Nimonic Alloy Components Manufacturing Service

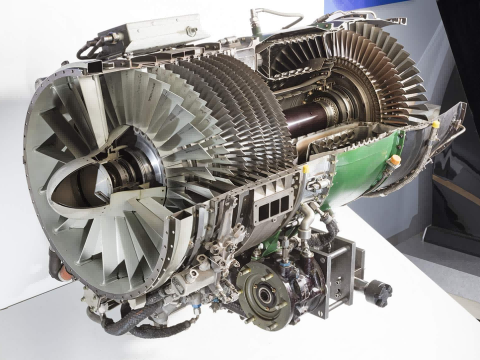

Neway Precision Works manufactures high-performance Nimonic alloy parts, specializing in turbine blades, combustion chambers, and aerospace components. Our advanced processes include precision casting, heat treatment, CNC machining, and material testing, ensuring exceptional strength, corrosion resistance, and high-temperature durability.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Nimonic Alloy Components Manufacturing

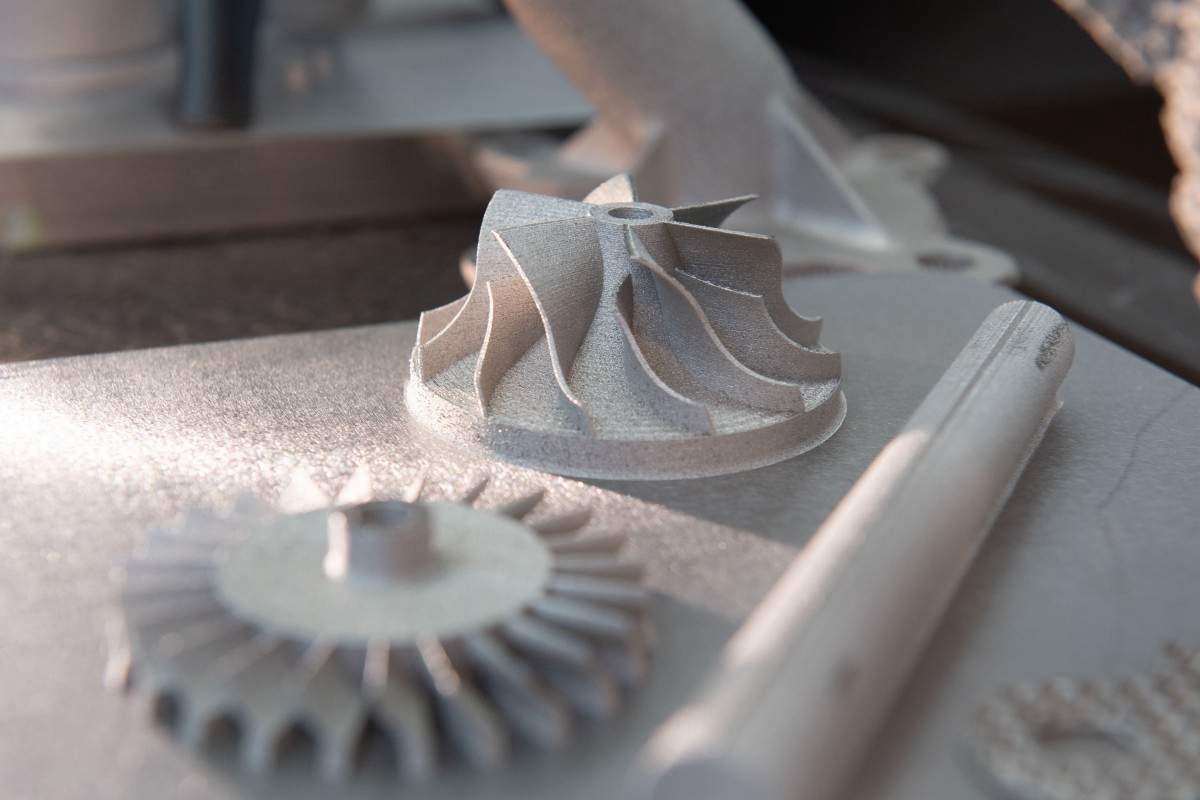

