Surface Treatments to Boost Corrosion Resistance in Superalloy Single Crystal Castings

In advanced manufacturing, particularly for high-performance materials like superalloys, ensuring component longevity and reliability in harsh environments is paramount. Superalloy components, commonly used in aerospace, power generation, and other critical industries, are often subjected to extreme temperatures, pressures, and corrosive environments. Surface treatment processes are crucial in ensuring that these parts can withstand such demanding conditions. One of the essential processes in achieving this is the Surface Corrosion Production Line, a vital step in enhancing the durability of superalloy parts, particularly Single Crystal Castings.

Superalloys, including those used in marine and oil and gas sectors, require advanced corrosion resistance to maintain performance in harsh operational environments. For high-performance applications such as turbine blades and high-temperature alloy engine components, corrosion resistance is essential for extending the life of parts and ensuring reliability over time. By applying surface treatments through the SCPL process, manufacturers can significantly improve the resistance of these critical components to corrosion and environmental degradation.

What is the Surface Corrosion Production Line Process?

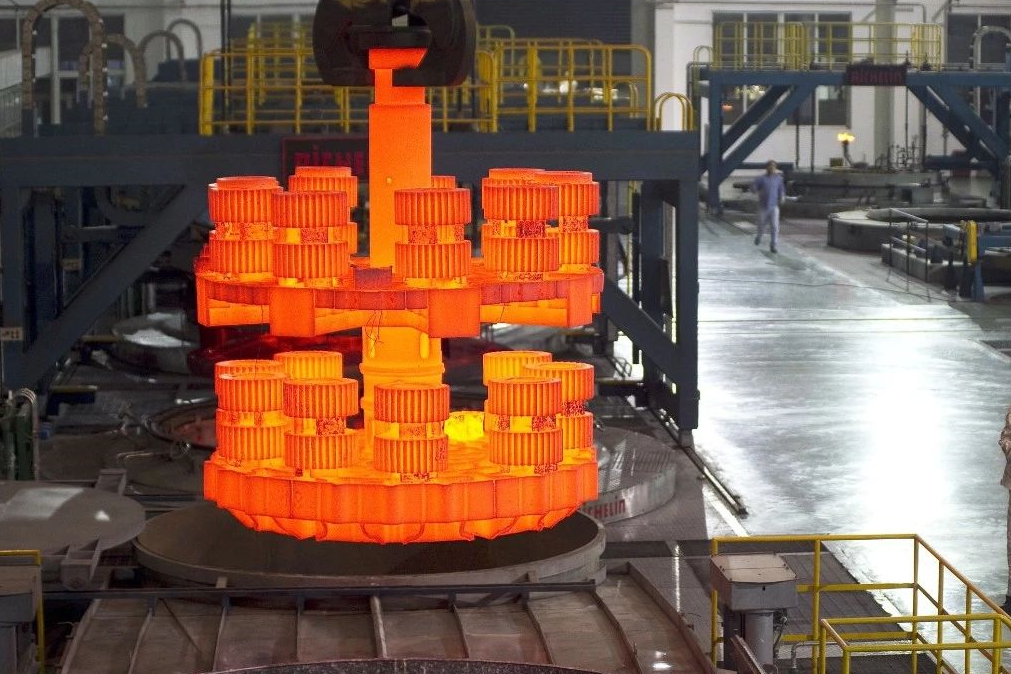

The Surface Corrosion Production Line (SCPL) is a specialized process designed to improve the corrosion resistance of superalloy components by treating their surfaces. This is achieved through a series of steps that typically include cleaning, preparation, and the application of protective coatings. The goal is to enhance the material's resistance to oxidation, corrosion, and other forms of surface degradation, which are common in high-temperature environments, especially in superalloy turbine disc manufacturing.

SCPL involves several techniques, including high-temperature oxidation testing, coating application, and sometimes chemical treatments. These processes ensure that the treated surface is resistant to wear and corrosion and capable of withstanding extreme conditions. For superalloy turbine blade single crystal casting, where surface integrity is crucial for performance, SCPL is particularly beneficial.

In the SCPL process, the superalloy component is first cleaned to remove any impurities or debris. This ensures that the subsequent treatments bond well with the material. Next, depending on the application, the part might undergo high-temperature oxidation or be coated with materials designed to resist corrosion. These treatments are optimized to suit the specific superalloy being used and the conditions to which it will be exposed, such as those in jet engine components.

