Superalloy Equiaxed Crystal Casting Service

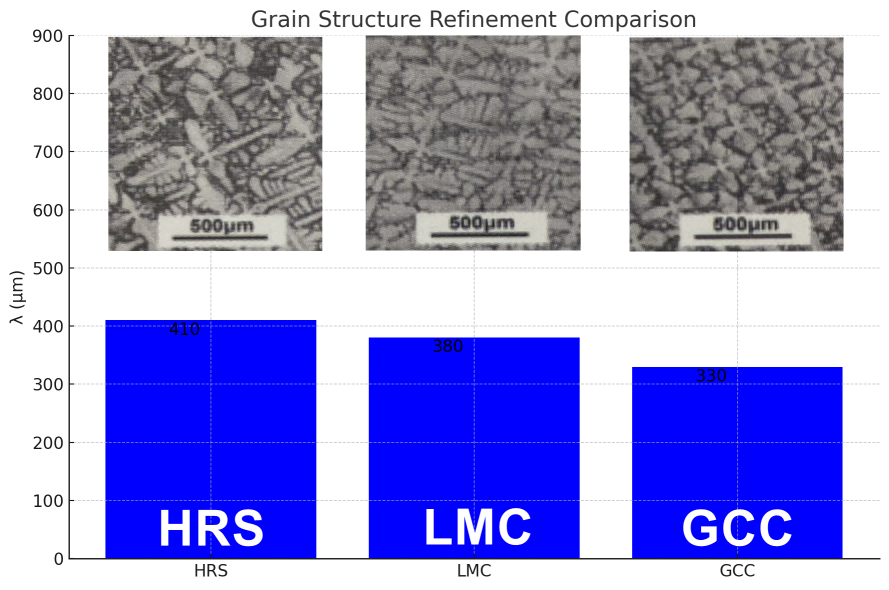

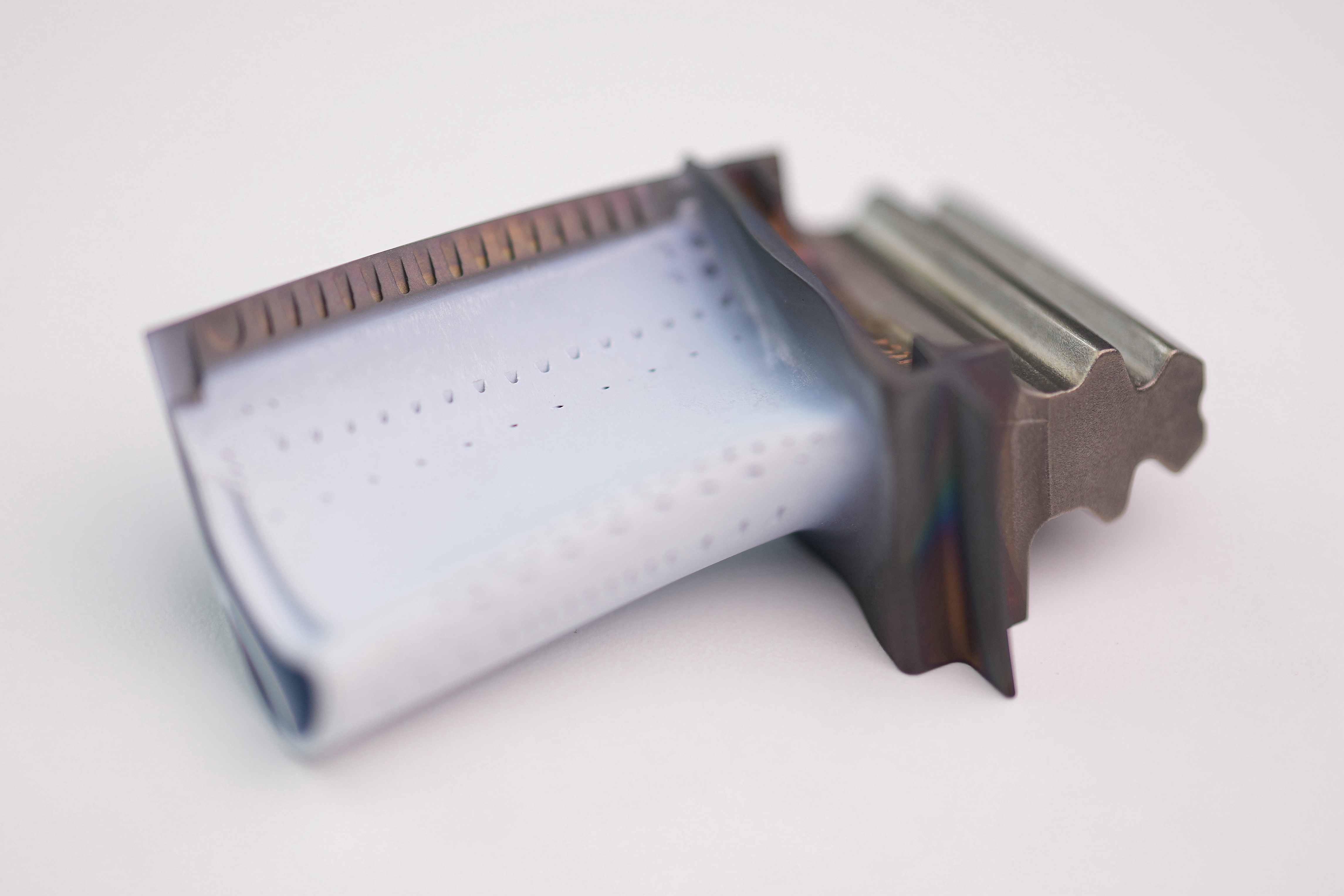

Superalloy Equiaxed Crystal Casting Service produces components with a uniform, granular crystal structure, enhancing mechanical strength and durability. This method is ideal for turbine parts, including disks and wheels, used in high-temperature, high-stress environments like gas turbines.

- Materials: Inconel alloy, Rene Alloy, Monel alloy, Hastelloy alloy, Stellite alloy, Titanium alloy, Nimonic alloy, Cobalt-based Alloys, Nickel-Chromium Alloys

- Post Process:

- Hot Isostatic Pressing (HIP)

- Heat Treatment

- Superalloy Welding

- Thermal Barrier Coating (TBC)

- Material Testing and Analysis

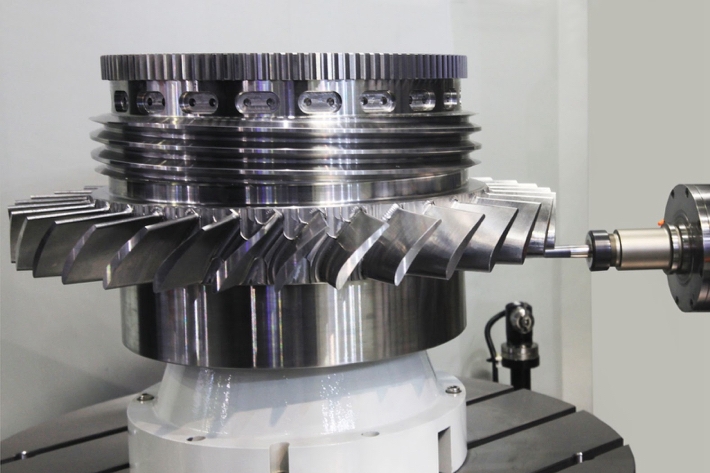

- Superalloy CNC Machining

- Superalloy Deep Hole Drilling

- Electrical Discharge Machining (EDM)

