Superalloy Welding Service

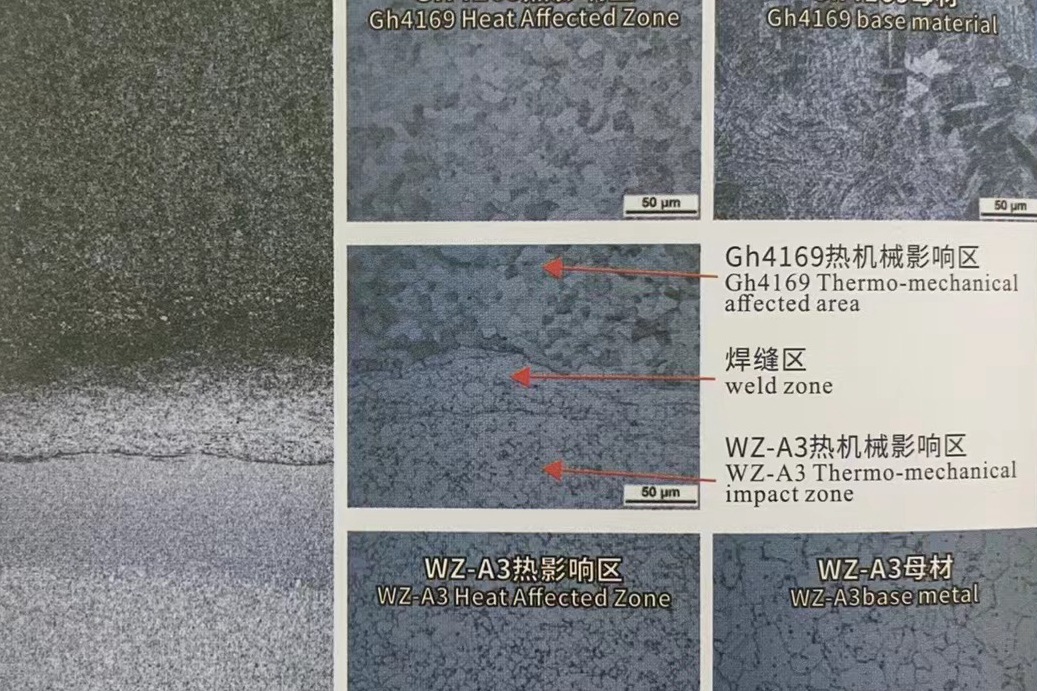

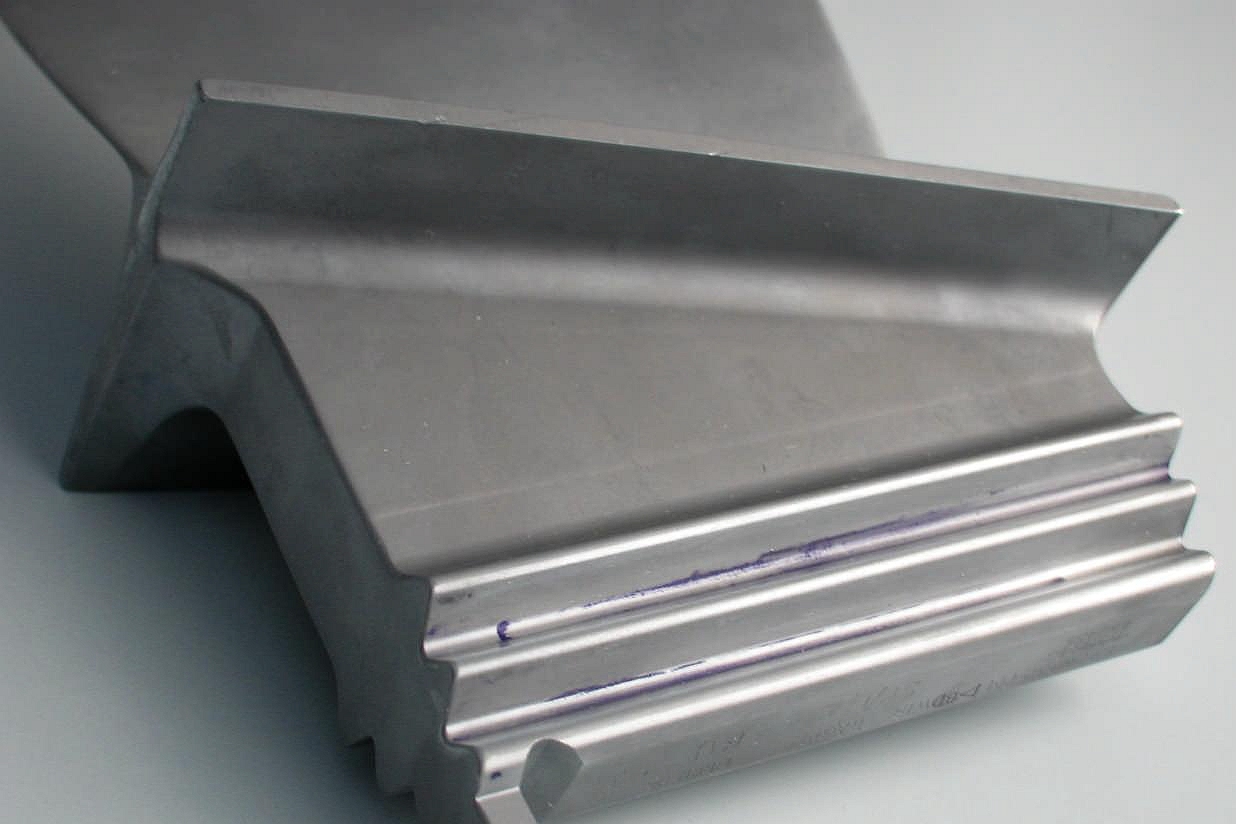

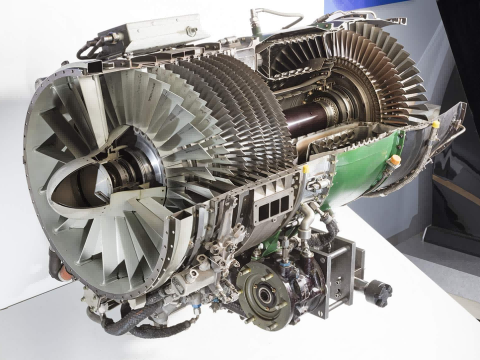

Superalloy Welding is a specialized service that involves joining high-temperature-resistant superalloys, such as Inconel, Hastelloy, and René alloys. It uses advanced techniques like TIG, MIG, or laser welding to ensure the weld maintains the alloy's structural integrity, corrosion resistance, and high-temperature performance under extreme conditions.

- We Offer Welding Service For Below Materials:

