Hastelloy alloy Parts Manufacturing Service

At Neway, we manufacture Monel alloy components using advanced methods like vacuum investment casting and precision forging. Post-processing includes heat treatment, CNC machining, and material testing to ensure strength and corrosion resistance. These components serve industries like aerospace and chemical, offering durability in extreme environments.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Hastelloy Alloy Components Manufacturing

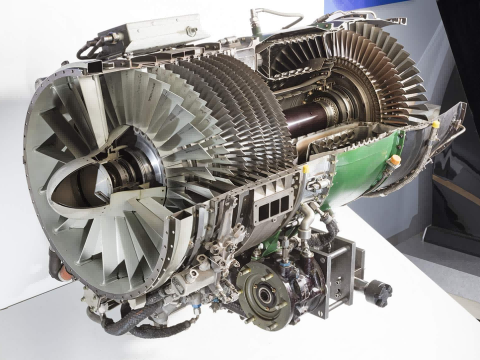

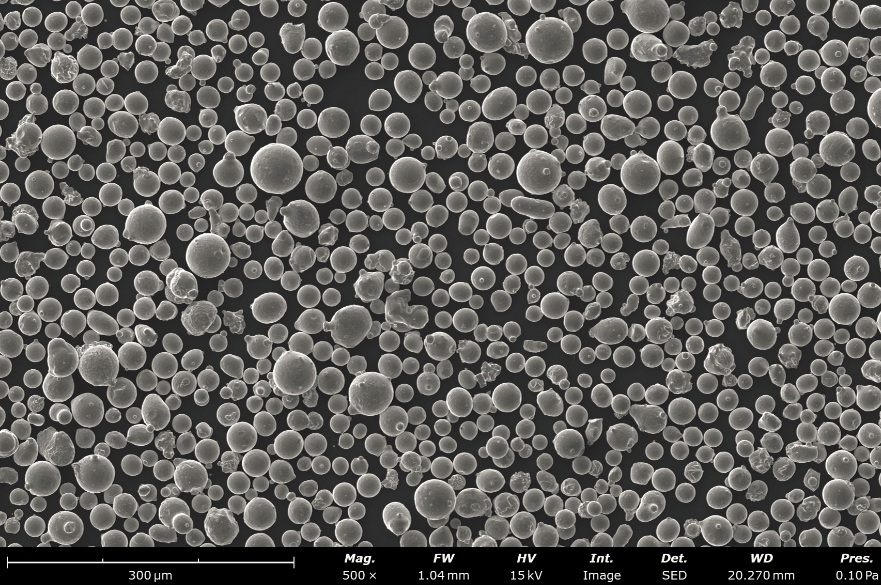

Neway manufactures Hastelloy alloy components using vacuum investment casting and precision forging techniques. Post-processing includes heat treatment, Hot Isostatic Pressing (HIP), and CNC machining for enhanced strength and corrosion resistance. These components, tested for high performance, are ideal for harsh environments in aerospace, chemical, and petrochemical industries.