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Industries and Applications for Equiaxed Crystal Castings

Equiaxed crystal casting is a key technology in producing high-performance components, particularly for industries that demand materials with excellent mechanical properties, heat resistance, and durability. Here are the primary industries and applications where equiaxed crystal casting is commonly utilized:

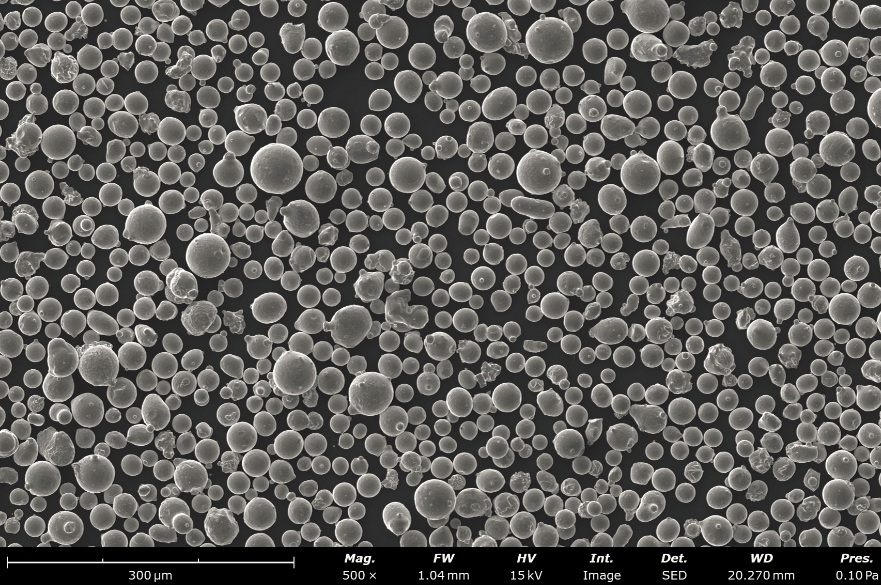

Equiaxed Crystal casting Materials

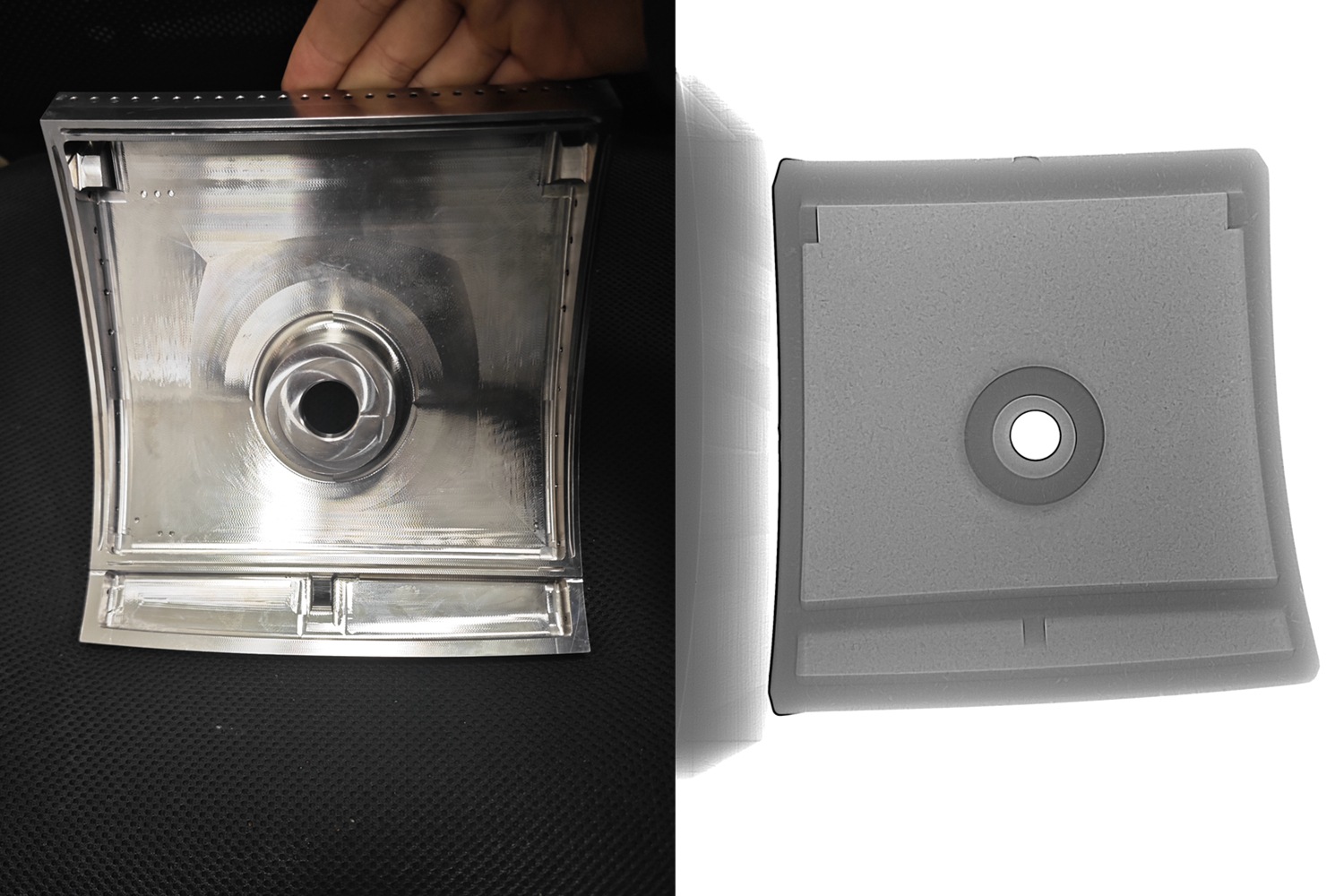

What We Can Do on Equiaxed Crystal Casting

We specialize in Single Crystal Casting for high-temperature components, offering superior creep resistance, thermal fatigue resistance, and oxidation resistance. This process is ideal for producing turbine blades, vanes, and aerospace parts that require precise grain structure control, ensuring enhanced mechanical properties and prolonged service life in extreme environments such as aerospace and power generation industries.

