Ti-15V-3Cr-3Sn-3Al

About Ti-15V-3Cr-3Sn-3Al Superalloy

Ti-15V-3Cr-3Sn-3Al, known as Titanium Grade 15-3-3-3, is recognized for its exceptional strength and high fatigue resistance. With the UNS designation R58153, this alloy conforms to ASTM B348 and F468 standards, ensuring its suitability for aerospace and industrial use. Ti-15V-3Cr-3Sn-3Al excels in maintaining mechanical properties under cyclic loads and elevated temperatures.

This alloy’s chemical composition, including chromium, vanadium, and tin, enhances corrosion resistance and durability. Ti-15V-3Cr-3Sn-3Al is a go-to material for high-performance applications requiring prolonged stability under repetitive stress.

Alternative Superalloys of Ti-15V-3Cr-3Sn-3Al

Comparable materials include Ti-10V-2Fe-3Al, Ti-6Al-4V, and Ti-5Al-5Mo-5V-3Cr. Ti-10V-2Fe-3Al offers similar high fatigue strength, while Ti-6Al-4V is widely favored for corrosion resistance and ease of use. Ti-5Al-5Mo-5V-3Cr performs reliably under high stress, making it another alternative for demanding environments.

The selection of these alternatives depends on specific mechanical or environmental conditions. Each alloy offers distinct advantages, from corrosion resistance to extreme fatigue performance.

Ti-15V-3Cr-3Sn-3Al Design Intention

Ti-15V-3Cr-3Sn-3Al was developed to meet the needs of applications requiring high strength, fatigue resistance, and long-term performance under cyclic loads. This alloy is primarily used in aerospace applications, where lightweight materials must perform under heavy stress. Chromium and tin add corrosion resistance, making the alloy durable in aggressive environments.

The presence of vanadium enhances strength, while the alloy’s ductility ensures it can withstand deformation without cracking. Ti-15V-3Cr-3Sn-3Al’s unique properties make it indispensable in components subjected to repeated loading and extreme temperatures.

Ti-15V-3Cr-3Sn-3Al Chemical Composition

The alloy's key elements contribute to its mechanical and corrosion resistance properties. Vanadium strengthens the alloy, chromium adds wear resistance, and tin boosts corrosion resistance.

Element | Composition (%) |

|---|---|

Aluminum (Al) | 2.5-3.5 |

Vanadium (V) | 9.0-11.0 |

Tin (Sn) | 2.5-3.5 |

Chromium (Cr) | 2.5-4.5 |

Iron (Fe) | 0.3-0.7 |

Ti-15V-3Cr-3Sn-3Al Physical Properties

Ti-15V-3Cr-3Sn-3Al offers high tensile strength and good thermal conductivity, supporting its use in high-performance aerospace applications.

Property | Value |

|---|---|

Density (g/cm³) | 4.6 |

Melting Point (℃) | 1700 |

Tensile Strength (MPa) | 1100 |

Thermal Conductivity (W/m·K) | 6.5 |

Modulus of Elasticity (GPa) | 115 |

Metallographic Structure of Ti-15V-3Cr-3Sn-3Al Superalloy

Ti-15V-3Cr-3Sn-3Al features a beta-phase titanium structure, which improves its ductility and toughness. This structure supports high fatigue resistance, ensuring the alloy can withstand cyclic loads. Additionally, the beta phase offers superior elongation properties, enabling the alloy to maintain stability under stress without cracking.

Ti-15V-3Cr-3Sn-3Al achieves a refined grain structure with proper heat treatment, enhancing strength and fatigue resistance. The metallurgical stability of this alloy ensures reliable long-term performance in demanding environments.

Ti-15V-3Cr-3Sn-3Al Mechanical Properties

This alloy exhibits excellent mechanical performance under cyclic stress and high temperatures.