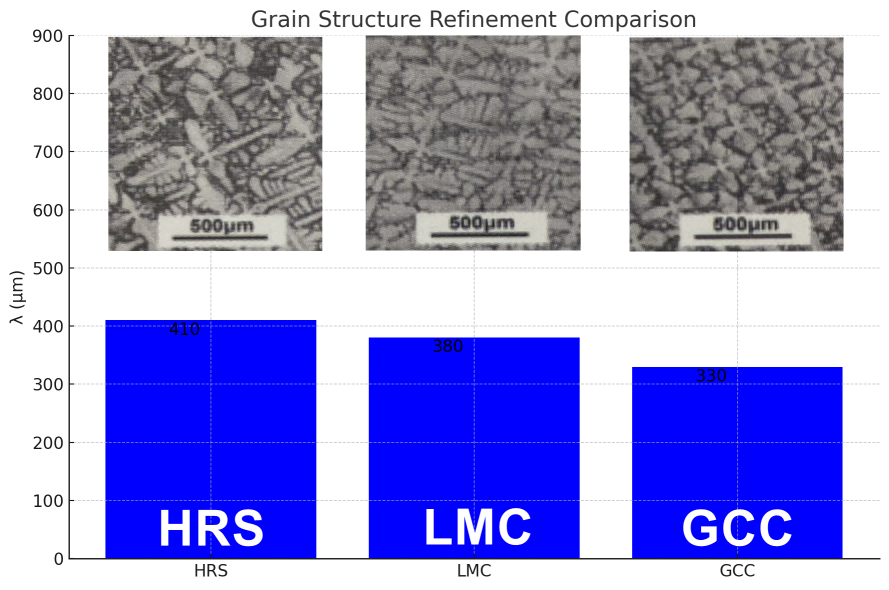

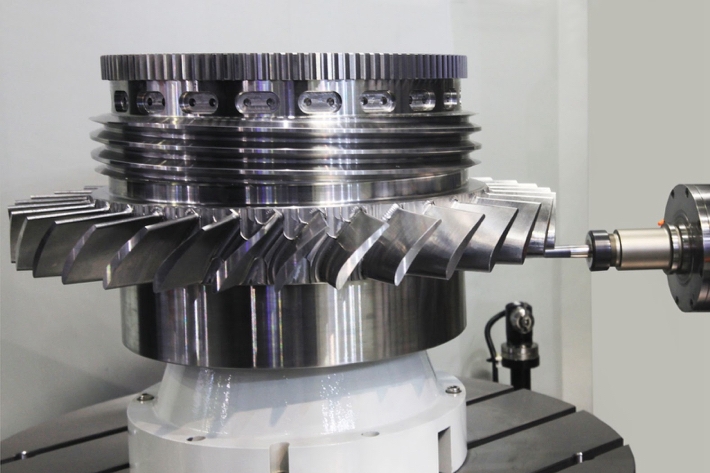

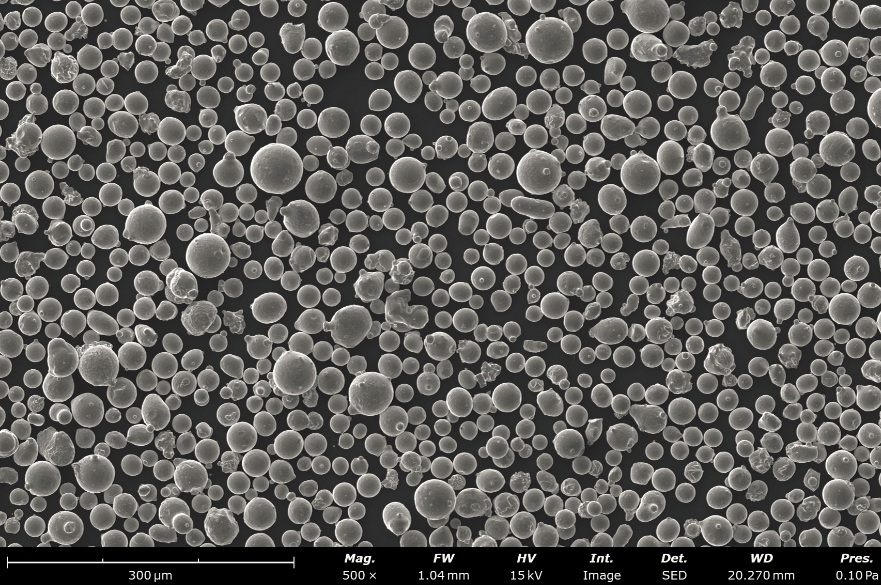

Neway Precision Works manufactures Nimonic alloy components using advanced processes such as vacuum investment casting, directional casting, and precision CNC machining. We enhance part strength and durability through heat treatment, hot isostatic pressing (HIP), and material testing, ensuring superior performance in high-temperature and corrosive environments, particularly for aerospace and turbine applications.

