High-Strength Ti6.5Al1Mo1V2Zr in SLM 3D Printing Applications

Ti6.5Al1Mo1V2Zr, commonly referred to as TA15, is a titanium alloy with a unique combination of high strength, corrosion resistance, and thermal stability. This alloy’s properties make it ideal for high-stress applications across aerospace, automotive, medical, and energy industries. Known for its robustness and reliability in extreme environments, TA15 stands out as a material of choice for parts that must endure high temperatures and demanding mechanical conditions.

Integrating Selective Laser Melting (SLM) technology with TA15 has expanded its application potential. SLM allows manufacturers to produce complex, high-strength components with remarkable precision by building parts layer by layer using a high-powered laser. This process, which requires no tooling and generates minimal waste, enables manufacturers to harness the full potential of TA15 in advanced applications where strength, durability, and precision are essential. The combination of TA15’s outstanding material properties with the flexibility of SLM technology has led to a new era of possibilities in precision manufacturing.

Material Properties of Ti6.5Al1Mo1V2Zr (TA15) in SLM 3D Printing

Ti6.5Al1Mo1V2Zr (TA15) is a titanium alloy primarily composed of titanium with 6.5% aluminum, 1% molybdenum, 1% vanadium, and 2% zirconium. This specific composition grants the alloy excellent mechanical properties, including high tensile strength and resistance to fatigue and creep. It also maintains structural stability and resists oxidation in high-temperature environments, making it particularly suitable for applications where thermal stability is paramount.

Compared to other titanium alloys, TA15 stands out due to its unique balance of strength and durability, even under extreme conditions. It is widely used in aerospace components such as engine parts and structural assemblies because of its ability to perform reliably in harsh environments without degrading. Furthermore, TA15’s resistance to wear and corrosion makes it ideal for marine and chemical applications, where exposure to corrosive elements can quickly wear down other materials.

SLM 3D printing further enhances these properties by enabling the precise control of material deposition and microstructure. The SLM process results in a dense, uniform part with minimal internal defects, which improves the fatigue resistance and overall strength of TA15 components. It makes SLM an ideal manufacturing method for TA15, producing lightweight, high-strength parts that meet the rigorous demands of industries such as aerospace, automotive, and energy.

SLM 3D Printing Process for Ti6.5Al1Mo1V2Zr: Methodology and Advantages

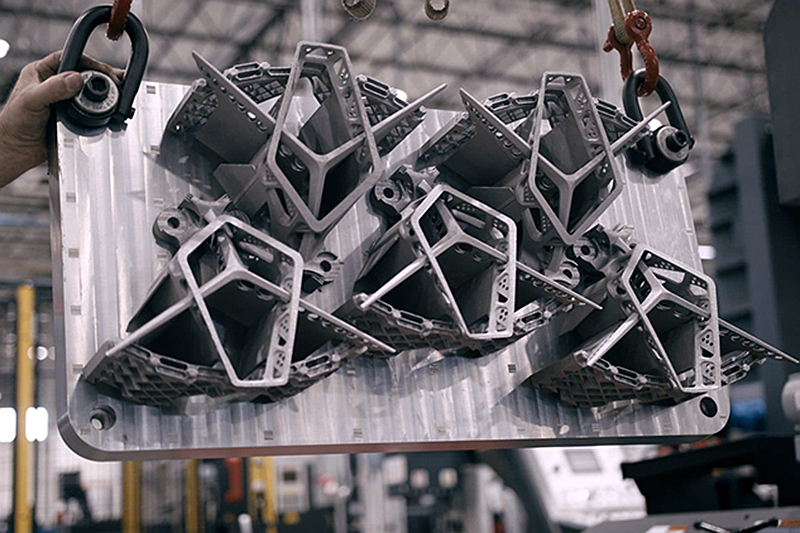

Selective Laser Melting (SLM) is an additive manufacturing technique that builds parts from a metal powder bed layer by layer. The process begins with a digital 3D model of the part sliced into thin layers. A layer of Ti6.5Al1Mo1V2Zr powder is then spread across the build platform, and a laser selectively melts the powder according to the layer’s geometry. This process repeats for each layer, with each newly melted layer bonding to the layer below it, ultimately forming the entire part.

