Internal Defect Detection in Superalloy Parts: Leveraging Ultrasonic Waves for Quality Assurance

Understanding Internal Defect Detection in Superalloy Parts

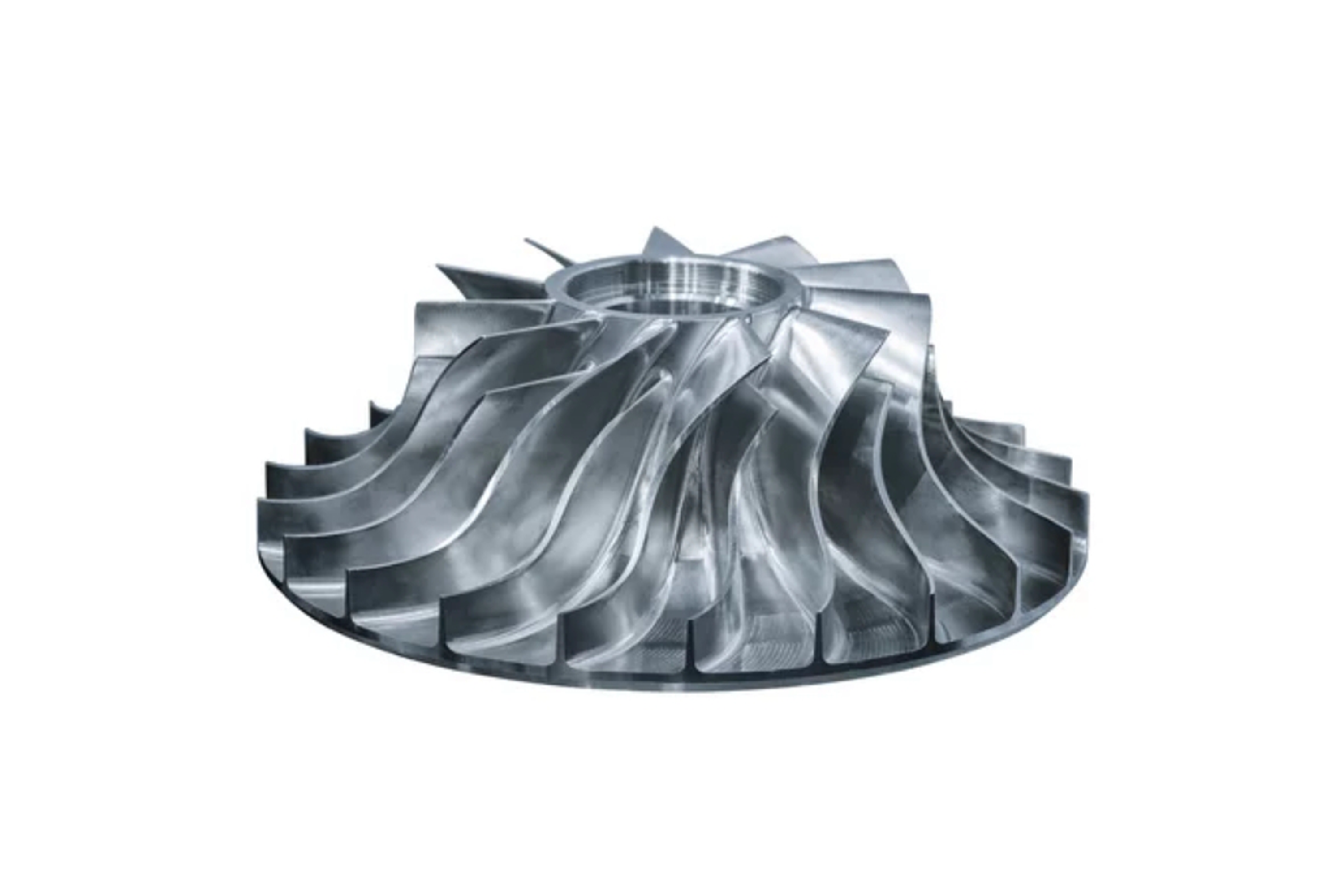

Quality assurance is a cornerstone in manufacturing high-performance parts, particularly for critical applications in aerospace, energy, and military defense. When it comes to superalloys, ensuring the internal integrity of components is essential for their reliability and performance in demanding environments. Superalloy parts, such as turbine blades, reactor vessel components, and heat exchanger parts, are subjected to extreme stresses and temperatures. Therefore, any internal defects, whether cracks, voids, or inclusions, can severely impact their structural integrity and safety.

One of the most effective methods for identifying internal defects is ultrasonic testing (UT). UT uses high-frequency sound waves to detect irregularities within the material, offering an invaluable tool for quality control in superalloy part manufacturing. This non-destructive testing (NDT) method ensures that superalloy components meet the rigorous standards set by industries like aerospace and aviation, power generation, and military defense. It allows manufacturers to detect flaws deep within the material without compromising the part’s functionality or structural integrity.

Ultrasonic testing can reveal critical defects that may not be visible through traditional surface inspections. It is beneficial for evaluating superalloy components, such as turbine blades and reactor vessel components, where structural failure due to internal flaws could result in catastrophic consequences. By employing ultrasonic testing, manufacturers ensure that only parts with the highest level of integrity are used in critical applications, enhancing safety and performance in high-stress environments.

What is Ultrasonic Wave Testing?

Ultrasonic testing is a well-established NDT method used to assess the internal structure of materials. The principle behind ultrasonic testing is relatively simple: high-frequency sound waves are introduced into the material, typically in the range of 1-20 MHz. A transducer generates these waves, which then propagate through the material. When the sound waves encounter internal defects or changes in the material’s properties (such as density or elasticity), they are reflected to the transducer. The time taken for the sound waves to return and the intensity of the reflected signal provide crucial information about the location, size, and nature of any defects present within the material.