Post Process for Hastelloy Casting Components

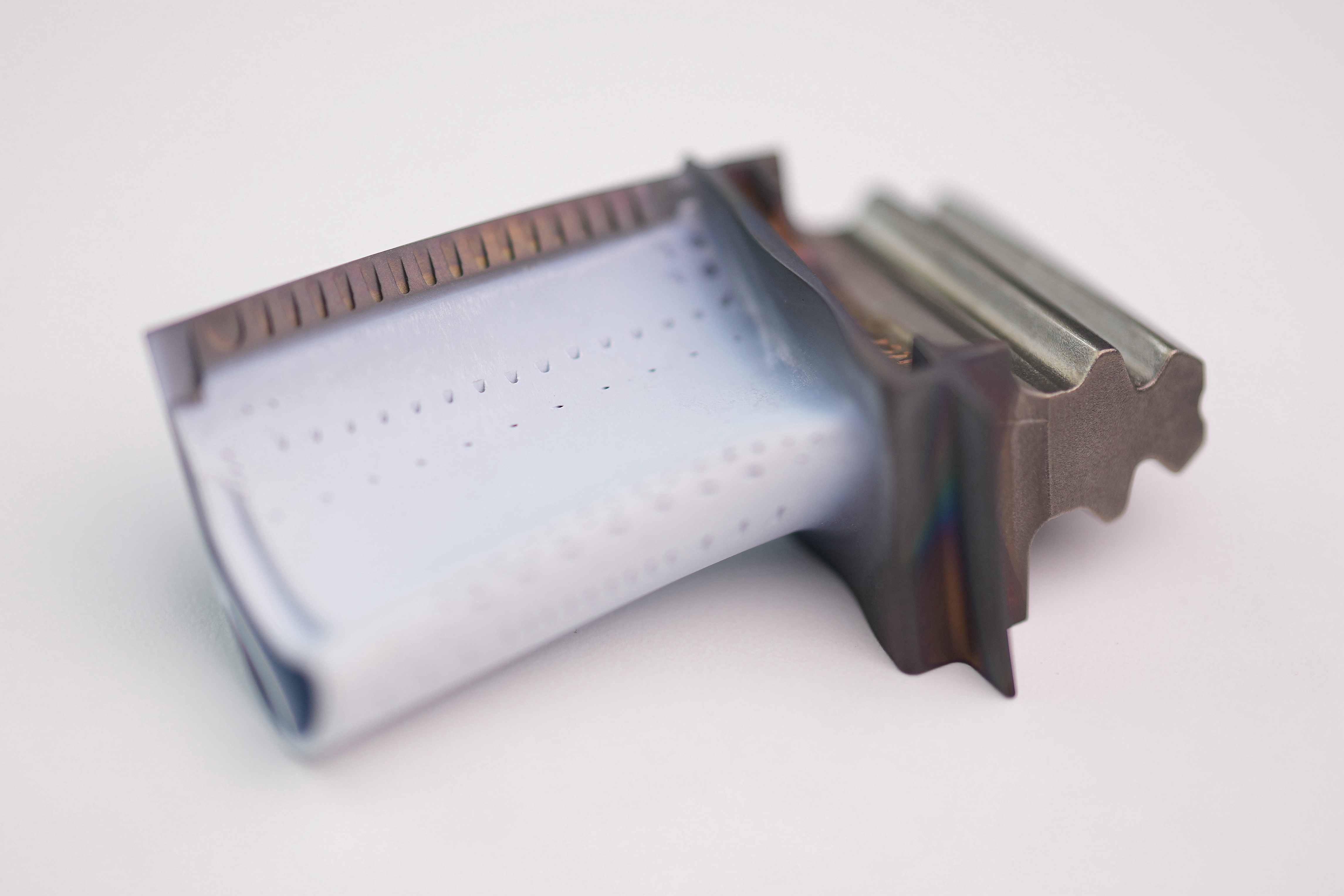

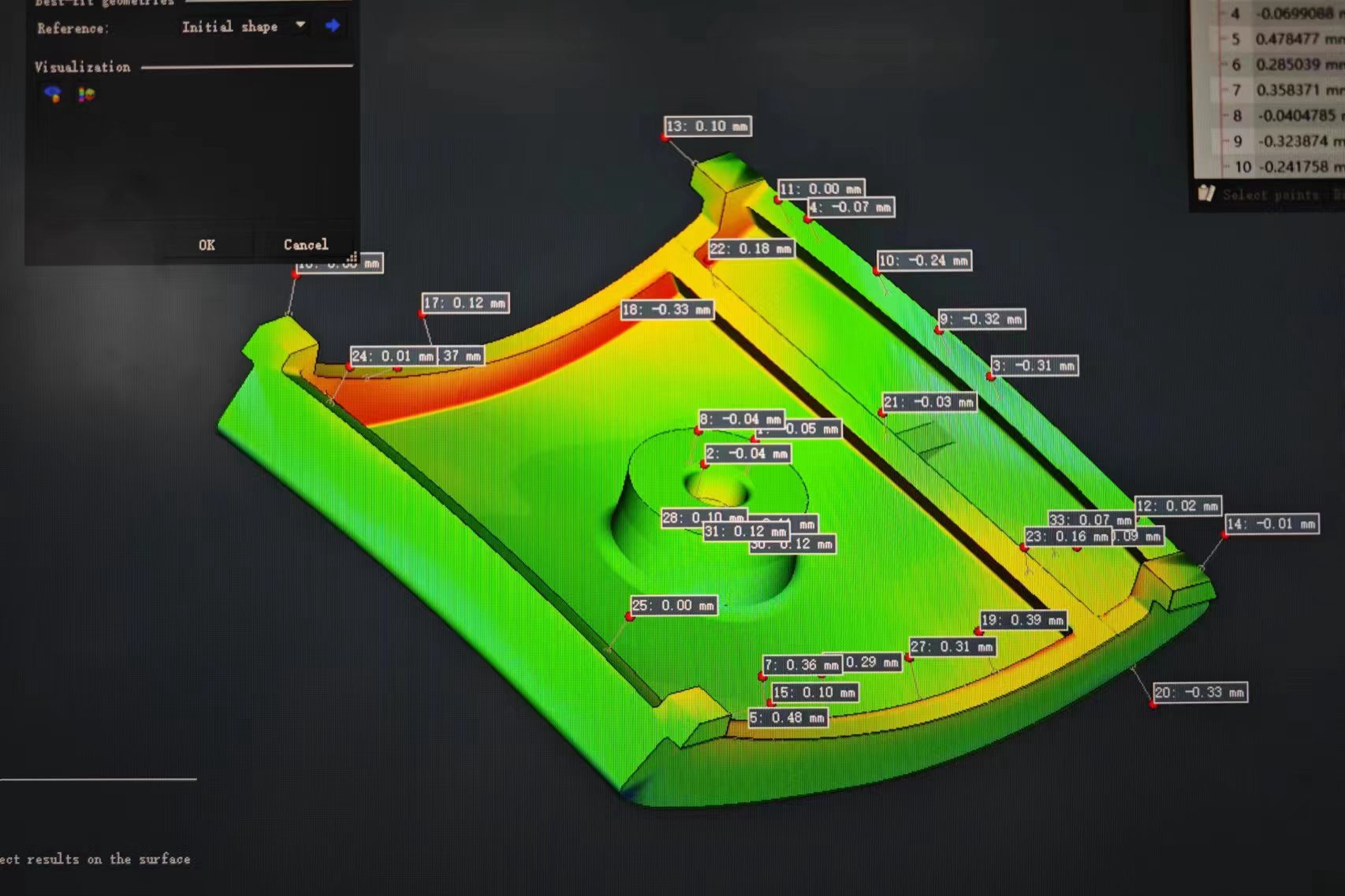

The post-process for Hastelloy casting components ensures optimal performance and durability through advanced techniques. This includes Hot Isostatic Pressing (HIP) to eliminate porosity, heat treatment to enhance mechanical properties, welding for precise joins, Thermal Barrier Coating (TBC) for high-temperature protection, CNC machining for tight tolerances, deep hole drilling, Electrical Discharge Machining (EDM) for intricate features, and thorough material testing and analysis for quality assurance.

Hastelloy alloy Materials

Hastelloy Alloy Available In Neway

Neway utilizes Hastelloy alloys like C-276, C-22, and B-3, known for excellent corrosion resistance, high strength, and durability in extreme environments. These alloys offer protection against acids, chlorides, and oxidation, making them ideal for demanding applications in aerospace, chemical, and oil & gas industries.

