Functions of Finite Element Analysis (FEA) In Manufacturing

Finite Element Analysis (FEA) is indispensable in producing high-performance superalloy parts. By simulating real-world conditions, FEA helps engineers predict mechanical, thermal, and structural behaviors during manufacturing and operation. This ensures that superalloy components meet the rigorous demands of aerospace, energy, oil and gas, and automotive industries. FEA allows manufacturers to optimize designs, prevent defects, and improve overall efficiency, making it a critical aspect of superalloy parts production.

Different Processes for Superalloy Parts That Require FEA

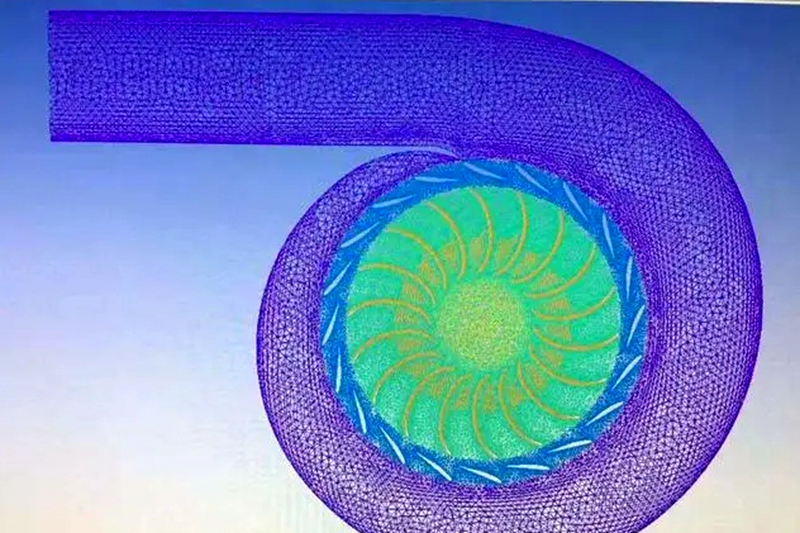

Superalloy parts undergo various manufacturing processes, each benefiting significantly from FEA (Finite Element Analysis). Vacuum investment casting, for instance, uses FEA to model shrinkage, solidification, and potential defect formation. This helps optimize mold design, ensuring consistent quality in complex parts like turbine blades. Single crystal casting relies on FEA to simulate heat flow and stress during cooling, preventing the formation of defects that could compromise the integrity of the grain structure. In equiaxed crystal casting, FEA evaluates grain growth and mechanical properties, ensuring the uniformity and reliability of the final product.

Directional casting benefits from FEA simulations to optimize grain orientation, which enhances mechanical properties like creep resistance and fatigue life. Powder metallurgy processes use FEA to analyze particle compaction and sintering behavior, ensuring defect-free, high-strength components. In forging, FEA models deformation patterns and stress distribution, enabling engineers to achieve optimal grain flow and mechanical performance.

CNC machining employs FEA to analyze tool-part interactions, preventing surface defects and optimizing cutting parameters. Finally, 3D printing uses FEA to simulate thermal and stress behaviors during layer-by-layer construction, ensuring the final part's dimensional accuracy and structural integrity.

Benefits of FEA for Different Superalloys

Different superalloys exhibit unique properties and are used in applications requiring high strength, thermal resistance, and durability. Finite Element Analysis (FEA) provides tailored benefits to each type of superalloy, ensuring they perform optimally in their respective environments.

Nickel-Based Superalloys

Nickel-based superalloys, such as Inconel, CMSX, and Rene, benefit from FEA in optimizing creep resistance, thermal stability, and fatigue life. These materials are commonly used in turbine blades and jet engines, where extreme temperatures and mechanical stresses are constantly challenging. FEA allows engineers to predict how these alloys will behave under such conditions, ensuring their reliability and longevity.

Cobalt-Based Superalloys

Cobalt-based superalloys, such as Stellite, are valued for their wear resistance and thermal fatigue properties. FEA helps simulate wear mechanisms and predict performance under high-stress, high-temperature conditions. This makes cobalt-based superalloys ideal for components like valve seats and turbine nozzles, where durability is critical.

Titanium Alloys

Titanium alloys, such as Ti-6Al-4V, are prized for their lightweight properties and excellent strength-to-weight ratio. FEA enhances the design of titanium alloy components by predicting deformation and optimizing stress distribution. These alloys are widely used in aerospace and automotive applications, where reducing weight without compromising performance is essential.

Iron-Based Superalloys

Iron-based alloys, often used in heat exchangers and pumps, benefit from FEA in evaluating their strength and wear resistance. Structural analysis through FEA ensures these alloys can handle thermal and mechanical stresses in demanding industrial environments.

Post-Process Comparison

FEA is vital in evaluating and optimizing post-processing techniques for superalloy parts. These processes, such as Hot Isostatic Pressing (HIP), heat treatment, welding, and coating applications, are critical for enhancing material properties and ensuring component performance.

Hot Isostatic Pressing (HIP) eliminates internal voids and improves material density. FEA simulates the effects of pressure and heat during the HIP process, ensuring complete densification and uniform material properties. This simulation helps predict potential weaknesses and optimize the process for components like turbine discs and structural parts.