learn more

Direct Reading Spectrometer

learn more

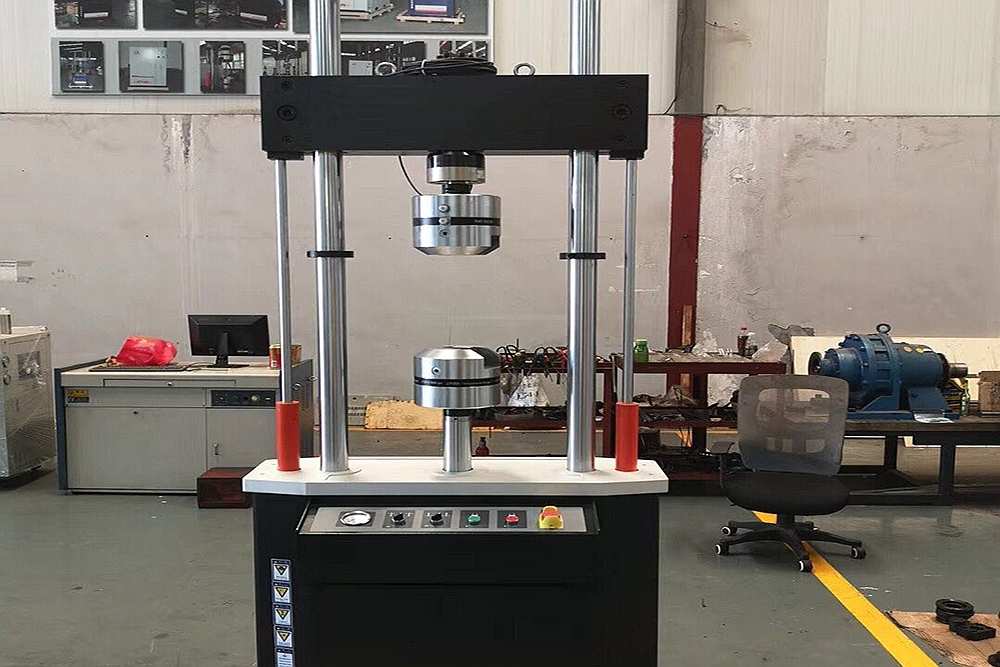

Tensile Testing Machine Checking

learn more

X-ray Checking

learn more

Thermal Physical Properties Test Platform

learn more

Corrosion Production Line

learn more

Dynamic and Static Fatigue Tester

learn more

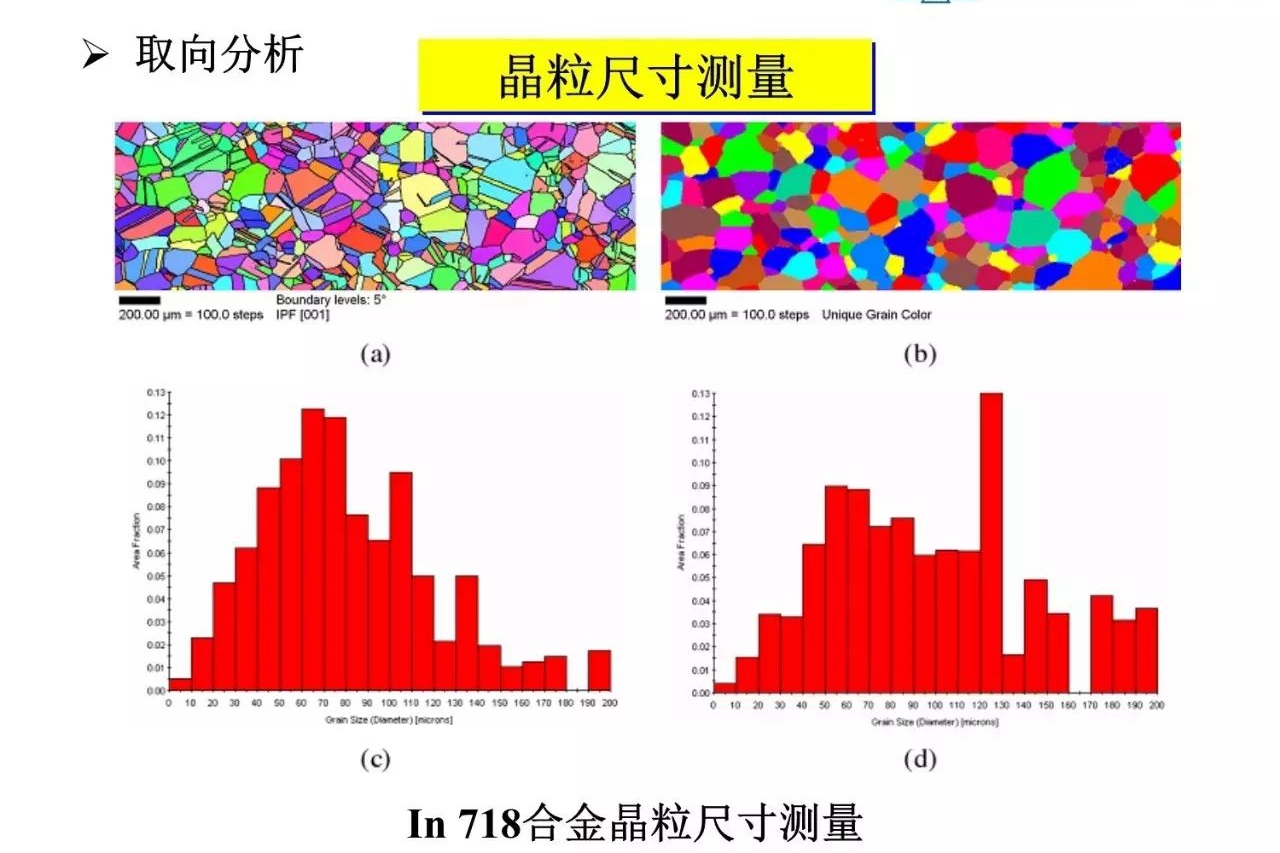

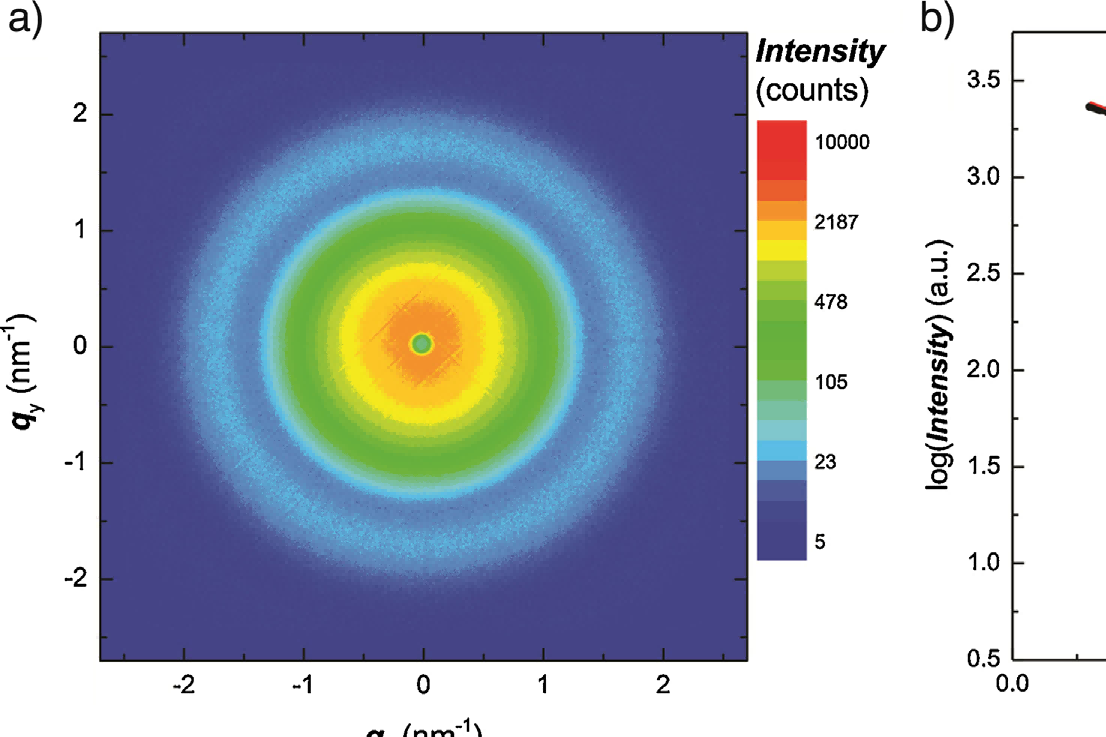

Electron Backscattering Diffractometer (EBSD)

learn more

Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES)

