Custom Superalloy Parts Gallery

Superalloy Parts We Made

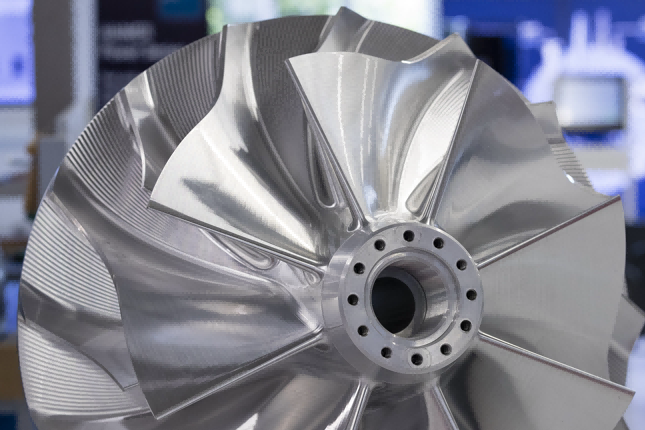

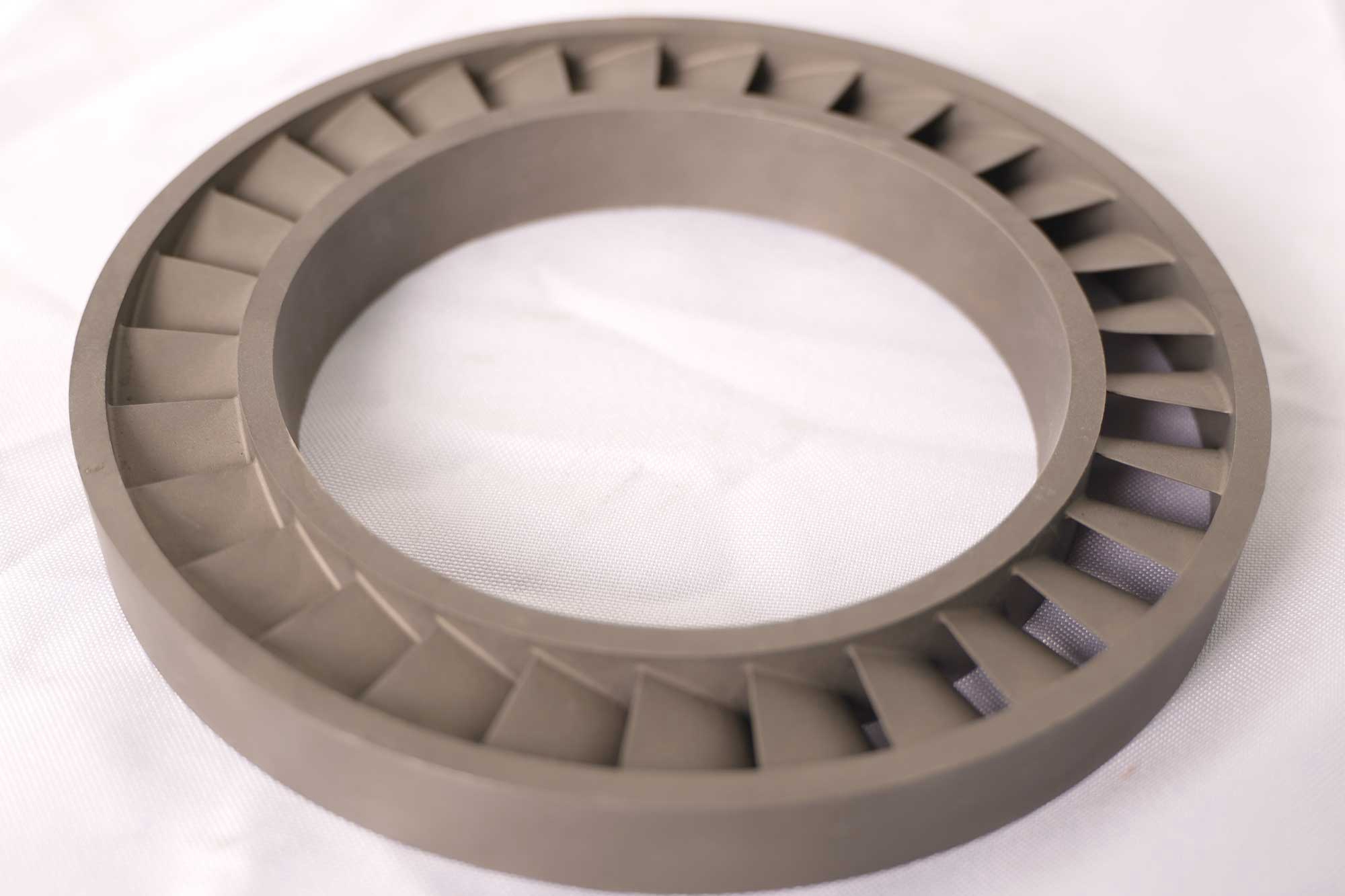

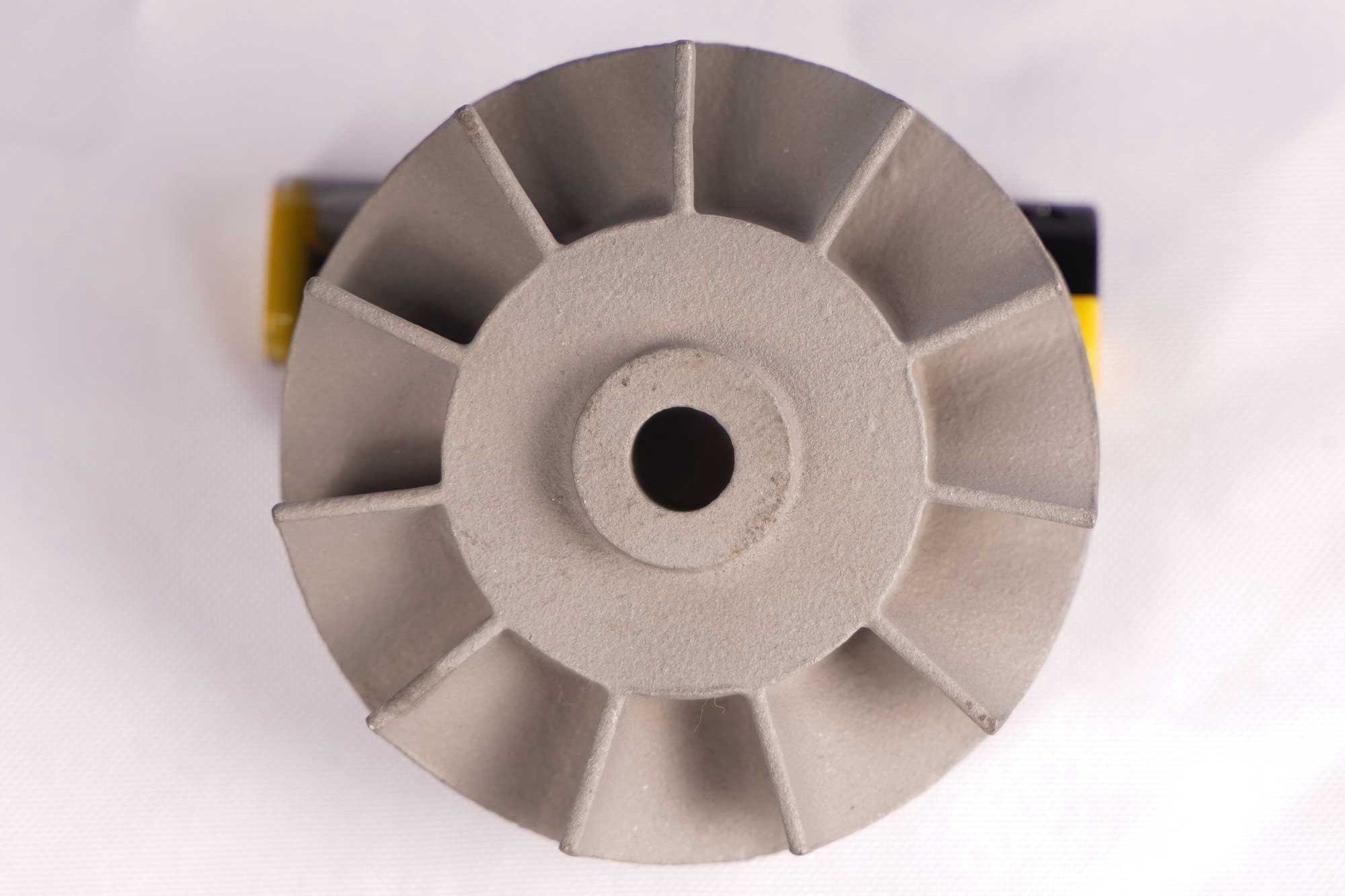

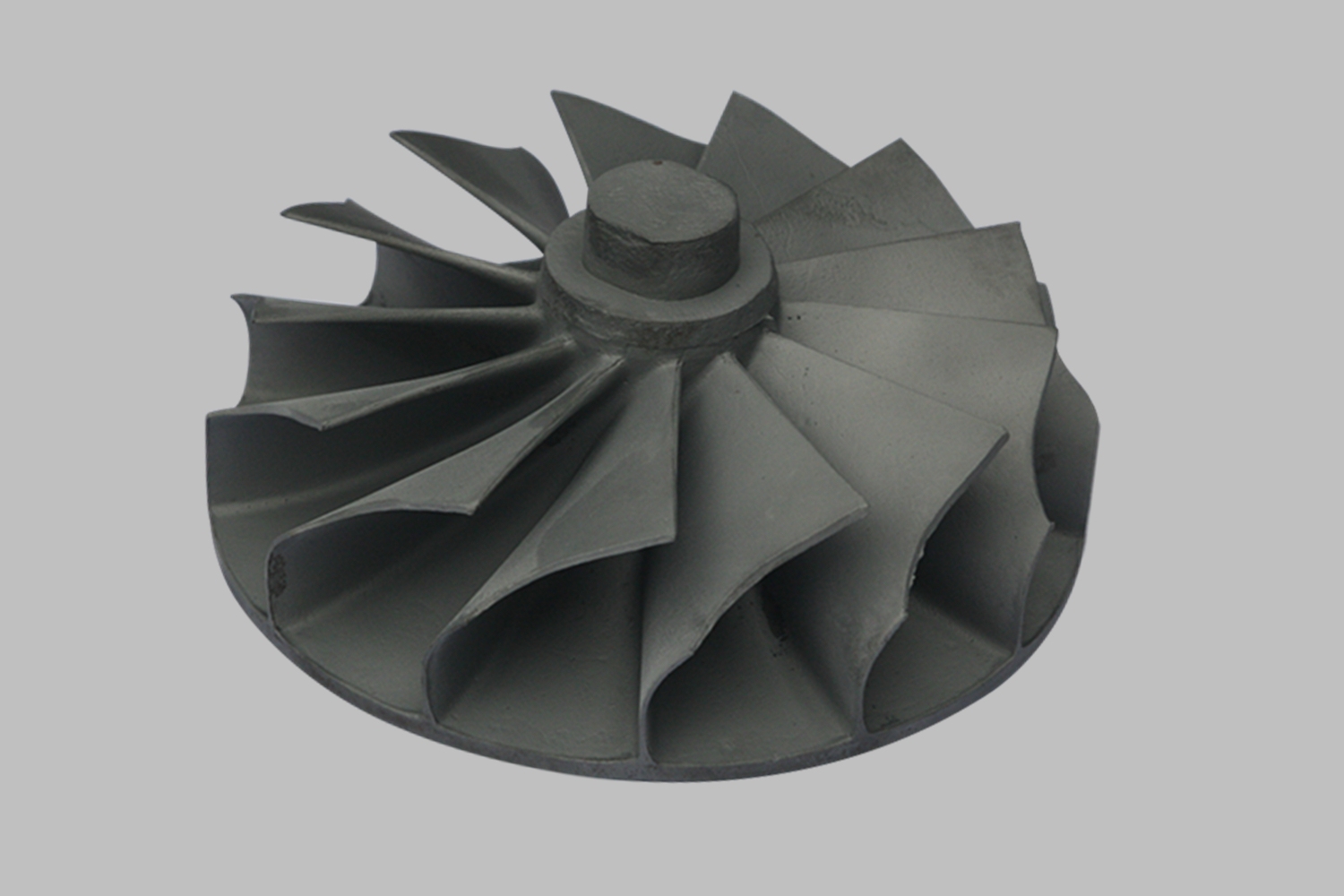

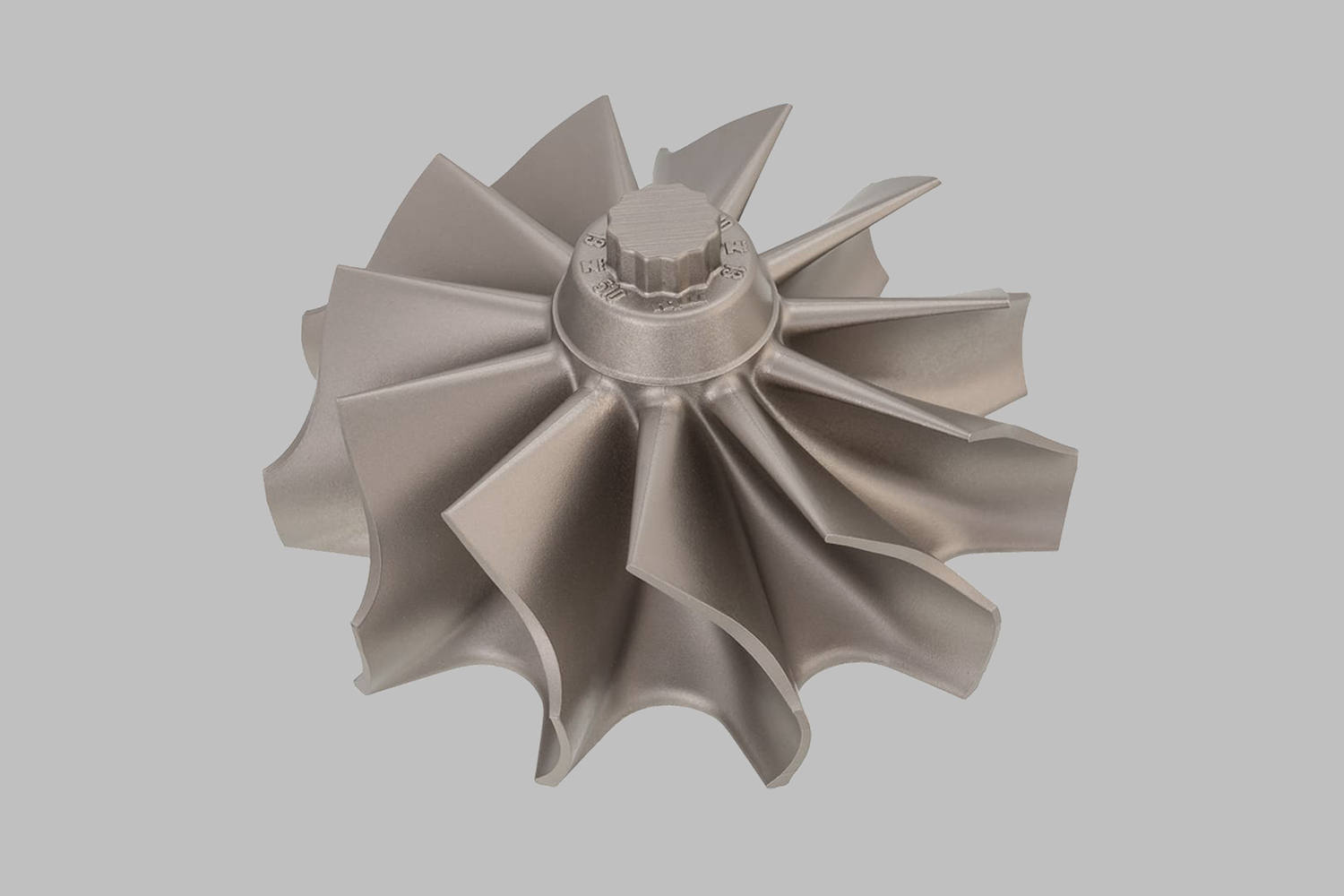

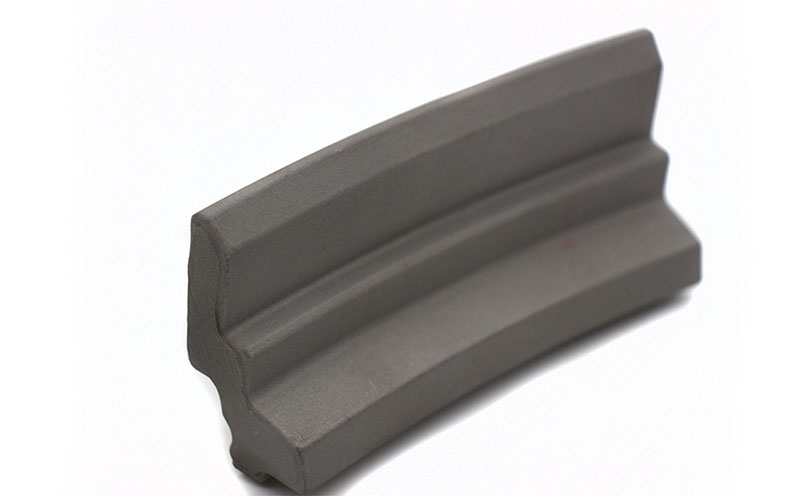

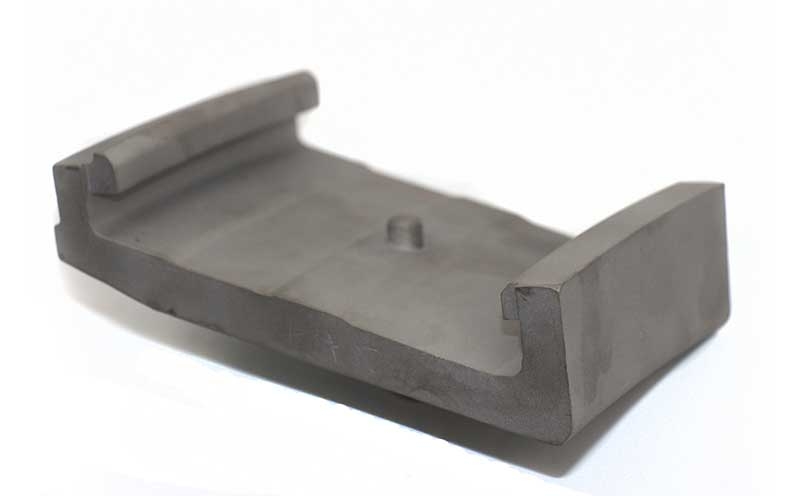

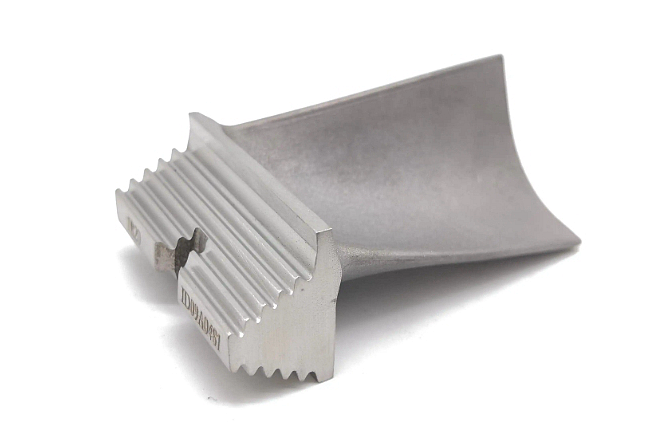

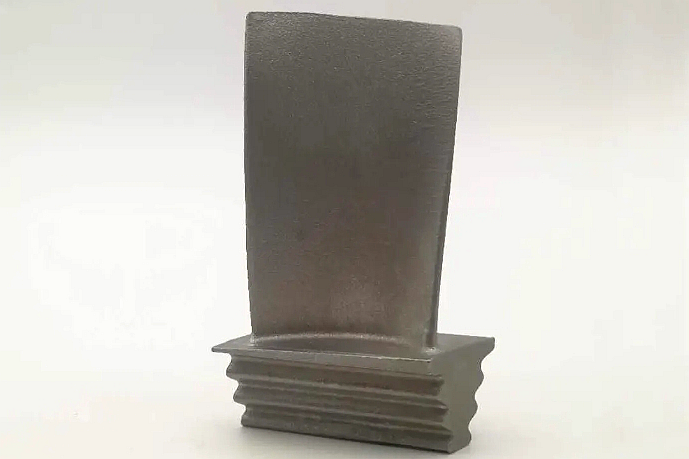