Mechanical Property | Value |

|---|---|

Tensile Strength (MPa) | 703-820 |

Yield Strength (MPa) | 690 |

Hardness (HRC) | 25-30 |

Elongation (%) | 12% |

Elastic Modulus (GPa) | 110-115 |

Key Features of Ti-15V-3Cr-3Sn-3Al Superalloy

High Strength-to-Weight Ratio Ti-15V-3Cr-3Sn-3Al delivers excellent mechanical strength with minimal weight, making it ideal for aerospace applications.

Exceptional Fatigue Resistance: The alloy's resistance to cyclic stress ensures reliability in applications subjected to repeated loading, such as aerospace and industrial components.

Thermal Stability Ti-15V-3Cr-3Sn-3Al retains its mechanical properties up to 288°C, making it suitable for high-temperature environments.

Corrosion Resistance Chromium and tin elements enhance corrosion resistance, extending the alloy’s service life in aggressive conditions.

Long-Term Durability This alloy offers exceptional performance under cyclic stress, ensuring long-lasting reliability in high-stress applications.

Ti-15V-3Cr-3Sn-3Al Superalloy’s Machinability

Ti-15V-3Cr-3Sn-3Al is unsuitable for Vacuum Investment Casting due to its beta-phase structure, which can lead to challenges during solidification. It is more effective in applications where mechanical properties are achieved through cold working. Learn more about Vacuum Investment Casting.

This alloy is unsuitable for Single Crystal Casting since the composition favors cold workability over directional grain growth. Single crystal structures are best reserved for nickel-based superalloys. Explore more about Single Crystal Casting.

Ti-15V-3Cr-3Sn-3Al performs well in Equiaxed Crystal Casting, offering consistent grain structure and reliable mechanical performance for high-stress applications. Check details on Equiaxed Crystal Casting.

Due to the alloy’s cold workability, it is not typically used for Directional Casting. The focus remains on stable beta-phase grains rather than elongated structures. Read more about Superalloy Directional Casting.

Due to its cold-forming focus, ti-15V-3Cr-3Sn-3Al is inappropriate for Powder Metallurgy Turbine Disc production. Explore alternative superalloys for such uses in Powder Metallurgy Turbine Disc.