learn more

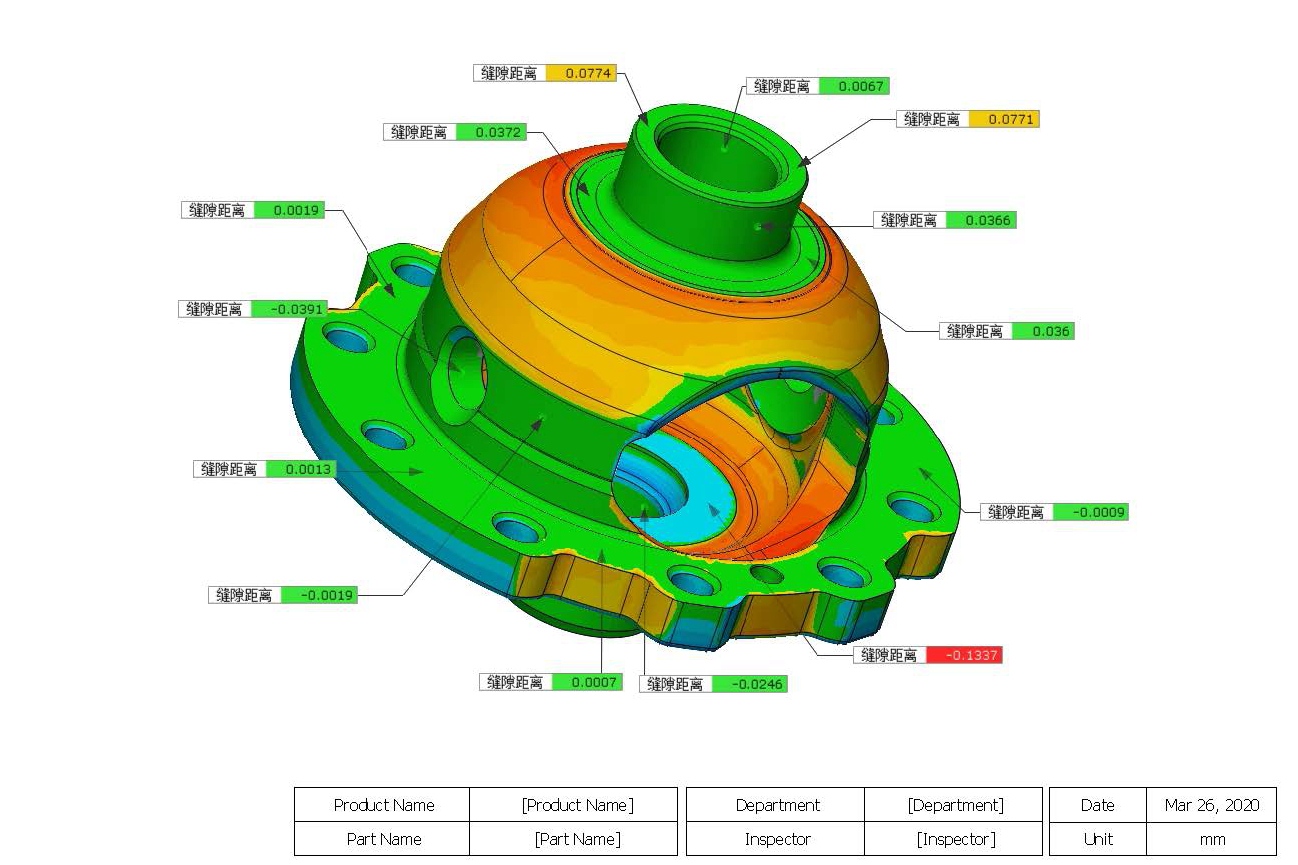

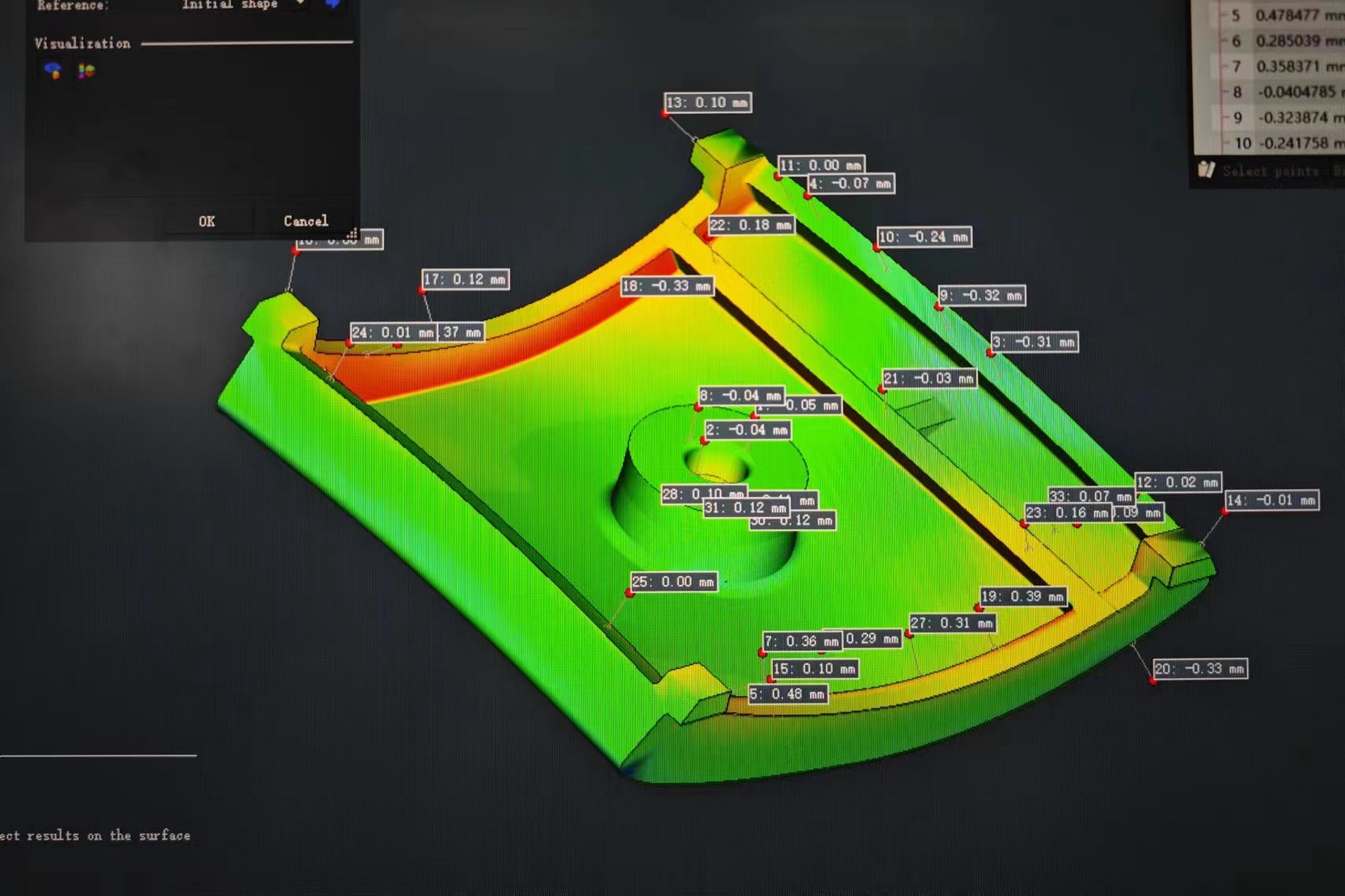

3D Scanning Measuring Instrument Checking

learn more

Coordinate Measuring Machine (CMM)

learn more

Glow Discharge Mass Spectrometer (GDMS)

