High-Performance LENS Printing for Titanium Alloy TC11

Laser Engineered Net Shaping (LENS) has emerged as a transformative technology in additive manufacturing, enabling the production of high-performance metal components with intricate geometries and enhanced mechanical properties. This advanced process combines laser technology with metal powders to build parts layer by layer directly from CAD data, allowing for highly customizable designs and precise manufacturing control. Among the materials suitable for LENS printing, Titanium Alloy TC11 is particularly notable for its strength, corrosion resistance, and ability to withstand extreme conditions. These attributes make it ideal for applications in high-stress environments, especially in industries like aerospace, automotive, and marine.

Suitable Materials for High-Performance LENS Printing

Titanium Alloys

Titanium alloys, specifically TC11, are ideal for LENS printing due to their superior strength-to-weight ratio, corrosion resistance, and durability under thermal stress. TC11, an alpha-beta titanium alloy, is fortified with aluminum and tin, enhancing its thermal stability, weldability, and ability to retain its strength at elevated temperatures. These properties make TC11 a preferred choice for applications requiring materials that can endure cyclical stresses and extreme temperatures. Other titanium alloys, such as Ti-6Al-4V and TA15, are also popular in LENS printing, but TC11’s unique composition makes it particularly well-suited for high-performance structural and load-bearing components.

Inconel

Inconel, a family of nickel-chromium superalloys, is well-known for its excellent oxidation and corrosion resistance, especially in high-temperature environments. Frequently used in aerospace and power generation industries, Inconel alloys such as Inconel 718 and Inconel 625 perform exceptionally well under thermal and oxidative stresses. The LENS process is well-suited for Inconel, as it allows for the precise deposition and solidification necessary to retain the alloy’s strength and durability.

Hastelloy

Hastelloy alloys, another group of high-performance materials, are ideal for applications in chemically aggressive environments. These nickel-based alloys exhibit remarkable corrosion and stress corrosion cracking resistance, making them essential in chemical processing, marine, and oil and gas industries. With LENS technology, Hastelloy parts can be manufactured with the precision and flexibility needed for custom designs, especially in components exposed to high temperatures and corrosive substances.