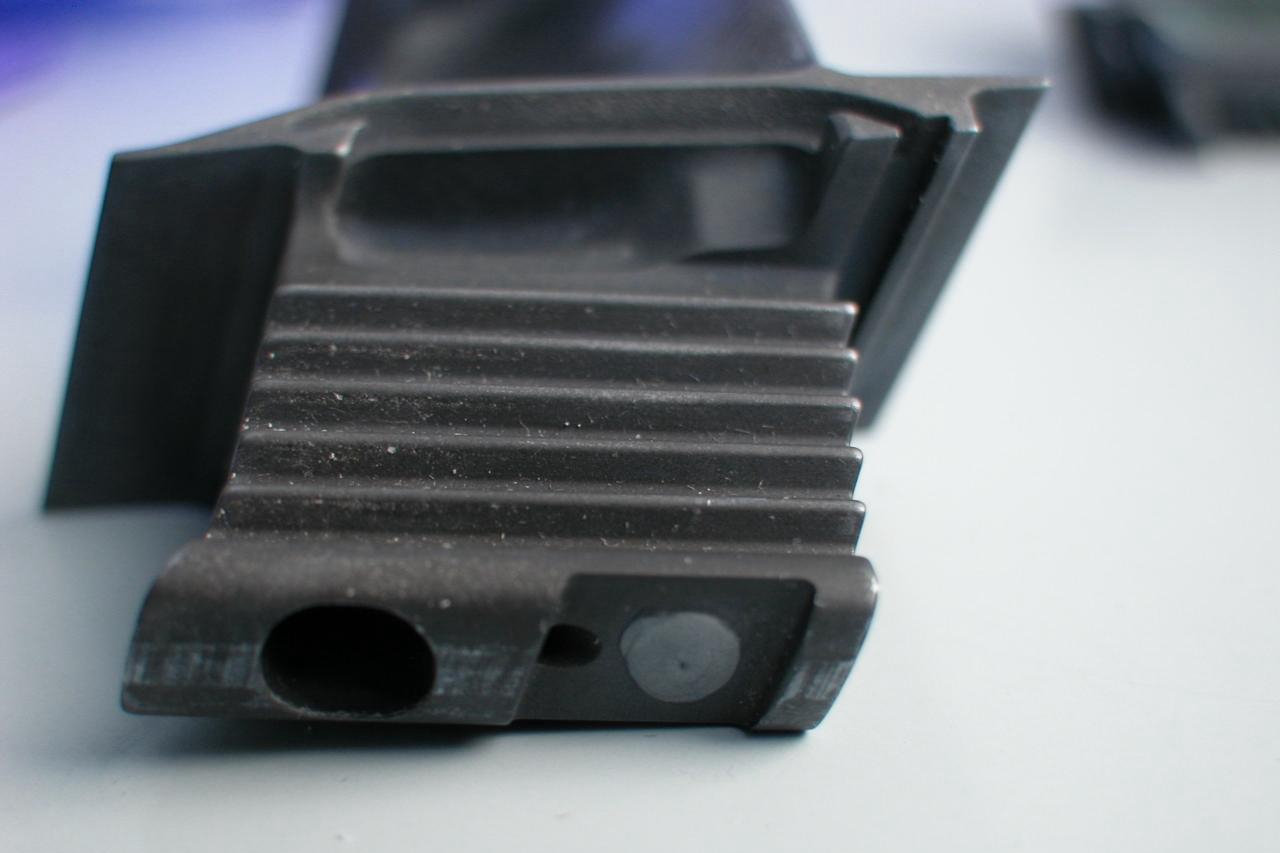

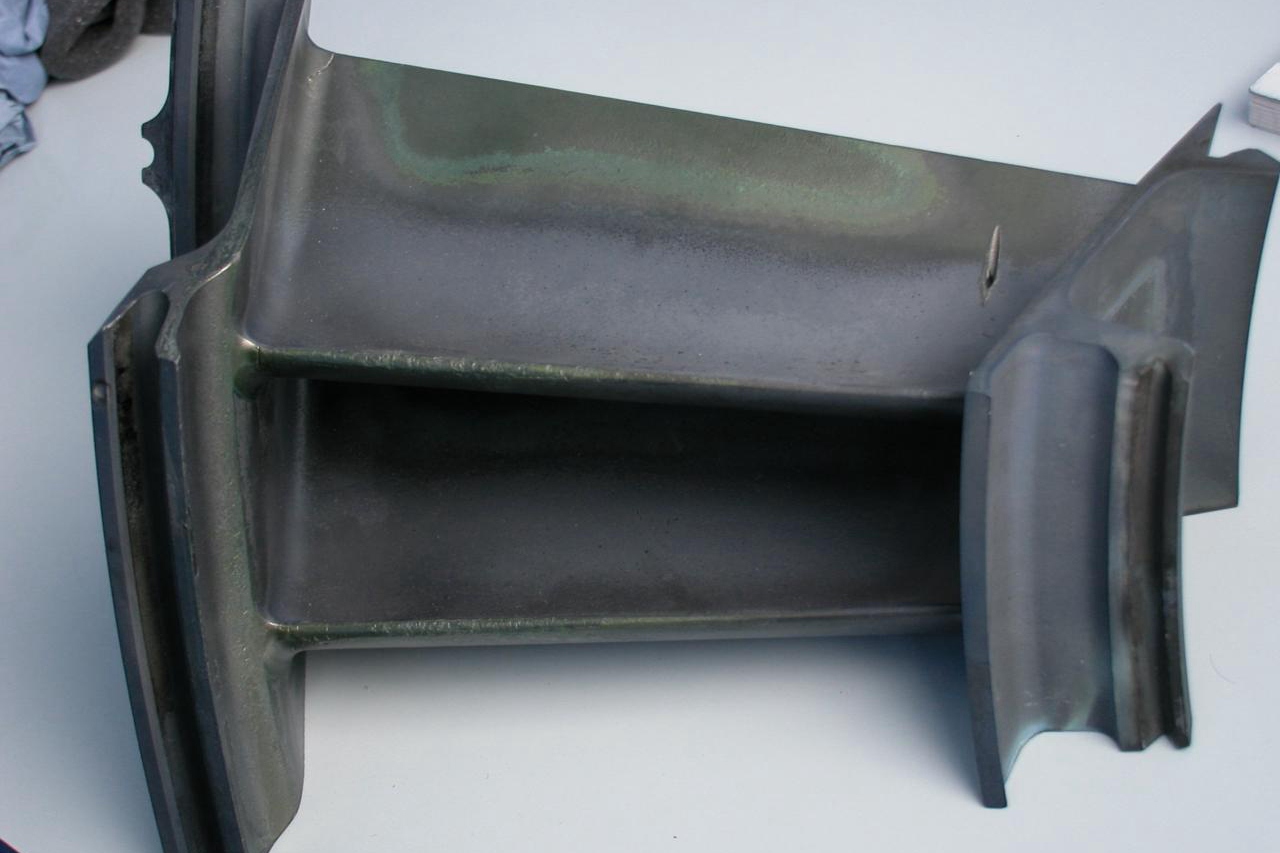

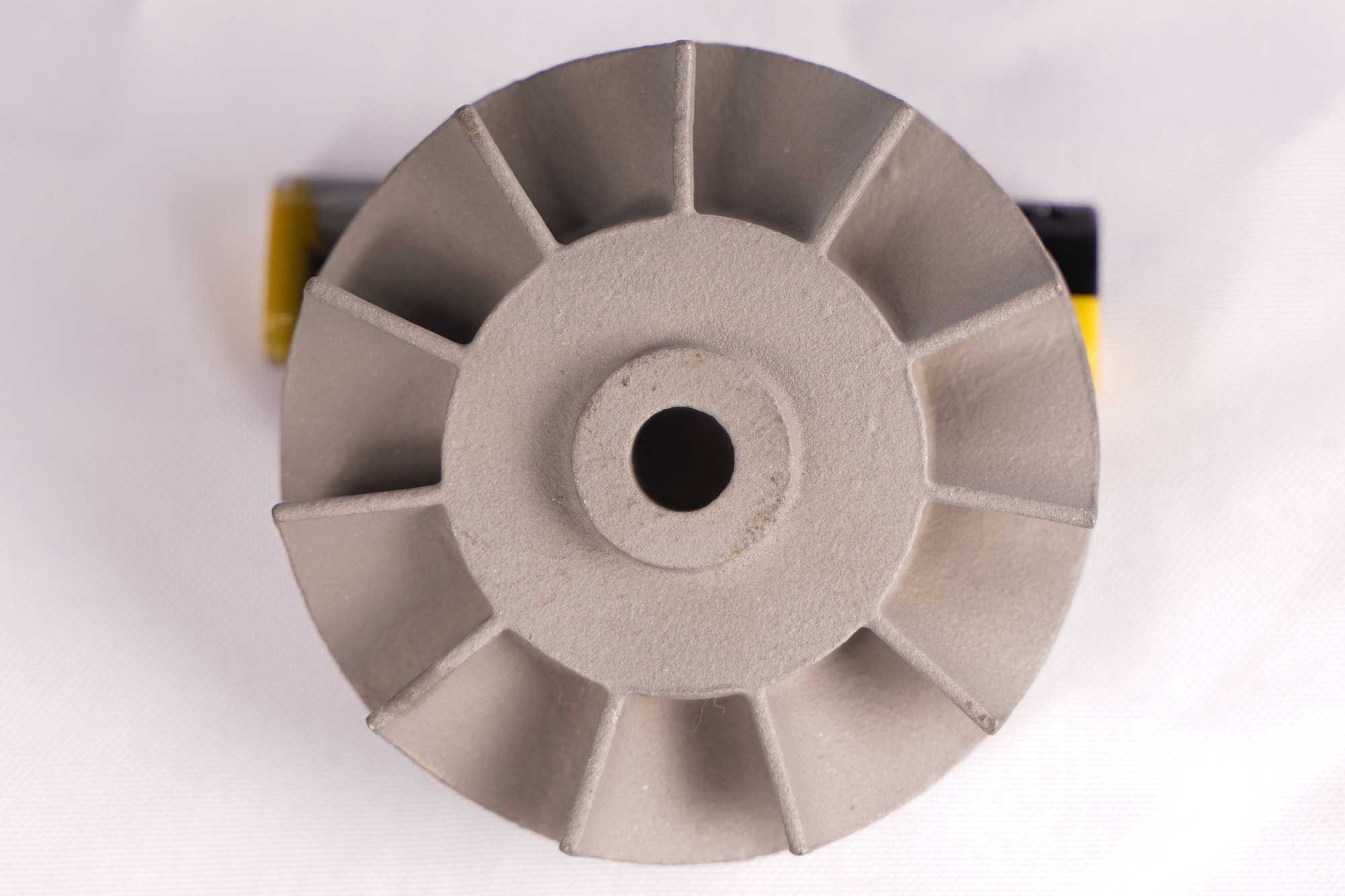

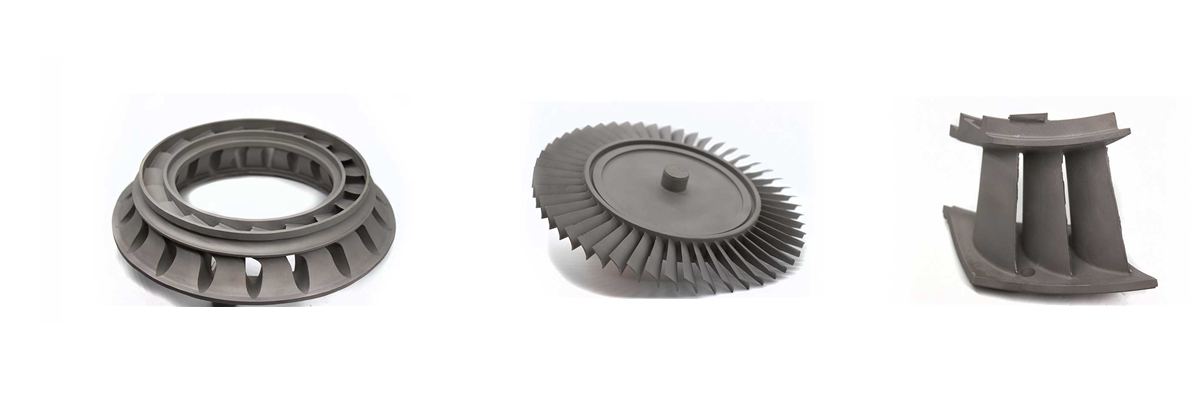

- Vacuum Investment Castings

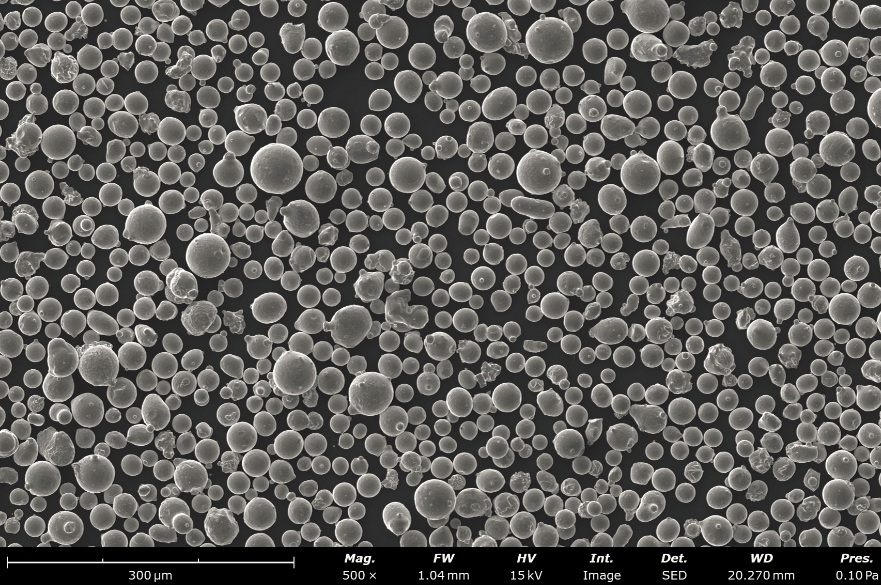

- Powder Metallurgy Parts

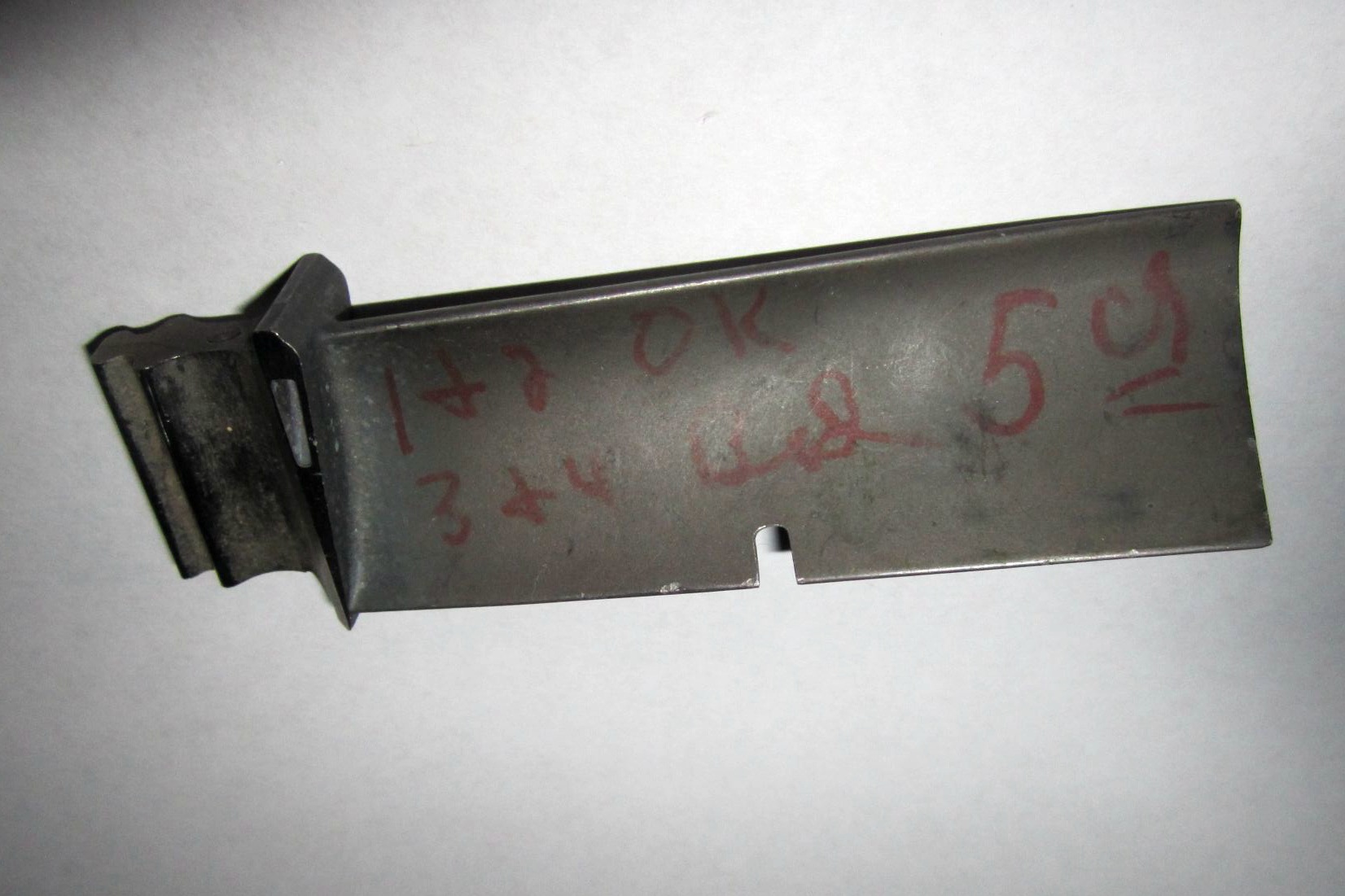

- Precision Forging Parts

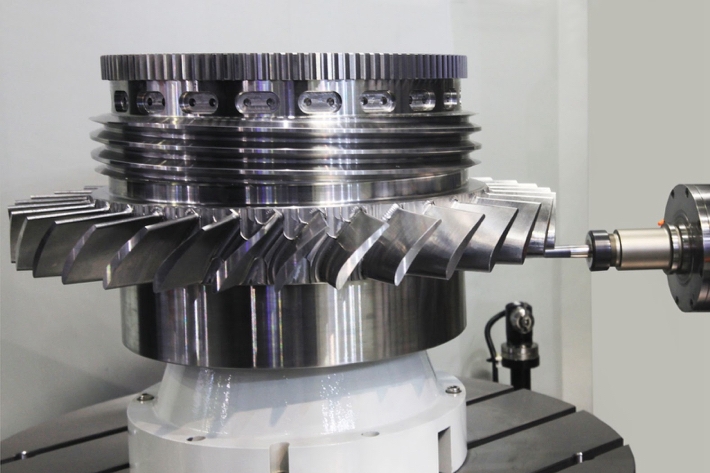

- CNC Machined Parts

