Superalloy Energy Parts Supplier

Custom Superalloy Energy Parts Manufacturing Service

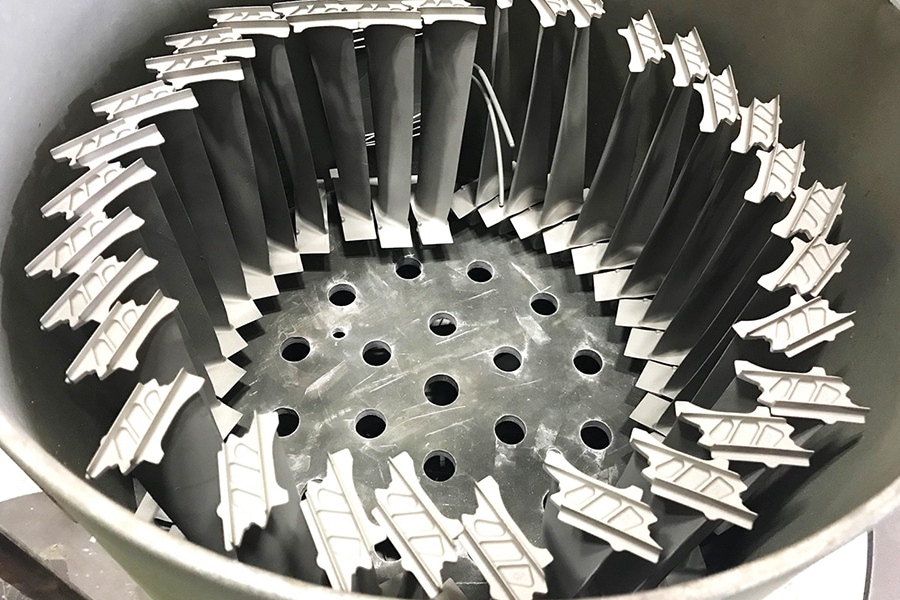

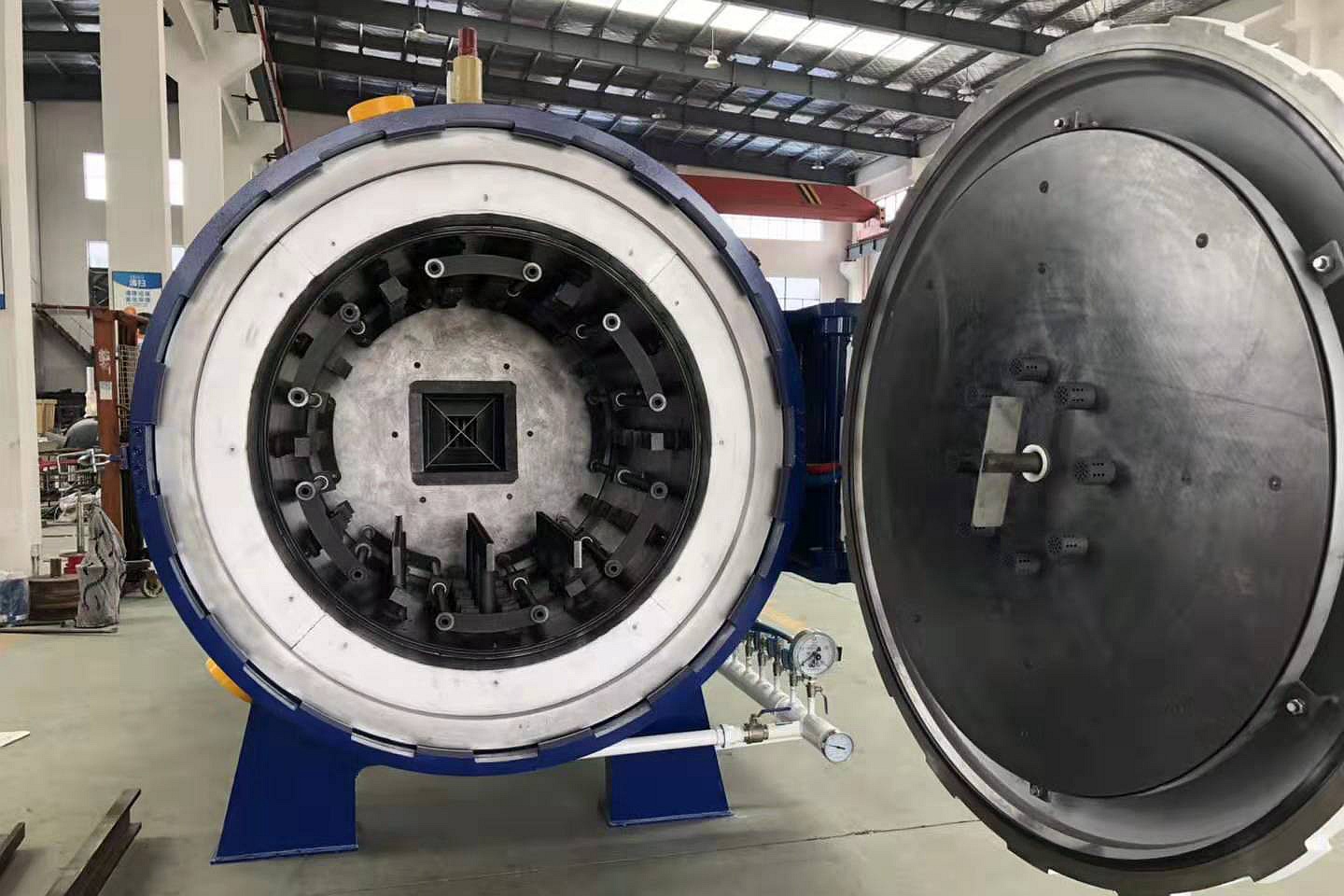

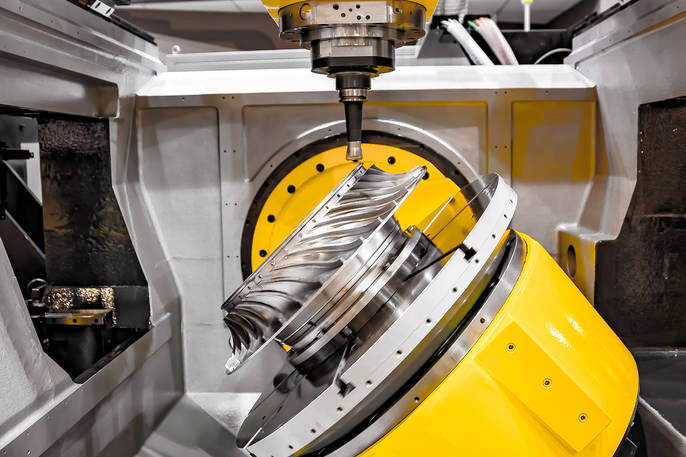

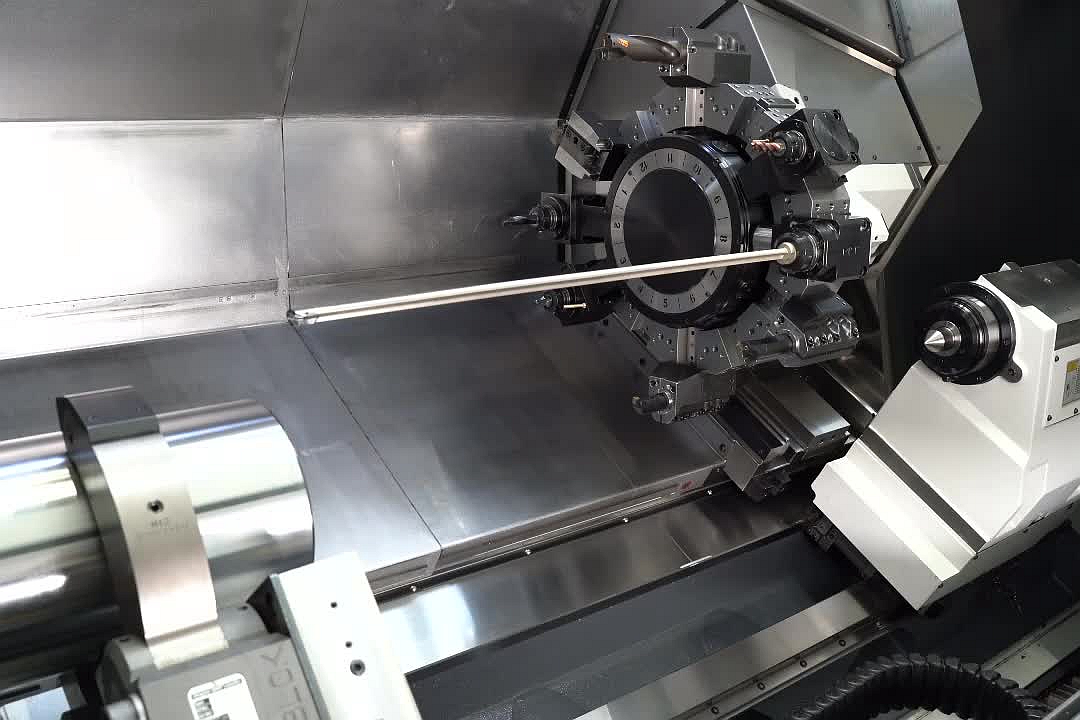

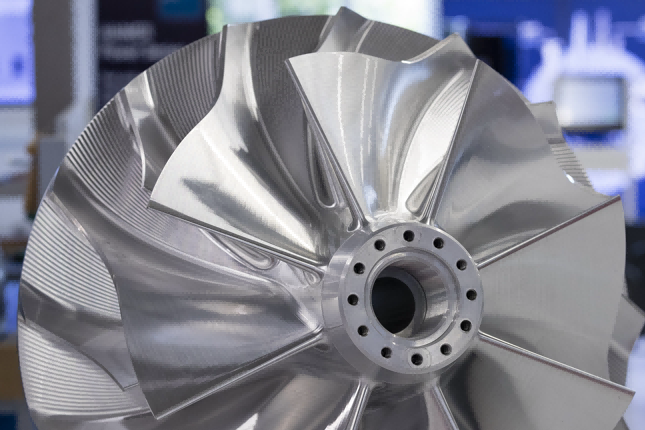

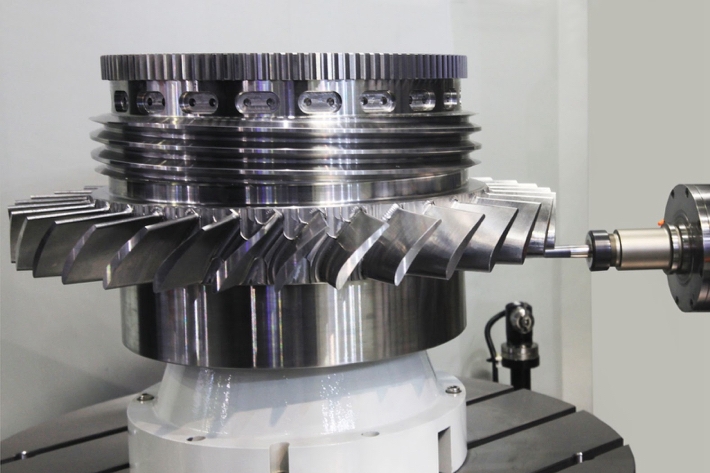