Manufacturing Process of Titanium Alloy TC11 with LENS Technology

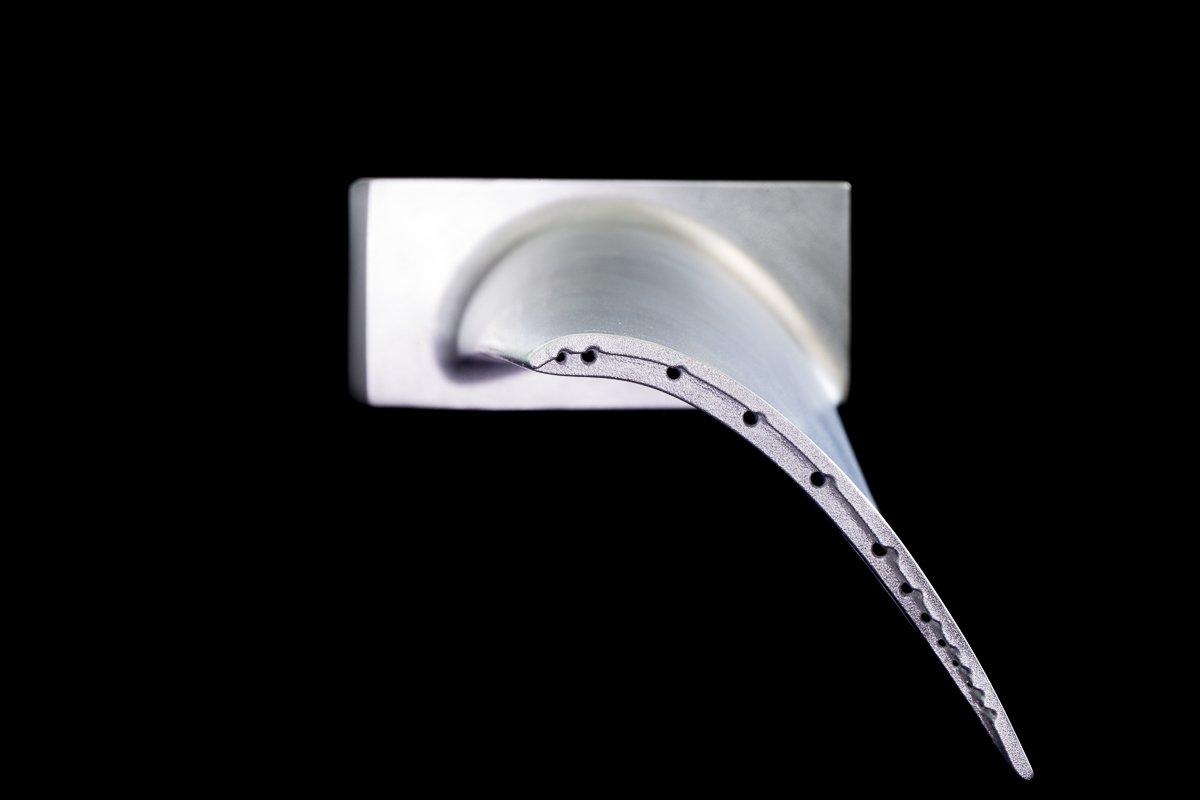

The LENS process for manufacturing TC11 parts begins with the controlled delivery of TC11 metal powder to a focused laser beam, which melts the powder and fuses it into a solid structure. The laser’s high energy allows for the layer-by-layer construction of complex shapes and precise geometries, resulting in near-net shapes that require minimal post-processing. In contrast to traditional manufacturing, LENS enables the efficient production of intricate internal structures and channels that are challenging to achieve using conventional methods.

For Titanium Alloy TC11, the LENS process provides specific benefits, such as minimal material waste and faster production times. TC11 components can be fabricated to near-final specifications, reducing the need for excess machining and conserving costly titanium materials. The LENS system operates within a controlled environment to protect the TC11 powder from contamination, ensuring the purity and integrity of the final part.

However, manufacturing TC11 components with LENS does come with challenges. Titanium has high thermal conductivity, and TC11 is no exception; this characteristic makes it susceptible to thermal distortions if temperature control is not carefully managed. Process parameters like laser power, scan speed, and powder flow must be meticulously calibrated to achieve optimal results. This attention to detail minimizes the risks of warping, residual stress, and dimensional inaccuracies, ensuring that each layer of TC11 is accurately deposited without sacrificing the material’s mechanical integrity.

Post-Processing Techniques for LENS-Printed Titanium Alloy TC11 Components

Heat Treatment

After the LENS printing process, heat treatment is essential to enhance the mechanical properties of TC11. This post-processing step involves subjecting the component to specific heating and cooling cycles to relieve internal stresses, improve hardness, and optimize tensile strength. For TC11, heat treatment may involve annealing to improve ductility, solution treatment, and aging to maximize strength. Control temperature and duration are crucial to achieving the desired microstructure and mechanical properties.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a vital post-processing technique for improving the density and fatigue resistance of LENS-printed TC11 parts. HIP involves applying high pressure and elevated temperatures to the component in an inert gas environment, eliminating internal voids and reducing porosity. HIP significantly enhances structural integrity for TC11 parts used in high-stress applications, making it an indispensable step in ensuring the part’s longevity and reliability under cyclical loads.

Surface Finishing (Machining and Polishing)

Although LENS printing offers high precision, surface finishing may be necessary to achieve the required smoothness and dimensional accuracy for TC11 parts. Machining and polishing are common post-processing steps that help remove surface irregularities and meet tight tolerances, especially for aerospace and automotive components. Smooth surfaces reduce drag in aerospace applications and improve corrosion resistance by minimizing areas where corrosion could initiate, prolonging the component’s lifespan.

Testing and Quality Assurance for LENS-Printed TC11 Components

Microstructure Analysis and Metallographic Testing

Microstructure analysis is crucial for ensuring that LENS-printed TC11 components meet the stringent quality standards required in high-stress applications. Manufacturers can assess whether the LENS process has produced a uniform, defect-free structure by examining the grain structure, phase distribution, and potential defects. This analysis is particularly important for TC11, as its grain structure and phase composition directly influence its performance in applications subject to cyclic loading and extreme temperatures.

Tensile and Fatigue Testing

Tensile and fatigue testing is conducted on LENS-printed components to verify the mechanical properties of TC11. Tensile testing measures the material’s ultimate strength and elongation, ensuring the TC11 part can withstand the anticipated loads. Fatigue testing, conversely, assesses the material’s ability to endure cyclic stresses without failure, a crucial factor for components in aerospace, automotive, and power generation industries.