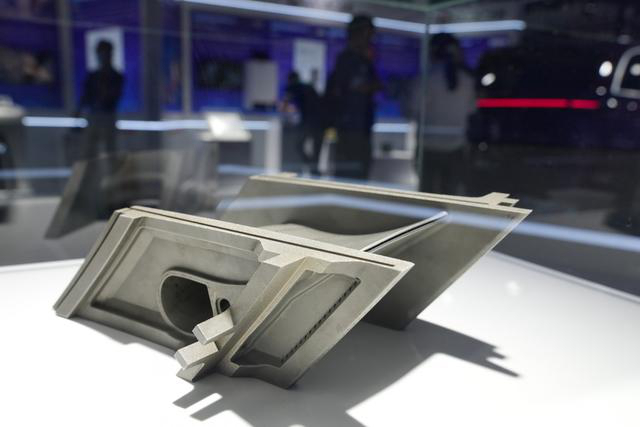

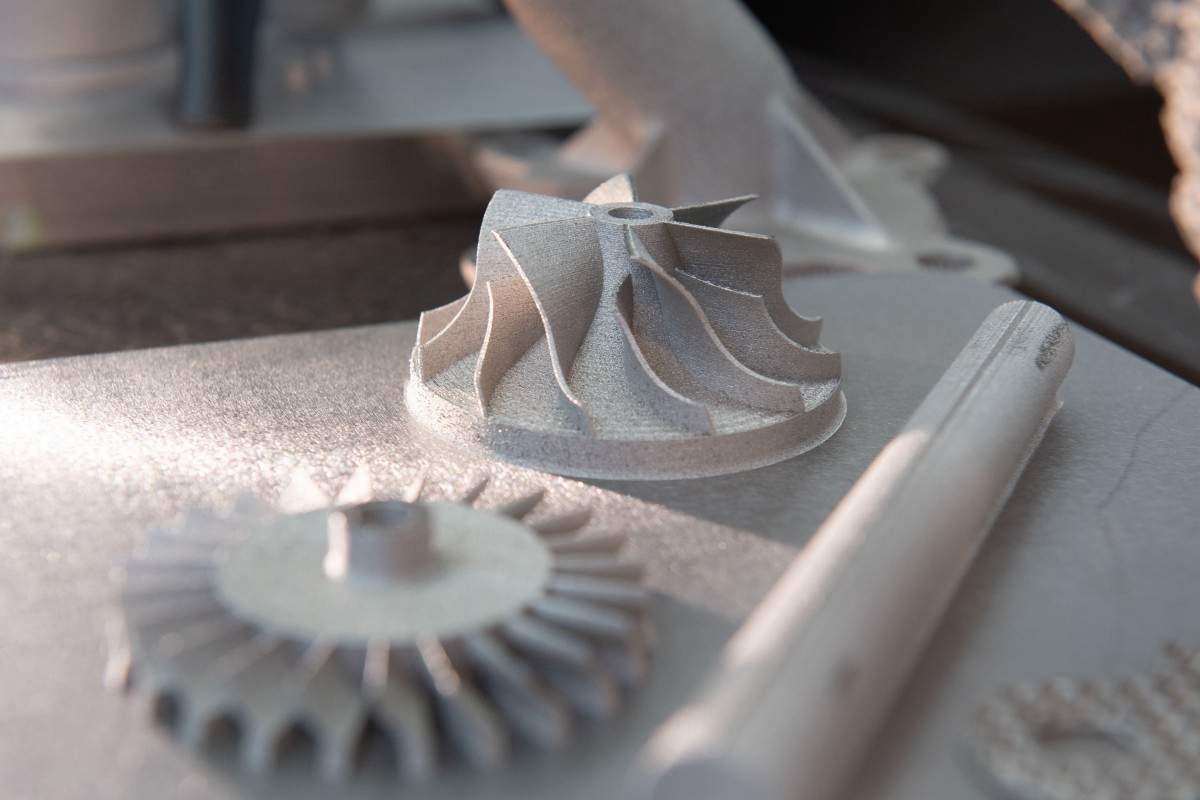

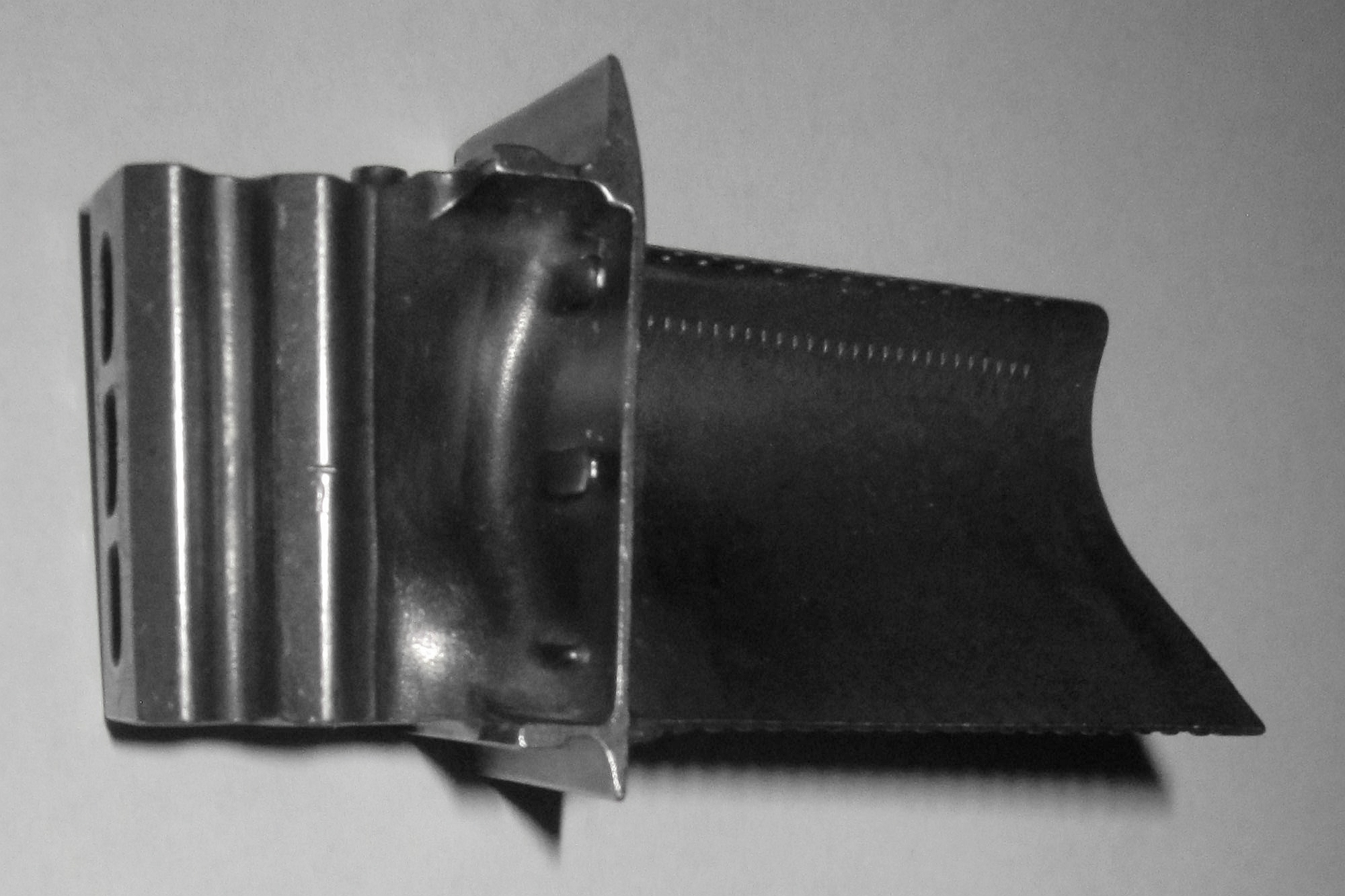

Hastelloy Alloy Parts Manufacturing Case Study