SLM offers several advantages when manufacturing with TA15. First, the technology enables significant material efficiency. Only the powder required for each layer is melted, and any unused powder can be recycled for future builds, minimizing waste. Second, SLM allows for unprecedented design flexibility. Complex geometries, including internal channels, lattice structures, and intricate shapes, can be achieved without the limitations of traditional manufacturing methods. This design freedom is precious in applications requiring lightweight structures with optimized mechanical properties.

For Ti6.5Al1Mo1V2Zr, the SLM process also offers the benefit of precision-controlled melting and cooling, which improves the alloy’s microstructure and enhances its performance in high-stress applications. By carefully controlling each layer’s temperature and cooling rate, SLM produces parts with minimal thermal distortion and consistent mechanical properties, resulting in high-strength, reliable components that meet stringent industry standards.

Post-Processing Techniques for SLM-Printed Ti6.5Al1Mo1V2Zr Parts

After SLM printing, post-processing is essential to refine the mechanical properties further and prepare the TA15 (Ti6.5Al1Mo1V2Zr) components for end-use applications. Common post-processing steps include:

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) reduces internal porosity and increases the density of SLM-printed TA15 parts. By applying high pressure and temperature, HIP eliminates voids within the material, enhancing the part’s fatigue resistance and overall mechanical strength. This step is crucial for applications where parts are subjected to cyclic loads and high mechanical stress, improving reliability in the aerospace and energy sectors.

Heat Treatment

Heat treatment improves the thermal stability and mechanical properties of TA15. Specific heat treatment techniques, such as aging, increase the alloy’s hardness and tensile strength. Heat treatment also relieves internal stresses within the material, ensuring that the parts maintain their structural integrity under high-stress conditions. This process is precious for parts in aerospace and automotive applications that experience significant temperature fluctuations, enabling the material to withstand demanding environments.

Surface Finishing

Surface finishing techniques such as polishing, CNC machining, and coating improve the dimensional accuracy, surface smoothness, and wear resistance of TA15 parts. These steps are essential for parts that require tight tolerances and precise surface quality, particularly in assemblies that experience friction or high wear. For instance, polished surfaces are critical in components that interact with other parts to prevent wear and ensure seamless operation, especially in high-performance systems.

Quality Control and Assurance

Each post-processing technique contributes to the performance, reliability, and durability of SLM-printed TA15 components. Rigorous quality control measures ensure that the final product meets all necessary specifications, making these parts ready for demanding applications in the aerospace, automotive, and energy industries.

Testing and Inspection of Ti6.5Al1Mo1V2Zr SLM Parts

Quality assurance is critical for SLM-printed TA15 components, particularly for high-stakes applications. NewayAero employs a range of advanced testing and inspection methods to confirm the integrity, precision, and performance of each part:

Coordinate Measuring Machine (CMM) Testing

Coordinate Measuring Machine (CMM) Testing ensures dimensional accuracy by comparing the finished part’s geometry to the original CAD model. This process verifies that each component adheres to tight tolerances, essential for applications where precision is paramount.

X-ray and CT Scanning

X-ray and CT Scanning allow for non-destructive inspection of the part’s internal structure, identifying potential flaws such as porosity or micro-cracks. These techniques are invaluable for confirming that TA15 components are free from internal defects that could compromise their mechanical properties.

Scanning Electron Microscope (SEM) Analysis

Scanning Electron Microscope (SEM) Analysis provides insights into the material’s microstructure, allowing engineers to detect any surface or internal imperfections that could affect the part’s performance. SEM analysis is essential for ensuring the quality of the SLM process and confirming that the TA15 parts meet high industry standards.

Tensile and Fatigue Testing

Tensile and Fatigue Testing measure the part’s mechanical strength and endurance under stress. Tensile testing evaluates the material’s resistance to deformation, while fatigue testing assesses its durability under cyclic loading. These tests are critical for applications where TA15 parts experience repeated stress, as in aerospace engines and automotive components.