Nimonic alloy Materials

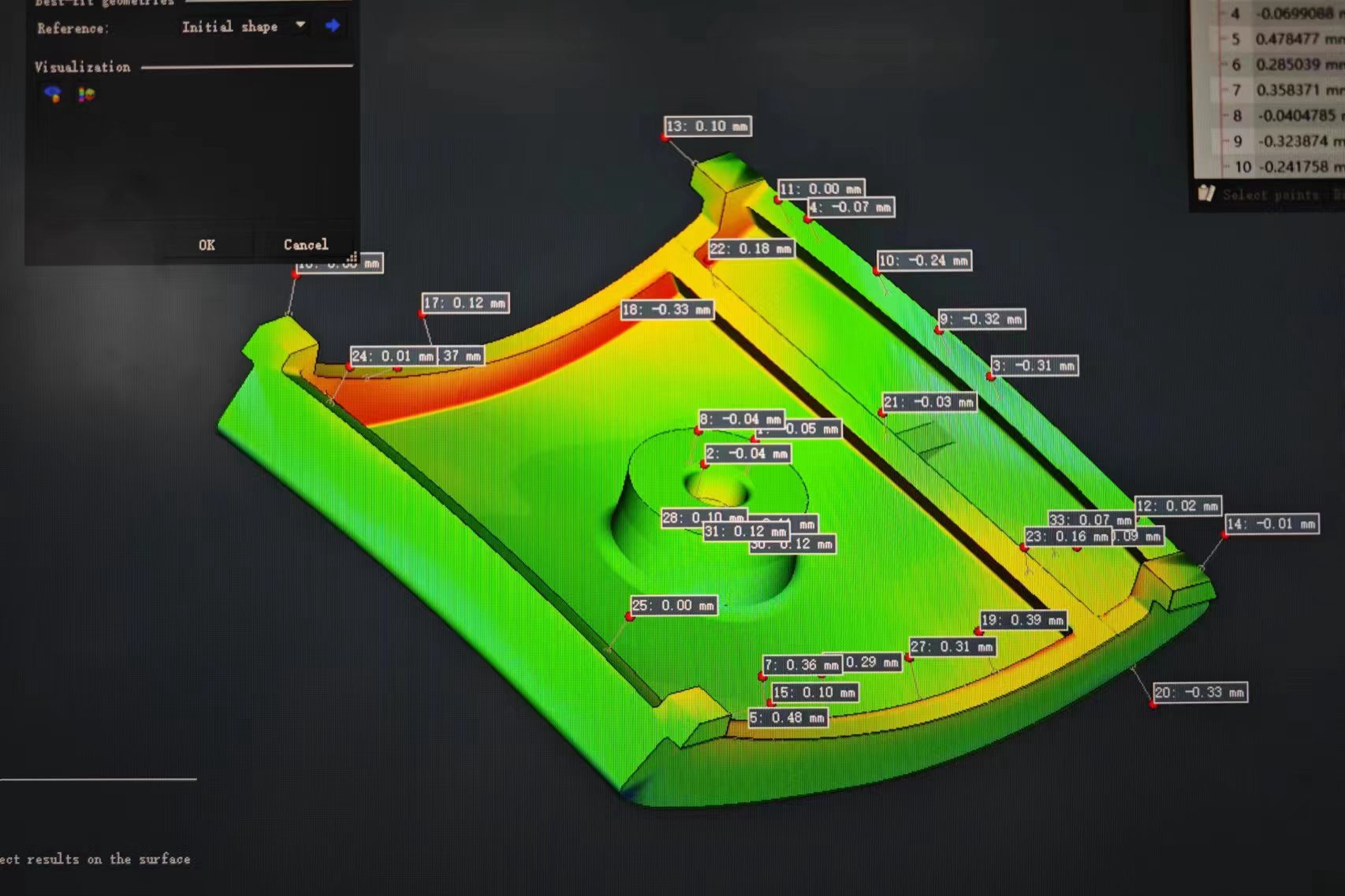

Nimonic Alloy Casting Components Post-Process Service

Our post-process services for Nimonic alloy casting components include precision Hot Isostatic Pressing (HIP) to eliminate porosity, heat treatment to enhance mechanical properties, and superalloy welding for seamless joints. We also offer Thermal Barrier Coating (TBC) for high-temperature protection, CNC machining for dimensional accuracy, and advanced material testing and analysis to ensure optimal performance and durability in critical applications.

Nimonic Alloy Available In Neway

Neway uses Nimonic alloys like Nimonic 75, 80A, and 90, offering excellent high-temperature strength, oxidation resistance, and corrosion resistance. These nickel-based superalloys are ideal for components in extreme environments, providing mechanical stability, creep resistance, and durability for aerospace, gas turbines, and industrial applications.