learn more

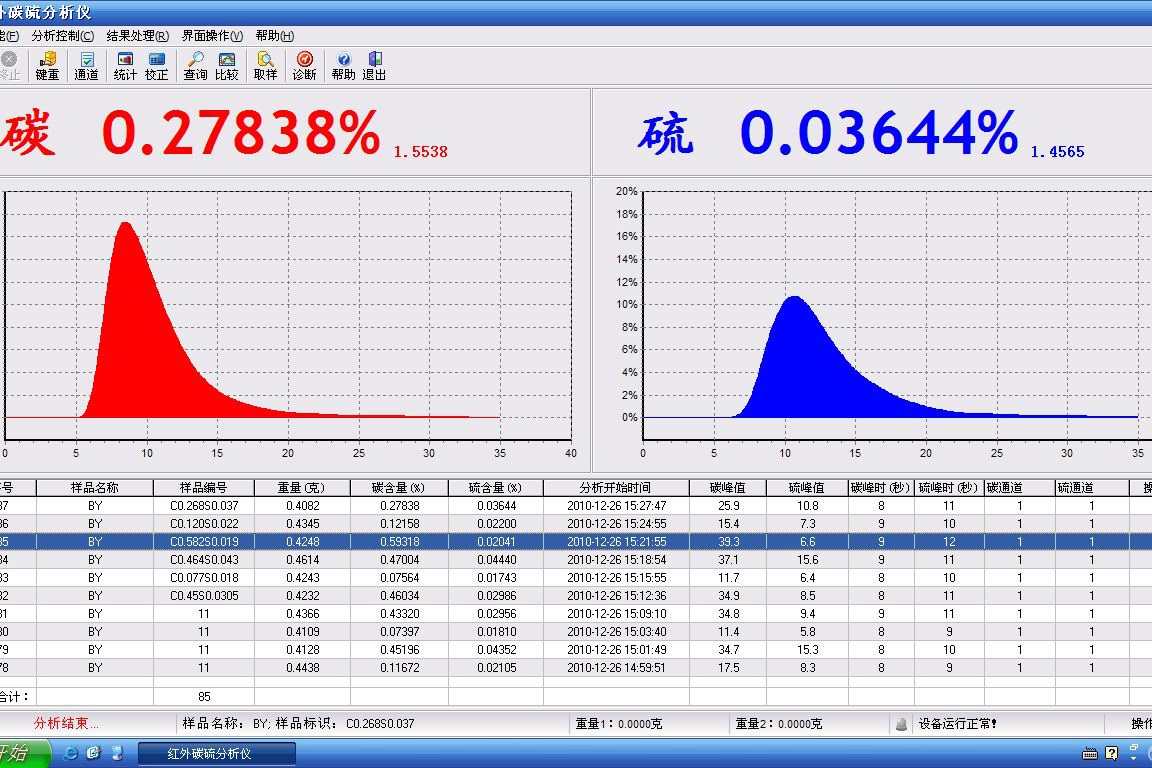

Carbon Sulfur Analyzer Checking

learn more

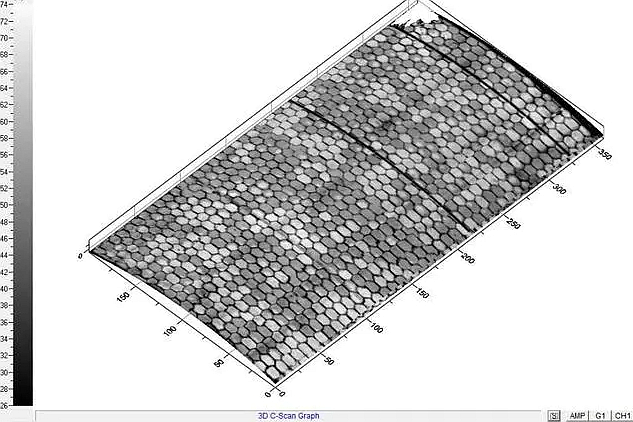

Water Immersion Ultrasonic Inspection

learn more

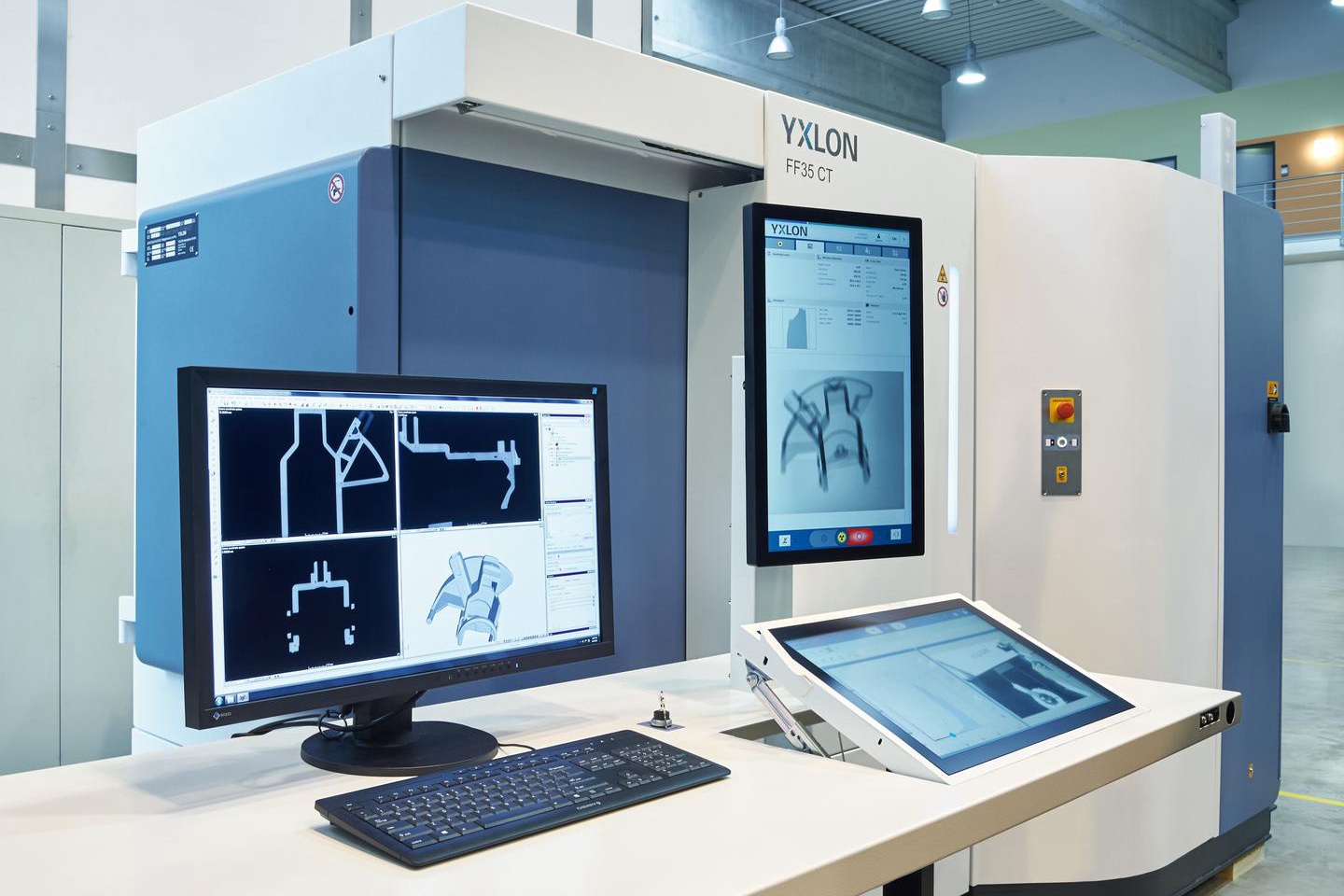

Line Array Industrial CT(GE)