Ultrasonic testing is often preferred for superalloy parts because it can detect internal flaws without damaging the components. It is ideal for high-value, high-performance materials used in critical applications. Water immersion ultrasonic inspection is a more specialized technique that enhances detection accuracy by submerging parts in a liquid coupling, offering greater clarity and sensitivity in detecting defects.

The Function of Ultrasonic Wave Testing in Superalloy Parts

The main function of ultrasonic testing in superalloy parts manufacturing is to detect and locate internal defects that could compromise the material’s strength and performance. These defects can arise during the manufacturing process—whether through casting, forging, machining, or 3D printing—or develop over time due to the part’s exposure to extreme environments. By identifying these flaws early, ultrasonic testing ensures the integrity of high-performance components used in aerospace, power generation, and automotive sectors.

Common defects that ultrasonic testing can identify include:

Cracks: Breaks or fissures in the material that may propagate under stress, leading to part failure. Ultrasonic testing helps detect these before they lead to catastrophic failures, especially in critical parts like turbine blades.

Porosity: Small voids or air pockets formed within the material, often due to improper casting or solidification processes. This can be critical when assessing superalloy investment castings that need flawless internal quality for optimal performance.

Inclusions: Foreign materials, such as slag or other impurities, are embedded within the alloy, which can weaken the part. Ultrasonic wave testing helps detect these inclusions in parts made using processes like superalloy precision forging.

Shrinkage: A defect that can occur during the cooling phase of casting, leading to localized weaknesses in the material. This is especially important in processes like superalloy single crystal casting, where structural integrity is vital.

Once the ultrasonic waves are transmitted through the superalloy part, the returned signals are analyzed to produce a comprehensive image of the material’s internal structure. Advanced UT equipment can create detailed digital maps of these internal defects, enabling manufacturers to take corrective action before the parts are used in critical applications. This technology ensures the quality and safety of parts, ultimately enhancing the reliability of components like heat exchangers and turbine components in the energy and aerospace industries.