Applications and Industries of Nimonic Alloy Casting Parts

Nimonic alloy casting parts are widely used in aerospace and aviation for turbine blades and exhaust components, power generation in gas turbines, and oil and gas for high-temperature valves and fittings. They are also applied in marine, nuclear, and automotive industries, delivering exceptional resistance to heat, oxidation, and corrosion, ensuring reliable performance in extreme environments where durability and precision are essential.

learn more

Aerospace and Aviation

learn more

Power Generation

learn more

Oil and Gas

learn more

Energy

learn more

Marine

learn more

Mining

learn more

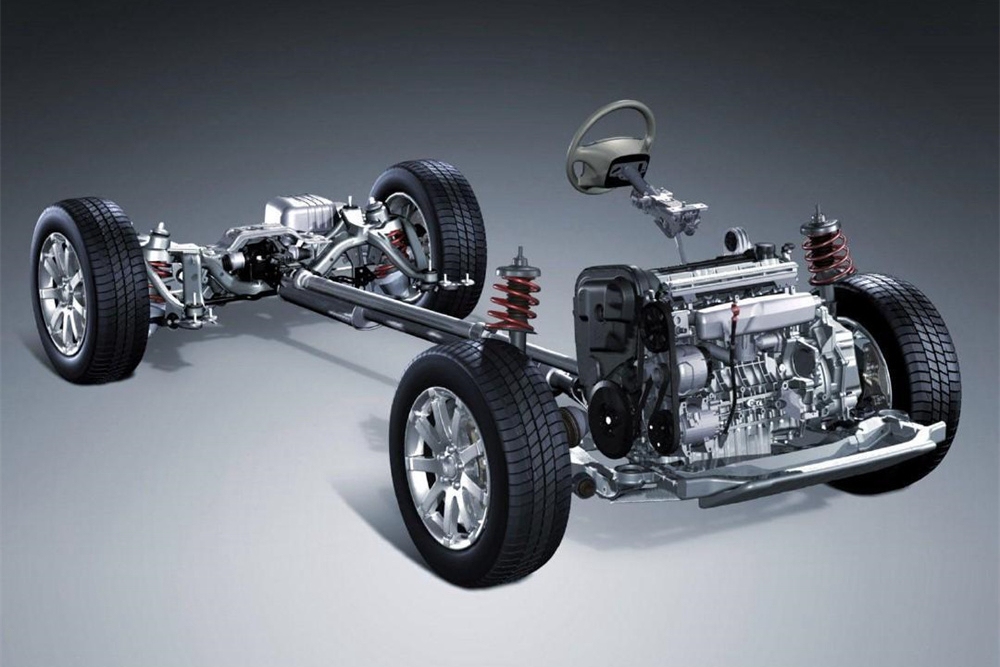

Automotive

learn more

Chemical Processing

learn more

Pharmaceutical and Food

learn more

Military and Defense