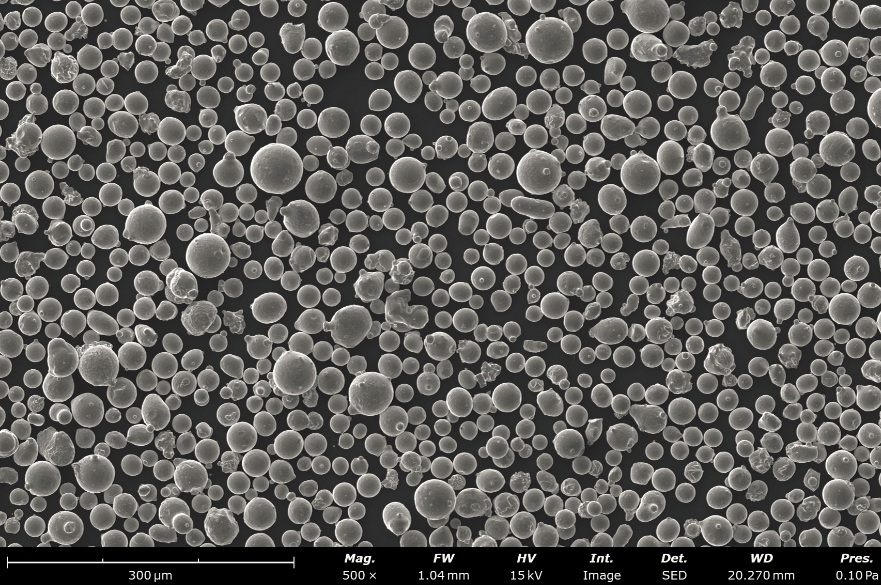

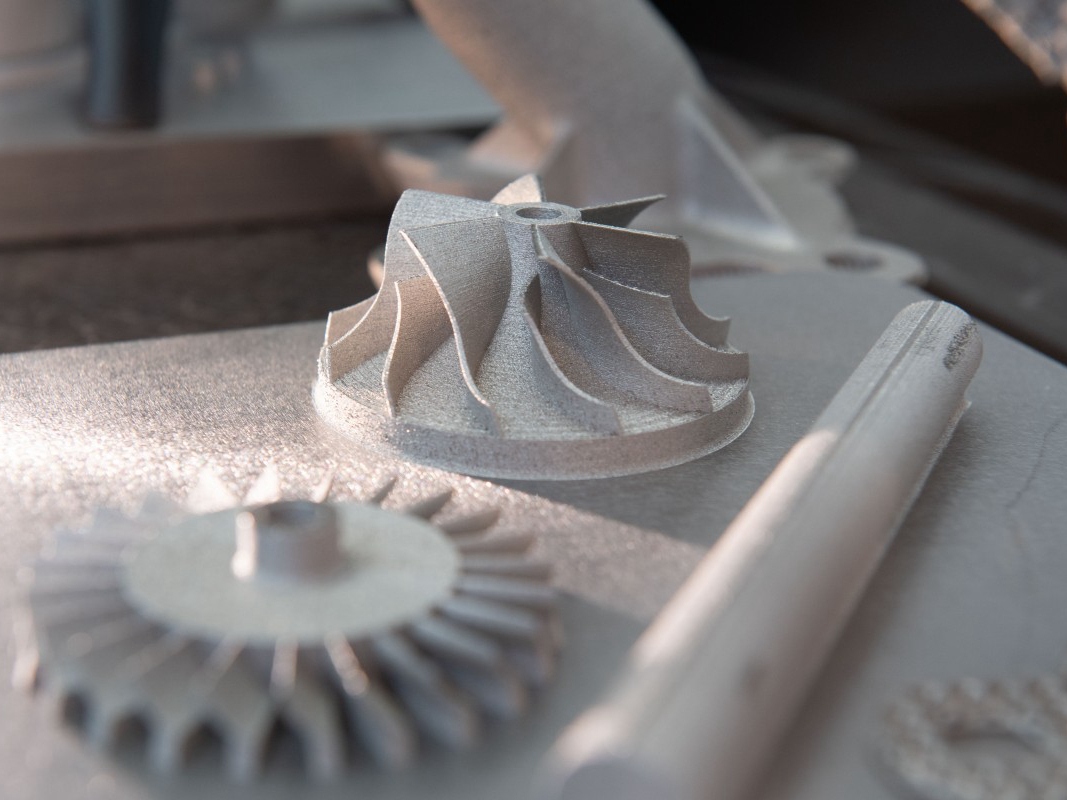

Neway offers processes like vacuum investment casting, directional casting, powder metallurgy, precision forging, HIP, and CNC machining. They manufacture custom nuclear parts like turbine blades, nozzles, valves, and impellers from high-temperature alloys for energy applications.

