Enhance High-Temperature Alloy Parts with Advanced Welding

High-Temperature Alloys in Critical Applications

High-temperature alloys are essential in industries where materials must endure extreme thermal and mechanical stresses. These alloys, such as superalloys, titanium, and other specialized materials, play a critical role in applications where performance, reliability, and safety are paramount. Industries like aerospace, power generation, chemical processing, and marine engineering rely on these advanced materials to manufacture components that can withstand high heat, intense pressure, and aggressive environments. For instance, turbine blades in jet engines or gas turbines are exposed to temperatures above 1,000°C, requiring alloys that maintain their strength and stability under such conditions.

Relevance to Neway Precision Works

Neway Precision Works Ltd. specializes in the manufacturing and processing high-temperature alloys, offering a wide range of services to industries such as aerospace, petrochemical, and power generation. With expertise in materials like Inconel, CMSX, Hastelloy, and Monel, Neway ensures the production of components that meet the most stringent performance requirements. Neway's solutions ensure the long-term performance of high-temperature alloys in critical operations, from casting superalloy parts to precision machining, welding, and post-processing.

Importance of Welding in High-Temperature Alloy Manufacturing

Welding enhances high-temperature alloy components' performance, reliability, and longevity. Advanced welding techniques allow manufacturers to join complex geometries, repair damaged parts, and create new, high-performance components. However, welding high-temperature alloys presents unique challenges due to the materials' susceptibility to cracking, porosity, and distortion. Advanced welding methods, precise control, and post-processing are essential to achieving high-quality, durable parts for industries where failure is not an option.

Selecting the Right High-Temperature Alloys for Welding

High-temperature alloys, particularly superalloys, are the backbone of many critical aerospace and power generation components. Superalloys, such as Inconel, CMSX series, Monel, Hastelloy, and Titanium alloys, exhibit exceptional strength and resistance to thermal and mechanical stresses, making them ideal for applications in extreme environments. For example, Inconel alloys (e.g., Inconel 718) are widely used in gas turbines and jet engines due to their excellent oxidation resistance at high temperatures.

Alloy Properties

Each superalloy is designed with specific properties to withstand harsh environments. Creep resistance is one of the most critical properties, allowing components to maintain strength under prolonged stress at high temperatures. Corrosion resistance is another essential property, especially for alloys in aggressive environments like chemical processing or marine applications. Furthermore, high-temperature stability ensures that these alloys do not degrade or lose their mechanical properties when exposed to extreme conditions. For example, CMSX-2 and Rene 104 are ideal for environments where extreme thermal and mechanical stress is a concern.

Welding Suitability

Welding high-temperature alloys presents several challenges, mainly due to the materials' sensitivity to heat. Inconel alloys are prone to cracking when welded because of their high nickel content. CMSX single-crystal alloys require precise control of cooling rates to prevent damage to their microstructure. Welding these materials demands highly skilled operators and specialized equipment to manage the heat-affected zone (HAZ) and ensure the welded joint maintains the integrity and strength of the base material. Hastelloy C-276 is often chosen for welding applications due to its excellent weldability and resistance to oxidation.

Alloy Composition Control

Neway Precision Works takes great care in controlling the alloy composition during manufacturing. Neway ensures the alloys' performance remains consistent during welding and other manufacturing processes by ensuring a precise mix of elements, such as nickel, chromium, molybdenum, and aluminum. This composition control is crucial in maintaining the material's resistance to oxidation, creep, and thermal fatigue. For example, the careful formulation of Rene N6 ensures superior high-temperature strength and long-term reliability, even under extreme welding conditions.

Advanced Welding Techniques in High-Temperature Alloy Processing

Welding Methods

Advanced welding methods are essential for processing high-temperature alloys like superalloys and titanium. Some of the most commonly used techniques include:

Tungsten Inert Gas (TIG) Welding: TIG welding offers excellent precision, making it ideal for high-performance alloys. It allows for fine control over the heat input, reducing the risk of defects. It is especially crucial in applications like single crystal casting, where the integrity of the crystal structure must be preserved.

Metal Inert Gas (MIG) Welding: MIG welding is faster than TIG but requires a precise balance of heat and filler material for high-temperature alloys like Inconel and Hastelloy. Careful control is necessary to avoid degrading the material's properties.

Laser Welding: This technique uses concentrated laser beams to melt and join metal, providing deep penetration and precise control over the weld pool. It is highly effective for superalloy precision forging, ensuring minimal heat-affected zones and maintaining material integrity.

Electron Beam Welding: Electron beam welding is often used for parts that require high precision and minimal heat distortion. It is particularly beneficial for turbine blade life extension in aerospace applications, where exacting requirements are necessary for fatigue and creep resistance.

Plasma Arc Welding: Plasma welding combines the precision of TIG welding with the increased heat of an arc, offering better control for welding thicker materials, often used in high-temperature components that demand superior strength.

Process Control

One of the critical challenges when welding high-temperature alloys is controlling the heat input. Excessive heat can lead to material degradation, particularly in alloys like Inconel and CMSX. To mitigate this risk, Neway employs advanced temperature control systems during welding. It ensures that the alloys retain their strength and resistance to creep at elevated temperatures.