learn more

Nuclear

learn more

More Cases

learn more

New Technology

learn more

Products Gallery

learn more

Various Industries

learn more

Surface Finishings

learn more

Post-Process

learn more

Manufacturing Technology

learn more

R&D and Simulation

learn more

Manufacturing Equipments

learn more

Testing Equipments

learn more

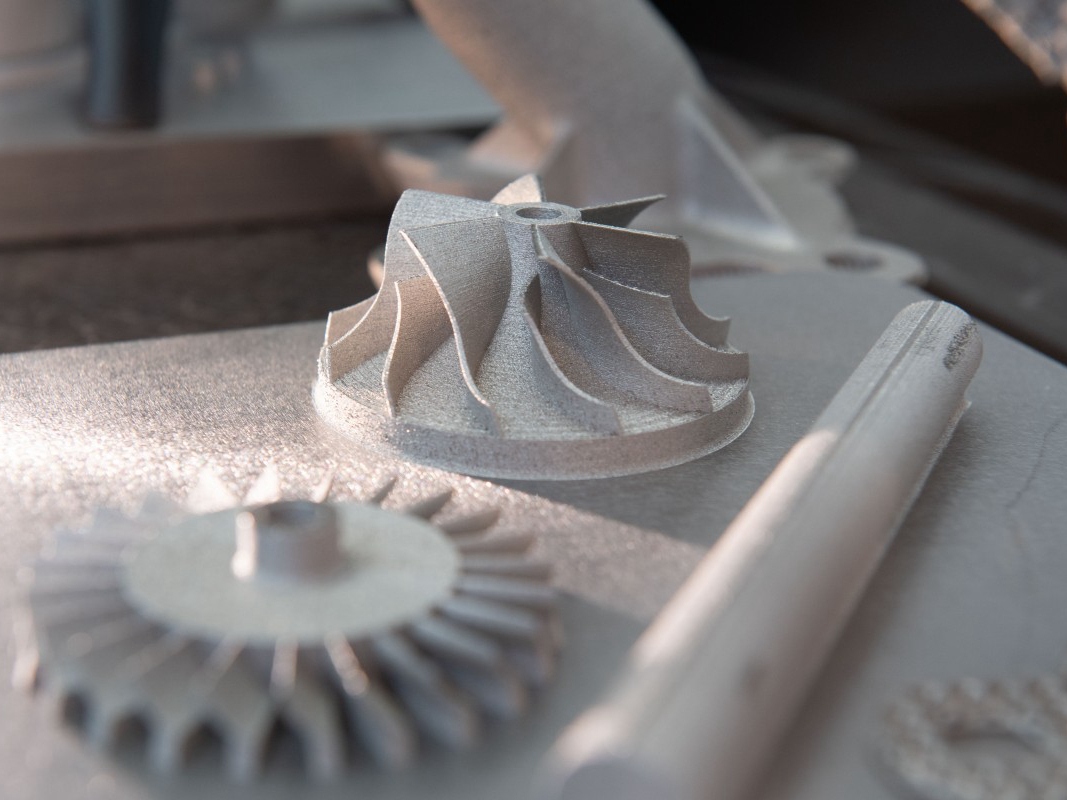

3D Printing Prototyping