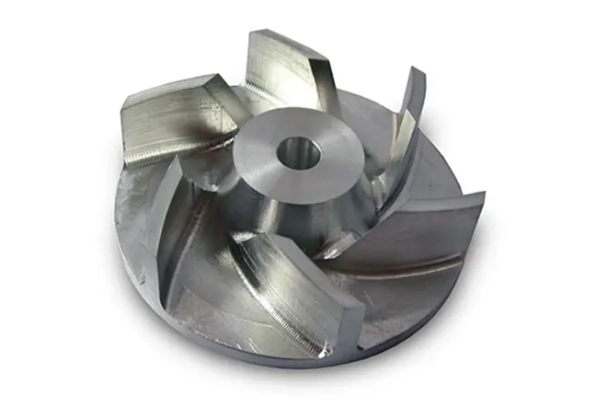

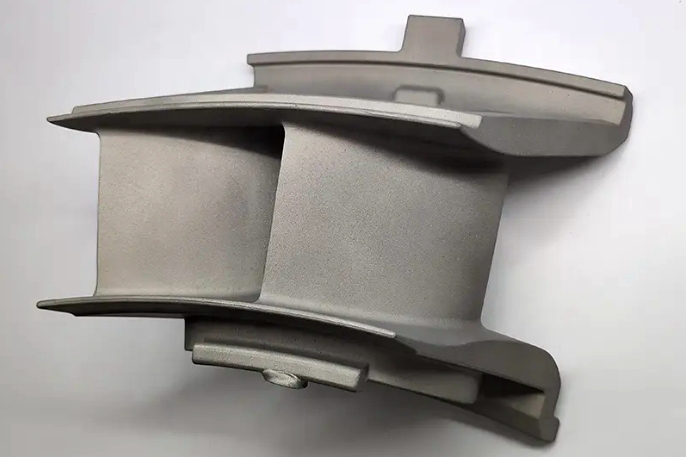

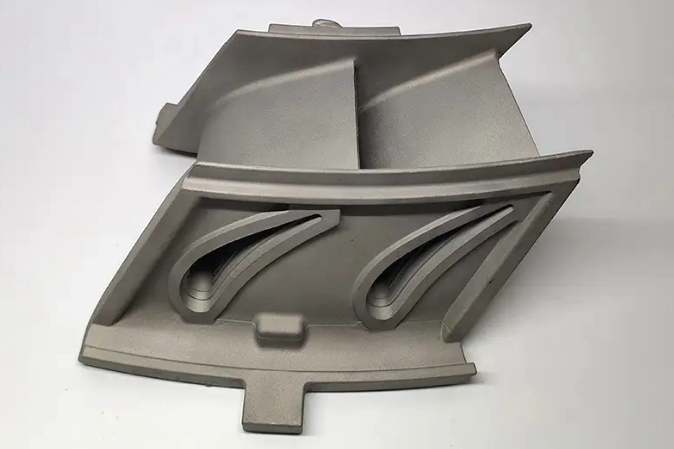

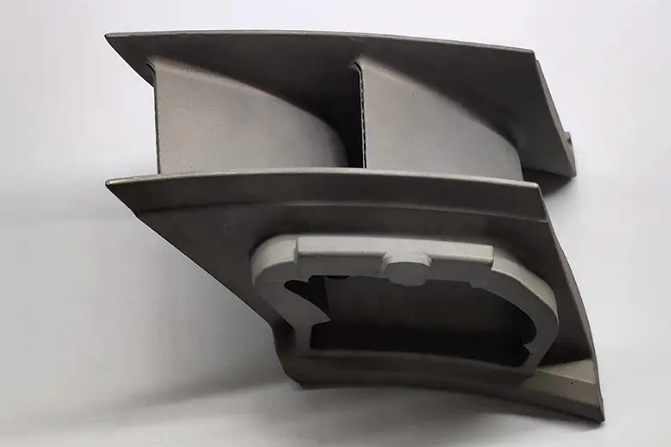

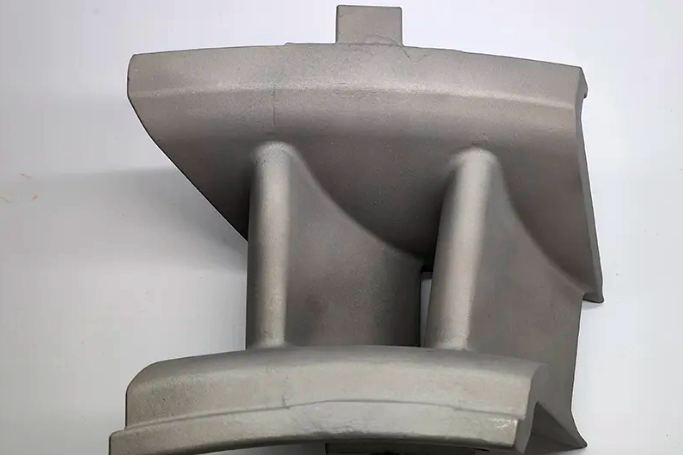

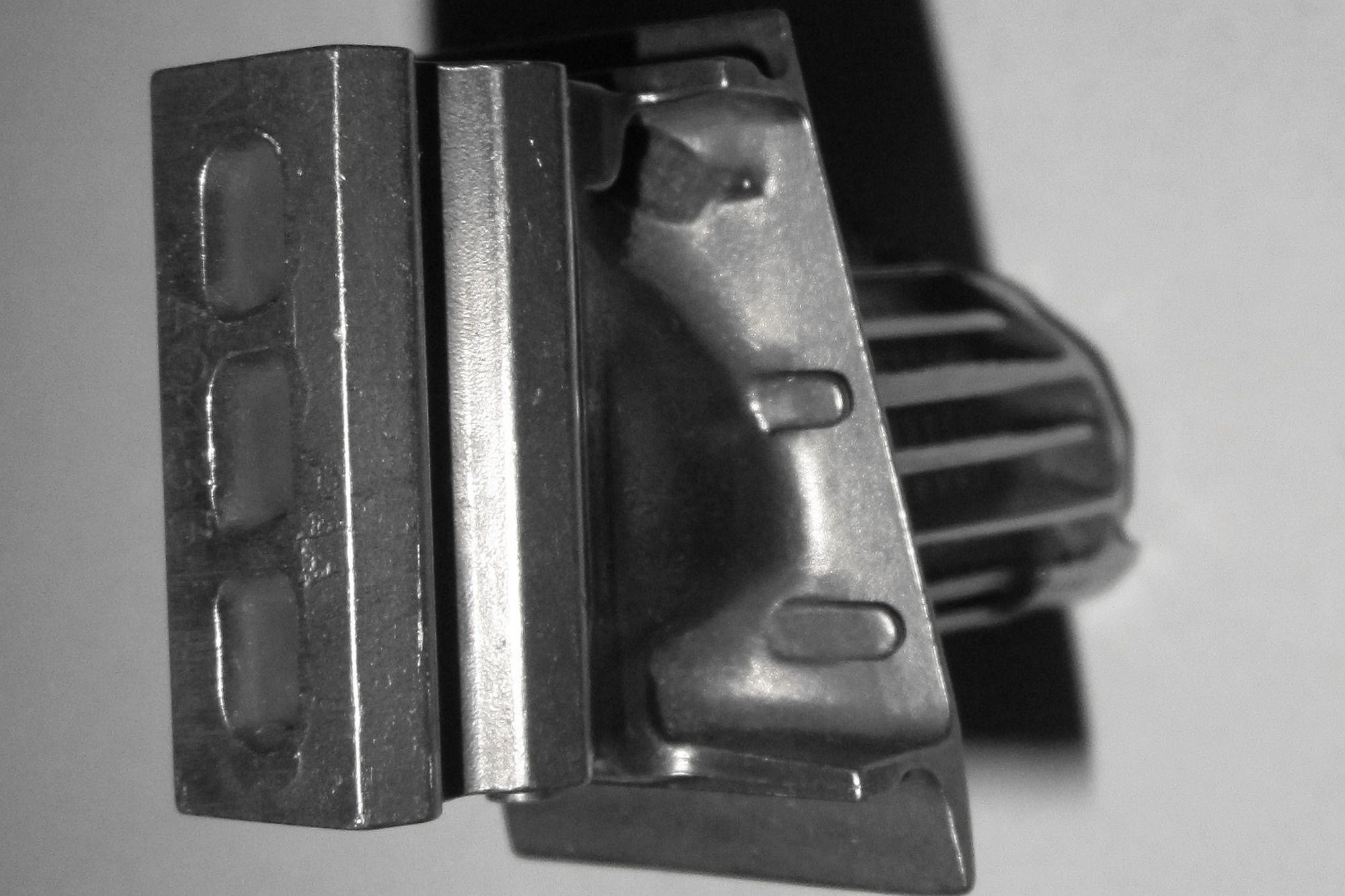

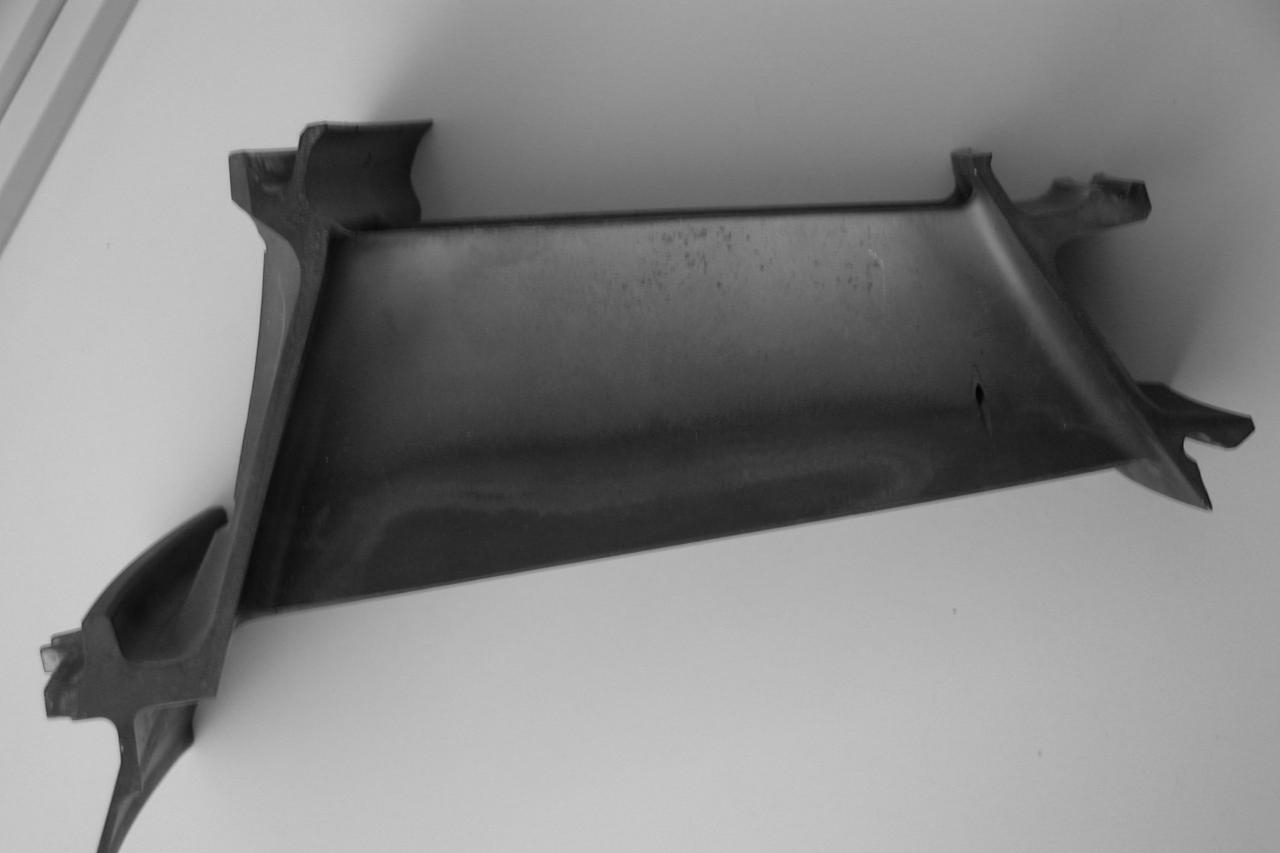

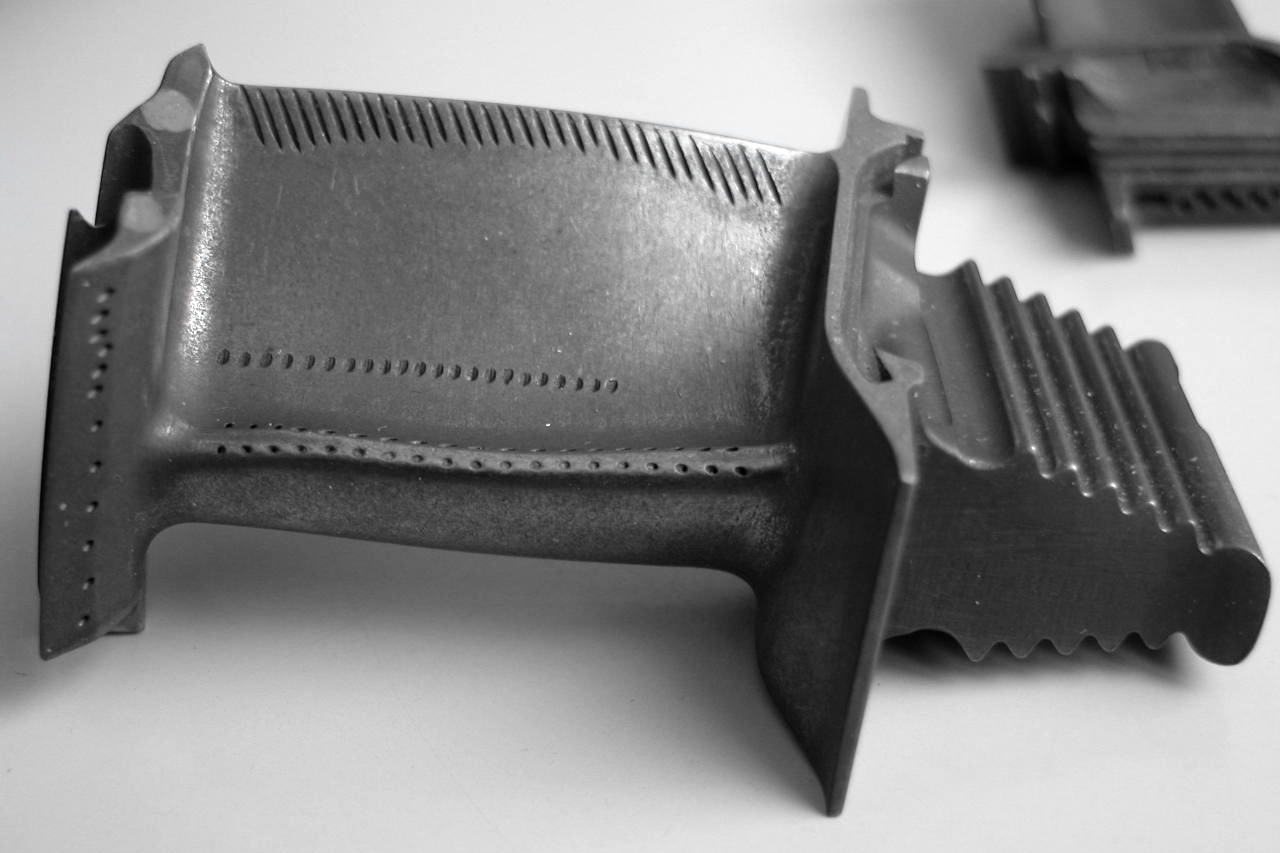

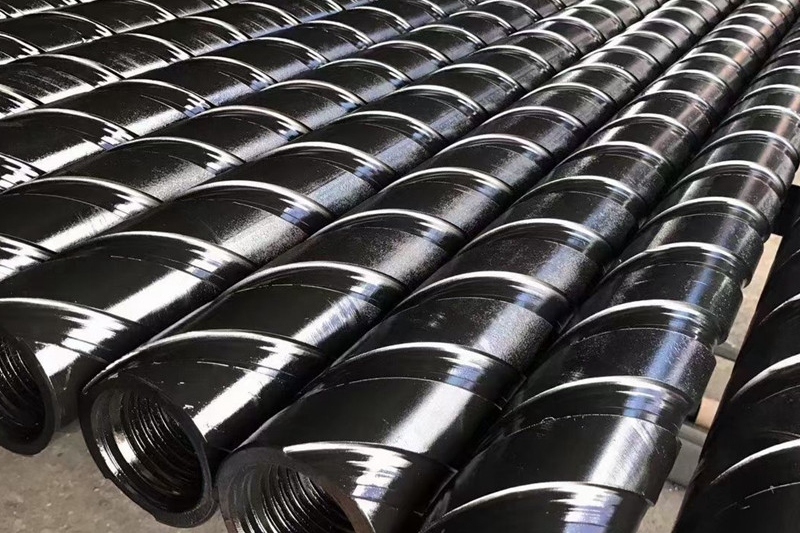