learn more

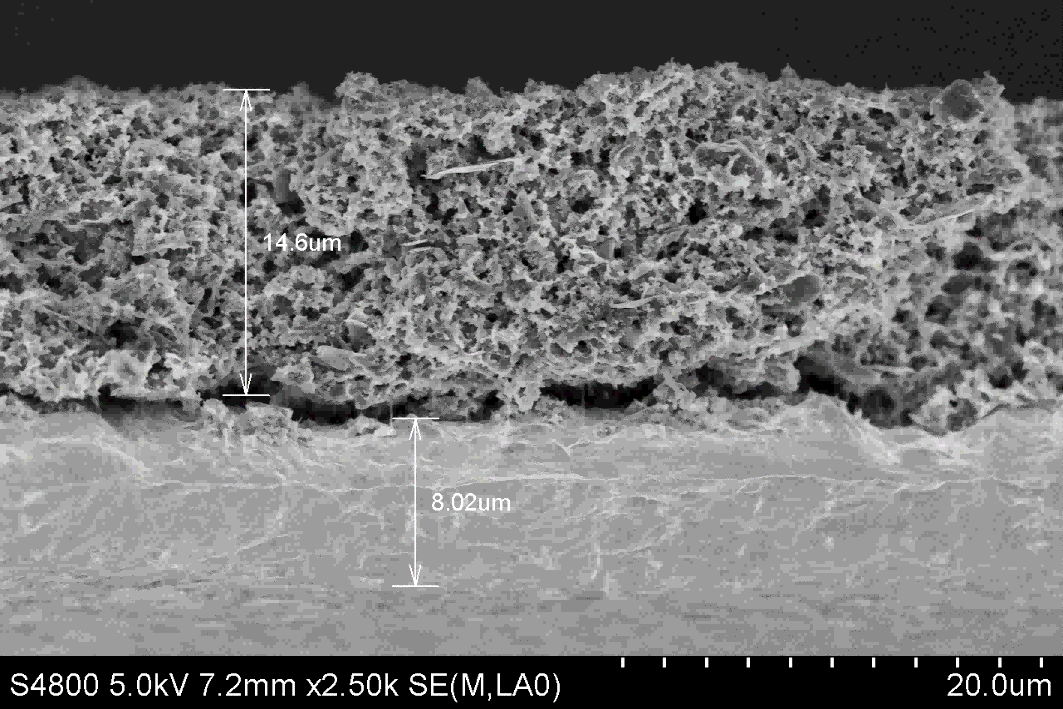

Scanning Electron Microscope (SEM) Checking

learn more

Simultaneous Thermal Analyzer (STA) Checking

learn more

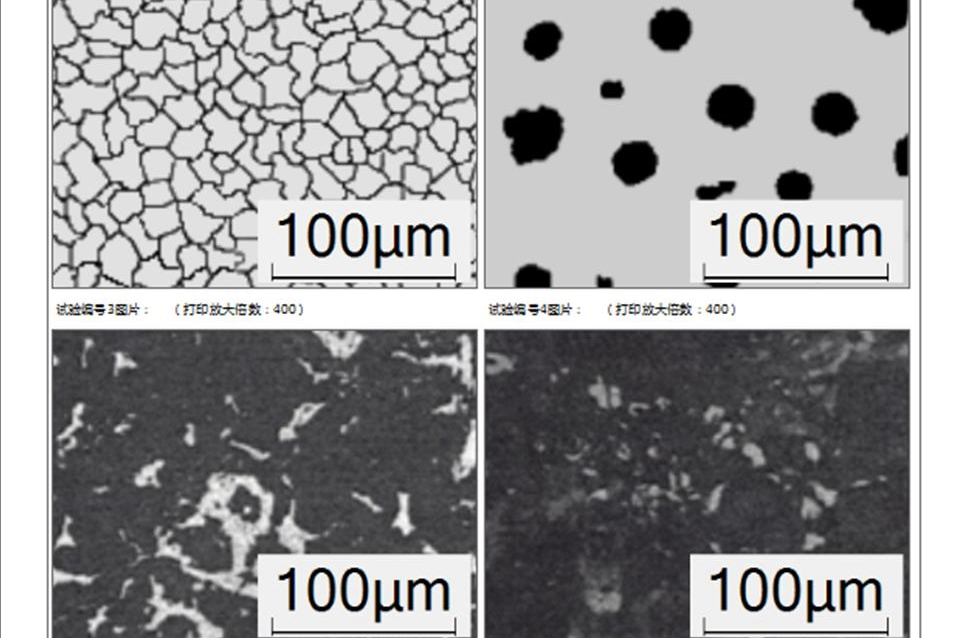

Metallographic Microscopy Checking

learn more

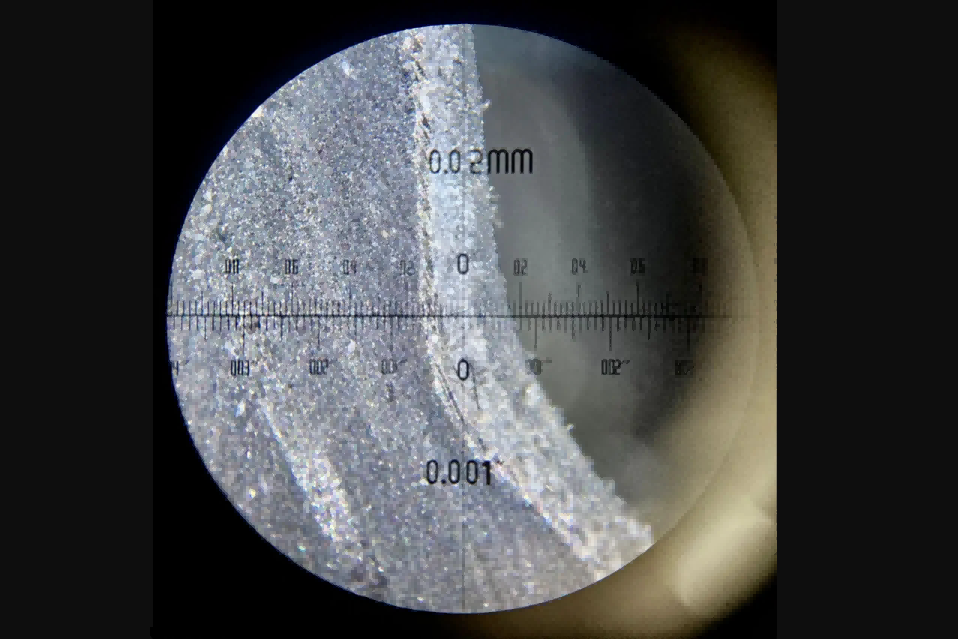

Stereo Microscope Checking

learn more

New Technology

learn more

Products Gallery

learn more

