Stellite F

About Stellite F

Stellite F is a cobalt-chromium alloy with excellent wear resistance at elevated temperatures. Although it lacks some formal classifications under ASTM or AMS standards, it shares properties with other high-performance cobalt alloys used in extreme conditions.

This alloy is specifically designed for applications requiring prolonged exposure to elevated temperatures, with excellent mechanical and thermal cycling properties. Stellite F exhibits remarkable hardness and resistance to abrasion, making it a preferred material for high-stress components in demanding industries.

Stellite F Basic Introduction

Stellite F is a cobalt-based superalloy with chromium as the primary alloying element. It offers a balance between hardness, fracture toughness, and corrosion resistance. Its strength and stability at elevated temperatures ensure consistent performance under harsh operating conditions.

The alloy is frequently used for high-wear components exposed to heat and mechanical stress, such as industrial tools, valves, and engine parts. Stellite F’s reliability and resistance to fatigue make it an optimal choice for high-temperature wear applications in aerospace, energy, and chemical processing.

Alternative Superalloys of Stellite F

Stellite F can be compared with other cobalt-based alloys like Stellite 6, Stellite 21, and Haynes 25, which offer similar wear and corrosion resistance properties. For lower-cost applications, stainless steel alloys such as 440C or hard-coated steels may be considered.

Nickel-based superalloys like Inconel 718 or Hastelloy C-276 provide alternatives in environments requiring higher corrosion resistance but may not match Stellite F’s wear resistance. Titanium alloys could also replace Stellite F in cases where weight reduction is essential, though they may not perform as well in high-wear scenarios.

Stellite F Design Intention

The design goal of Stellite F is to provide exceptional wear resistance and strength at high temperatures while maintaining fracture toughness. This alloy was developed under severe mechanical loads, especially in elevated temperatures and thermal cycling conditions.

Stellite F is intended for components requiring long service life with minimal degradation. Its low carbon content improves toughness, while chromium enhances wear resistance and corrosion protection. This design makes Stellite F ideal for parts in turbines, industrial tools, and chemical processing equipment that endure extreme conditions.

Stellite F Chemical Composition

Element | Content (wt%) |

|---|---|

Cobalt (Co) | Balance |

Chromium (Cr) | 25.0-30.0 |

Carbon (C) | 1.0-1.5 |

Nickel (Ni) | 3.0 max |

Silicon (Si) | 1.0 max |

Manganese (Mn) | 1.0 max |

Stellite F Physical Properties

Stellite F offers outstanding physical properties, ensuring high performance under demanding conditions.

Property | Value |

|---|---|

Density (g/cm³) | 8.82 |

Melting Point (℃) | 1370 |

Thermal Conductivity (W/(m·K)) | 12.8 |

Modulus of Elasticity (GPa) | 210 |

Metallographic Structure of Stellite F Superalloy

The microstructure of Stellite F consists of a cobalt-rich matrix reinforced by chromium carbides. These carbides are finely dispersed throughout the matrix, contributing to the alloy’s hardness and wear resistance.

The microstructure remains stable in high-temperature environments, preventing softening or structural degradation. This makes Stellite F particularly effective in maintaining its mechanical integrity under prolonged thermal and mechanical cycling.

Stellite F Mechanical Properties

Property | Value |

|---|---|

Tensile Strength (MPa) | ~850 |

Yield Strength (MPa) | ~500 |

Hardness (HRC) | ~45-50 |

Elongation (%) | ~5-8 |

Fatigue Strength (MPa) | ~250 |

Elastic Modulus (GPa) | ~205 |

Key Features of Stellite F Superalloy

High-Temperature Wear Resistance Stellite F excels in wear resistance, especially under elevated temperatures, making it ideal for components exposed to friction and abrasion in hot environments.

Superior Fracture Toughness With excellent fracture toughness, Stellite F ensures durability under extreme mechanical loads, reducing the likelihood of brittle failure.

Thermal Fatigue Resistance The alloy maintains strength and dimensional stability through multiple heating and cooling cycles, offering long-term reliability in high-temperature applications.