Which Superalloy Parts Require Ultrasonic Testing?

Ultrasonic testing (UT) is a highly effective method for evaluating the internal quality of superalloy parts across various manufacturing processes. Using high-frequency sound waves, UT can detect internal defects that may compromise the structural integrity of parts used in high-stress, high-performance applications. The following superalloy parts particularly benefit from ultrasonic testing:

Superalloy Castings

Superalloy castings, such as turbine blades, combustion chambers, and gas turbine components, are prone to defects like porosity, shrinkage, and microcracks. These flaws can significantly affect the performance and safety of critical components. UT is essential for detecting these internal imperfections, ensuring that the castings meet the required strength, durability, and performance specifications for demanding applications like aerospace and energy. Through vacuum investment casting and other casting processes, ultrasonic testing plays a key role in preventing defective parts from entering service.

Forged Parts

The forging process subjects superalloy materials to extreme heat and pressure to achieve desired shapes, improving material strength. However, the process can also introduce internal defects such as cracks, voids, or non-metallic inclusions. Parts like turbine discs, shafts, and gears—critical for industries like aerospace and power generation—require rigorous inspection for internal integrity. UT is crucial for identifying these potential flaws, ensuring that the forged parts maintain their strength and can withstand the extreme mechanical forces they will encounter during operation.

CNC Machined Superalloy Parts

After superalloy parts undergo CNC machining, the material may still contain microfractures, inclusions, or distortions that could affect performance. Parts such as engine casings, compressor blades, and other precision-engineered components are subject to stress during machining, which can result in subtle internal defects. Ultrasonic testing is essential for verifying the integrity of CNC-machined parts, helping manufacturers ensure that they meet stringent specifications and will perform reliably in their intended applications.

3D Printed Superalloy Parts

Additive manufacturing, or 3D printing, enables the creation of highly complex geometries but also introduces challenges such as material inconsistencies, porosity, and microstructural flaws. Superalloy parts produced via 3D printing, especially in industries like aerospace and defense, require careful inspection to ensure their structural integrity. Ultrasonic testing offers a non-destructive way to detect internal defects in 3D-printed components, ensuring they meet the required standards for strength and durability in high-performance environments.

By integrating ultrasonic testing throughout the production process, manufacturers can ensure that superalloy parts—cast, forged, CNC machined, or 3D printed—are free from defects that could compromise their reliability, safety, and performance. This helps maintain the high standards necessary for applications in aerospace, energy, and other demanding industries.

Comparison with Other Defect Detection Processes

Ultrasonic testing (UT) is one of several NDT methods to detect internal defects in superalloy parts. While it offers numerous advantages, comparing it with other widely used techniques is essential to understand its strengths and limitations better.

X-ray Inspection

X-ray inspection is commonly used to detect internal defects, especially in materials like metals and alloys. However, X-rays are more suited for surface-level or near-surface defects. Ultrasonic testing, conversely, can probe deeper into materials, making it ideal for detecting internal flaws in thicker superalloy components like turbine discs. Additionally, ultrasonic waves can map the size and shape of defects in real-time, providing a more detailed inspection. X-ray CT scanning, which offers 3D imaging, is also a powerful tool but may not be as effective in real-time defect mapping as ultrasonic methods.

Eddy Current Testing

Eddy current testing is effective for detecting surface cracks and corrosion, particularly in non-ferrous alloys. However, it is less sensitive to more profound internal defects than ultrasonic testing, making ultrasonic testing the preferred choice when assessing the integrity of thick-walled superalloy parts or castings. Eddy current is also more limited when evaluating thicker or more complex geometries, where ultrasonic waves are more effective at detecting flaws.

Magnetic Particle Inspection (MPI)

MPI is mainly used to detect surface and near-surface defects in ferromagnetic materials. Since superalloys are often non-magnetic, MPI is not adequate for this application. Ultrasonic testing, applying to both magnetic and non-magnetic materials, provides a more versatile solution for detecting internal flaws in superalloy parts. This makes it an essential tool for inspecting various alloys used in high-performance applications such as aerospace and power generation.