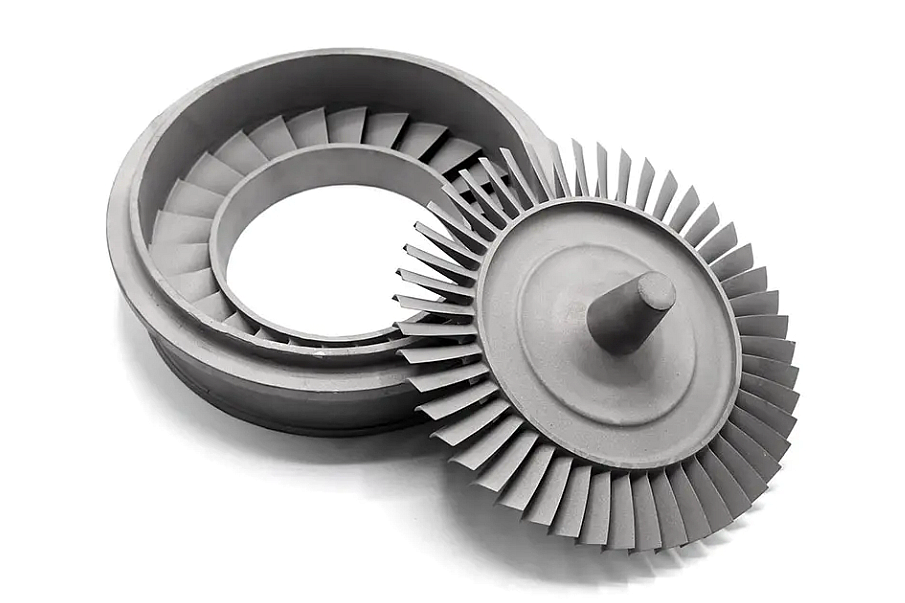

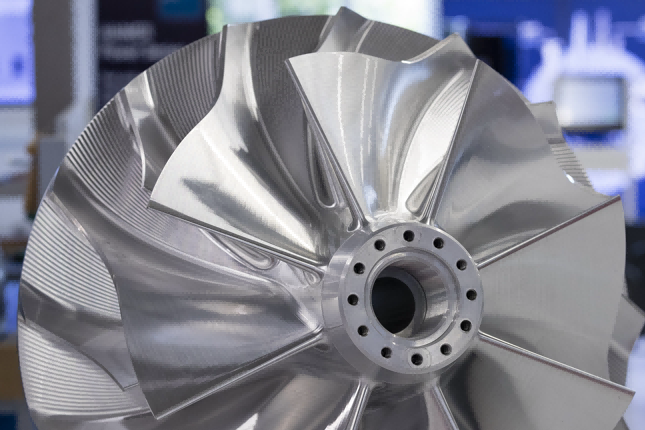

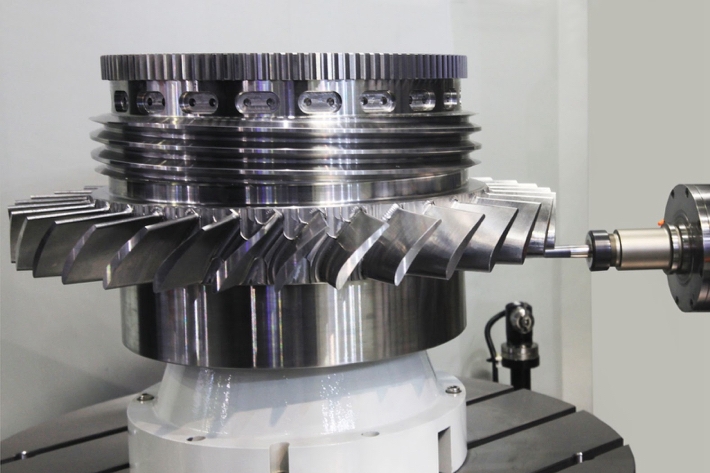

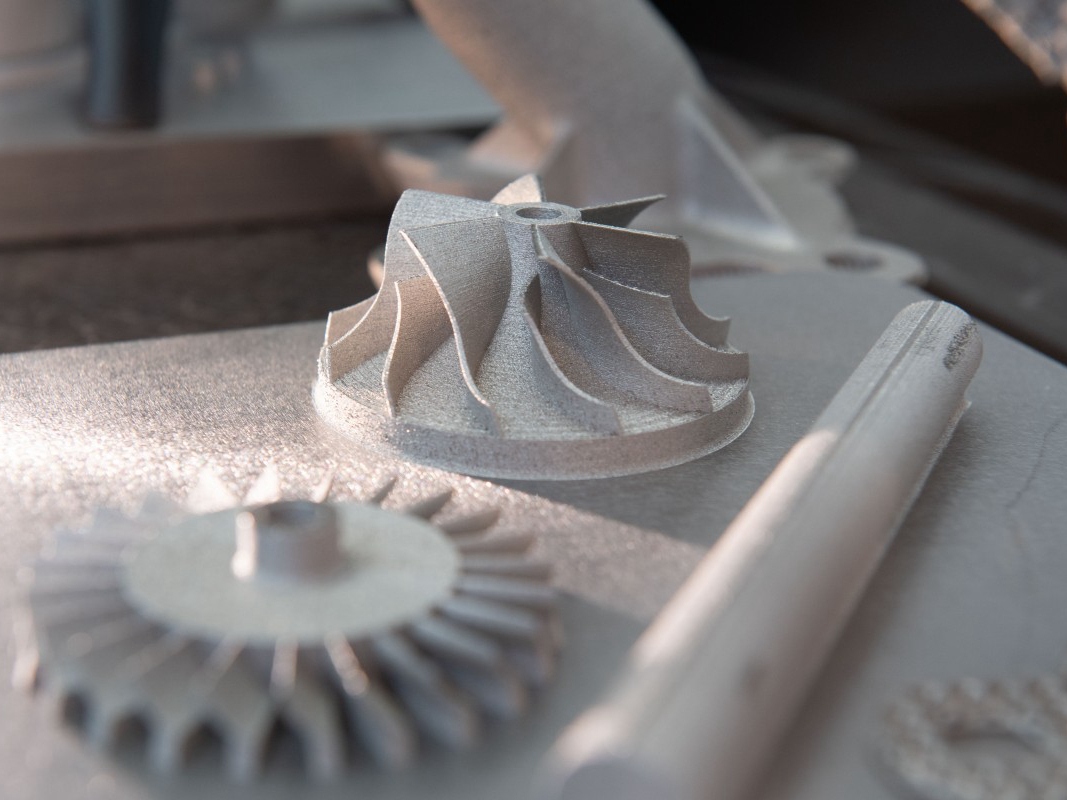

Neway specializes in manufacturing high-performance parts like turbine blades, impellers, turbine discs, combustion chambers, casings, and nozzle rings. These components, crafted from advanced alloys, are used in critical industries such as aerospace, aviation, oil & gas, and chemical processing, ensuring durability in extreme environments.