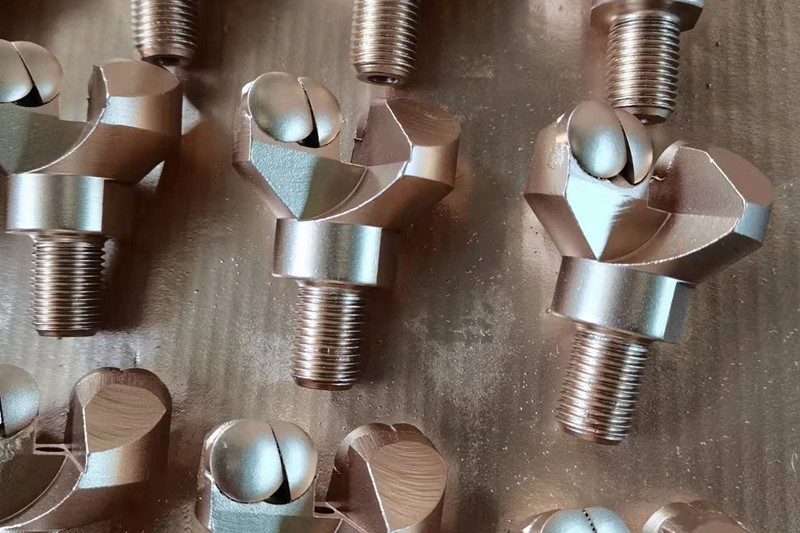

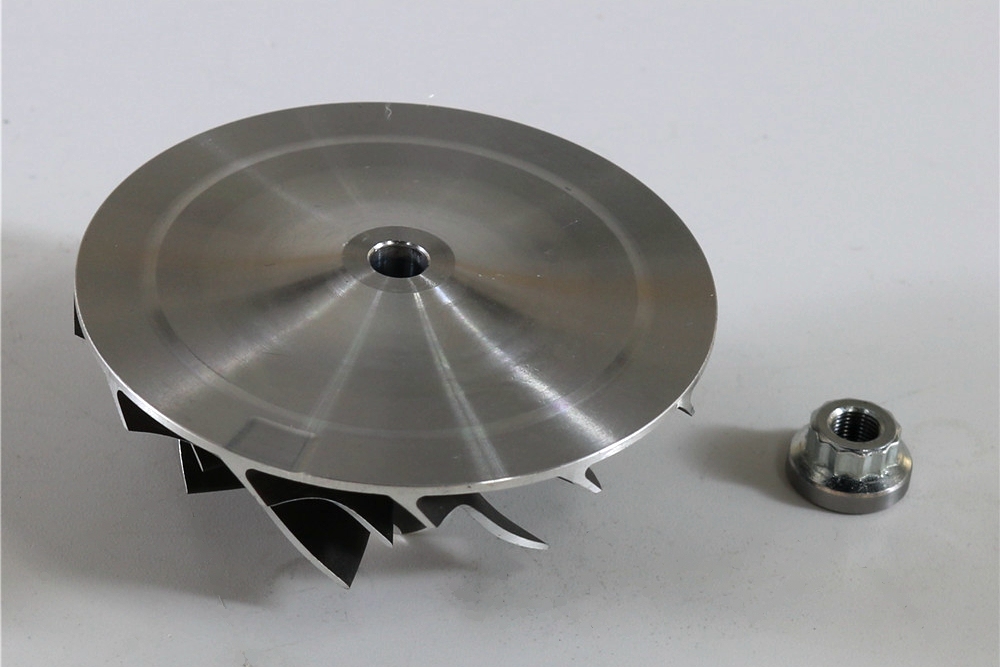

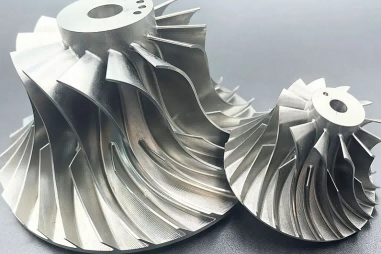

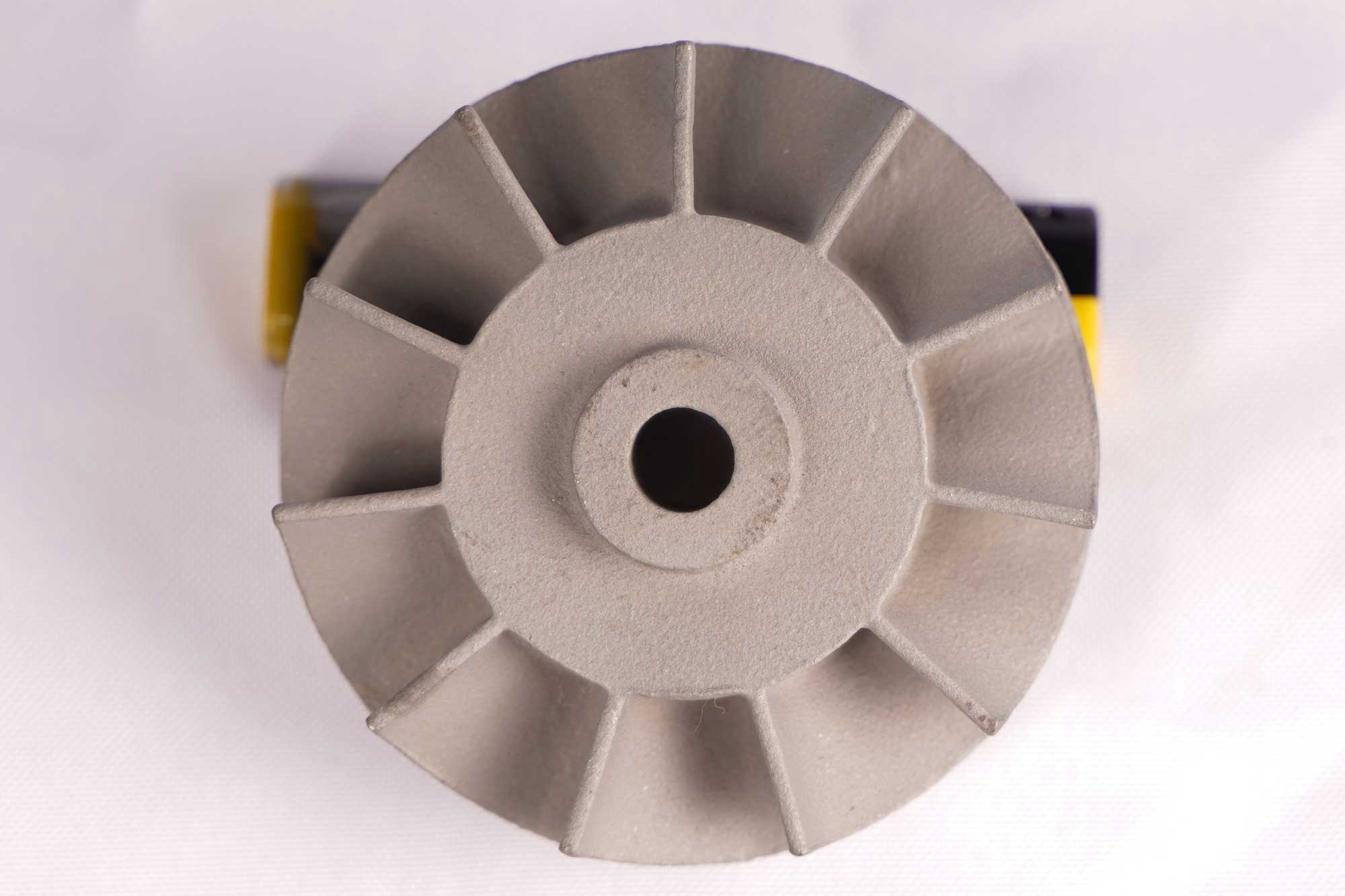

We produce superalloy parts like turbine blades, combustion chambers, turbine discs, impellers, nozzle rings, afterburners, and gas turbines, mainly for aerospace, power generation, oil, gas, and marine industries, designed to endure extreme heat and stress conditions.