Corrosion Resistance Chromium content provides resistance to corrosion in harsh chemical environments, making Stellite F suitable for chemical processing and marine applications.

Longevity in Severe Conditions Stellite F’s microstructure ensures sustained performance under mechanical stress, ensuring long service life for industrial components in extreme conditions.

Stellite F Superalloy’s Machinability

Vacuum Investment Casting: Stellite F is not well-suited for Vacuum Investment Casting due to its high wear resistance and carbide structure, which complicates casting. It is more effectively fabricated through other processes, such as machining or welding.

Single Crystal Casting: Stellite F is not applicable for Single Crystal Casting as it relies on a cobalt-rich matrix and carbide phases, which are incompatible with the single-crystal structure requirements.

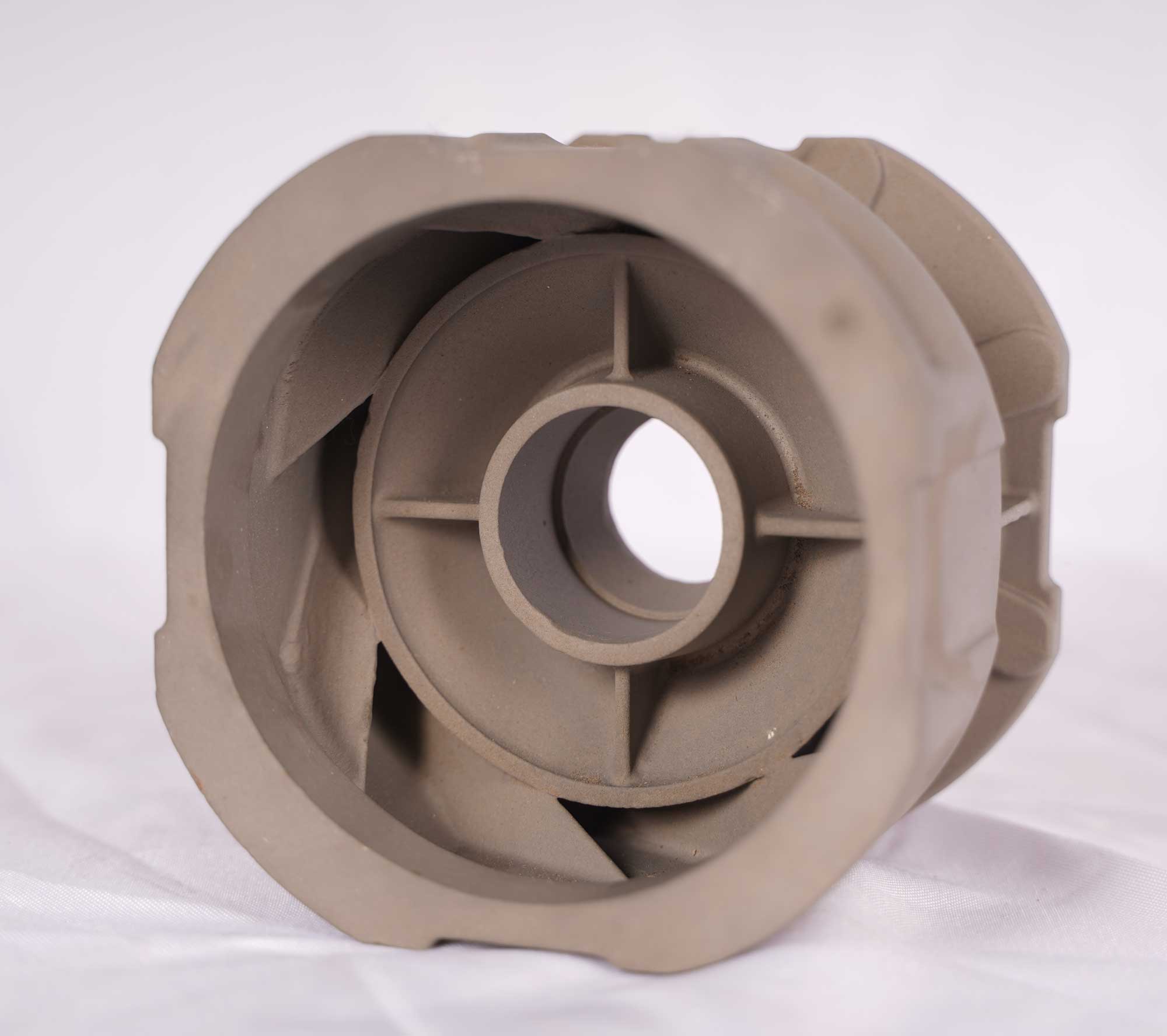

Equiaxed Crystal Casting: Stellite F can be used in Equiaxed Crystal casting since its grain structure and wear-resistant properties align with the mechanical needs of this casting method.

Directional Casting: The alloy’s wear resistance and thermal stability make it worthwhile for Superalloy Directional Casting when abrasion resistance is essential.

Powder Metallurgy Turbine Disc: The powder metallurgy turbine disc is not typically suitable for Stellite F, as it is optimized for direct wear applications rather than turbine discs that require extremely high-temperature strength.

Precision Forging: Stellite F is less ideal for Superalloy Precision Forging due to its limited ductility and machining challenges.

Superalloy 3D Printing: Superalloy 3D Printing of Stellite F is possible, particularly for wear-resistant coatings and small parts, but the high cobalt content complicates printing.

Superalloy CNC Machining: CNC Machining is preferred for Stellite F, although its hardness demands specialized tools and techniques.

Superalloy Welding: Stellite F suits Superalloy Welding applications, especially when wear-resistant overlays are required on critical components.

Hot Isostatic Pressing (HIP): Hot Isostatic Pressing (HIP) may be used for complex parts to improve mechanical properties and eliminate porosity in Stellite F components.

Stellite F Superalloy Applications