Various Industries

learn more

Surface Finishings

learn more

Post-Process

learn more

Manufacturing Technology

learn more

R&D and Simulation

learn more

Manufacturing Equipments

learn more

Testing Equipments

learn more

3D Printing Prototyping

learn more

FAQs

learn more

Contact

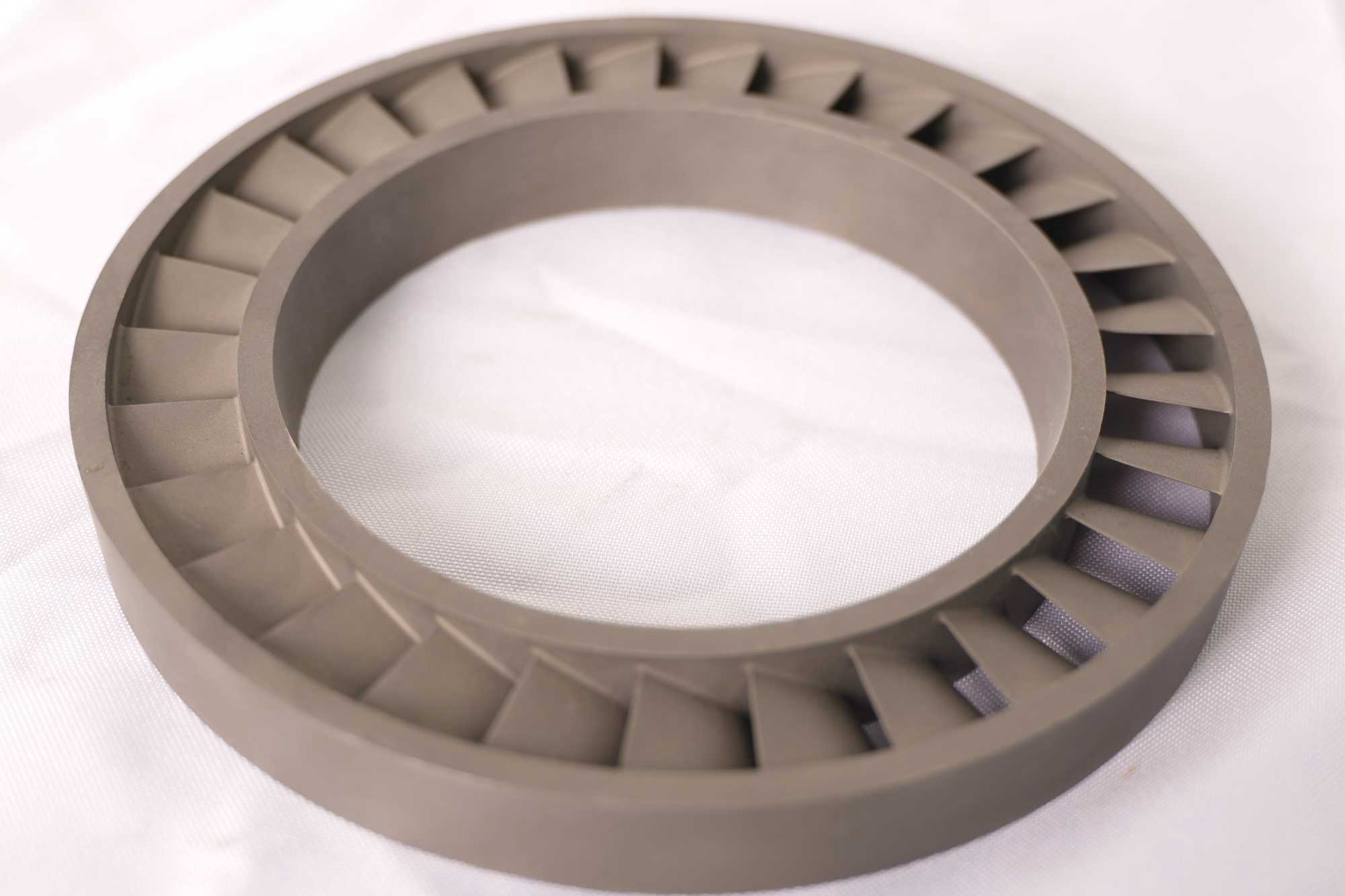

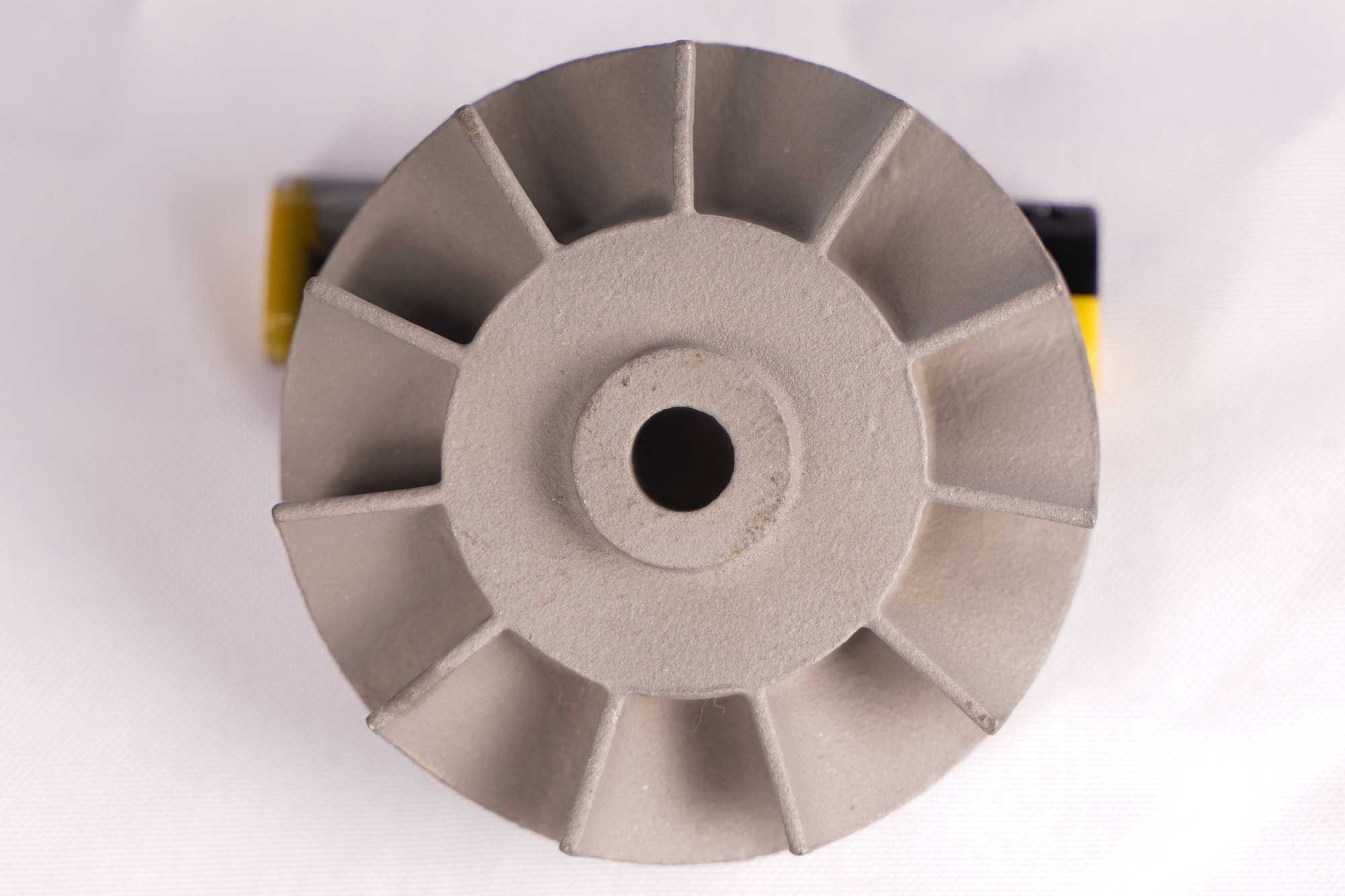