Non-Destructive Testing (NDT)

Non-destructive testing (NDT) methods such as X-ray and ultrasonic testing detect internal flaws in TC11 parts without compromising their integrity. These methods allow for thoroughly inspecting LENS-printed components and identifying potential defects such as porosity, cracks, or inclusions. In industries where safety is paramount, NDT ensures that only flawless components are delivered, maintaining high-stakes applications' reliability.

Dimensional Testing (CMM)

Dimensional testing using Coordinate Measuring Machines (CMM) ensures that all LENS-printed TC11 components meet precise design specifications. Accurate dimensional testing is essential for parts that require tight tolerances, such as those used in engines, transmissions, or structural assemblies. For TC11 components, CMM testing confirms that each part conforms to exacting standards for fit and function, minimizing the risk of assembly issues or performance deficiencies.

Industries Leveraging LENS-Printed TC11 Components

Aerospace and Aviation

The aerospace and aviation industry benefits significantly from LENS-printed TC11 components, particularly for applications that require materials with high-temperature performance and lightweight characteristics. TC11’s high strength-to-weight ratio and thermal stability make it ideal for manufacturing components like structural parts, engine components, and exhaust systems. The ability to produce complex geometries with LENS further enhances TC11’s utility in aerospace, allowing engineers to create lightweight, high-strength parts that contribute to fuel efficiency and overall aircraft performance.

Automotive and Motorsports

In the automotive and motorsports sectors, high-performance vehicles rely on TC11 for components that endure high stresses and temperatures. LENS-printed TC11 parts are commonly used in engines, transmissions, and suspension systems, where weight reduction and durability are critical. By leveraging LENS technology, manufacturers can quickly produce custom or small-batch TC11 components that optimize performance and reduce vehicle weight, contributing to increased speed and efficiency in competitive racing environments.

Marine and Chemical Processing

Marine and chemical processing industries benefit from TC11’s corrosion resistance and mechanical strength, making it suitable for applications where exposure to saltwater, chemicals, and high pressures demands robust materials. LENS printing allows for the creation of custom TC11 components that meet specific demands, whether for propellers, pumps, or equipment used in chemical processing plants. By manufacturing parts with precise tolerances and corrosion-resistant properties, LENS-printed TC11 components provide longevity and reliability in challenging operational environments.

Applications of LENS-Printed TC11 Components

Engine and Transmission Parts

Engine and transmission components are prime applications for LENS-printed TC11, given the material’s ability to withstand high stresses and temperatures. TC11’s strength and stability make it ideal for critical parts in engines and transmissions, where durability and performance are paramount. With LENS technology, manufacturers can produce these components with greater precision, enhancing performance and extending the lifespan of high-performance engines.

Aerospace Structural Components

Aerospace applications benefit from TC11’s strength-to-weight ratio and ability to withstand high temperatures. LENS-printed TC11 parts are used in structural components such as brackets, beams, and load-bearing elements in aircraft and satellite designs. These components require reduced weight without compromising strength, making TC11 an ideal material choice for advanced aerospace structures.

Custom and Prototype Parts

LENS technology allows for the rapid prototyping and production of unique TC11 components, a valuable advantage in research and development. Engineers can test various designs, configurations, and structural concepts with TC11 without extensive tooling or molds. This capability enables experimentation with experimental aerospace components, specialized machinery, and one-off parts for industries like automotive and defense.

Heat Exchanger Components

Heat exchangers are critical in energy and chemical processing industries, where efficient thermal management is essential. TC11’s thermal stability and resistance to corrosion make it a reliable material for these applications. LENS-printed TC11 components in heat exchangers can withstand extreme temperatures and resist degradation from exposure to aggressive chemicals, ensuring consistent performance and longevity.

FAQs

What benefits does Titanium Alloy TC11 offer in high-performance LENS printing applications?

How does the LENS process contribute to the manufacturing efficiency of Titanium TC11 parts?

What are the critical differences between TC11 and other titanium alloys used in LENS printing?

What post-processing techniques are essential to ensure the durability of LENS-printed TC11 parts?

Which industries have the most extensive applications for LENS-printed TC11 components?