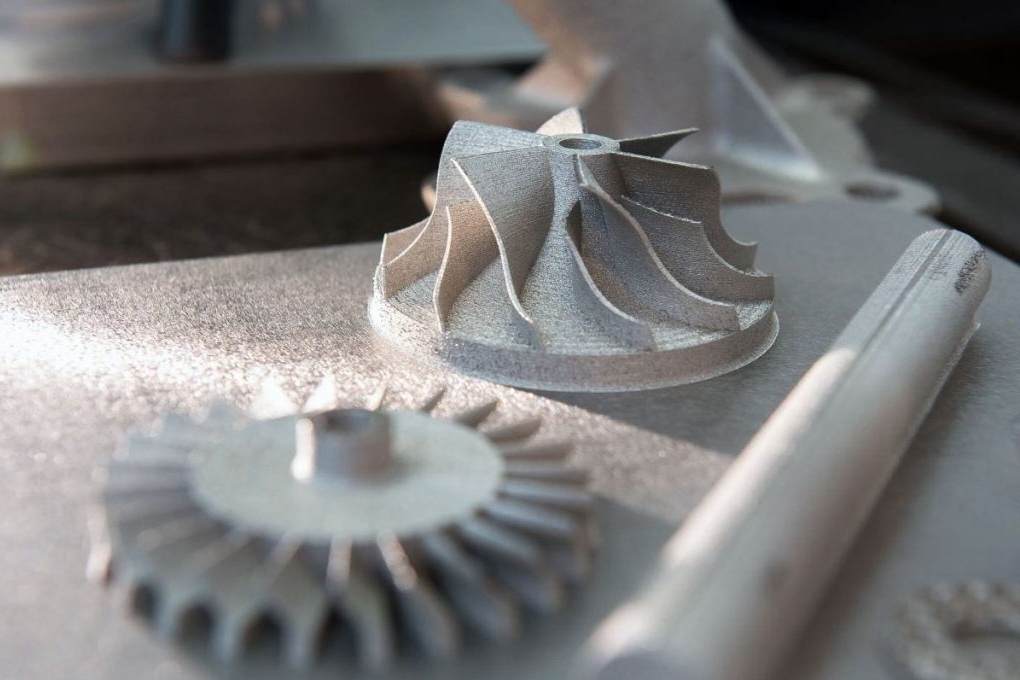

- 3D Printed Parts

- Superalloys: Inconel alloy, CMSX Series, Monel alloy, Hastelloy alloy, Stellite alloy, Nimonic alloy, Titanium alloy, Rene Alloys, Single Crystal Alloy

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Benefits of Superalloy Welding on Superalloy Castings

Superalloy welding enables the repair and joining of complex castings without compromising strength or heat resistance. It ensures structural integrity, extends component lifespan, and restores damaged parts, reducing downtime. Welding also supports design flexibility by enabling intricate assemblies and modifications, making it ideal for aerospace, energy, and power generation industries where performance and durability are critical.

When Does Superalloy Parts Need Welding Service?

Superalloy parts require welding service when repairing cracks, porosity, or defects from casting, forging, or machining. It is essential for joining complex components, restoring damaged turbine blades, or fixing worn areas in high-stress applications. Welding also addresses design modifications, enhances fatigue resistance, and ensures structural integrity in extreme environments like aerospace, energy, and chemical industries.