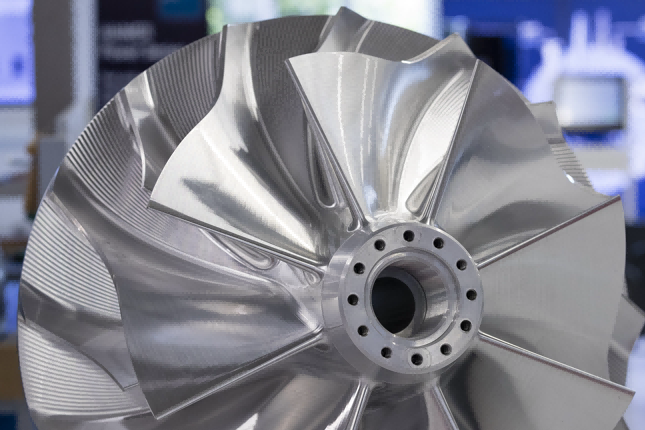

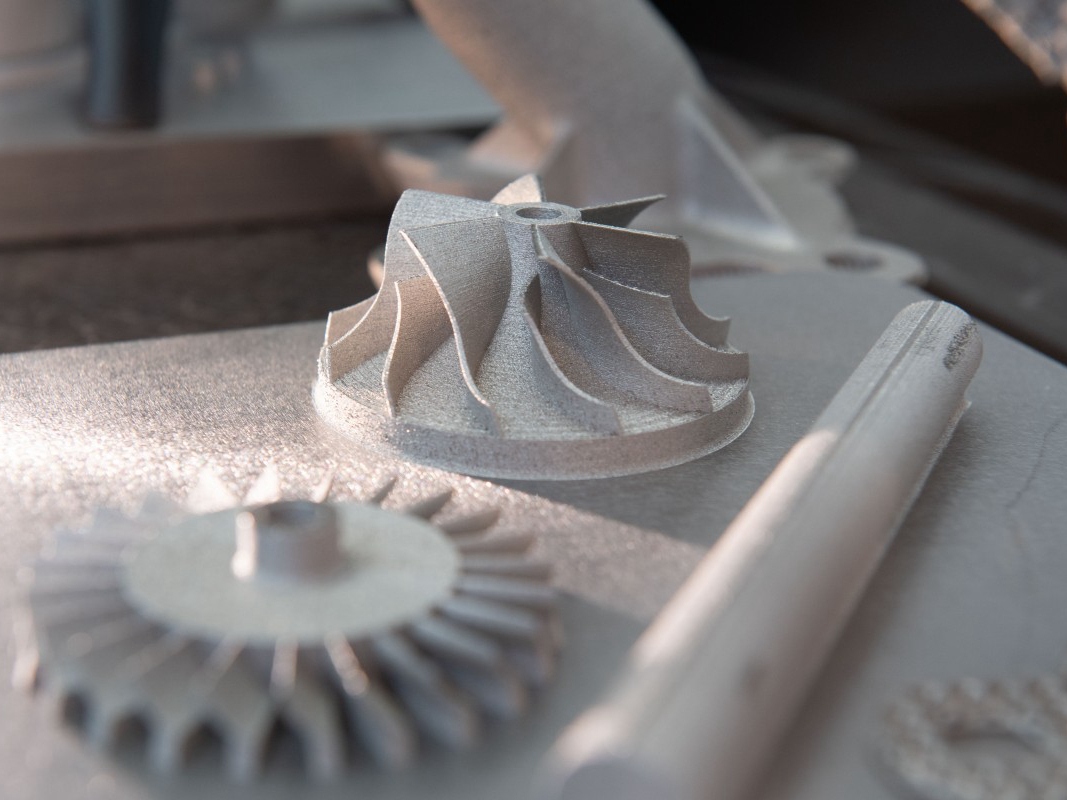

Equiaxed Crystal Castings Gallery

Equiaxed crystal castings are used in turbine blades, combustion chambers, casings, guide vanes, impellers, and turbine discs, primarily in aerospace, gas turbines, and energy sectors, where high-temperature resistance and mechanical strength are essential.

Let's Start A New Project Today