Dye Penetrant Testing

Dye penetrant testing is effective for detecting surface cracks and defects. However, it is limited to identifying only surface imperfections and cannot detect subsurface defects. Ultrasonic testing can identify surface and internal defects, making it a more comprehensive solution for superalloy parts that may experience hidden failures, especially in high-stress environments.

In summary, while each defect detection process has its own advantages, ultrasonic testing stands out for its ability to thoroughly examine internal defects, especially in thick, high-performance materials like superalloys. Its versatility and depth make it an essential technique in the superalloy components manufacturing industry.

Industry and Application of Ultrasonic Wave Testing in Superalloy Parts

Ultrasonic testing (UT) is critical across many industries that rely on superalloy parts for their high-performance applications. Some key industries and applications include:

Aerospace and Aviation

Superalloy parts, such as turbine blades, combustion chambers, and engine components, are used extensively in the aerospace sector. These components must withstand extreme temperatures and pressures in jet engines. UT ensures the integrity of these parts by detecting internal defects, such as cracks or voids, that could compromise their performance and safety during flight.

Power Generation

In power generation, gas turbines, turbine discs, and heat exchangers are critical components that must operate efficiently and safely in high-temperature environments. Ultrasonic testing helps detect internal defects in these superalloy turbine discs, ensuring they meet stringent quality control standards and perform reliably over their operational life, reducing the risk of failures in power plants.

Oil and Gas

The oil and gas industry relies on durable and reliable superalloy components such as valves, pumps, and pressure vessels exposed to extreme stress and corrosive environments. UT is essential in inspecting these parts to ensure they meet high-quality standards and remain safe and functional throughout their lifespan. For example, superalloy pump components undergo ultrasonic testing to detect internal flaws, ensuring their durability in harsh operational environments.

Energy

In the energy sector, superalloys are used in energy generation and storage systems, including nuclear reactors and energy-efficient turbines. Nuclear reactor components, fuel system modules, and corrosion-resistant piping must meet the highest standards of quality and reliability. UT is crucial for verifying the integrity of these critical components, ensuring they perform safely in high-risk, high-temperature environments.

Marine

Superalloy parts in the marine industry, such as propulsion systems, propellers, and engine components, are subjected to harsh environments that can cause wear and corrosion. Ultrasonic testing helps maintain the reliability of these critical components by identifying internal defects that could affect their performance or lead to failures during operation. For example, superalloy turbine blades in marine applications undergo UT to detect cracks or other internal issues.

Military and Defense

Superalloy components used in military and defense applications, such as missile segments, armor systems, and high-performance weaponry, must meet the highest standards of quality and reliability. UT ensures these parts are accessible from internal defects that could affect their performance in critical missions. For example, superalloy missile components undergo ultrasonic testing to ensure their strength and functionality under extreme conditions.

Nuclear

In the nuclear industry, ultrasonic testing is widely used to assess the quality of superalloy components used in reactor vessels, heat exchangers, and corrosion-resistant piping. These parts must be inspected to ensure their performance in highly radioactive and high-temperature environments. UT plays a key role in detecting internal flaws that could jeopardize the safety and reliability of nuclear power systems.

Ultrasonic testing is an essential inspection method that ensures the quality and performance of superalloy components used in these industries. By identifying internal defects early, UT helps improve high-performance parts' safety, durability, and efficiency across a wide range of critical applications.

FAQs

What is the difference between ultrasonic testing and X-ray inspection for superalloy parts?

How deep can ultrasonic waves penetrate into superalloy materials?

Can ultrasonic testing detect surface cracks in superalloy parts?

What are the limitations of ultrasonic testing when applied to 3D printed superalloy parts?

How does ultrasonic testing help improve the safety and reliability of superalloy components in aerospace applications?