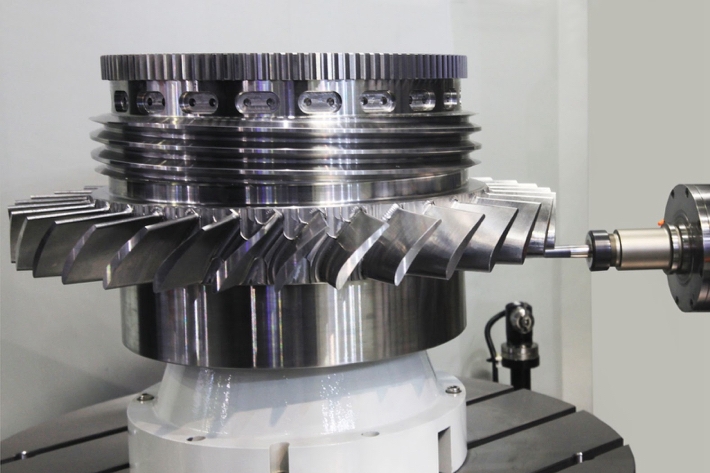

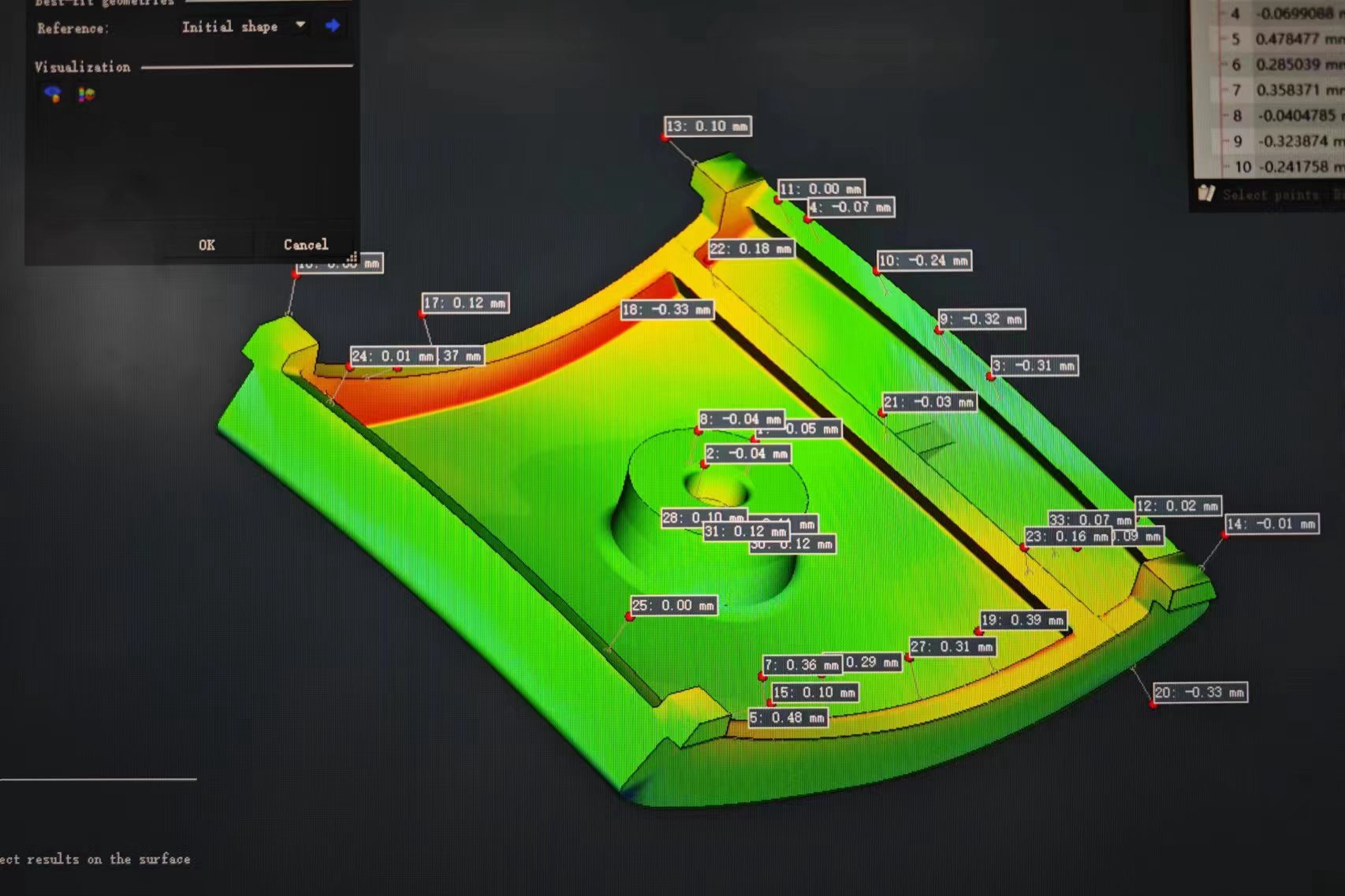

More Post Process Available At Neway

Neway offers comprehensive post-processing services for high-temperature alloy parts, including Hot Isostatic Pressing (HIP), heat treatment, superalloy welding, thermal barrier coating (TBC), material testing and analysis, superalloy CNC machining, deep hole drilling, and electrical discharge machining (EDM). These processes ensure optimal mechanical properties, precision, and durability for aerospace, petrochemical, and industrial applications.

About Custom Superalloy Components Manufacturing

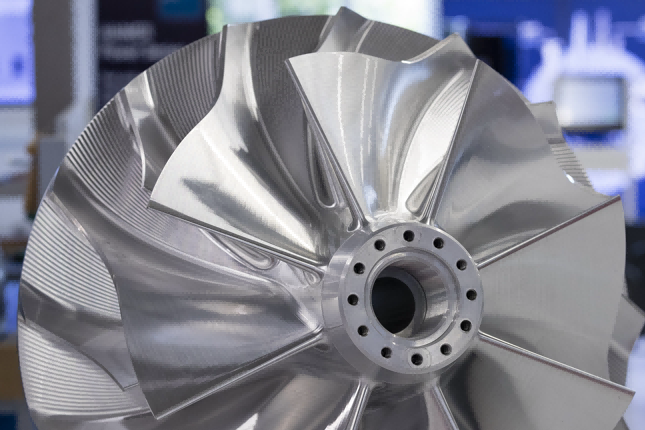

We manufacture custom superalloy components designed for demanding applications. Using advanced casting, forging, and powder metallurgy, we produce turbine blades, discs, and precision parts with excellent heat resistance, corrosion resistance, and mechanical strength. Our tailored solutions ensure reliability in aerospace, power generation, and industrial environments, meeting the highest performance standards for extreme operating conditions.