Energy Superalloy Parts Manufacturing Solutions

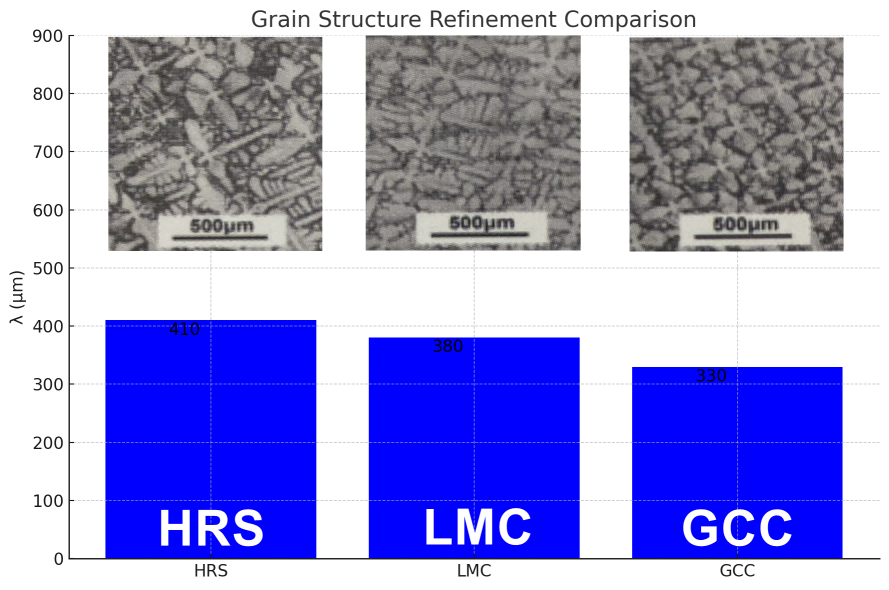

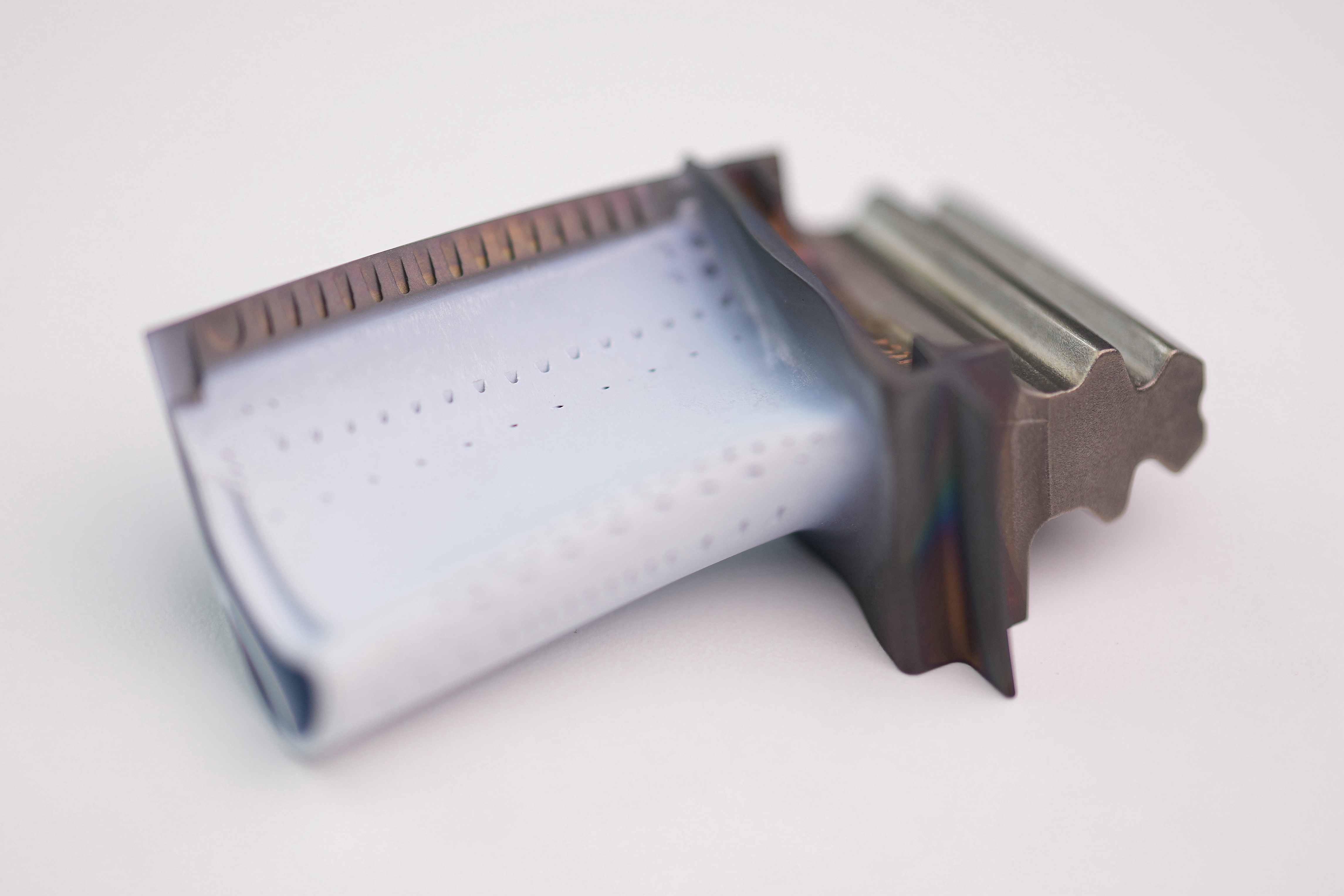

Neway uses vacuum investment casting, directional and equiaxed casting, and single-crystal casting for energy superalloy parts. It applies precision forging, powder metallurgy, and CNC machining for detailed components like turbine blades and discs. Post-processing includes Hot Isostatic Pressing (HIP), thermal barrier coatings (TBC), heat treatment, welding, and deep hole drilling, ensuring high performance in extreme energy applications.

Energy Industry Superalloy Selection Solution

The energy industry selects superalloys like Inconel, CMSX, Nimonic, Rene, and Hastelloy for their exceptional strength, heat resistance, and corrosion protection. These materials are vital in gas turbines, heat exchangers, boilers, and reactors, ensuring efficient performance in extreme environments. Their durability and thermal stability enhance reliability in power plants, renewable energy systems, and thermal energy storage solutions.

Energy Parts Post Process and Surface Treatment Solutions

Neway offers post-processing like Hot Isostatic Pressing (HIP), heat treatment, and welding for superalloy turbine blades, discs, and combustion chambers. Surface treatments include Thermal Barrier Coatings (TBC) for nozzle rings and afterburners. CNC machining, deep hole drilling, and Electrical Discharge Machining (EDM) are applied for precision energy components, enhancing durability and performance in extreme environments.

