors that benefit from this testing method include:

Aerospace and Aviation

Superalloys are widely used in aerospace and aviation applications, particularly in turbine engines, exhaust systems, and other high-stress components. Material homogeneity is crucial for the safety and efficiency of these parts, and water immersion ultrasonic testing ensures that these components meet stringent quality standards. Turbine blades, compressor blades, and combustion chambers require this testing to ensure uniform performance at high temperatures. This is vital for components like superalloy jet engine parts, which are subjected to extreme operational conditions and must maintain their structural integrity to avoid catastrophic failures.

Power Generation

In power generation, superalloys are used in components such as heat exchangers, turbine blades, and gas turbines. These parts operate in extremely harsh environments, where material defects could lead to failure and downtime. Water immersion ultrasonic testing ensures these components' integrity, helping prevent catastrophic failures and maintain operational efficiency. For example, superalloy heat exchanger components are tested for material consistency to ensure reliable performance over long periods in high-temperature, high-pressure environments.

Oil and Gas

Superalloy components are used extensively in drilling and pressure systems in the oil and gas industry. The high temperatures and pressures in extraction and refining require materials that can withstand extreme conditions without compromising strength. Water immersion ultrasonic testing helps ensure the material homogeneity of these parts, reducing the risk of failures and improving overall system reliability. For instance, parts like high-temperature alloy pump components undergo this testing to verify their structural integrity, reducing the risk of catastrophic failure in demanding oil and gas operations.

Marine

In marine applications, superalloys are used in underwater components, such as propulsion systems and structural parts of ships and submarines. These parts are exposed to corrosive environments, and water immersion ultrasonic testing helps to ensure material consistency, providing confidence in the longevity and performance of these critical components. Parts like superalloy naval ship modules benefit from this testing, which verifies that they can withstand harsh seawater conditions without compromising structural integrity.

Automotive

Automotive applications, such as turbochargers, exhaust systems, and other high-temperature components, require superalloys that maintain their material homogeneity under extreme conditions. Ultrasonic testing is used to detect material inconsistencies that could lead to early failure, ensuring the longevity and performance of these parts. For example, superalloy exhaust system components are subject to water immersion ultrasonic testing to ensure their strength and durability over time in the harsh thermal cycles of automotive engines.

Military and Defense

Superalloys are also used in military and defense applications, including missile systems, aircraft, and armored vehicles. The material integrity of these parts is critical to ensure their reliability in life-threatening situations. Water immersion ultrasonic testing helps guarantee that the superalloy components meet the required material properties for strength and durability. Components such as superalloy armor system parts are tested to ensure their reliability under extreme mechanical and environmental conditions, preventing potential failures in high-stakes defense applications.

Water immersion ultrasonic testing is crucial across these industries to detect material inconsistencies and ensure superalloy components' long-term performance and safety, making it an essential part of quality assurance and reliability in high-performance environments.

FAQs

What is the role of water in water immersion ultrasonic testing?

How does water immersion ultrasonic testing compare to traditional ultrasonic testing methods?

Which types of superalloy parts are most commonly tested using water immersion ultrasonic methods?

How does water immersion ultrasonic testing detect material homogeneity in superalloy components?

In what industries is water immersion ultrasonic testing most commonly applied to superalloy parts?