learn more

Aerospace and Aviation

learn more

Power Generation

learn more

Oil and Gas

learn more

Energy

learn more

Marine

learn more

Mining

learn more

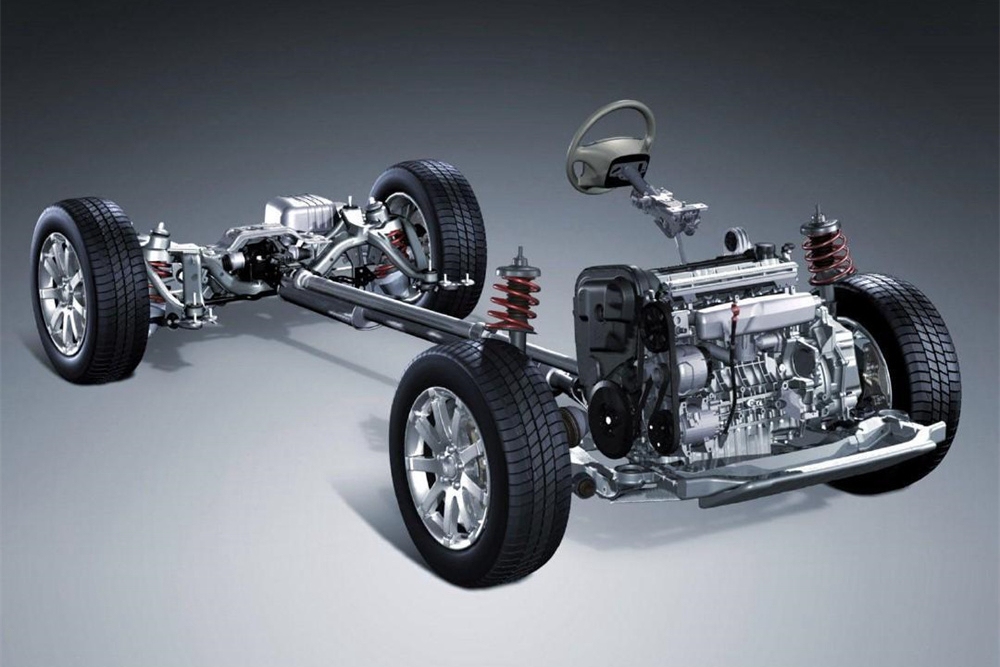

Automotive

learn more

Chemical Processing

learn more

Pharmaceutical and Food

learn more

Military and Defense

learn more

Nuclear

learn more

More Cases

learn more

New Technology

learn more

Products Gallery

learn more

Various Industries

learn more

Surface Finishings

learn more

Post-Process

learn more

Manufacturing Technology

learn more

R&D and Simulation

learn more

Manufacturing Equipments

learn more

Testing Equipments

learn more

3D Printing Prototyping

learn more

FAQs

learn more

Contact

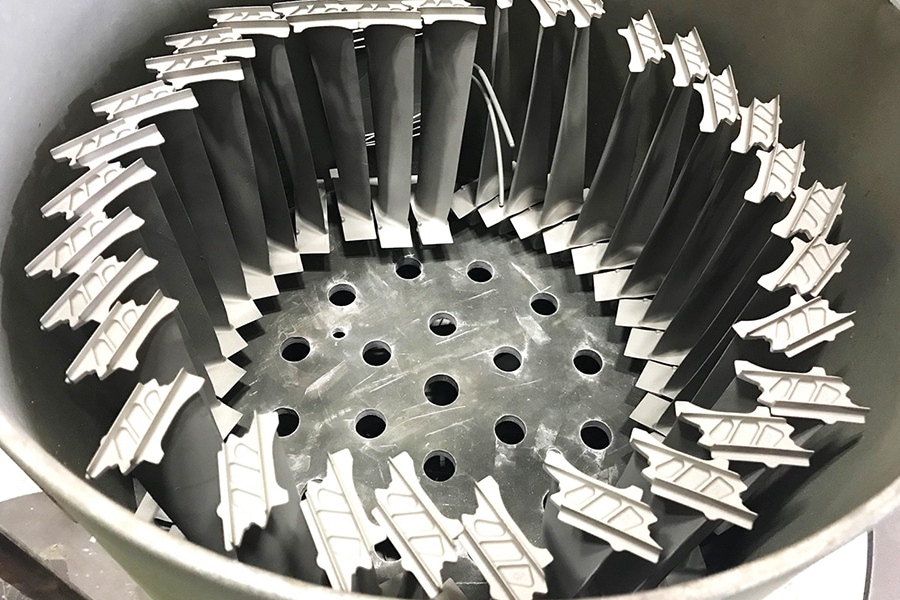

Custom Hastelloy Alloy Components Gallery

Neway has produced custom Monel alloy components, including valves, pump impellers, and marine fittings, designed for superior corrosion resistance in harsh environments. These parts are tailored for the oil & gas, marine, and chemical industries, ensuring long-term durability and performance under extreme pressure, temperature, and corrosive conditions.

Let's Start A New Project Today