Superalloy Components In Energy Industry

Neway has produced superalloy components such as turbine blades, impellers, combustion chambers, nozzle rings, and turbine discs for the energy industry. These are made using processes like vacuum investment casting, directional and single crystal casting, precision forging, and powder metallurgy. Post-processes include CNC machining, HIP, heat treatment, welding, and applying Thermal Barrier Coatings (TBC) for durability.

learn more

Direct Reading Spectrometer

learn more

Tensile Testing Machine Checking

learn more

X-ray Checking

learn more

Thermal Physical Properties Test Platform

learn more

Corrosion Production Line

learn more

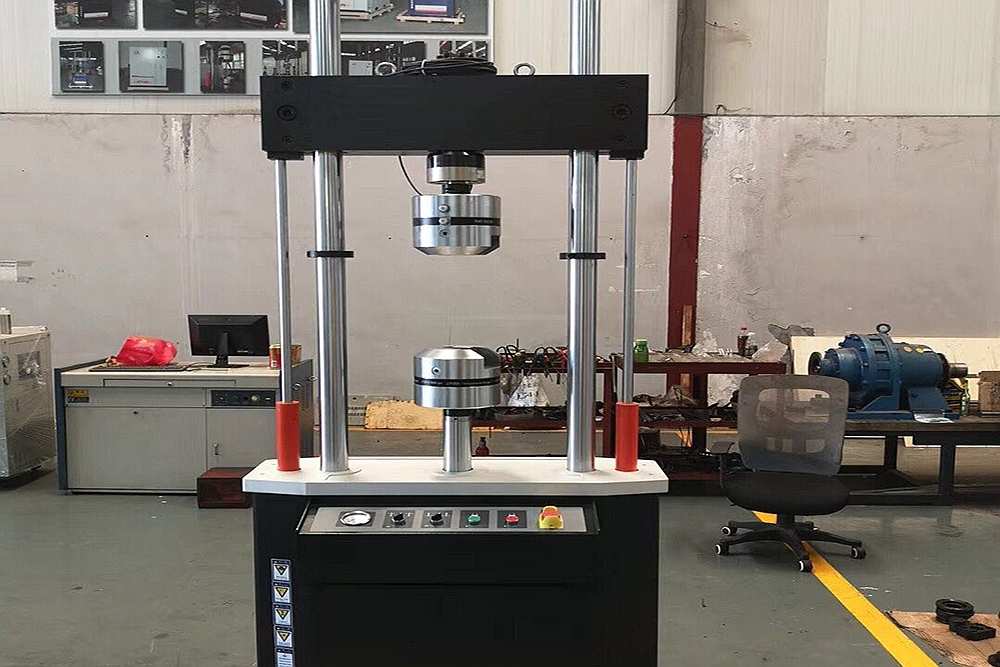

Dynamic and Static Fatigue Tester

learn more

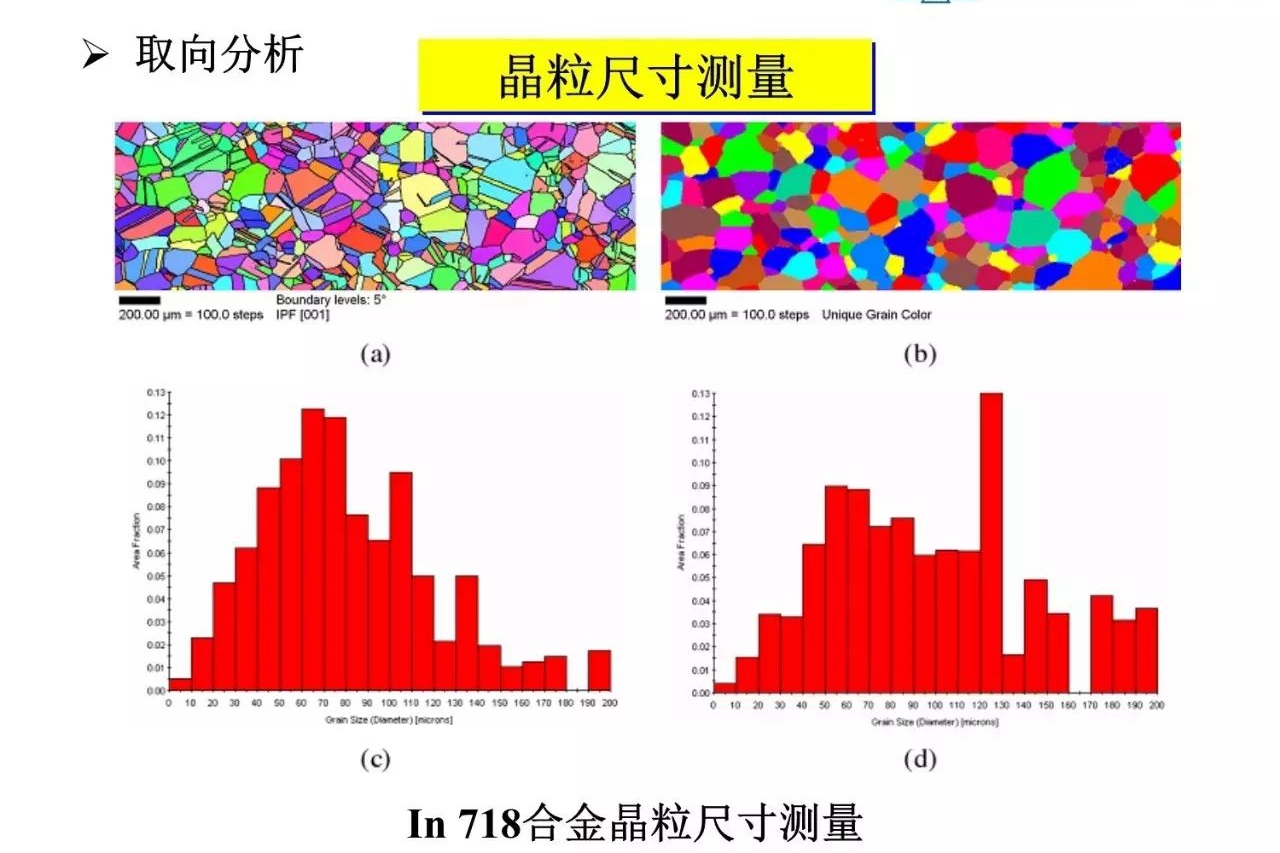

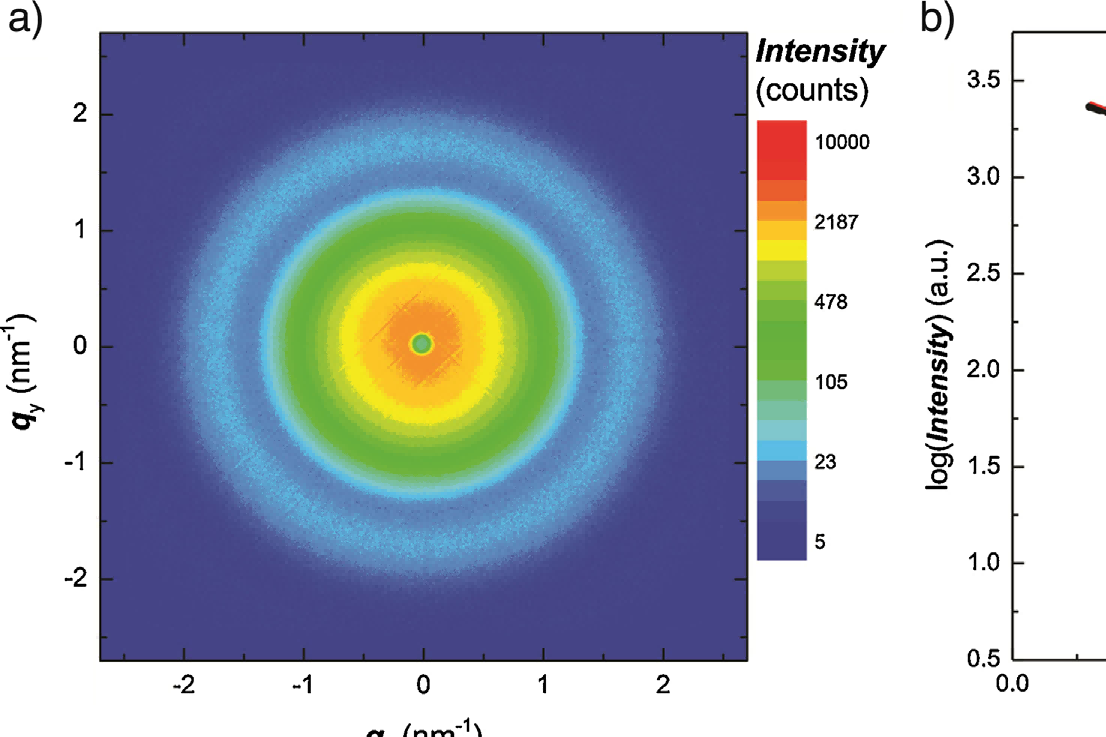

Electron Backscattering Diffractometer (EBSD)