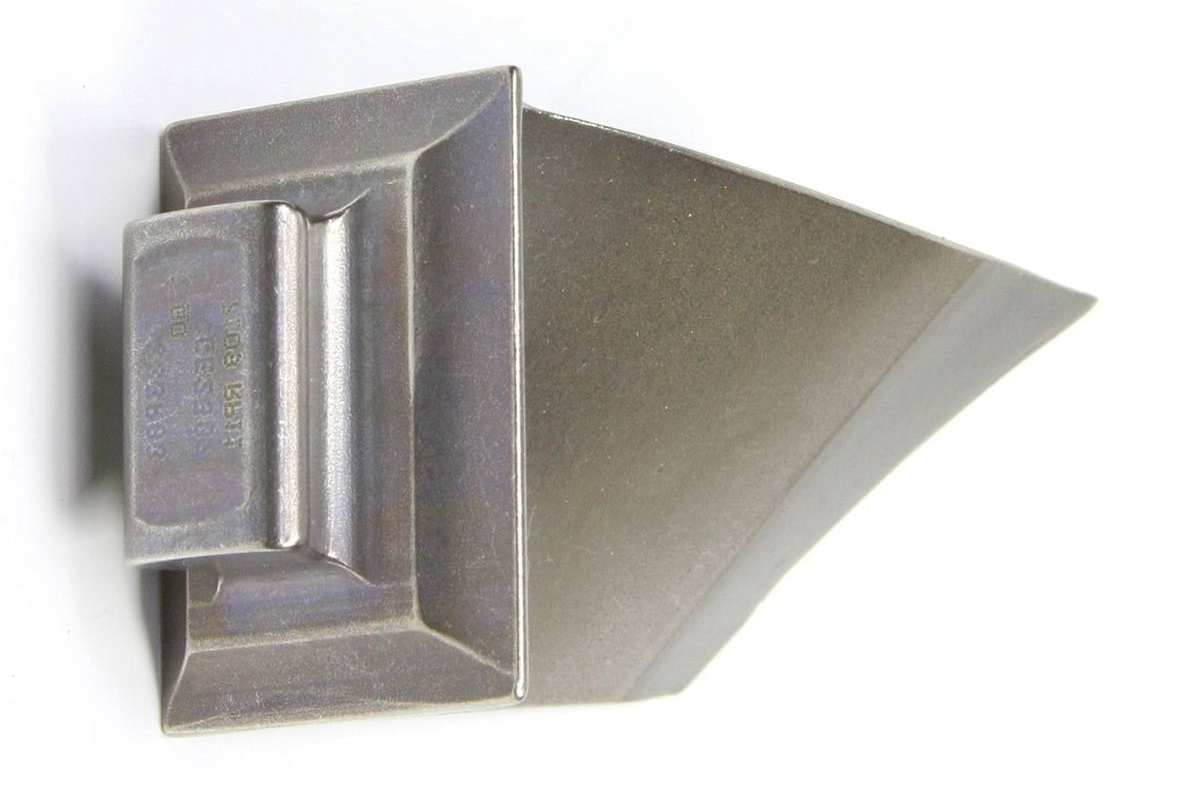

This alloy is suitable for Precision Forging, leveraging its strength and fatigue resistance to shape complex, high-stress components. Find out more about Superalloy Precision Forging.

Ti-15V-3Cr-3Sn-3Al is unsuitable for Superalloy 3D Printing since its mechanical properties depend on cold working rather than powder-based techniques. Learn about Superalloy 3D Printing.

Given its stability and tolerance for precise cuts, the alloy works well in Superalloy CNC Machining. See details on CNC Machining.

Welding Ti-15V-3Cr-3Sn-3Al can be challenging, but Superalloy Welding is possible with controlled heat input to prevent cracking. Discover more about Superalloy Welding.

Ti-15V-3Cr-3Sn-3Al is not recommended for Hot Isostatic Pressing (HIP) as its beta-phase properties are optimized for cold-working rather than high-pressure densification. Learn more about Hot Isostatic Pressing (HIP).

Ti-15V-3Cr-3Sn-3Al Superalloy Applications

Due to its high fatigue strength, this alloy is utilized in structural airframe components and landing gear in the Aerospace and Aviation industry. Explore Aerospace and Aviation.

For Power Generation, Ti-15V-3Cr-3Sn-3Al supports components in turbines and generators where long-term stress resistance is essential. Visit Power Generation.

The alloy offers corrosion resistance in oil and gas for downhole tools and pipelines operating in aggressive environments. Read more about Oil and Gas.

It serves power transmission applications requiring lightweight and fatigue-resistant materials within the energy sector. Learn about Energy.

The Marine industry uses this alloy for propellers and shafts that demand high corrosion and fatigue resistance. Find out more about Marine.

In Mining, the alloy supports drilling components, where toughness and resistance to cyclic stress are crucial. Explore Mining.

For the Automotive industry, Ti-15V-3Cr-3Sn-3Al is used in racing components due to its lightweight properties and durability. Visit Automotive.

In Chemical Processing, the alloy's corrosion resistance extends the life of vessels and reactors. Check out Chemical Processing.

The alloy offers safety in high-corrosion environments for the pharmaceutical and food industries, ensuring product purity. Discover more about Pharmaceuticals and Food.

In Military and Defense, it supports lightweight armor and high-strength structural components. See details on Military and Defense.

Nuclear applications leverage the alloy's durability in radiation-prone environments. Learn more about Nuclear.

When to Choose Ti-15V-3Cr-3Sn-3Al Superalloy

Ti-15V-3Cr-3Sn-3Al is ideal for high-performance components where fatigue resistance and lightweight properties are critical. This alloy excels in applications that experience cyclic stress, such as aerospace structures, automotive parts, and oilfield tools. Its resistance to corrosion and wear ensures long service life under extreme conditions.

Ti-15V-3Cr-3Sn-3Al offers a tailored solution for specialized applications when custom superalloy parts are required. Explore custom superalloy parts to leverage this alloy’s strengths for your needs.