Thermal and Corrosion Testing

Thermal and Corrosion Testing verify TA15’s resistance to high temperatures and corrosive environments. These tests are essential for components used in aerospace, oil and gas, and energy industries, where exposure to heat, pressure, and corrosive elements is expected.

Industry Applications of SLM-Printed Ti6.5Al1Mo1V2Zr Components

The unique properties of Ti6.5Al1Mo1V2Zr (TA15), combined with the precision of SLM, make this alloy ideal for a wide range of high-performance applications across various industries:

Aerospace

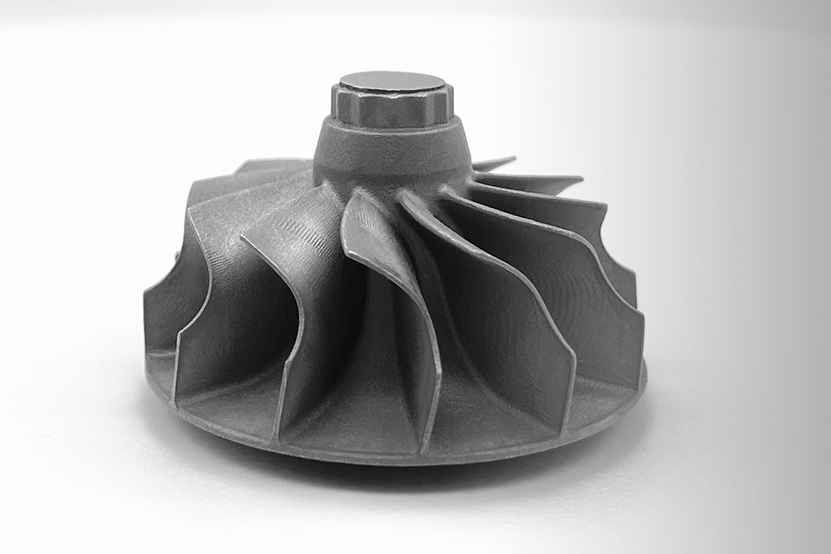

TA15’s high strength and thermal stability make it an excellent choice for aerospace applications. Under extreme conditions, components like engine parts, structural assemblies, and fasteners benefit from TA15’s durability and reliability. The precision of SLM allows for optimized designs that reduce weight while maintaining strength, enhancing the overall efficiency of aerospace systems, especially in critical parts such as superalloy jet engine components.

Automotive

TA15 is used in performance parts such as turbocharger components, exhaust systems, and engine brackets in the automotive sector. SLM-printed TA15 parts provide high strength-to-weight ratios and heat resistance, contributing to developing lightweight, high-performance vehicles that meet stringent efficiency standards. These properties are particularly valued in motorsports and high-performance automotive applications.

Medical

The biocompatibility and strength of TA15 make it suitable for orthopedic implants and medical devices. SLM technology enables the creation of customized, patient-specific implants that match individual anatomical structures, providing a high-strength, durable solution for medical applications. TA15’s corrosion resistance ensures longevity and reliability within the human body, making it an excellent choice for medical-grade applications.

Energy

TA15 is used in power generation components exposed to high heat and mechanical stress, such as turbine blades and heat exchangers. SLM-printed TA15 parts enhance energy efficiency by allowing for complex cooling channels and lightweight designs that improve thermal management, ensuring durability under the demanding conditions of power generation systems.

Oil and Gas

The oil and gas industry requires materials that withstand high pressures, temperatures, and corrosive environments. TA15’s corrosion resistance and durability make it ideal for drilling, extraction, and pressure containment equipment applications. SLM technology allows for the rapid production of TA15 parts that meet the demanding requirements of this industry, providing the strength and resilience essential for high-performance oil and gas components.

FAQs

What are the main benefits of using Ti6.5Al1Mo1V2Zr in SLM 3D printing?

How does SLM technology enhance the properties of Ti6.5Al1Mo1V2Zr components?

What post-processing steps are typically used for SLM-printed Ti6.5Al1Mo1V2Zr parts?

In which industries are SLM-printed Ti6.5Al1Mo1V2Zr most commonly used?

How does NewayAero ensure the quality of SLM-printed Ti6.5Al1Mo1V2Zr components?