Custom Superalloy Components Gallery

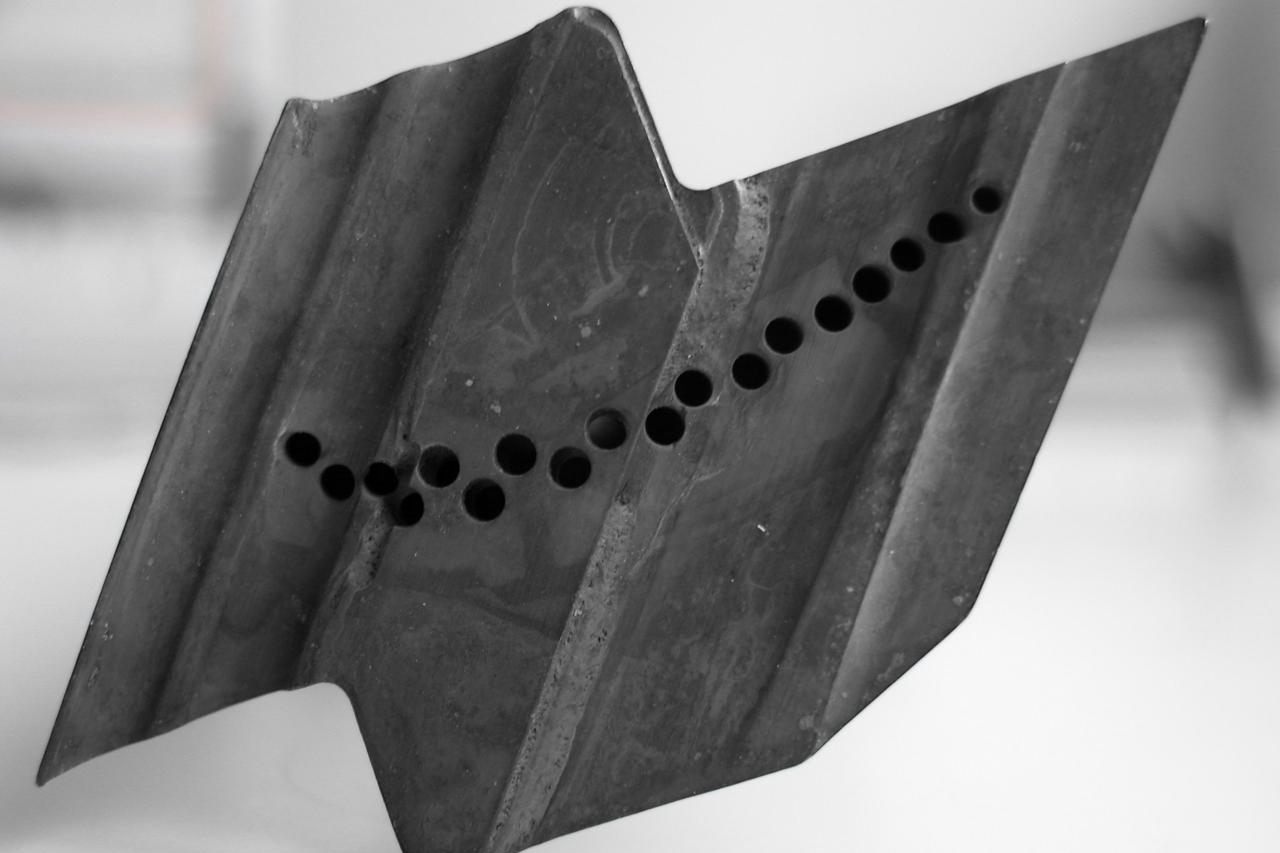

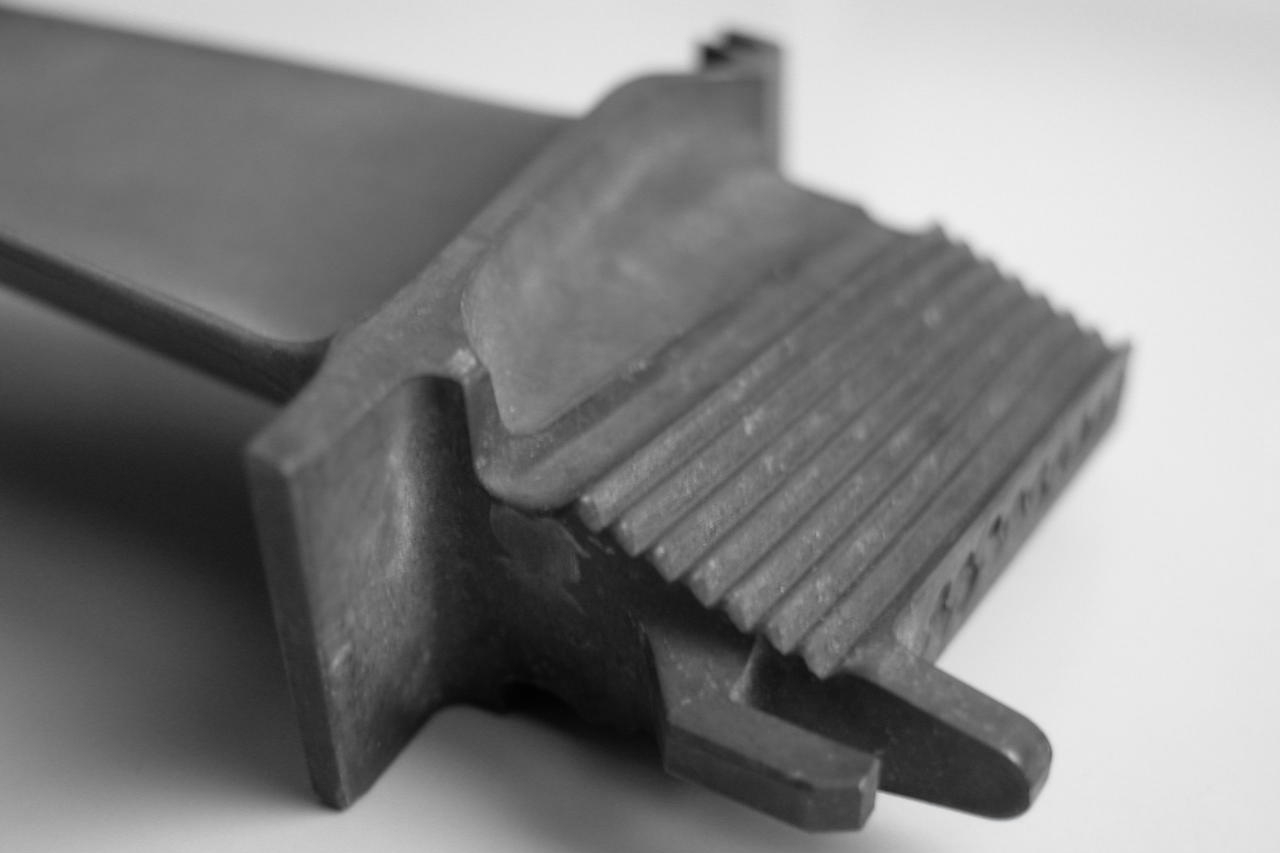

We manufacture high-temperature alloy parts using advanced processes like vacuum investment casting, powder metallurgy, precision forging, CNC machining, and 3D printing. Our products undergo rigorous post-processing, including Hot Isostatic Pressing (HIP), heat treatment, welding, Thermal Barrier Coating (TBC), CNC machining, deep hole drilling, and Electrical Discharge Machining (EDM). These components, such as turbine blades, combustion chambers, impellers, and nozzle rings, serve critical industries like aerospace, power generation, oil and gas, energy, marine, and military. Our parts are designed for extreme environments, offering high durability, heat resistance, and precision, while meeting stringent industry standards for performance and reliability.