Avoiding recrystallization in single-crystal casting is another critical consideration. During welding, it's crucial to maintain the orientation of the crystal structure to avoid reduced performance and premature failure. The heat input and process must be precisely managed, especially for parts like single-crystal turbine blades, where crystal direction and uniformity are critical.

Welding for Complex Geometries

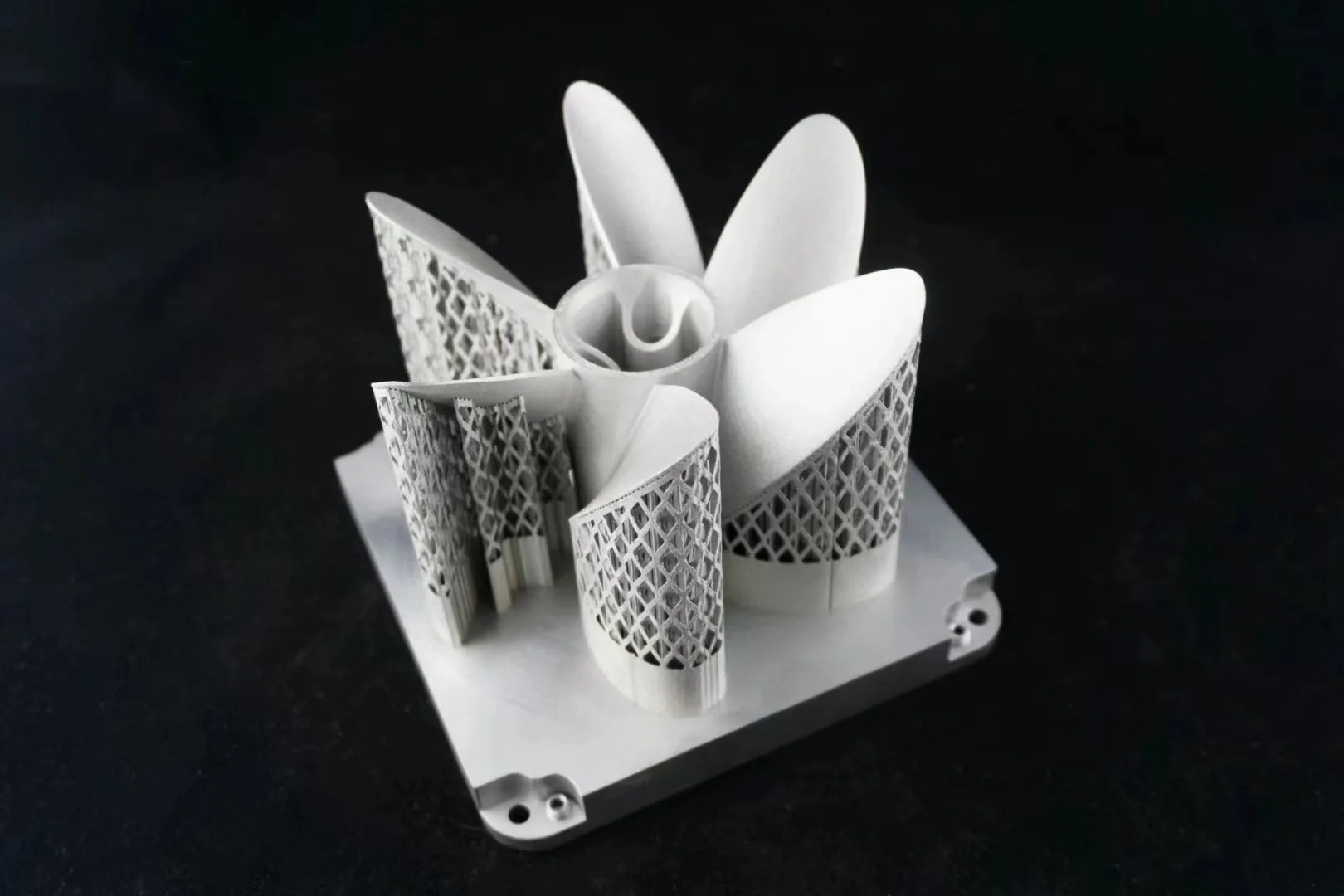

High-performance components like turbine blades, guides, and discs often feature complex geometries. Neway uses advanced fixtures and robotic welding systems to achieve precise and repeatable welds, even in intricate designs. This technology allows for accurate welding of parts with tight tolerances, ensuring that each component meets the high standards required for critical applications in aerospace and power generation industries. The ability to weld complex geometries is essential for achieving the high performance required in vacuum investment castings and directional solidification.

Post-Weld Heat Treatment

Post-weld heat treatment (PWHT) is a critical step in restoring the mechanical properties of welded superalloy parts. Welding can introduce stresses and microstructural changes that weaken the material. PWHT involves heating the component to a specific temperature and holding it for a set period to relieve these stresses and promote the desired microstructure. This process is essential for high-temperature alloys, where precise control of heat treatment is required to avoid compromising material properties. Proper PWHT enhances the creep and fatigue resistance of parts used in aerospace and gas turbine engines, ensuring longevity and reliability in demanding environments.