learn more

FAQs

learn more

Contact

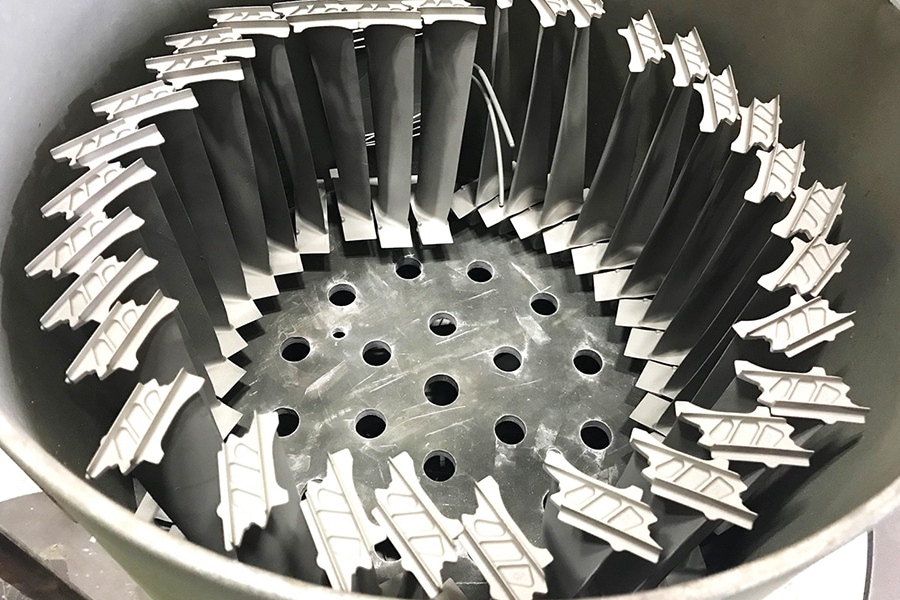

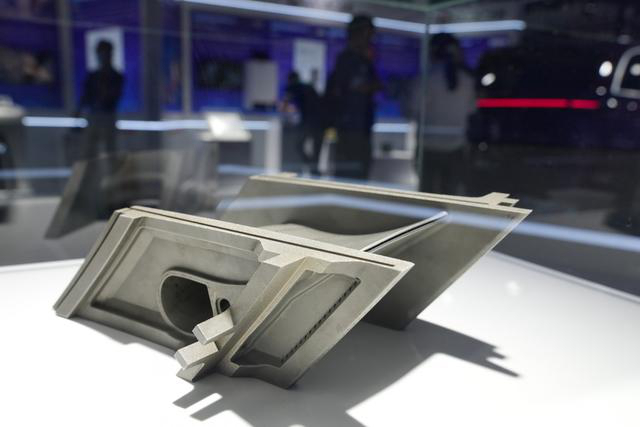

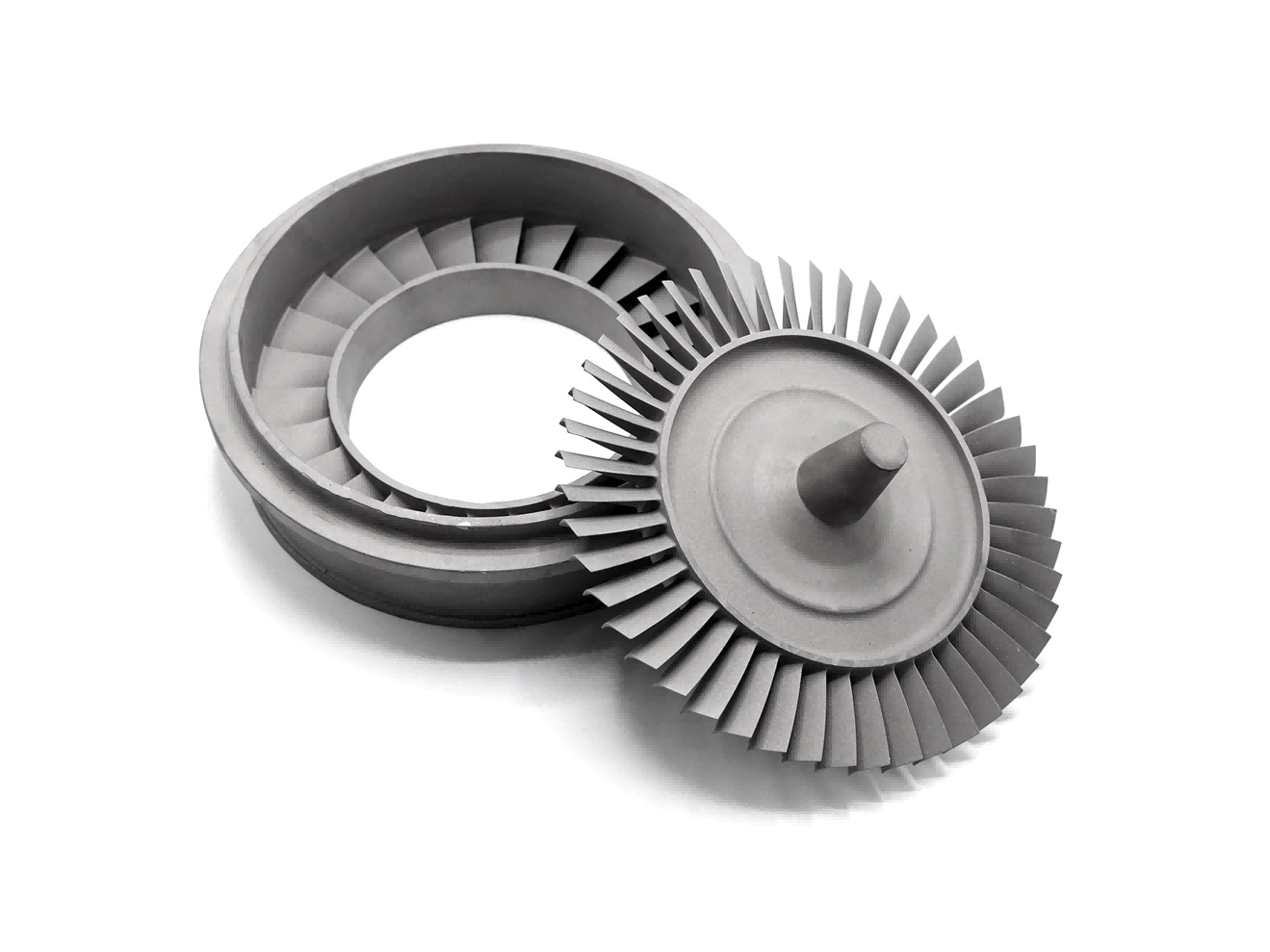

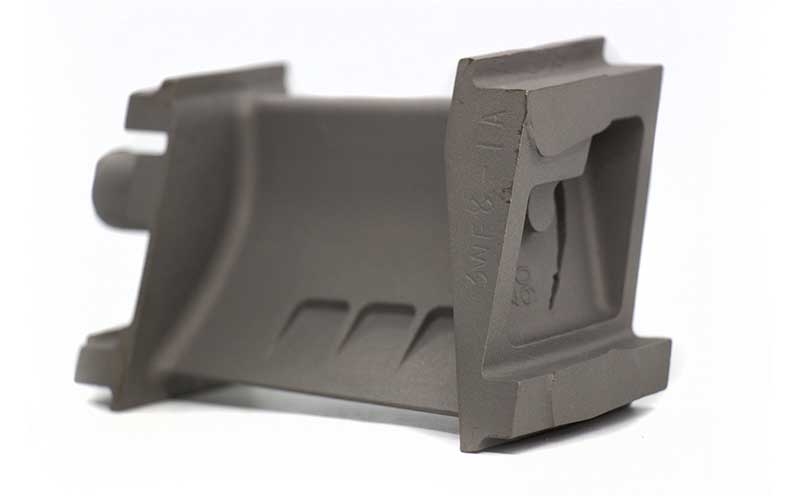

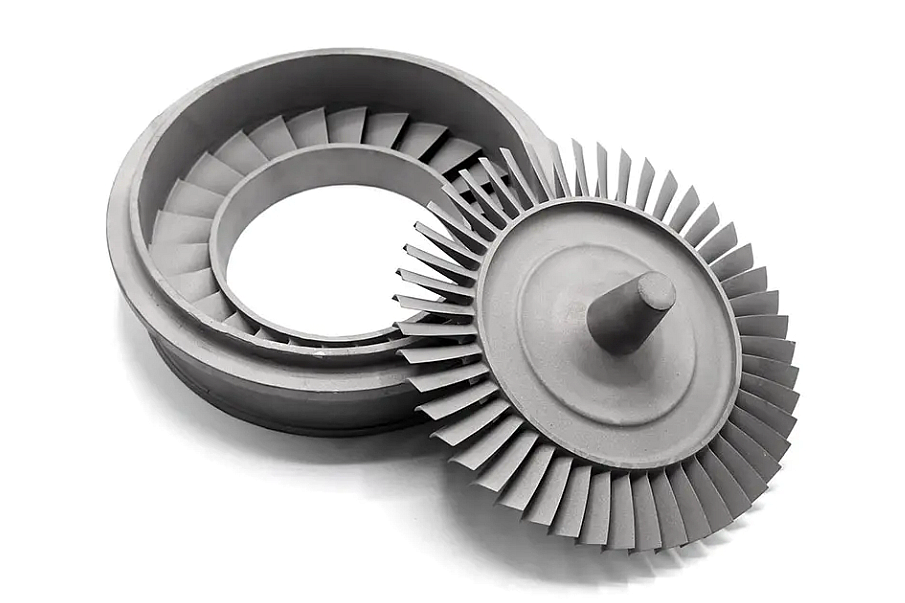

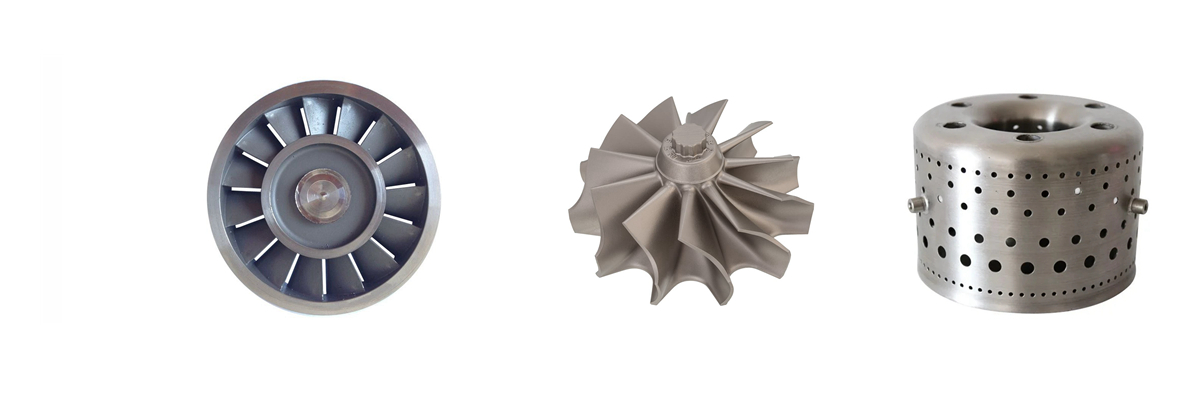

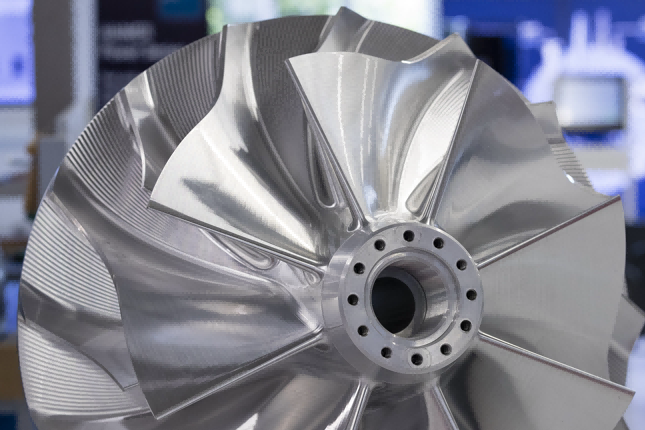

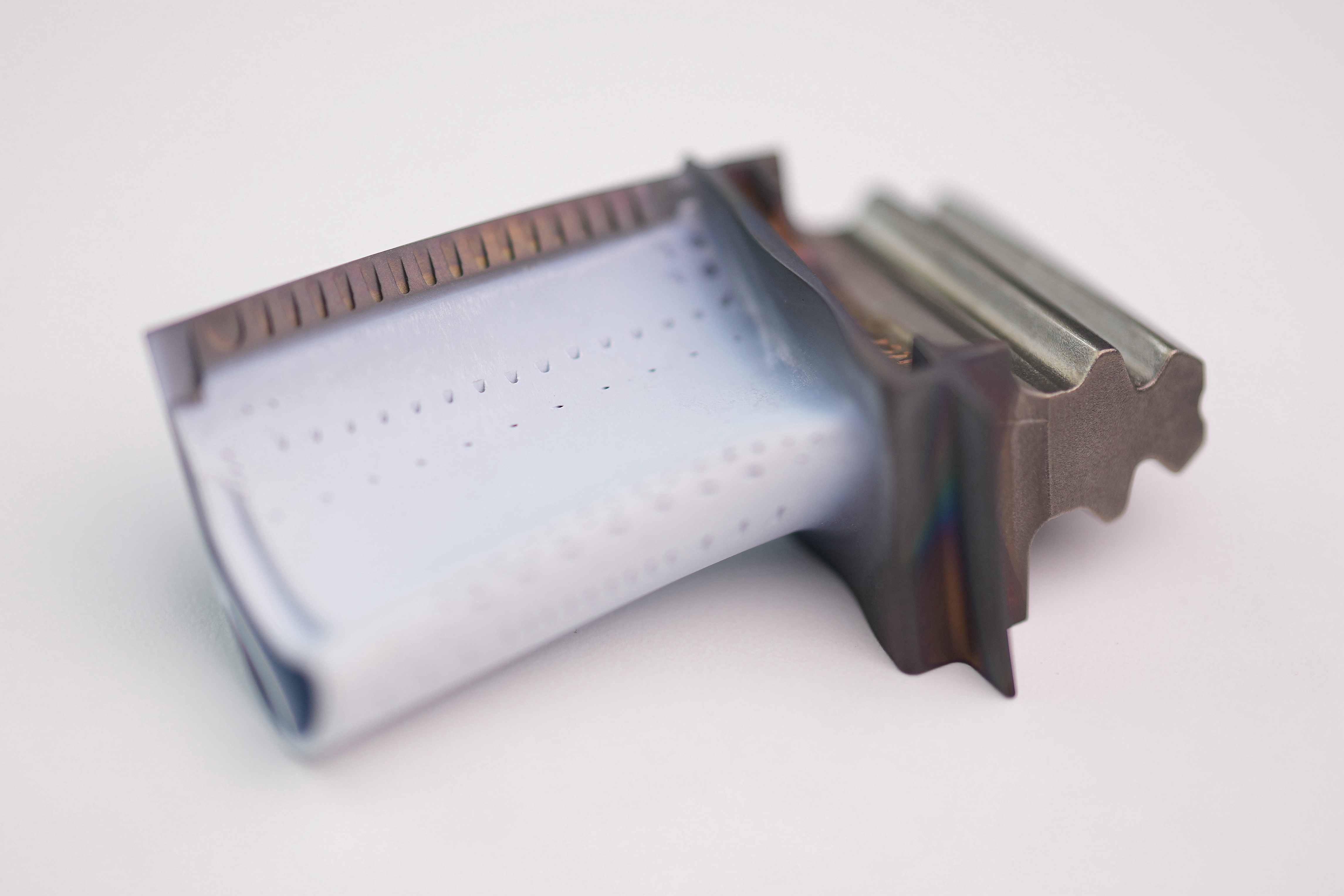

Custom Nimonic Alloy Components Gallery

Neway has produced custom Nimonic alloy components, including bespoke turbine blades, afterburners, and exhaust nozzles for aerospace clients. We've also manufactured precision-engineered gas turbine discs and combustion liners for power generation. These parts were tailored to withstand extreme temperatures, corrosion, and mechanical stresses in demanding operational environments.

Let's Start A New Project Today