learn more

Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES)

learn more

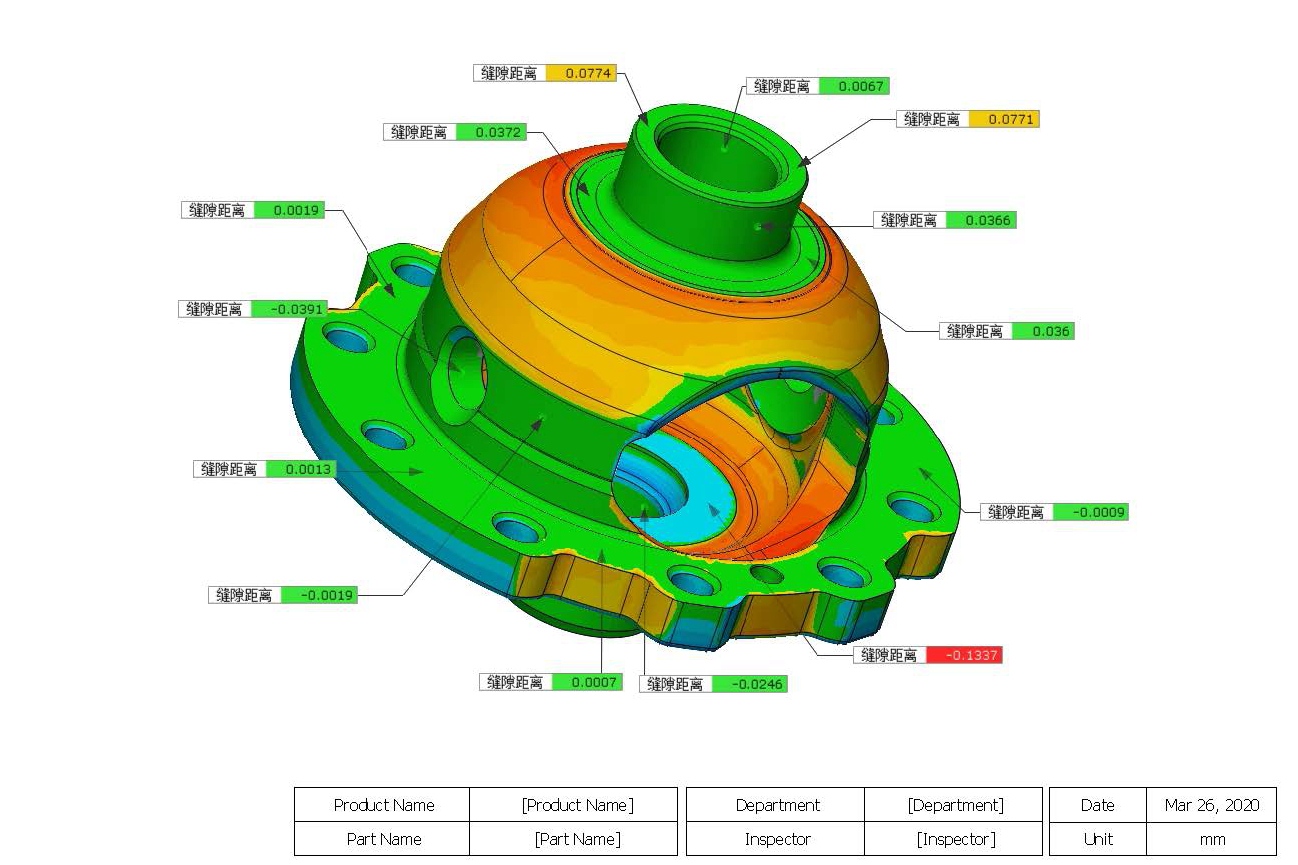

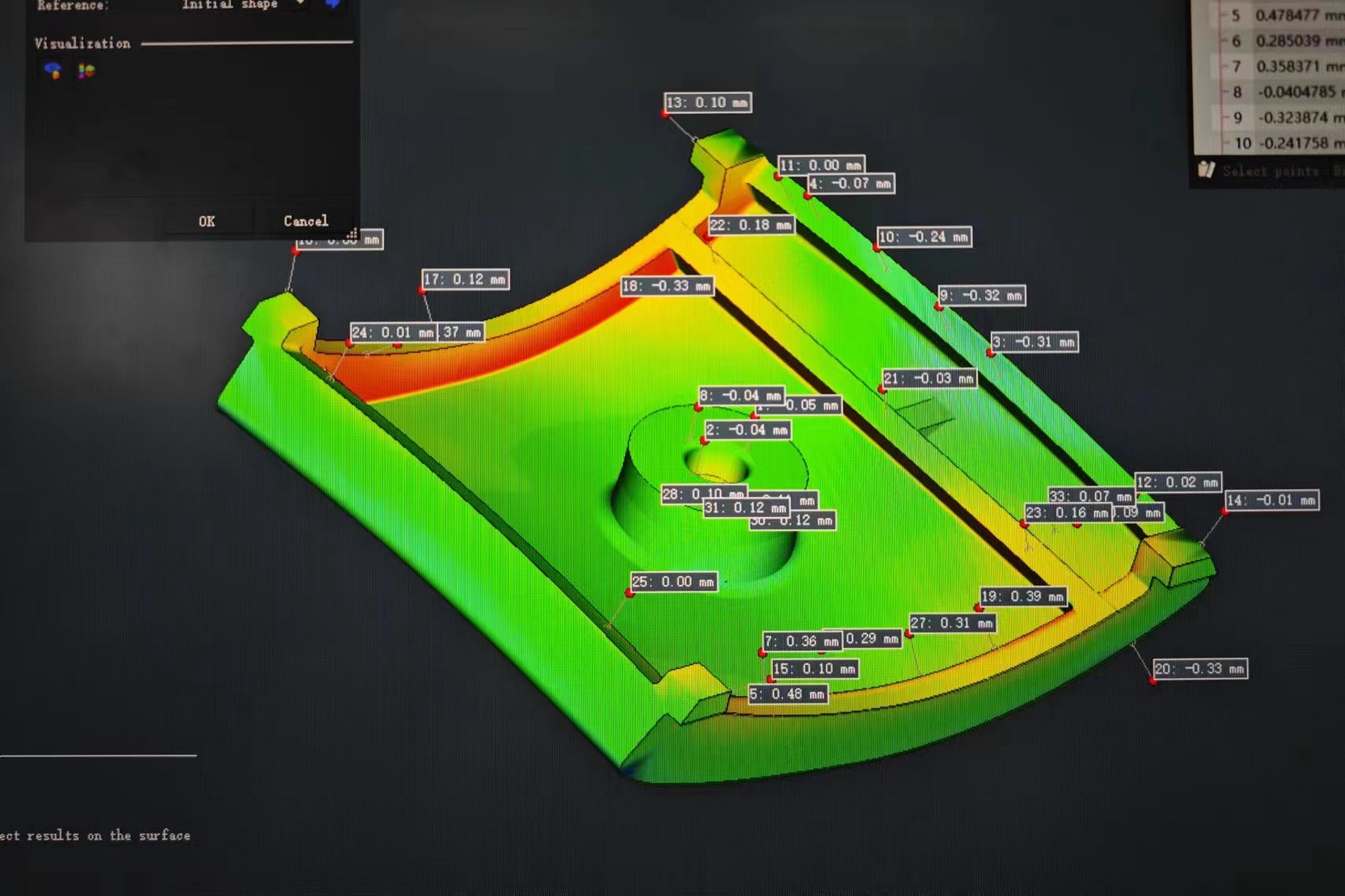

3D Scanning Measuring Instrument Checking

learn more

Coordinate Measuring Machine (CMM)