learn more

Aerospace and Aviation

learn more

Power Generation

learn more

Oil and Gas

learn more

Energy

learn more

Marine

learn more

Mining

learn more

Automotive

learn more

Chemical Processing

learn more

Pharmaceutical and Food

learn more

Military and Defense

learn more

Nuclear

learn more

More Cases

learn more

New Technology

learn more

Products Gallery

learn more

Various Industries

learn more

Surface Finishings

learn more

Post-Process

learn more

Manufacturing Technology

learn more

R&D and Simulation

learn more

Manufacturing Equipments

learn more

Testing Equipments

learn more

BLOGS

learn more

FAQs

learn more

Contact

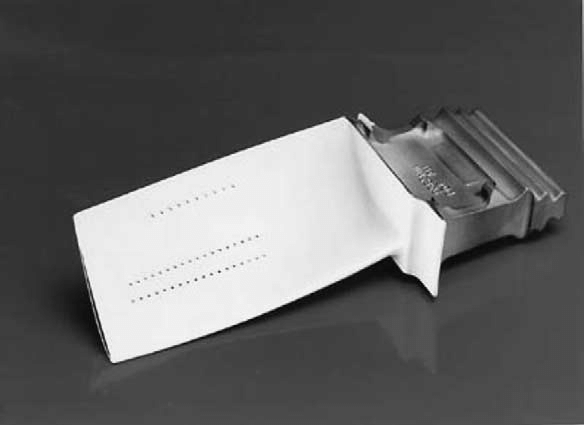

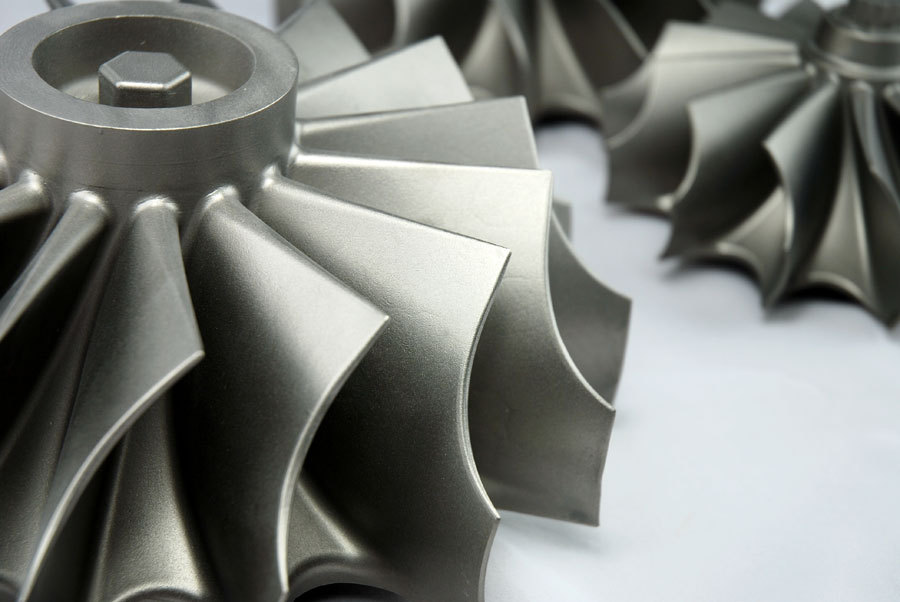

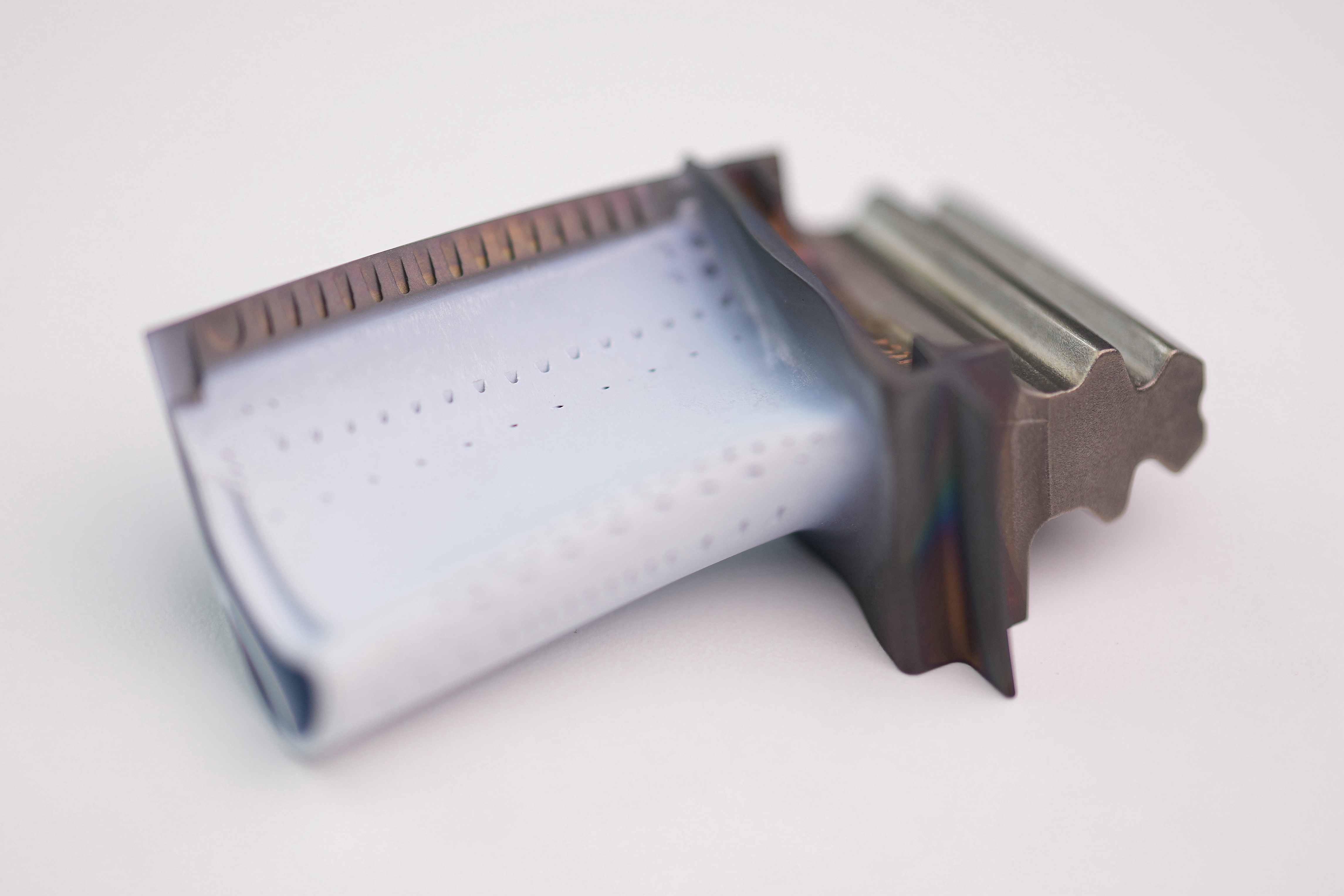

Super Alloy Parts Welding Gallery

We often use welding as a post-process for products such as single-crystal turbine blades, equiaxed and directional castings, powder metallurgy turbine discs, precision-forged parts, combustion chambers, casings, nozzle rings, afterburners, gas turbines, and guide vanes. These components are primarily used in the aerospace and energy sectors.

Let's Start A New Project Today