The Function of the Surface Corrosion Production Line

The primary function of the SCPL is to improve the corrosion resistance of superalloy components, making them more durable and reliable in demanding conditions. High-performance alloys, especially superalloys, are used in extreme environments subjected to high temperatures, aggressive chemicals, and constant stress. Without proper surface treatment, these components would degrade quickly, resulting in reduced performance, increased maintenance costs, and, ultimately, part failure. This is particularly critical for aerospace and power generation industries, where reliability is paramount for safety and efficiency.

In the case of Single Crystal Castings, which are often used in turbine blades and other critical aerospace components, surface integrity is essential. Single crystal castings are known for their high strength and resistance to thermal fatigue, but their susceptibility to corrosion and oxidation can limit their operational life. SCPL helps to mitigate these issues by forming a protective layer on the surface, which shields the part from oxidation and other forms of degradation. This layer is often an oxide or protective coating that can withstand the high temperatures encountered in turbine engines, combustion chambers, and other high-stress environments, improving the part's longevity and reliability.

In addition to corrosion resistance, SCPL can improve the thermal properties of superalloy components. This is especially important for parts like turbine blades, which are exposed to extremely high temperatures during operation. The protective coating applied in SCPL can reduce heat absorption, allowing the component to maintain its strength and integrity at elevated temperatures. It makes them more efficient and durable in industries that rely on high-performance alloys like aerospace and energy.

Superalloy Parts that Benefit from Surface Corrosion Production Line

The Surface Corrosion Production Line (SCPL) is a versatile process that enhances the performance of a wide range of superalloy parts, ensuring they can withstand extreme environments such as high temperatures, corrosive gases, and mechanical stresses. Below are some of the superalloy components that significantly benefit from SCPL treatment:

Superalloy Castings

Superalloy castings are commonly used in aerospace, power generation, and defense applications, where they are exposed to high-temperature oxidation and corrosion. Castings made from materials such as Inconel, CMSX, and Rene alloys are particularly vulnerable to degradation when exposed to extreme temperatures. The Surface Corrosion Production Line treatment enhances their resistance to oxidation, allowing these cast components to maintain their structural integrity throughout their service life in critical environments like jet engines and turbine systems.

Forging Parts

Forged superalloy parts, including turbine blades, compressor blades, and structural components, are designed to endure high mechanical and thermal stresses. These parts are often exposed to aggressive corrosive elements, which can degrade their performance. SCPL treatment is particularly effective in improving the surface resistance of these forged components to pitting, oxidation, and other forms of corrosion, thus extending their operational life and enhancing their overall performance in aerospace and power generation industries.

CNC Machined Superalloy Parts

CNC machined superalloy parts, including precision components for engines, seals, and valves, often feature microscopic surface defects that can promote corrosion if left untreated. Even with fine machining, these parts can still exhibit inconsistencies that may compromise their durability. The Surface Corrosion Production Line provides a uniform surface finish that improves the corrosion resistance of these machined parts. This treatment helps to protect the parts from environmental factors like moisture, high temperatures, and aggressive chemicals, ensuring long-term performance and reliability.

3D Printed Superalloy Parts

Additive manufacturing, or 3D printing, offers great flexibility in producing complex geometries for superalloy components. However, the surface finish of 3D-printed parts can often be inconsistent, with issues like roughness or porosity. These inconsistencies can make the parts more susceptible to corrosion. The Surface Corrosion Production Line treatment smooths out these surface irregularities, enhancing the corrosion resistance of 3D-printed components. This ensures that parts used in high-performance applications, such as turbine blades or aerospace components, meet stringent performance standards and operate reliably in harsh environments.

By applying the Surface Corrosion Production Line treatment to these superalloy components, manufacturers can significantly improve their corrosion resistance, ensuring that they perform optimally in demanding applications. Whether for castings, forged parts, CNC machined components, or 3D printed parts, SCPL treatment is essential for maintaining superalloy parts' structural integrity and longevity in extreme environments.

Comparison with Other Surface Treatment Processes

While the Surface Corrosion Production Line offers numerous benefits, it is essential to understand how it compares with other surface treatment processes in superalloy component manufacturing.

Anodizing

Anodizing is a widely used process for improving the corrosion resistance of metals, particularly aluminum. However, anodizing does not provide the same protection against high-temperature oxidation as SCPL. SCPL, with its specialized coatings, is designed to withstand the extreme conditions encountered in superalloy applications, such as those found in aerospace and gas turbine components, where high temperatures and corrosive gases are prevalent.