Enhancing Weld Integrity and Performance

Heat Treatment

Post-weld heat treatment (PWHT) is used to restore the integrity of the alloy by eliminating residual stresses created during the welding process. For superalloys, this treatment helps improve fatigue and creep resistance, which are critical properties for components exposed to high temperatures. The precise temperature control during PWHT ensures that the part's microstructure is optimized for performance under operating conditions, particularly in demanding environments such as aerospace and power generation.

Surface Finishing

Surface finishing processes such as grinding, polishing, and shot peening are essential to improve the surface quality of welded superalloy parts. These processes enhance the part's fatigue strength and ensure a smooth, defect-free surface that can withstand aggressive environments. A fine surface finish for high-temperature applications also helps minimize the risk of stress concentrations that could lead to premature failure. Techniques like shot peening are vital in enhancing mechanical properties and extending the component's lifespan by inducing beneficial compressive stresses on the surface.

Hot Isostatic Pressing (HIP)

HIP is a post-processing technique to eliminate internal porosity in welded superalloy parts. This process involves applying high temperature and pressure to the part, which helps achieve a uniform density and microstructure. HIP ensures the part is free from internal voids, which can lead to weak spots and failures in high-stress applications. This process is particularly critical for components that maintain structural integrity and high performance in demanding environments, such as turbine blades or aerospace engine parts.

Ensuring Weld Quality and Structural Integrity

Nondestructive testing (NDT) is critical in assessing the quality of welded joints without compromising the part's integrity. Common methods include:

X-ray and Ultrasonic Testing

X-ray and ultrasonic testing are used to detect any voids, cracks, or other internal defects. This method benefits superalloy parts, where internal flaws could compromise performance under extreme conditions. Like in high-temperature superalloy applications, ensuring that welded parts are free of defects is critical to their structural integrity.

Eddy Current Testing

Eddy current testing is ideal for detecting surface or near-surface defects, particularly in susceptible applications. It is particularly relevant in superalloy casting, where surface defects can significantly influence the component's strength, especially in the aerospace and power generation industries.

Mechanical Testing

The performance of welded superalloy parts is assessed through various mechanical tests, including:

Tensile Testing

Tensile testing measures the material's ability to withstand tension without breaking. This test is critical when assessing materials like superalloys used in high-stress applications, such as turbine blades and other aerospace components.

Fatigue Testing

Fatigue testing simulates the repetitive stresses a part will endure during operation. Ensuring fatigue resistance is crucial for welded parts made from directional cast superalloys to prevent failure over the part's lifespan.

Creep Testing

Creep testing assesses the material's resistance to slow deformation under constant stress at high temperatures. It is particularly relevant to welded superalloys used in components subjected to high thermal loads, such as gas turbines, where long-term deformation could lead to catastrophic failures.

Microstructure Analysis

Analyzing the microstructure of the weld is crucial to ensure the material maintains its integrity. Techniques like metallographic microscopy and electron backscatter diffraction (EBSD) help detect grain boundaries, phase transformations, and the distribution of precipitates, ensuring the weld achieves the desired mechanical properties. These techniques are similar to those used in superalloy microstructure analysis to ensure the alloy performs well under high-stress conditions.

Dimensional Accuracy

After welding, the final part's dimensions must be verified against the design specifications. CMM and 3D scanning provide accurate, repeatable measurements to ensure the part meets the required tolerances. Like the precision measurement required for superalloy components, dimensional accuracy in welded parts is crucial for fit and function in high-performance applications.

Enhancing the Performance of Welded High-Temperature Alloy Parts

Aerospace and Aviation

Welded superalloy parts are essential in the aerospace and aviation sectors. Components like turbine blades, combustor liners, and nozzle rings are subjected to extreme temperatures and mechanical stresses. Welding enhances their performance by providing a seamless connection, improving strength, and ensuring these components can operate reliably over long periods.

Power Generation

Gas, steam, and other power generation equipment require high-performance, welded superalloy parts. Welding is used to repair and manufacture critical components, ensuring they can withstand the harsh environments inside power plants.

Chemical Processing and Petrochemical

High-temperature alloys are commonly used in the chemical and petrochemical industries, where components like pressure vessels and reactors are exposed to corrosive and extreme conditions. Welding these parts ensures a long service life and operational efficiency in challenging environments.

Marine and Military

Marine and military applications rely on welded superalloy parts, particularly in naval propulsion systems and engines. These components must resist corrosion, fatigue, and high-temperature stresses, making welding a crucial process in their production.

FAQs

What are the key challenges in welding superalloy materials like Inconel and CMSX?

How does post-weld heat treatment improve the integrity of welded high-temperature alloys?

What welding techniques are most suitable for manufacturing turbine blades from superalloys?

How does Neway Precision Works ensure the quality of welded high-temperature alloy parts?

What types of testing are used to verify the performance of welded superalloy components?