learn more

single-crystal-casting-parts

learn more

Leading Supplier of Superalloy Single Crystal Casting Turbine Blades

learn more

High-Temperature Alloy Single Crystal Casting Turbine Blade Company

learn more

Custom Single Crystal Casting Turbine Blade Manufacturer

learn more

Single Crystal Casting Turbine Blade Customization Factory

learn more

Trusted Manufacturer of Single Crystal Casting Turbine Blades

learn more

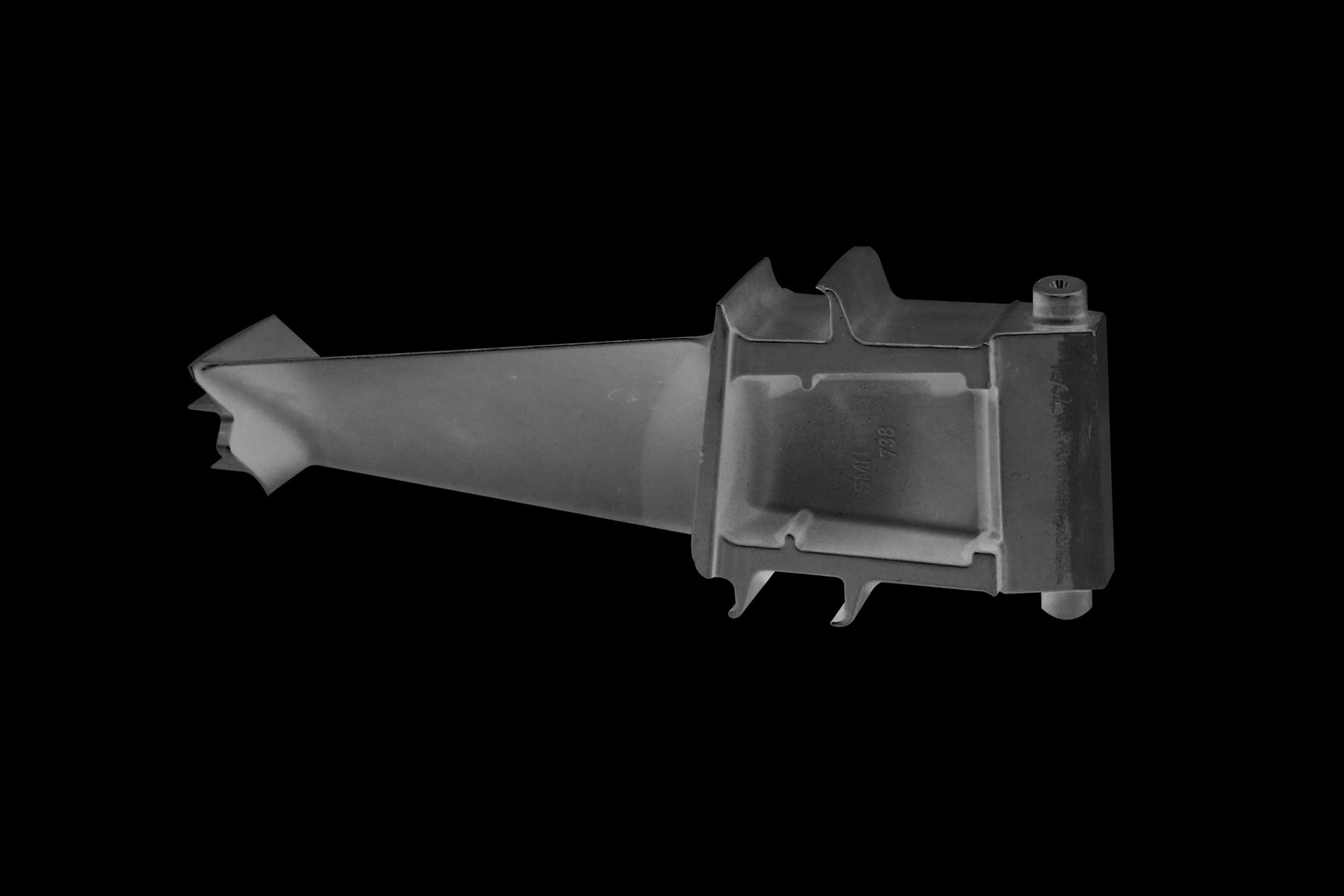

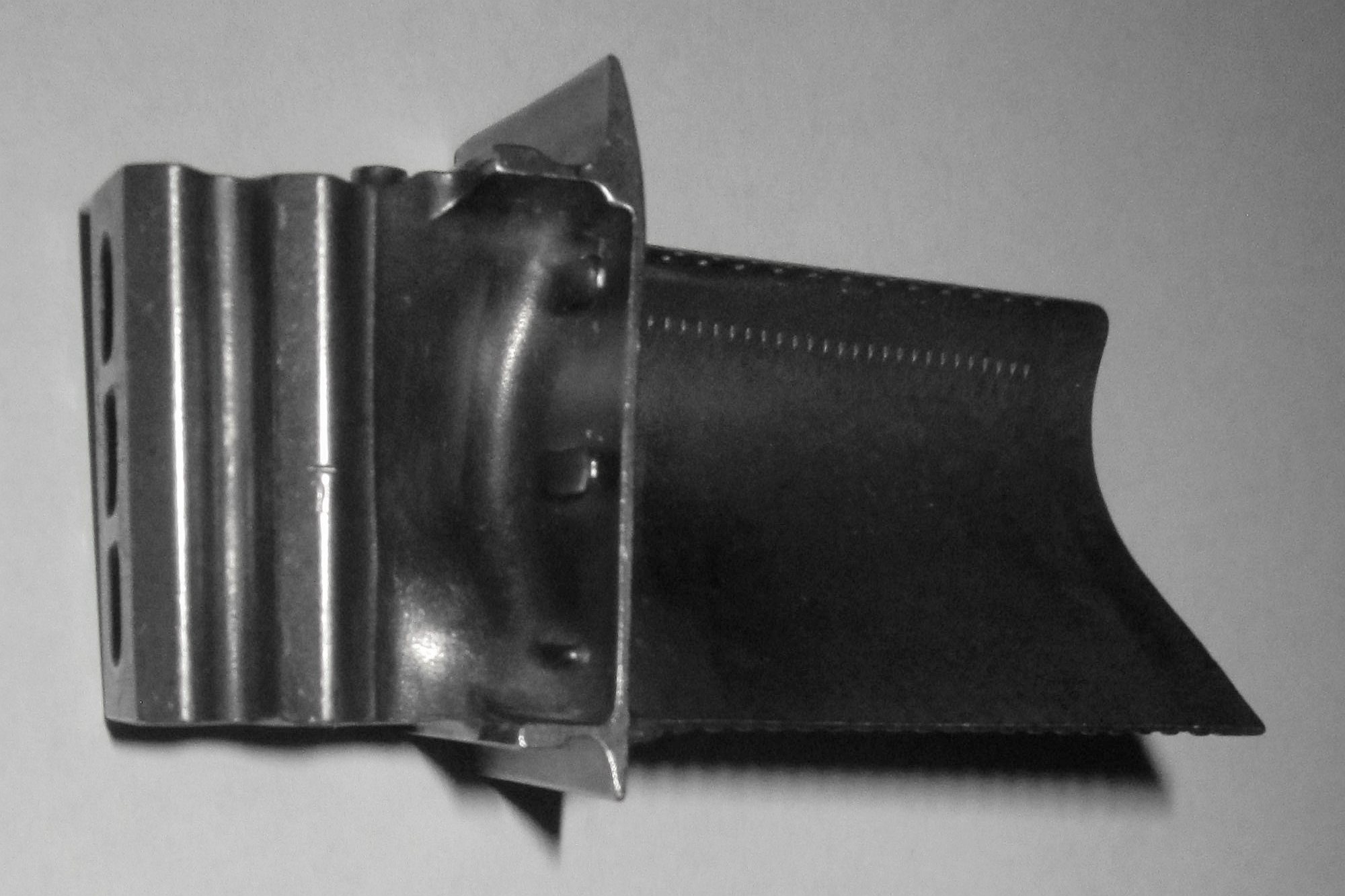

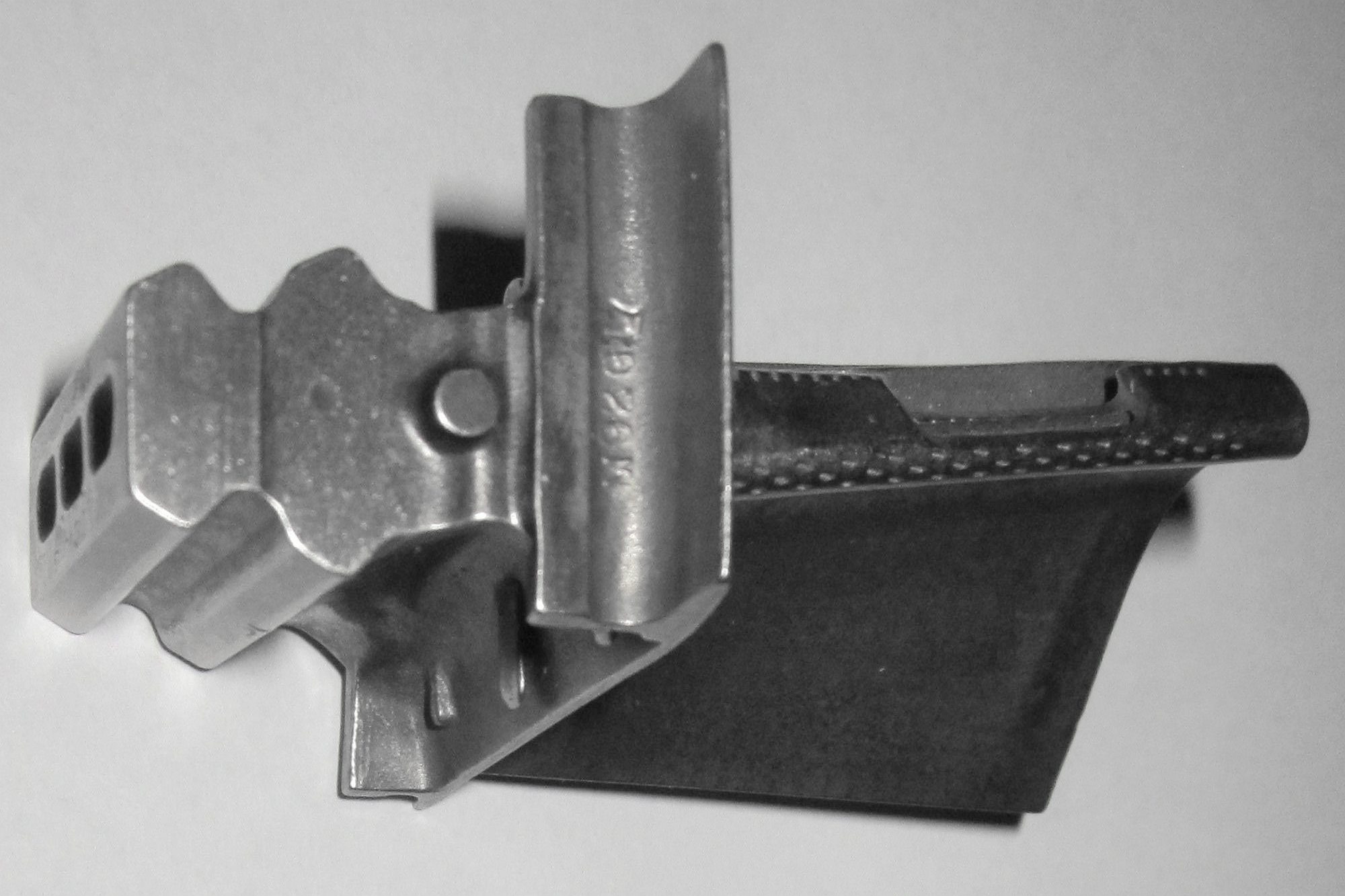

directional-casting-superalloy-parts-manufacturer

learn more

Rene N5 Superalloy Components via Directional Casting Foundry

learn more

Inconel 718 Superalloy Components Produced by Directional Casting Manufacturer

learn more

Nimonic 80A Directional Casting Superalloy Parts Production Facility

learn more

Inconel 713 Superalloy Parts through Directional Casting Manufacturer

learn more

Inconel 738 Superalloy Components Manufactured by Directional Casting Company

learn more

directional-casting-superalloy-parts-manufacturer

learn more

Inconel Superalloy Equiaxed Crystal Casting Production Expert

learn more

Rene Superalloy Equiaxed Crystal Casting Production Company

learn more

Hastelloy Superalloy Equiaxed Crystal Casting Manufacturing Unit

learn more

Nimonic Superalloy Equiaxed Crystal Casting Production Foundry

learn more

Stellite Superalloy Equiaxed Crystal Casting Fabrication Service

learn more

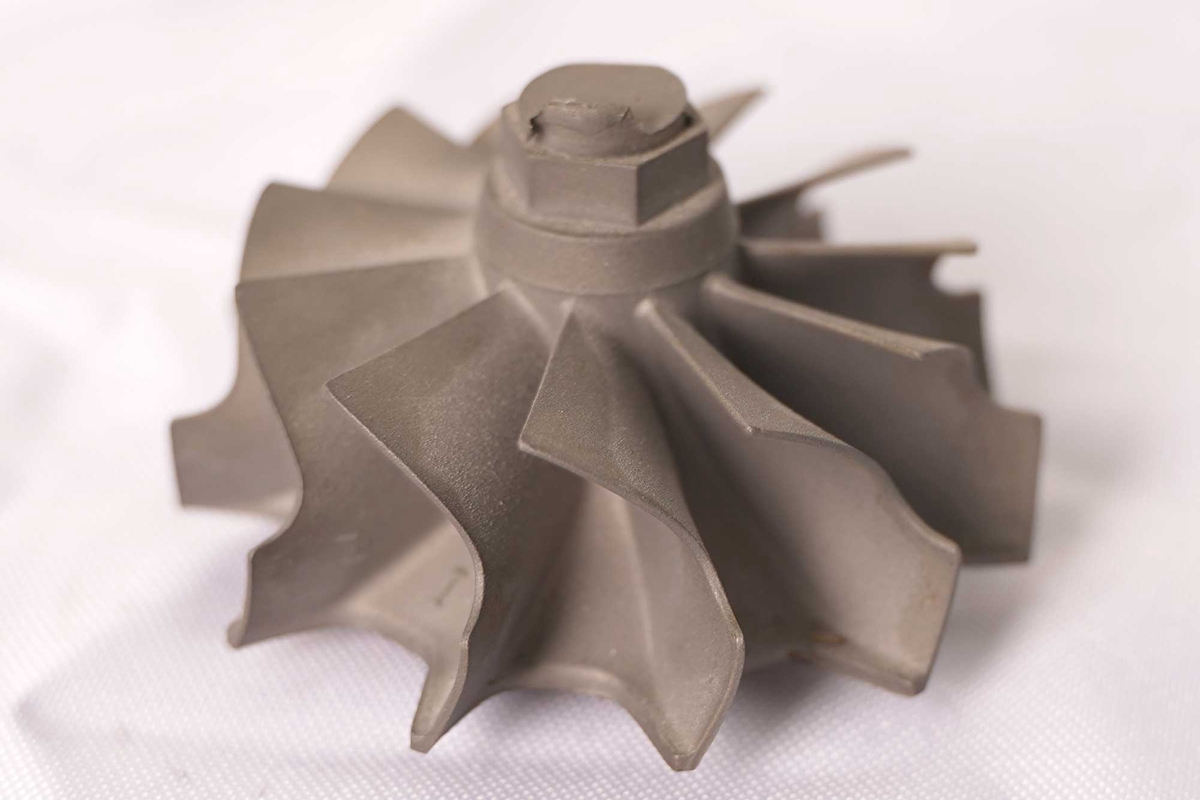

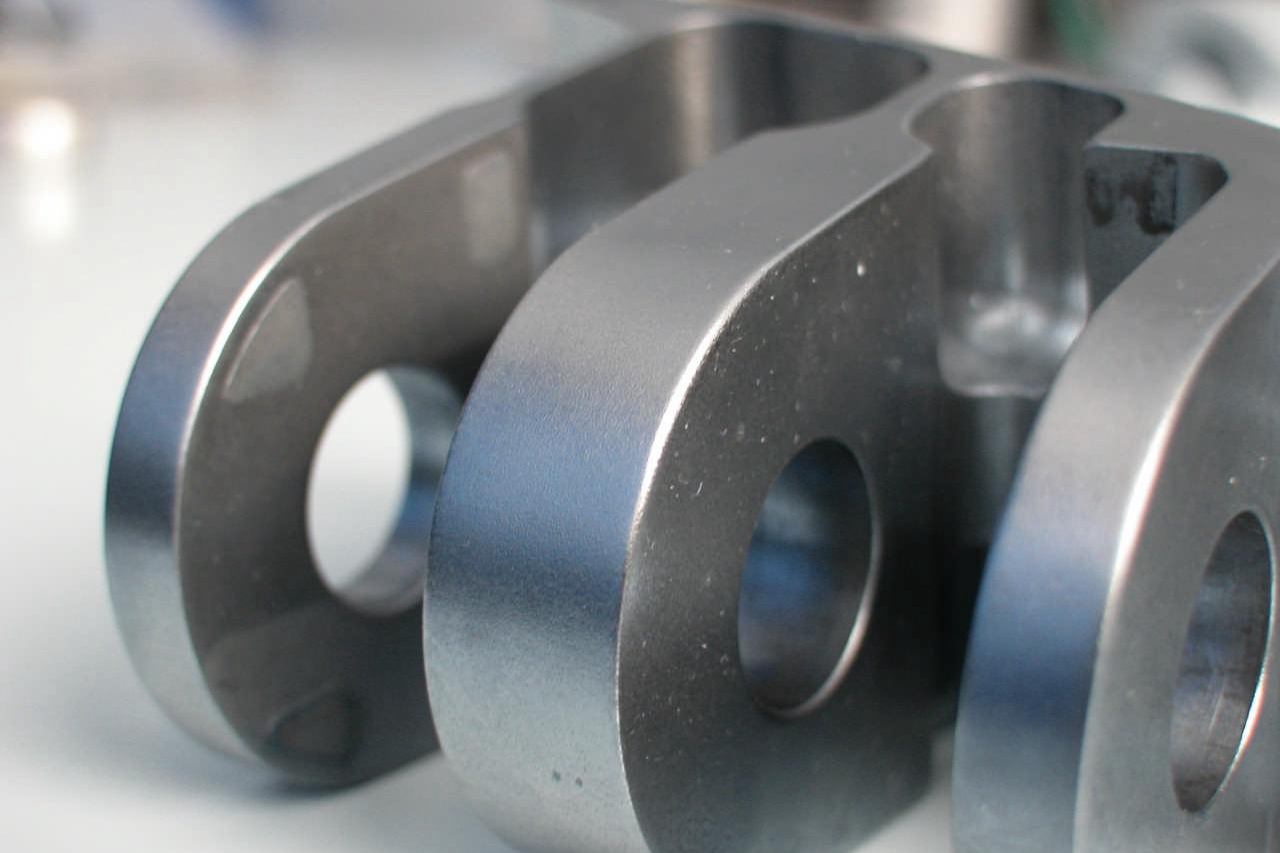

powder-metallurgy-superalloy-parts-manufacturer

learn more

Precision Machining Services for Superalloy Turbine Discs

learn more

Custom CNC Machining for Superalloy Powder Metallurgy Parts

learn more

Superalloy Turbine Disc CNC Manufacturing and Fabrication

learn more

Advanced CNC Machining Solutions for Powder Metallurgy Parts

learn more

Expert Fabrication of Superalloy Turbine Discs Using CNC Machining

learn more

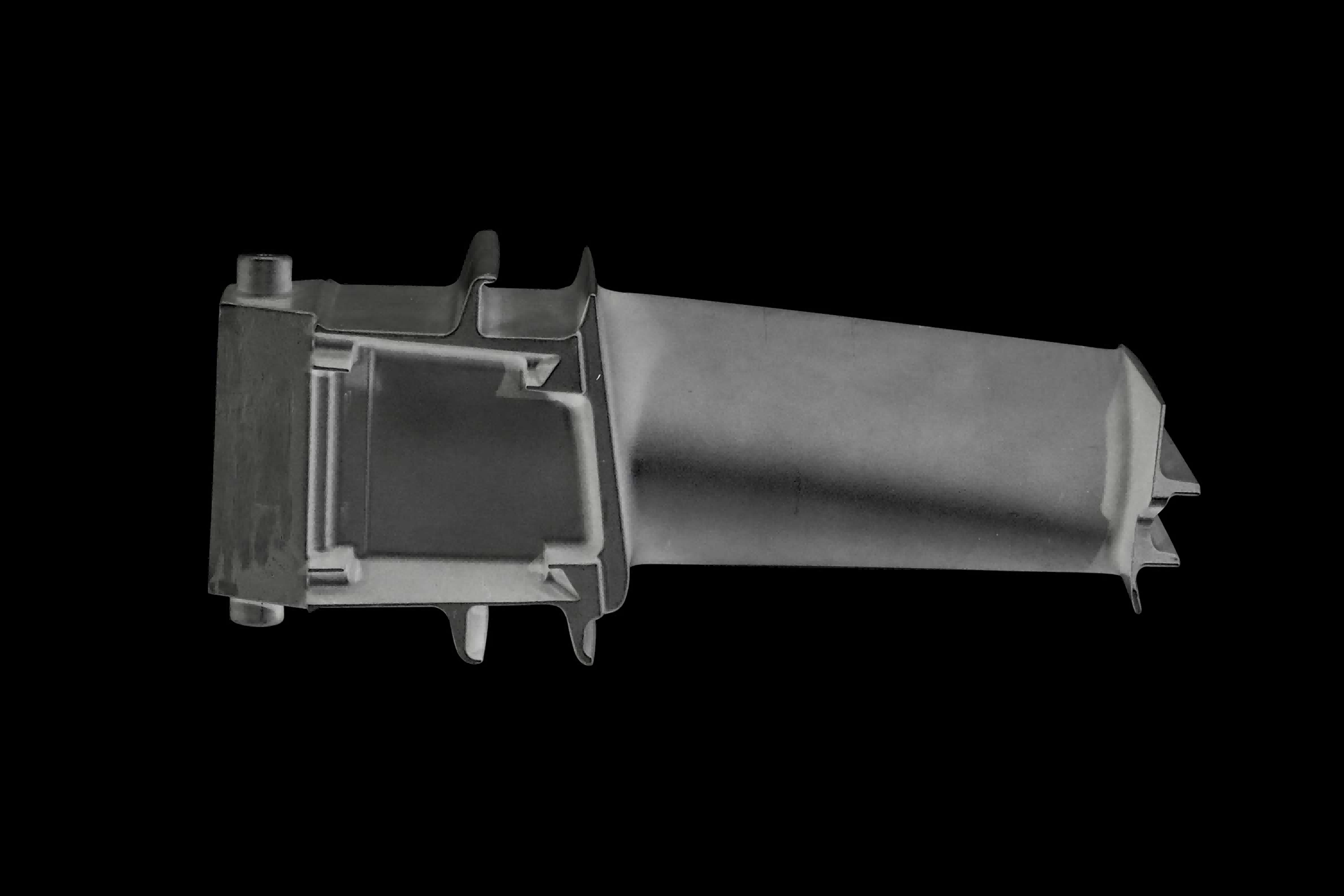

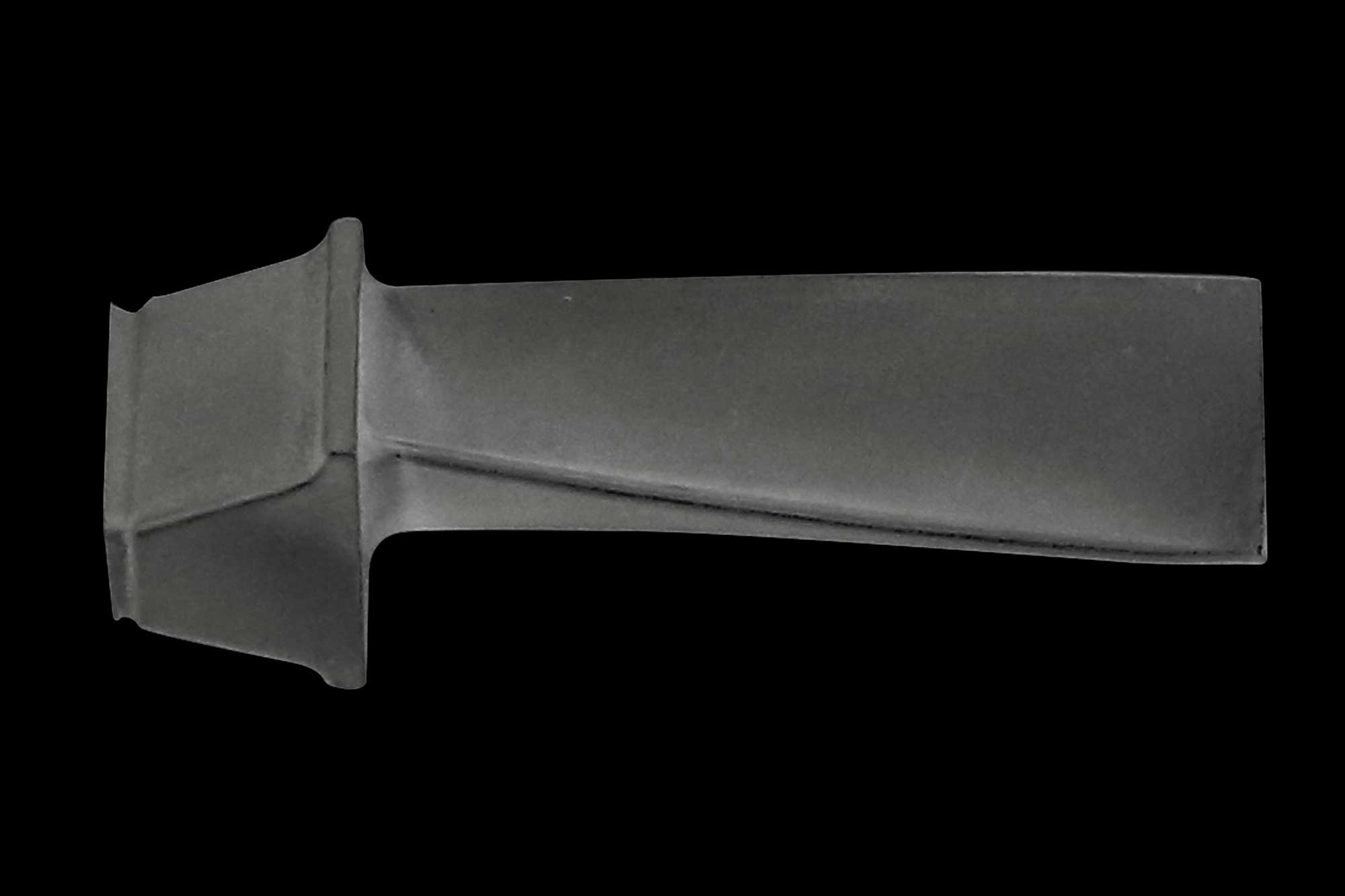