Electroplating

Electroplating is another surface treatment technique that improves corrosion resistance by depositing a thin metal layer onto the surface. While electroplating can improve surface properties, it is less effective than SCPL in high-temperature resistance. SCPL coatings, such as those used in turbine blade manufacturing, are designed to endure extreme thermal cycling, ensuring a longer-lasting protective layer in high-stress environments.

Heat Treatments

Heat treatments like carburizing or nitriding can improve hardness and wear resistance but are less effective in improving corrosion resistance in high-temperature environments. Heat treatment processes improve the material's structural integrity but may not be sufficient to prevent oxidation in superalloy components exposed to high-temperature conditions. SCPL, on the other hand, is specifically tailored to enhance corrosion resistance without compromising the material's strength or thermal properties.

Ceramic Coating

In some cases, ceramic coatings can offer superior protection against high temperatures and corrosion. However, these coatings are often brittle and may not provide the same durability and uniformity as SCPL coatings. SCPL treatments, being more advanced and integrated into the production line, tend to provide a more consistent and reliable result, making them ideal for high-temperature alloy components used in aerospace and power generation industries.

Overall, while each process has its strengths and is suitable for particular applications, SCPL stands out for its ability to combine corrosion resistance with high-temperature durability in a way that is essential for superalloy parts used in aerospace, power generation, and similar industries.

Industry Applications and Benefits

The Surface Corrosion Production Line (SCPL) is widely used in industries that rely on superalloy components for critical applications. SCPL treatment plays a crucial role in enhancing the corrosion resistance of parts, ensuring their durability and long-term performance in challenging environments. Some key sectors that benefit from SCPL treatment include:

Aerospace and Aviation

In aerospace and aviation, turbine blades, nozzle guide vanes, and combustion chambers used in jet engines must withstand extremely high temperatures and oxidative environments. SCPL ensures these parts maintain their performance and structural integrity during long-term operation. For instance, superalloy turbine blades treated with SCPL are better equipped to resist oxidation and degradation under harsh conditions inside jet engines, increasing safety and reducing the need for frequent replacements.

Power Generation

In power generation, gas and steam turbines used in power plants are subjected to high temperatures and aggressive conditions. SCPL-treated parts like turbine blades, seals, and casings benefit from enhanced resistance to corrosion, improving efficiency and reducing maintenance needs. Parts such as superalloy heat exchanger components also benefit from SCPL, which helps them maintain thermal efficiency while extending their operational life.

Oil and Gas

The oil and gas industry requires components used in offshore drilling, extraction equipment, and deep-water systems to withstand extreme temperatures and corrosive environments. SCPL helps to protect parts such as pump components, heat exchangers, and valves, ensuring their longevity and reliability. SCPL treatment is critical for parts exposed to harsh chemicals and pressure, like superalloy pump components, ensuring they can perform reliably in high-stress conditions.

Military and Defense

In the military and defense sector, superalloy components used in missiles, armored systems, and aerospace applications require maximum durability and reliability. SCPL-treated parts ensure that they can withstand extreme conditions, including high temperatures, radiation, and mechanical stress. For example, superalloy missile segments benefit from SCPL by maintaining their structural integrity under intense conditions, contributing to mission success and safety.

Nuclear

In the nuclear industry, superalloy parts such as reactor vessel components and control rods are exposed to high levels of radiation and heat. SCPL helps ensure these parts remain corrosion-resistant and perform reliably over extended periods, reducing downtime and maintenance costs. SCPL treatment enhances the durability of critical components like superalloy reactor vessel components, ensuring their safe and efficient operation in nuclear power plants.

In conclusion, SCPL treatment offers significant benefits across various industries by enhancing the corrosion resistance of superalloy components, improving their longevity, and reducing the risk of failure. By providing superior protection against oxidation, chemicals, and extreme environmental stresses, SCPL helps these industries maintain high performance and safety levels.

FAQs

What is the Surface Corrosion Production Line and how does it work?

Which superalloy parts benefit the most from the Surface Corrosion Production Line?

How does SCPL compare to traditional surface treatment methods like anodizing or electroplating?

What industries rely on SCPL for enhancing superalloy component durability?

Can SCPL be applied to all types of superalloy parts, including 3D printed components?