learn more

Glow Discharge Mass Spectrometer (GDMS)

learn more

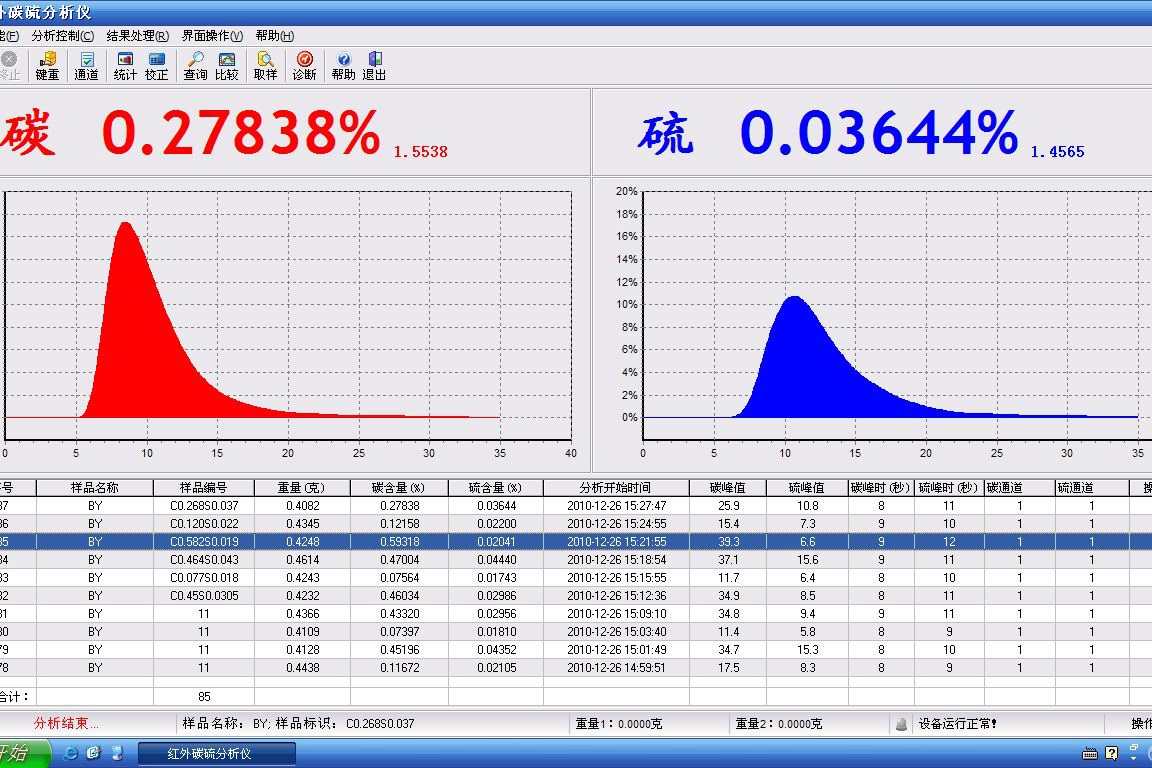

Carbon Sulfur Analyzer Checking

learn more

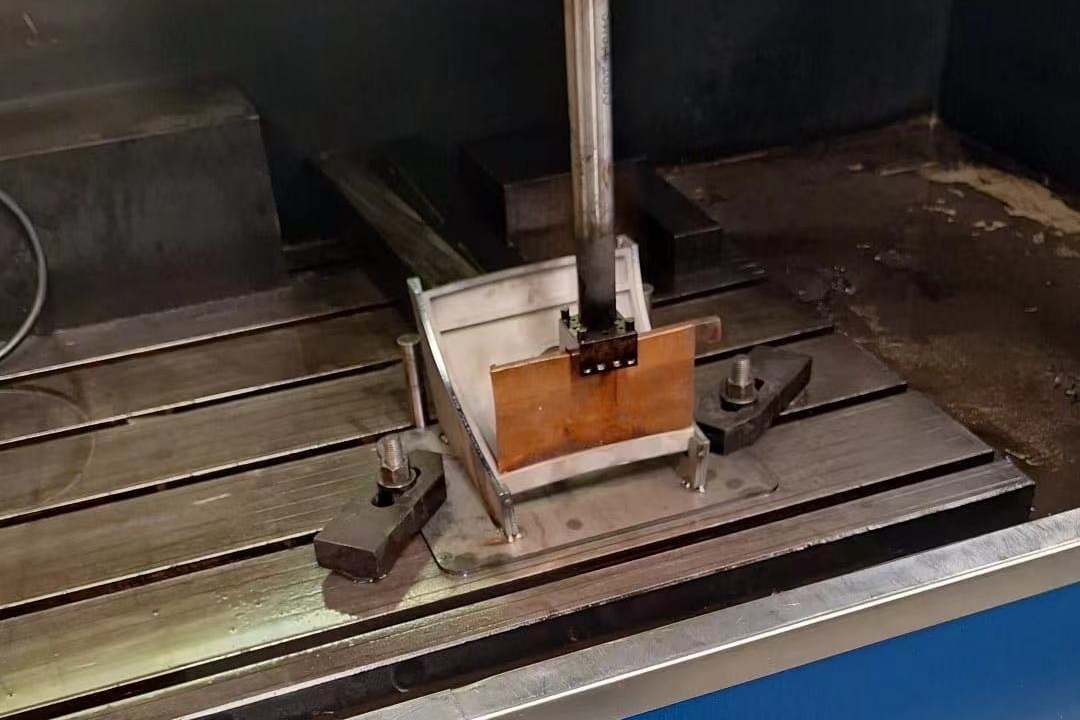