Aerospace and Aviation: Stellite F is widely used in Aerospace and Aviation for turbine engine components, valve seats, and wear-resistant coatings on tools exposed to high temperatures.

Power Generation: Power generation provides critical wear resistance for steam and gas turbines, where long service life under extreme conditions is essential.

Oil and Gas: Stellite F is applied in Oil and Gas for valve seats, bearings, and components that resist corrosion and wear in high-pressure environments.

Energy: In the Energy sector, Stellite F is used for pumps, seals, and parts that operate at elevated temperatures, ensuring continuous reliability.

Marine: Stellite F performs well in Marine environments, providing corrosion-resistant coatings for propellers, pumps, and valve parts.

Mining: The alloy is highly valued in Mining applications for wear plates, cutters, and tools exposed to abrasive conditions.

Automotive: In Automotive applications, Stellite F ensures durability in fuel injectors, valve seats, and other high-stress engine components.

Chemical Processing: Stellite F resists corrosion and chemical degradation in Chemical Processing facilities, ensuring long-term performance in aggressive environments.

Pharmaceutical and Food: In the Pharmaceutical and Food industries, Stellite F is employed in valves and processing equipment to ensure wear resistance and safety under sanitary conditions.

Military and Defense: Stellite F plays a role in Military and Defense for high-wear components, such as ammunition feed systems and protective coatings on heavy machinery.

Nuclear: The alloy finds applications in Nuclear reactors for wear-resistant components that endure radiation and extreme temperatures.

When to Choose Stellite F Superalloy

Stellite F should be selected when wear resistance and durability under high-temperature conditions are critical. It is best used in environments requiring custom superalloy parts that resist mechanical and thermal fatigue over extended periods. Components exposed to high-pressure, corrosive, or abrasive conditions—such as valves, bearings, and pumps—benefit significantly from Stellite F.

This alloy is ideal for aerospace, oil and gas, and power generation, where reliability and minimal downtime are essential. If the application involves exposure to both heat and wear, Stellite F ensures long-lasting performance, reducing maintenance frequency and operational costs.