vacuum-investment-casting-superalloy-parts-manufacturer

learn more

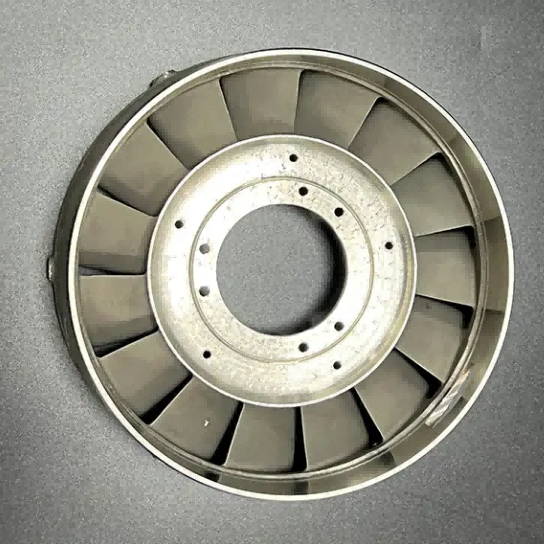

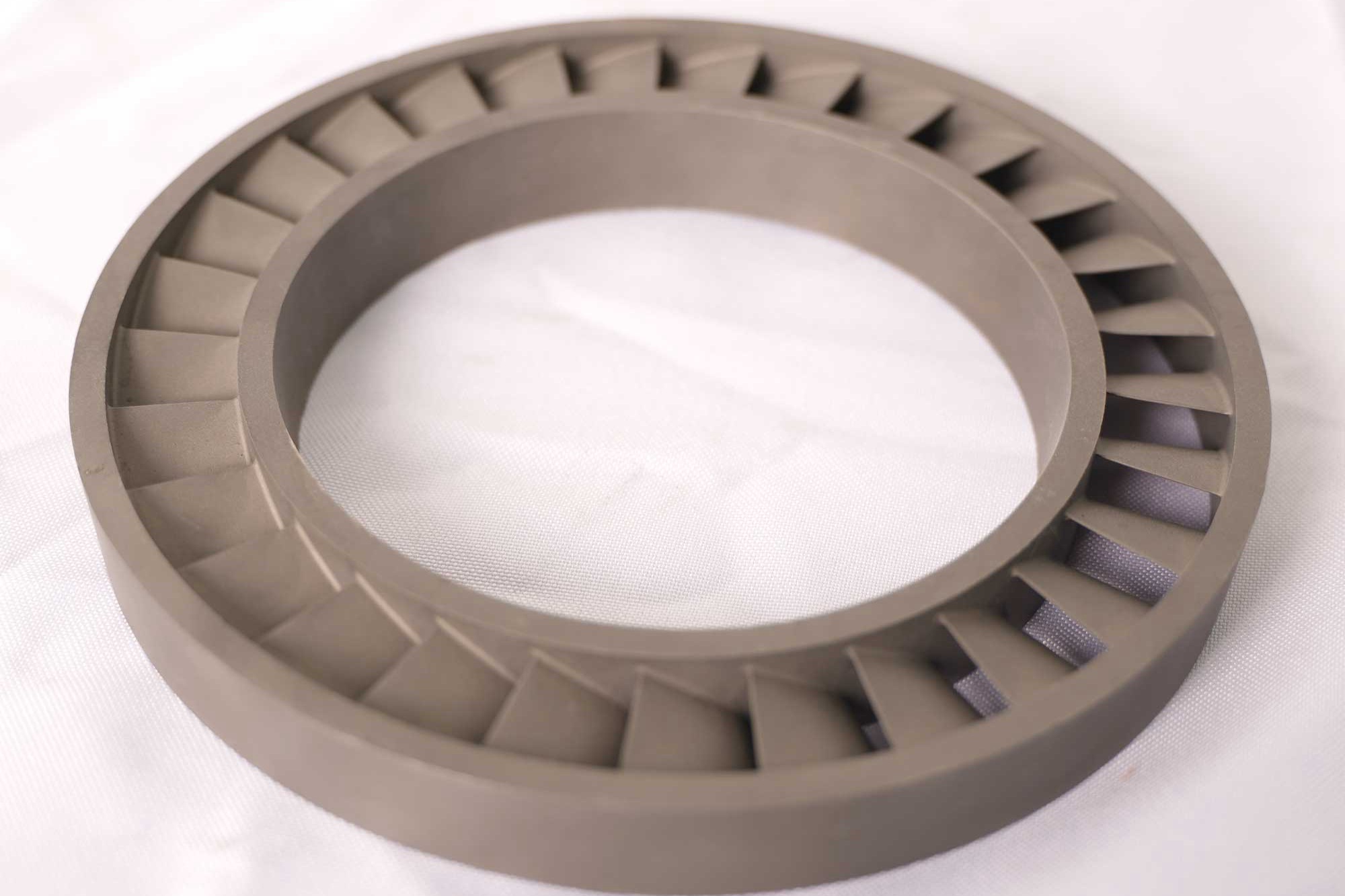

Special High-Temperature Alloy Investment Casting Nozzle Ring Manufacturer

learn more

Superalloy Vacuum Casting Turbine Components Production Factory

learn more

Superalloy Investment Casting Gas Turbine Nozzle Rings Corporation

learn more

Superalloy Vacuum Investment Casting Turbine Wheel Solutions

learn more

Superalloy Vacuum Investment Casting Turbo Parts Fabrication Services Provider

learn more

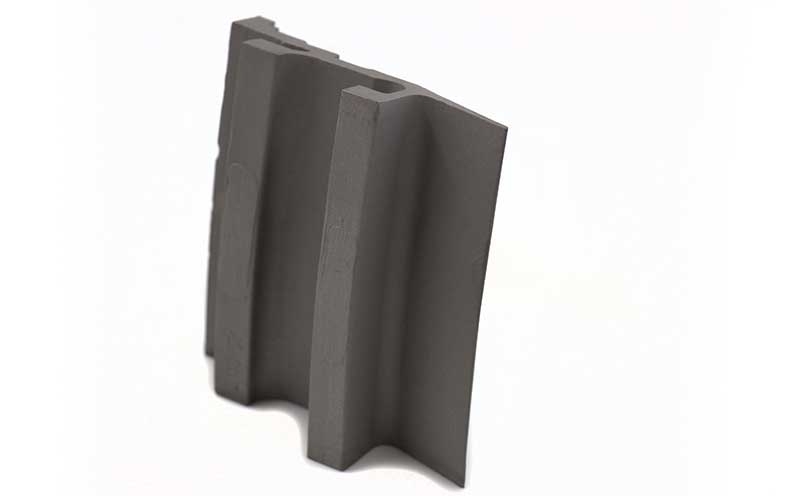

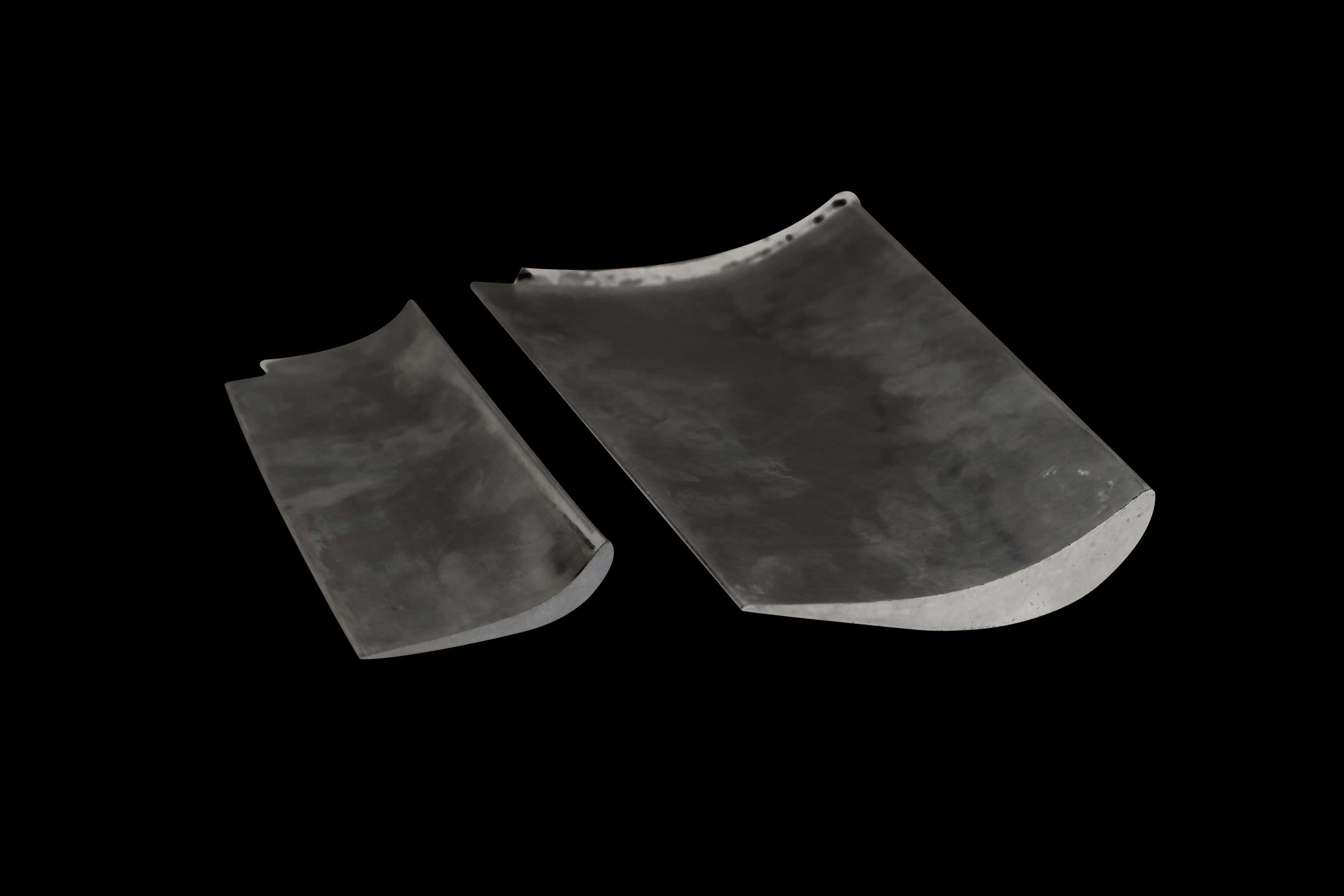

precision-forging-superalloy-parts-manufacturer

learn more

Precision Forging of Inconel Superalloy Segments Parts for High-Performance Application

learn more

Stellite Superalloy Segment Parts: Expert Precision Forging Services

learn more

Nimonic Superalloy Precision Forging Heat Shield for Superior Durability

learn more

Titanium Superalloy Precision Forging Heat Shields: Reliable and Efficient Solutions

learn more

Rene Superalloy Custom Parts: Custom Precision Forging Fabrication Services

learn more

isothermal-forging-superalloy-parts-manufacturer

learn more

Turbine Disc Precision Crafted with Inconel Alloy via Advanced Forging Techniques

learn more

Hastelloy Alloy Forging Solutions for High-Performance Turbofan Components

learn more

Stellite Alloy-Based Turbine Rotor Parts from Leading Superalloy Forging Supplier

learn more

Turbocharger Components Forged with Nimonic Alloys for Enhanced Durability

learn more

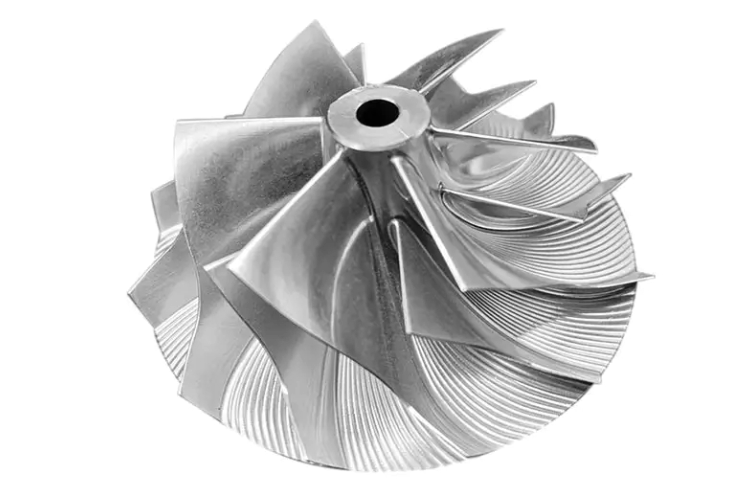

Titanium Alloy Turbine Disc Manufacturing Using Superior Isothermal Forging Methods

learn more

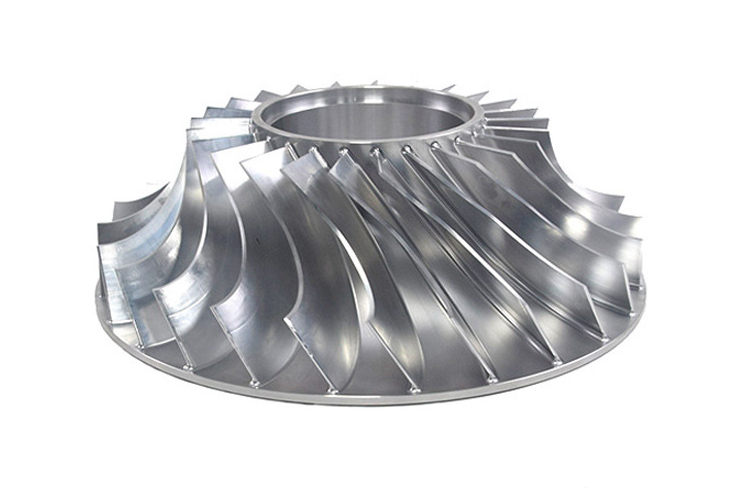

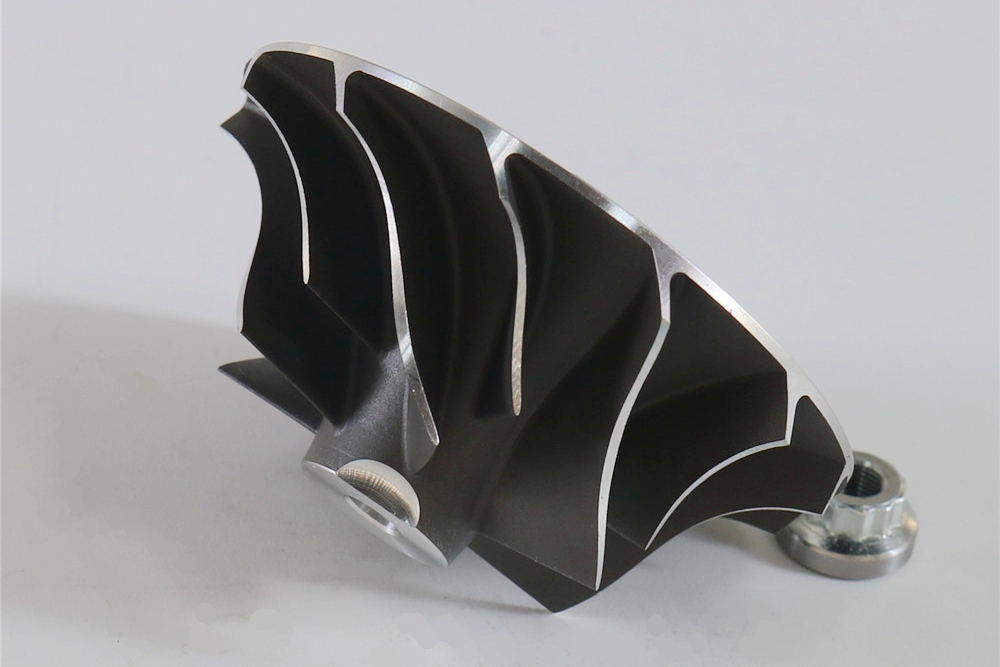

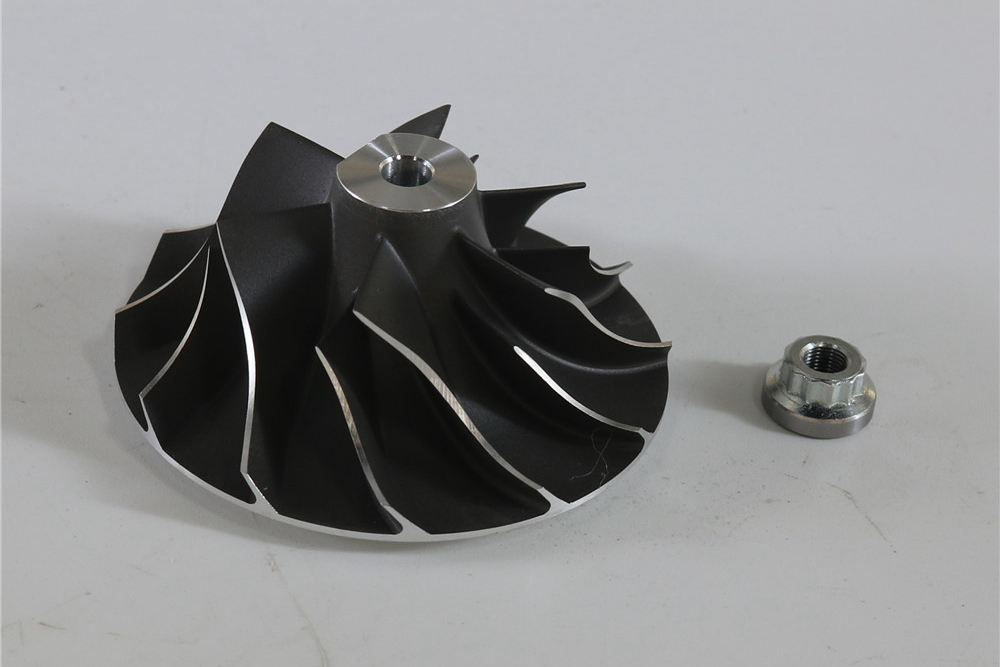

cnc-machining-superalloy-parts-manufacturer

learn more

Forced Induction System Components Machined with Inconel Alloy Precision CNC

learn more

Hastelloy Alloy CNC Machining for Turbo Supercharger Parts with Superior Accuracy