Heat treatment, another crucial post-process, benefits from FEA by modeling phase transformations and grain growth, enabling engineers to achieve desired mechanical properties like hardness, strength, and flexibility. Heat treatment simulations ensure critical components such as turbine blades meet operational requirements under high thermal and mechanical stress.

Superalloy Welding, often required for assembling superalloy components, involves significant thermal and mechanical stresses. FEA helps analyze heat-affected zones and residual stresses, preventing cracking and ensuring the weld’s structural integrity. This analysis is particularly vital in gas turbines, where weld integrity directly affects safety and performance.

Thermal Barrier Coating (TBC), applied to protect components from extreme heat, also relies on FEA to simulate thermal stresses and ensure proper adhesion and durability. These coatings are critical in high-temperature environments, and FEA for TBC helps engineers optimize coating thickness and composition to maximize performance and lifespan.

For processes like Electrical Discharge Machining (EDM), FEA evaluates the impact of thermal and mechanical stresses on the machined surface, minimizing micro-cracks and ensuring the component’s structural integrity. EDM simulations help refine machining parameters to achieve intricate geometries without compromising material properties.

Testing and Validation Supported by FEA

FEA is a design tool and a critical component of testing and validation in superalloy parts manufacturing. By simulating various loading conditions and environmental factors, FEA supports physical testing methods to ensure that components meet stringent quality standards.

Tensile and Fatigue Testing are two critical validation methods supported by FEA. Tensile testing evaluates a material’s ability to resist deformation under load, while fatigue testing assesses its behavior under cyclic loading. FEA provides valuable insights into how superalloys will respond to these conditions, correlating simulation results with physical test data to ensure accuracy.

Thermal and Creep Testing are particularly important for high-temperature applications, such as gas turbines and jet engines. FEA models the long-term behavior of superalloys under sustained thermal loads, helping engineers refine material selection and design to prevent failure.

Non-Destructive Testing (NDT) methods, such as ultrasonic and CT scanning, are enhanced by FEA. Simulations help identify potential defects, such as cracks or voids and predict how these defects might affect performance. This ensures that only defect-free components are approved for use.

Corrosion and Oxidation Testing is another area where FEA proves invaluable. By simulating material degradation mechanisms, FEA helps engineers understand how superalloys will perform in corrosive or oxidative environments, ensuring that parts meet their expected service life.

Industry and Applications for Superalloy Parts Requiring FEA

Superalloy components are critical in industries that demand high performance and reliability under extreme conditions. Finite Element Analysis (FEA) ensures that these parts meet the stringent requirements of their applications, optimizing their design for safety, durability, and efficiency.

Aerospace and Aviation

In the aerospace and aviation industry, turbine blades, jet engine components, and heat exchangers are subjected to extreme temperatures and mechanical loads. FEA helps engineers design components to withstand these conditions, ensuring safe and efficient operation. For example, superalloy jet engine components are subjected to FEA simulations to evaluate their structural performance under high thermal and mechanical stress.

Power Generation

Components like gas turbines, reactor vessels, and boiler parts benefit from FEA simulations to optimize efficiency and reliability in power generation. Superalloy components used in gas turbines and heat exchangers must handle high temperatures and stresses while maintaining efficiency over extended service periods. FEA plays a crucial role in designing these parts for maximum reliability.

Oil and Gas

In high-pressure and corrosive environments, the oil and gas industry uses superalloy components, such as pumps, valves, and pipelines. FEA predicts their performance and ensures they meet the rigorous demands of these applications. High-temperature alloy pump components, for example, undergo FEA to ensure their durability and integrity under extreme operational conditions.

Defense and Military

Components like missile segments, armor plating, and high-performance firearm parts in the defense and military sectors require FEA to ensure durability and precision. Superalloy armor system parts are designed to withstand impact and thermal loads, making FEA an essential tool for predicting performance in these demanding applications.

Automotive

In the automotive industry, superalloy components like turbochargers, exhaust systems, and heat shields are designed using FEA to optimize performance and reduce weight. Superalloy transmission component assemblies benefit from FEA simulations that help engineers optimize their structure for high temperature and mechanical load scenarios, ensuring reliable operation throughout the vehicle's life.

Chemical Processing

The chemical processing industries rely on superalloy reactors, heat exchangers, and pressure vessels to operate safely under high-stress and corrosive conditions. FEA plays a vital role in validating these designs and ensuring their reliability. Superalloy reactor vessel components undergo rigorous FEA analysis to determine their capability to resist corrosion and maintain mechanical integrity under extreme chemical processing conditions.

FEA is a critical tool for designing and validating superalloy parts that face high-temperature, high-pressure, and high-stress environments across these industries. By simulating the conditions under which these components operate, FEA ensures they meet their performance goals and continue to perform reliably throughout their intended lifespan.

FAQs

How does FEA improve the design and performance of superalloy parts in extreme environments?

What specific benefits does FEA provide for different superalloys like nickel-based and titanium alloys?

How is FEA used in post-processing techniques like HIP and thermal barrier coating applications?

What role does FEA play in predicting defects during manufacturing processes such as casting or 3D printing?

How do industries like aerospace and power generation benefit from FEA in superalloy component design?