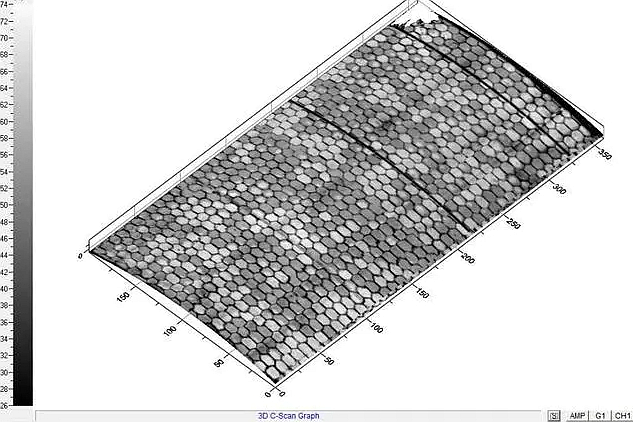

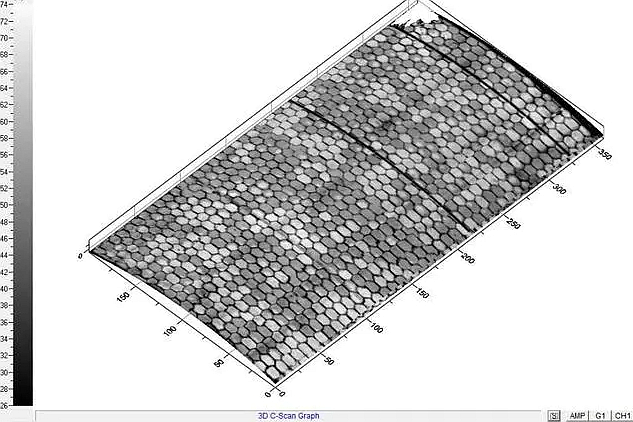

Water Immersion Ultrasonic Inspection

learn more

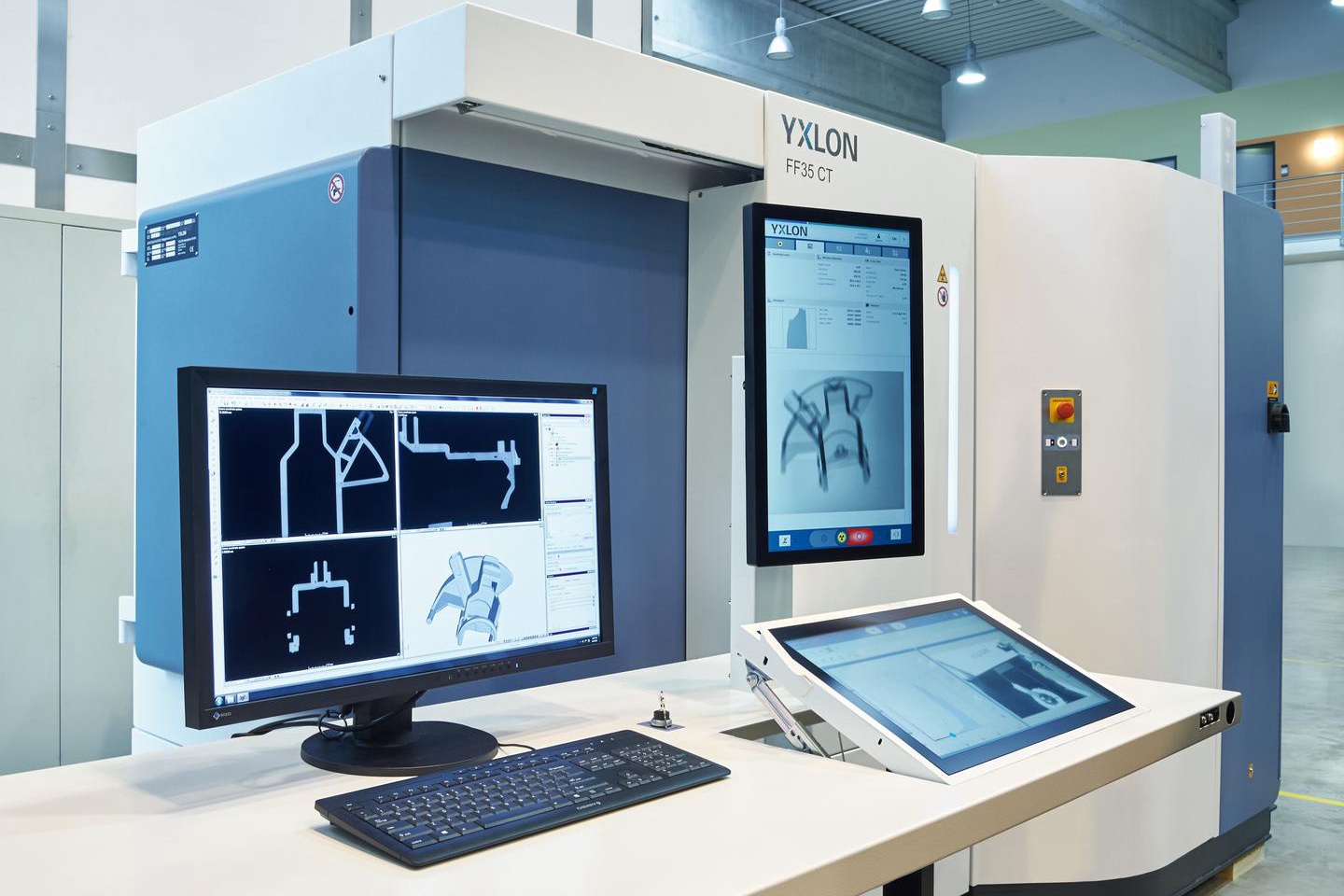

Line Array Industrial CT(GE)