learn more

Stellite Alloy CNC Machining Solutions for Boosting Compressor Components

learn more

Nimonic Alloy Turbo Booster Parts Precision Machined for Maximum Performance

learn more

Titanium Alloy CNC Machining Services for Reliable Turbocharging Unit Components

learn more

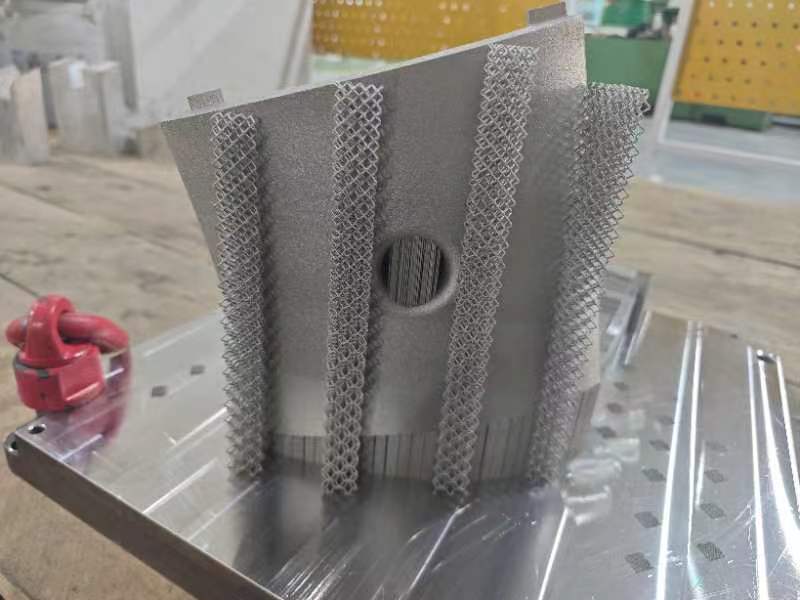

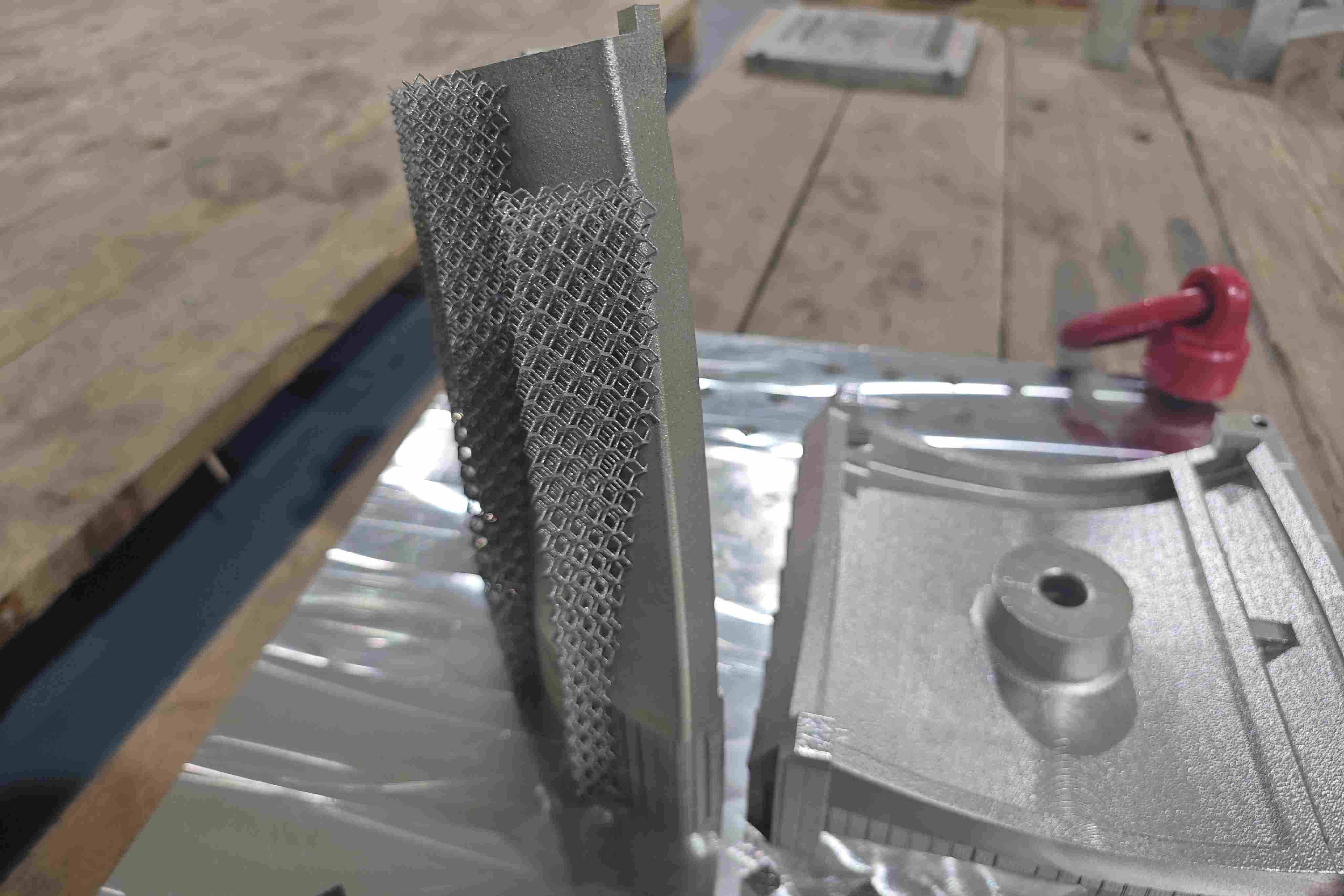

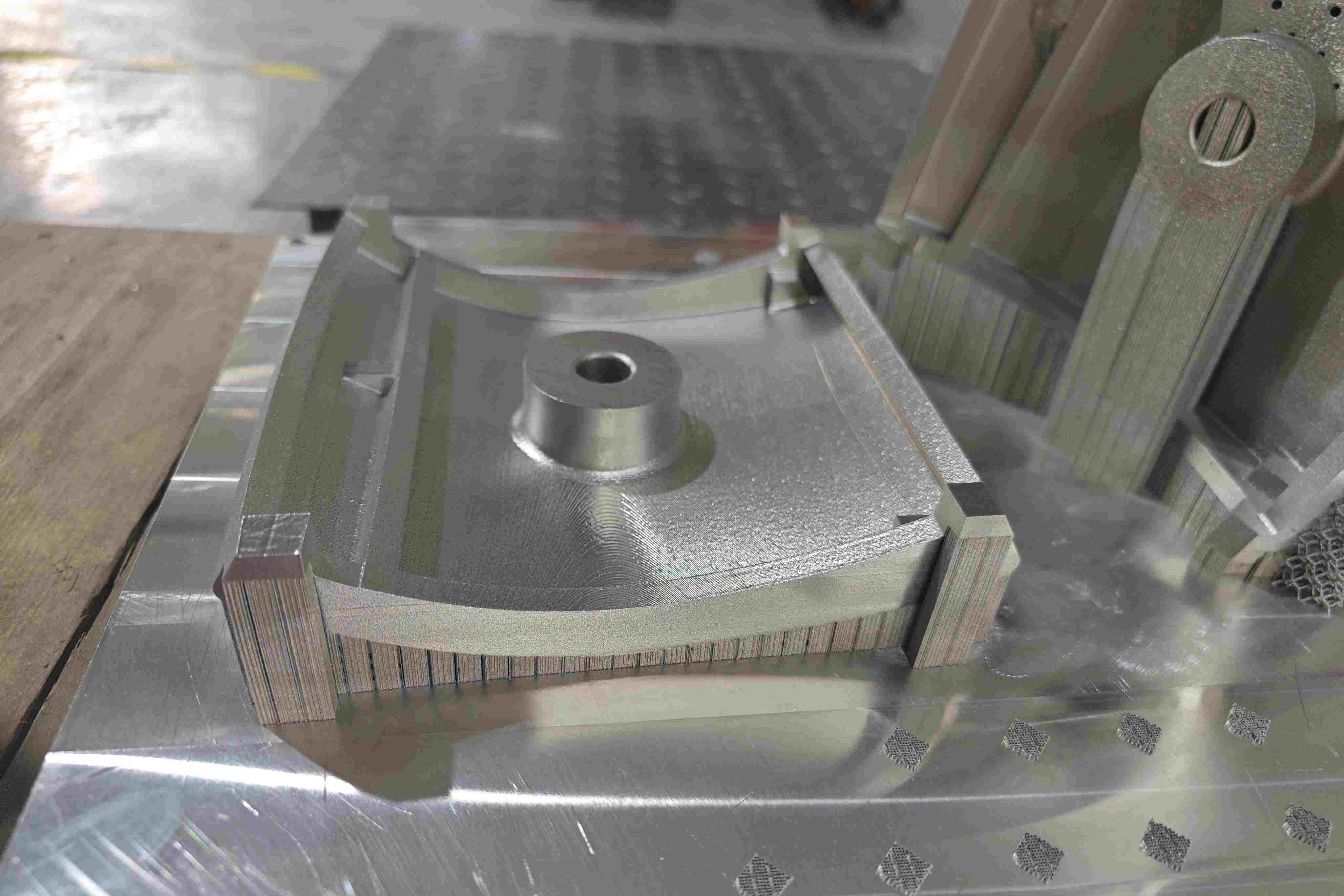

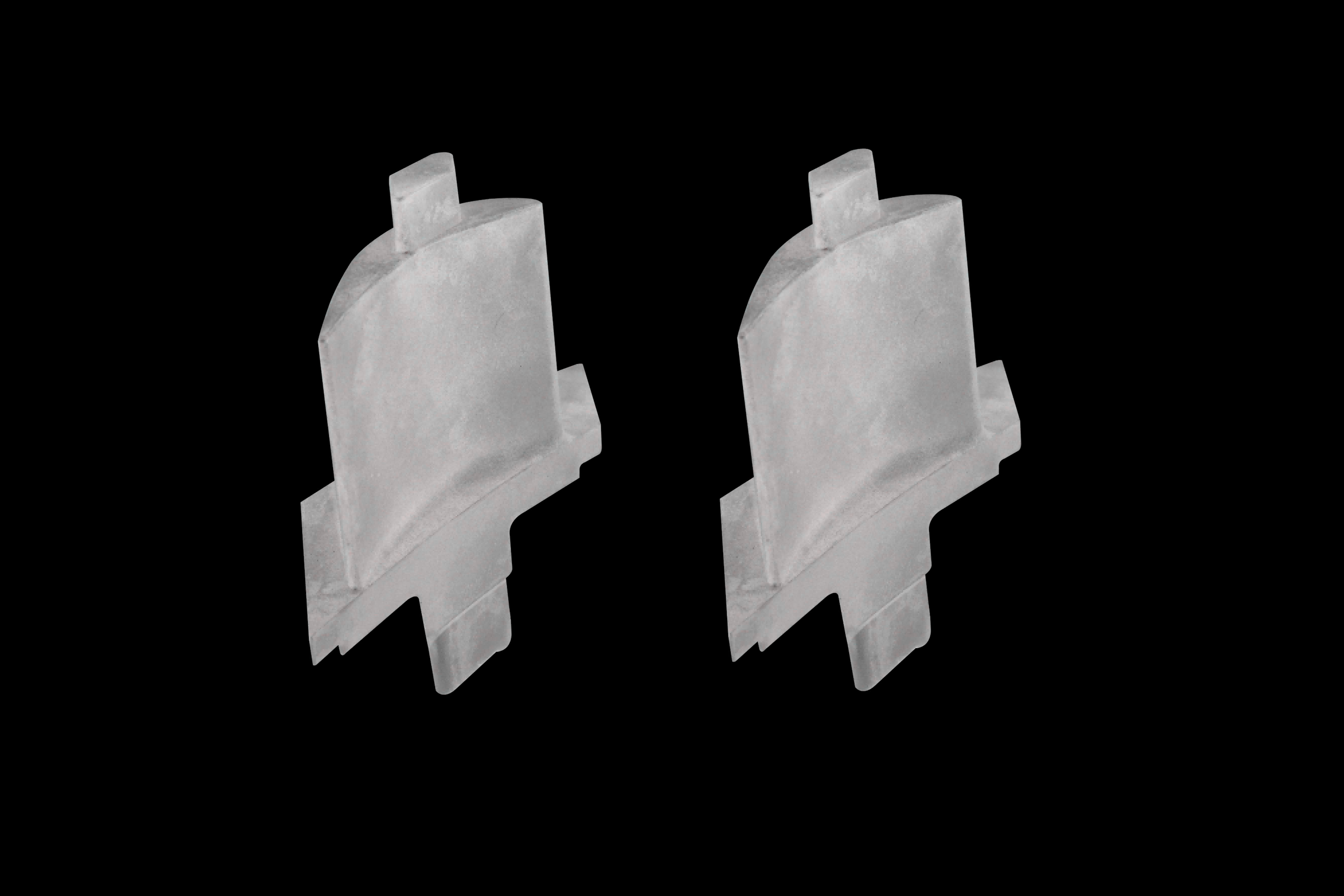

3d-printing-superalloy-parts-manufacturer

learn more

Inconel Alloy 3D Printed Thermal Barriers for Extreme Temperature Protection

learn more

Hastelloy Alloy Heat Protectors 3D Printed for Advanced Thermal Resistance

learn more

Stellite Alloy Insulating Shields 3D Printed for High-Temperature Applications

learn more

Nimonic Alloy Temperature Shields with Precision 3D Printing for Superior Insulation

learn more

Titanium Alloy Thermal Guards 3D Printed for Optimal Heat Resistance Performance

learn more

inconel-alloy-superalloy-parts-manufacturer

learn more

Casting Superalloys Inconel 625 Turbine Blade Vacuum Investment Casting Manufacturer

learn more

Superalloy Inconel 713 Turbine Blade Single Crystal Casting Supplier

learn more

High-Temperature Alloys Inconel 738 Turbine Blade Equiaxed Crystal Casting Company

learn more

Nickel Alloys Inconel 713C Turbine Blade Superalloy Directional Casting Factory

learn more

Cobalt Alloys Inconel 738LC Turbine Blade Isothermal Forging Foundry

learn more

cmsx-series-superalloy-parts-manufacturer

learn more

Casting Superalloys CMSX-4 Turbine Blade Single Crystal Casting Manufacturer

learn more

Superalloy CMSX-10 Turbine Blade Single Crystal Casting Supplier

learn more

High-Temperature Alloys CMSX-8 Turbine Blade Single Crystal Casting Company

learn more

Nickel-Based Alloys CMSX-6 Turbine Blade Single Crystal Casting Factory

learn more

Cobalt-Based Alloys CMSX-11 Turbine Blade Single Crystal Casting Foundry

learn more

monel-alloy-custom-superalloy-parts-manufacturer

learn more

Monel 400 Valve Parts Vacuum Investment Casting Manufacturer

learn more

Monel 401 Valve Components Equiaxed Crystal Casting Supplier

learn more

Monel 404 Pump Body Lost Wax Casting Company

learn more

Monel 450 Pump Components Single Crystal Casting Factory

learn more

Monel K500 Pump Parts Precision Investment Casting Foundry

learn more

hastelloy-alloy-custom-superalloy-parts-manufacturer

learn more

Hastelloy B Valve Parts Vacuum Investment Casting Manufacturer

learn more

Hastelloy B-2 Valve Components Equiaxed Crystal Casting Supplier

learn more

Hastelloy B-3 Pump Body Lost Wax Casting Company

learn more

Hastelloy C-4 Pump Components Single Crystal Casting Factory

learn more

Hastelloy C-22 Pump Parts Precision Investment Casting Foundry

learn more

stellite-alloy-custom-superalloy-parts-manufacturer

learn more

Turbine Nozzle Assembly Machined with Stellite Alloys for High-Precision Performance

learn more

Stellite Alloy Exhaust Nozzle Rings CNC Machined for Optimal Heat Resistance

learn more

Stellite 4 Alloy Turbine Guide Rings Precision Machined for Maximum Efficiency

learn more

Stellite 6B Gas Flow Nozzle Rings CNC Machined for Superior Strength and Precision

learn more

Stellite 6 CNC Machining for Turbine Vane Rings with Enhanced Durability

learn more

nimonic-alloy-custom-superalloy-parts-manufacturer

learn more

Casting Superalloys Nimonic 75 Nozzle Guide Vanes Vacuum Investment Casting Manufacturer

learn more

Superalloy Nimonic 80A Guide Vanes Equiaxed Crystal Casting Supplier

learn more

High-Temperature Alloys Nimonic 81 Guide Vanes Lost Wax Casting Company

learn more

Nickel-Based Alloys Nimonic 86 Guide Vanes Precision Casting Factory

learn more

Cobalt-Based Alloys Nimonic 90 Nozzle Guide Vanes Precision Investment Casting Foundry

learn more

titanium-alloy-custom-superalloy-parts-manufacturer

learn more

Ti-6Al-4V TC4 Turbocharger Wheels 3D Printing Manufacturer

learn more

Ti-6.5Al-1Mo-1V-2Zr TA15 Turbine Wheels Superalloy Precision Forging Supplier

learn more

Ti-13V-11Cr-3Al TC11 Turbocharger Blades CNC Machining Company

learn more

TA10 Turbocharger Components Isothermal Forging Factory

learn more

Titanium Turbocharger Vacuum Investment Casting Foundry

learn more

rene-alloy-custom-superalloy-parts-manufacturer

learn more

Casting Superalloys Rene 41 Turbine Nozzle Ring Vacuum Investment Casting Manufacturer

learn more

Superalloy Rene 65 Turbine Nozzle Ring Equiaxed Crystal Casting Supplier

learn more

High-Temperature Alloys Rene 77 Turbine Nozzle Ring Lost Wax Casting Company

learn more

Nickel-Based Alloys Rene 80 Turbine Nozzle Ring Directional Casting Factory

learn more

Cobalt-Based Alloys Rene N5 Turbine Nozzle Ring Precision Investment Casting Foundry

learn more

single-crystal-alloy-custom-superalloy-parts-manufacturer

learn more

PWA 1480 Turbomachine Blade Monocrystalline Casting Manufacturer

learn more

CMSX-2 High-Temperature Gas Turbine Blade Monocrystal Casting Supplier

learn more

Rene N5 Superalloy Aeroengine Blade Monocrystalline Casting Company

learn more

PWA 1484 Superalloy Compressor Blade Monocrystal Alloy Casting Factory

learn more

CMSX-4 High-Pressure Turbine Blade Monocrystal Alloy Casting Foundry

learn more

aerospace-and-aviation-superalloy-parts-manufacturer

learn more

Inconel Superalloy Aerospace Parts Custom Manufacturer for Aviation Applications

learn more

Hastelloy Superalloy Aerospace Parts Custom Supplier for Aviation Industry

learn more

Stellite Alloy High-Temperature Aerospace Parts Custom Company for Aviation

learn more

Nimonic Alloy High-Temp Aerospace Parts Custom Factory for Aviation Use

learn more

Titanium Alloy Aerospace Parts Custom Service for High-Temperature Applications

learn more

superalloy-parts-in-power-generation-industries

learn more

Power Generation Inconel Superalloy Parts Custom Nozzle Rings Manufacturer

learn more

Power Generation Hastelloy Superalloy Parts Custom Nozzle Rings Supplier

learn more

Power Generation Nimonic Superalloy Parts Custom Nozzle Rings Company

learn more

Power Generation Rene Superalloy Parts Custom Nozzle Rings Factory

learn more

Power Generation High-Temperature Parts Custom Nozzle Rings Foundry

learn more

superalloy-parts-in-oil-and-gas-industries

learn more

Oil and Gas Inconel Parts Custom Superalloy Components Manufacturer

learn more

Oil and Gas Hastelloy Parts Custom Superalloy Components Supplier

learn more

Oil and Gas Nimonic Parts Custom Superalloy Components Company

learn more

Oil and Gas Rene Parts Custom Superalloy Components Factory

learn more

Oil and Gas Parts High-Temperature Custom Components Foundry

learn more

superalloy-parts-in-energy-industries

learn more

Energy Gas Turbine Combustion Chamber Parts Custom Inconel Superalloy Components Manufacturer

learn more

Energy Gas Turbine Combustion Chamber Parts Custom Hastelloy Superalloy Components Supplier

learn more

Energy Gas Turbine Combustion Chamber Parts Custom Nimonic Superalloy Components Company

learn more

Energy Gas Turbine Combustion Chamber Parts Custom Rene Superalloy Components Factory

learn more

Energy Gas Turbine Combustion Chamber Parts High-Temperature Custom Components Foundry

learn more

superalloy-parts-in-marine-industries

learn more

Superalloy Parts Marine Turbine Blade Manufacturer

learn more

Marine Turbine Blade Superalloy Parts Supplier

learn more

Marine Turbine Blade Superalloy Parts Company

learn more

Superalloy Parts Marine Turbine Blade Factory

learn more

Marine Turbine Blade Superalloy Parts Foundry

learn more

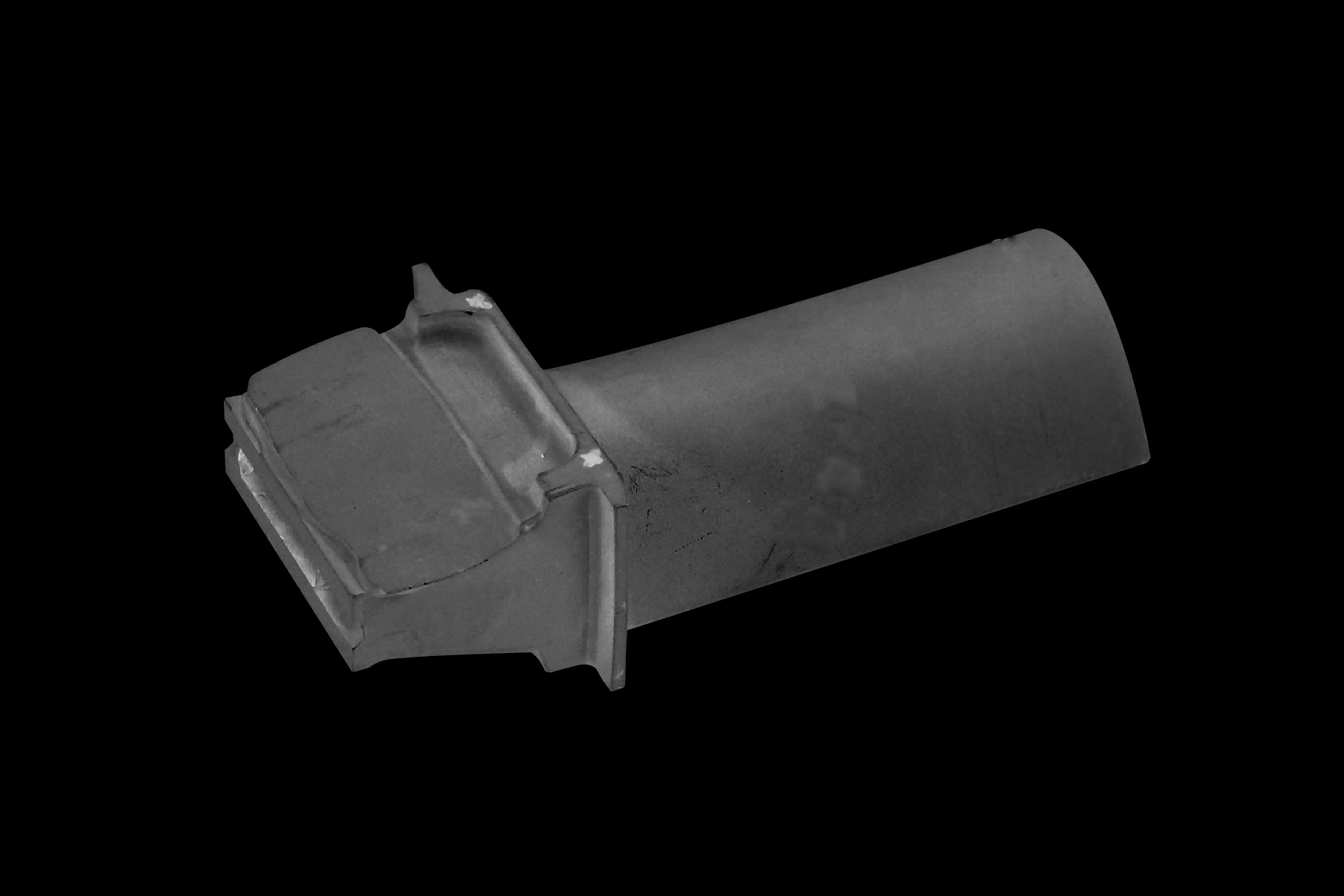

superalloy-parts-in-mining-industries

learn more

Superalloy Mining Tools Custom Parts Casting Supplier

learn more

Superalloy Mining Tools Custom Parts Casting Manufacturer

learn more

Superalloy Mining Tools Custom Parts Casting Company

learn more

Superalloy Mining Tools Custom Parts Casting Factory

learn more

Superalloy Mining Tools Custom Parts Casting Foundry

learn more

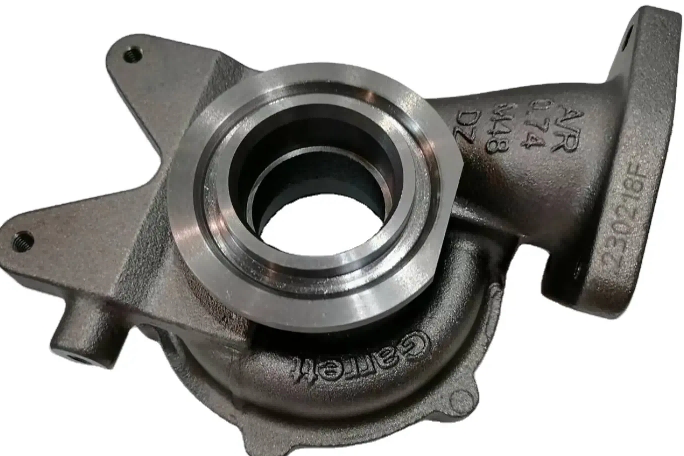

superalloy-parts-in-automotive-industries

learn more

Automotive Turbocharger Wheels Inconel CNC Machining Manufacturer

learn more

Automotive Turbocharger Blades Stellite CNC Machining Supplier

learn more

Automotive Turbine Wheels Nimonic CNC Machining Company

learn more

Automotive Turbocharger Discs Titanium Vacuum Investment Casting Factory

learn more

Automotive Turbocharger Components Rene Vacuum Investment Casting Foundry

learn more

superalloy-parts-in-chemical-processing-industries

learn more

Chemical Processing Monel Valve Components Vacuum Investment Casting

learn more

Chemical Processing Monel Pump Components Vacuum Investment Casting

learn more

Chemical Processing Monel Pump Impellers Equiaxed Crystal Casting

learn more

Chemical Processing Hastelloy Mixer Parts Valve Parts Lost Wax Casting

learn more

Chemical Processing Hastelloy High Corrosion Pump Equiaxed Crystal Casting

learn more

superalloy-parts-in-pharmaceutical-and-food-industries

learn more

Monel Alloy Sanitary Valves Casting Manufacturer

learn more

High-Temperature Alloys Sanitary Components Casting Company

learn more

Titanium Precision Components Casting Supplier

learn more

Hastelloy Sanitary Valve Bodies Casting Foundry

learn more

Nickel Alloys Pump Casings Casting Service

learn more

superalloy-parts-in-military-and-defense-industries

learn more

Casting Superalloys Turbine Blades Vacuum Investment Casting Manufacturer

learn more

Superalloy Turbine Blades Single Crystal Casting Supplier

learn more

High-Temperature Alloys Turbine Blades Equiaxed Crystal Casting Company

learn more

Inconel Alloy Turbine Blades Superalloy Directional Casting Factory

learn more

CMSX Series Turbine Blades Precision Forging Foundry

learn more

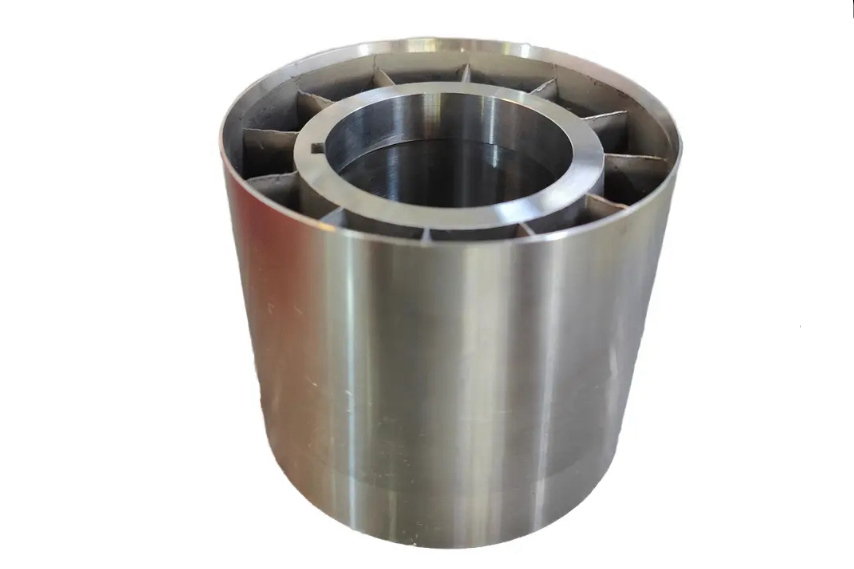

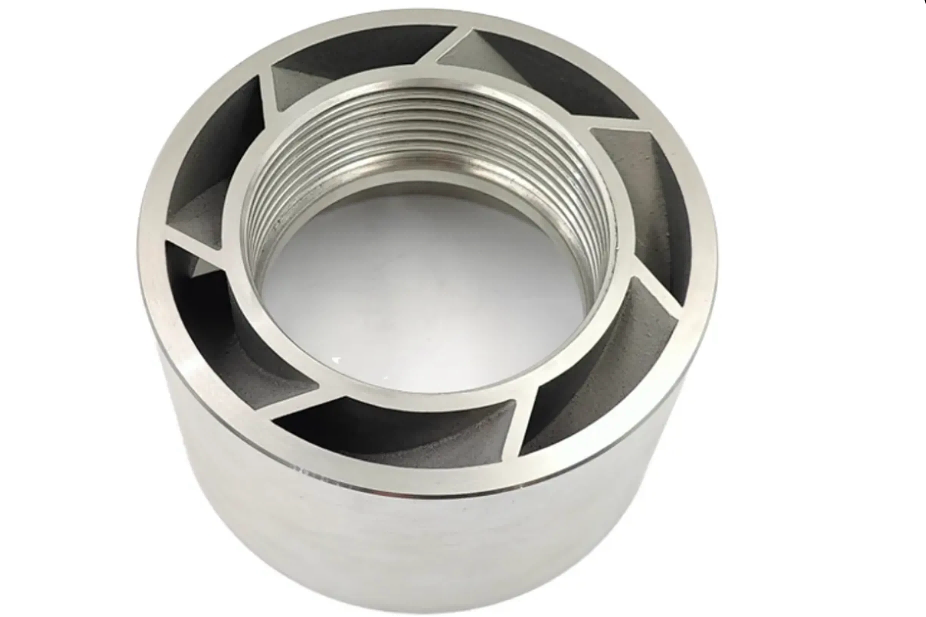

superalloy-parts-in-nuclear-industries

learn more

Nickel Alloys Nuclear Parts Superalloy Directional Casting Manufacturer

learn more

Cobalt Alloys Nuclear Parts Special Alloy Casting Supplier

learn more

Hastelloy Alloy Nuclear Parts Powder Metallurgy Turbine Disc Company

learn more

Stellite Alloy Nuclear Parts Superalloy Precision Forging Factory

learn more

Nimonic Alloy Nuclear Parts Hot Isostatic Pressing (HIP) Foundry

Let's Start A New Project Today