learn more

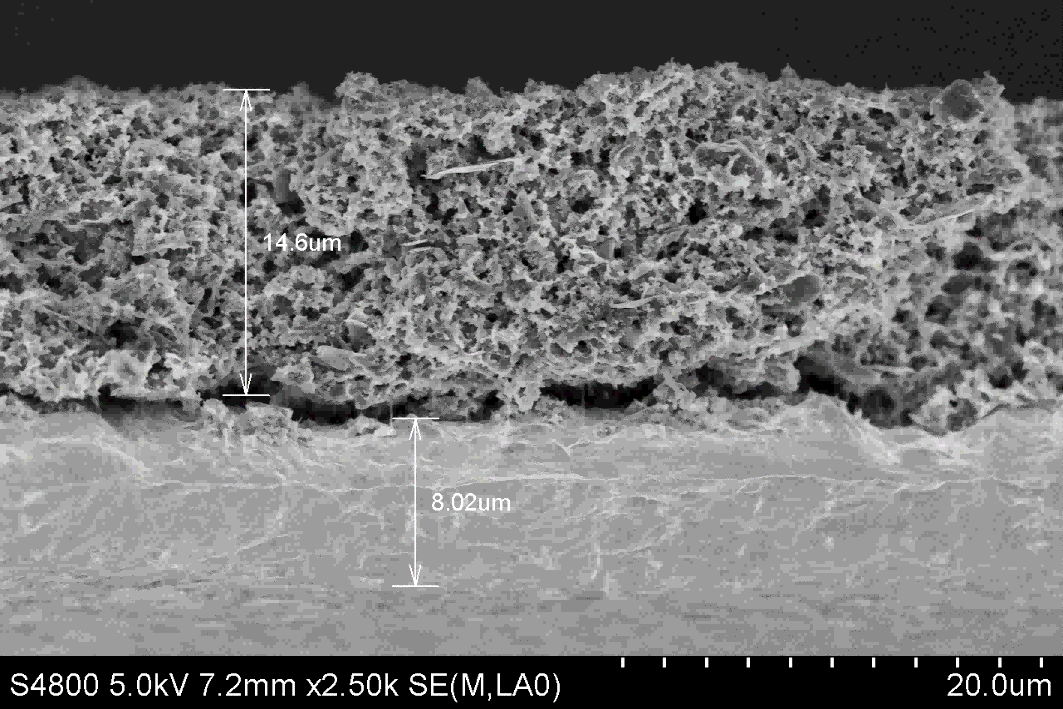

Scanning Electron Microscope (SEM) Checking

learn more

Simultaneous Thermal Analyzer (STA) Checking

learn more

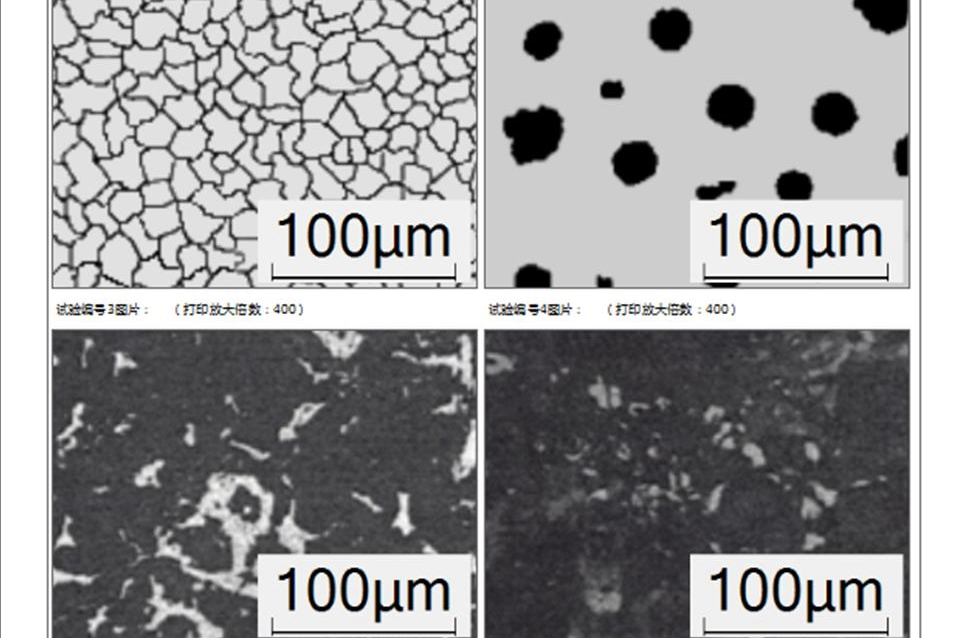

Metallographic Microscopy Checking

learn more

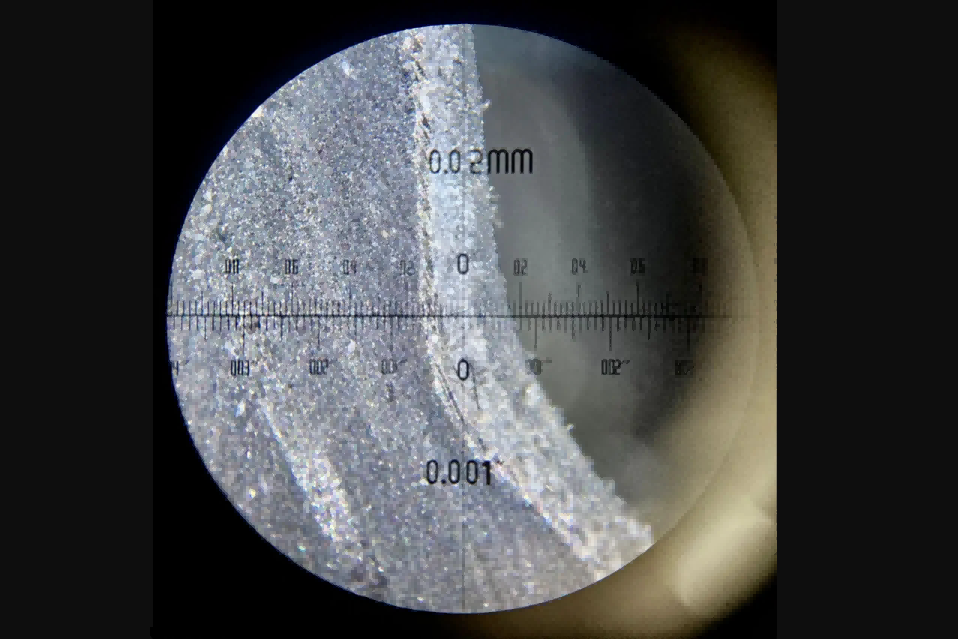

Stereo Microscope Checking

learn more

New Technology

learn more

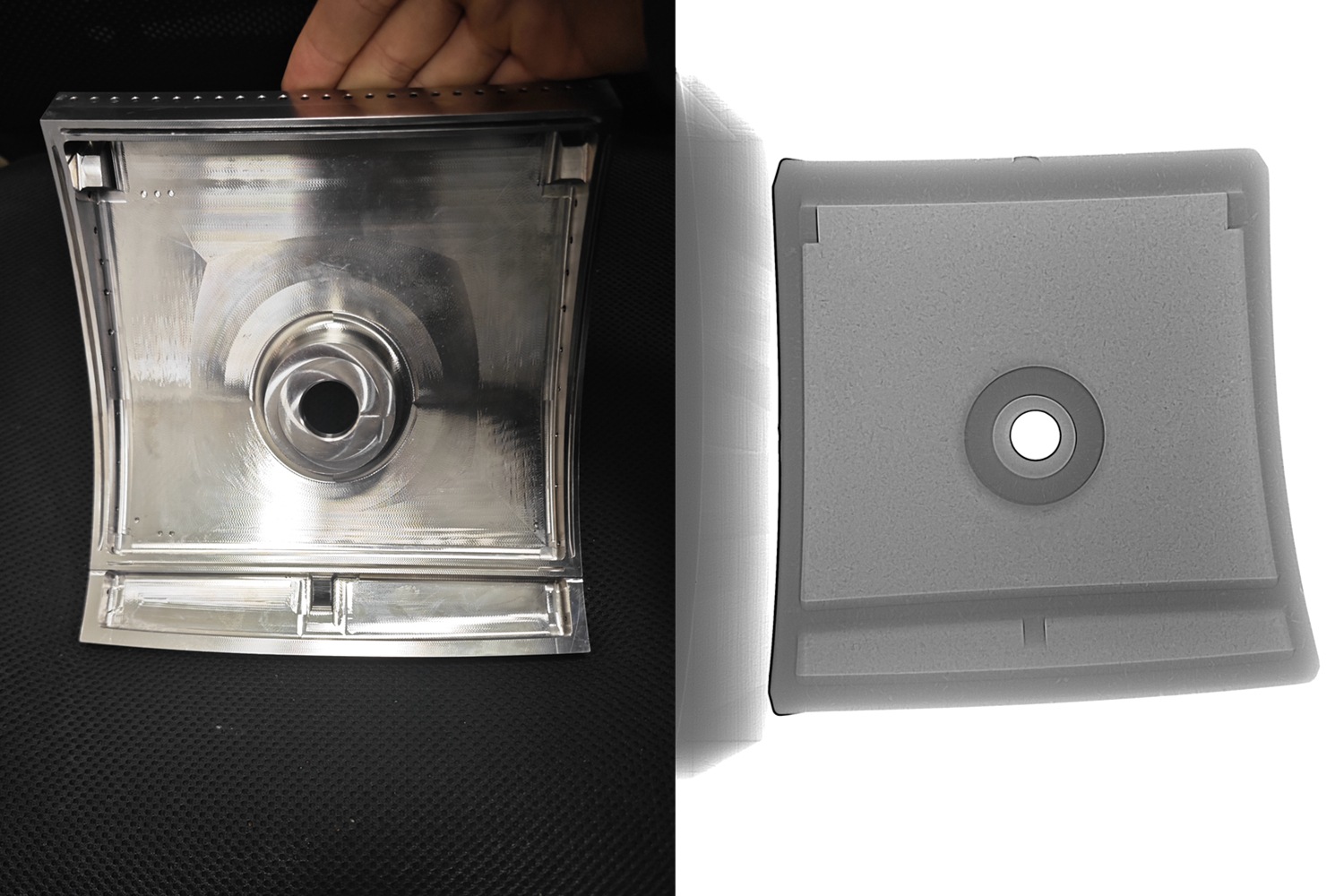

Products Gallery

learn more

Various Industries

learn more

Surface Finishings

learn more

Post-Process

learn more

Manufacturing Technology

learn more

R&D and Simulation

learn more

Manufacturing Equipments

learn more

Testing Equipments

learn more

3D Printing Prototyping

learn more

FAQs

learn more

Contact

Let's Start A New Project Today