Stress Relief in Superalloy Castings: Ensuring Dimensional Stability with Vacuum Heat Treatment

Superalloy castings are essential components used in aerospace and aviation, power generation, and oil and gas, where they must withstand extreme temperatures and mechanical stresses. One critical factor in ensuring the longevity and reliability of these high-performance materials is dimensional stability. Stress relief plays a vital role in preserving the integrity of superalloy castings, and vacuum heat treatment is the key to achieving this. In this blog, we will explore the importance of stress relief, how vacuum heat treatment works, the typical superalloys used, the post-processing steps involved, Hot Isostatic Pressing (HIP), testing methods like Tensile Testing, and the various industry applications of stress-relieved superalloy castings.

Understanding Stress Relief in Superalloy Castings

Stress relief is a heat treatment process to reduce residual stresses within materials that arise during casting, welding, machining, or assembly. These internal stresses can cause distortion, cracking, or premature failure of the material when it undergoes further processing or service. Managing residual stress is critical for maintaining performance over time for superalloy castings, which are often used in demanding applications like turbine blades or reactor components. This is particularly true when considering processes like vacuum heat treatment, which prevents oxidation and contamination while ensuring the material maintains its integrity.

When casting is subjected to heat or mechanical deformation, residual stresses develop due to differences in the cooling rate, phase transformations, or external forces applied during machining or welding. These stresses can lead to unwanted dimensional changes, surface cracking, and reduced fatigue strength. Stress relief helps mitigate these risks by allowing the material to relax and adjust to its final shape without causing further distortion or damaging the microstructure. The stress relief process ensures that the alloy retains the desired properties for high-performance applications, such as those used in aerospace.

Vacuum Heat Treatment for Stress Relief

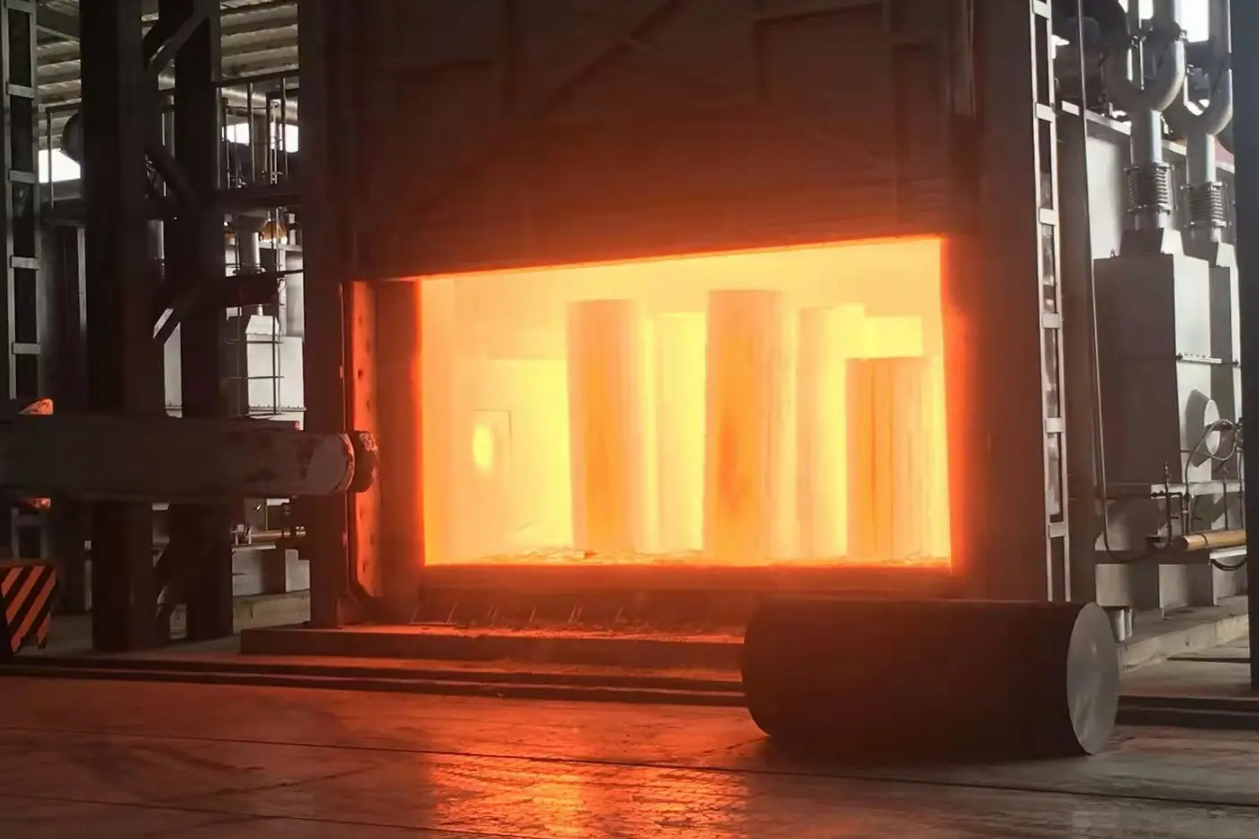

Vacuum heat treatment is an advanced method for performing stress relief on superalloy castings. This process involves heating the material in a vacuum furnace, where the absence of oxygen prevents oxidation and contamination, which could otherwise degrade the quality of the material. By using vacuum induction melting, manufacturers ensure that the material's purity is maintained throughout the heat treatment process.

The process begins by placing the superalloy components in a vacuum chamber. The chamber is then evacuated to remove any gases affecting the part’s surface. Once the vacuum is achieved, the temperature is raised to below the alloy’s critical transformation point—usually between 650°C and 900°C, depending on the specific superalloy. The purpose of this heat cycle is to allow the material’s internal stresses to relax without causing the formation of new stresses or damaging the material's properties. The vacuum environment significantly controls material composition, preventing unwanted chemical reactions.

After the temperature has stabilized, the material is slowly cooled in a controlled manner to avoid thermal shock and minimize the risk of warping or cracking. This gradual cooling ensures the part retains its original dimensions and mechanical properties. The careful management of cooling is a crucial aspect of vacuum investment casting that ensures the final part’s performance under extreme conditions.

Advantages of Vacuum Heat Treatment for Stress Relief

The key advantage of using vacuum heat treatment for stress relief in superalloy castings is the controlled environment it provides. Unlike traditional atmospheric heat treatment, which can expose the part to oxidation, decarburization, and contamination, vacuum heat treatment eliminates these risks by operating in a sealed chamber without exposure to atmospheric gases. The result is a more stable and uniform material with enhanced surface integrity. This is essential for superalloys used in high-performance applications, including turbine blades.

The vacuum environment also allows for exact temperature control, which is essential for achieving consistent results across components with complex geometries. Vacuum heat treatment ensures that the entire part experiences the same temperature and stress relief treatment, which is crucial for parts like turbine blades that must meet strict dimensional and mechanical specifications. This precise control is also a critical factor in vacuum precision casting.

Furthermore, vacuum heat treatment minimizes the chances of surface scaling and other forms of degradation that can occur in conventional heat treatment processes. This makes it especially beneficial for high-performance superalloys, often used in harsh operating conditions where surface quality and dimensional accuracy are critical. In these cases, vacuum heat treatment ensures that the superalloy parts meet the rigorous demands of industries like aerospace and energy.

Typical Superalloys Used for Stress Relief

The specific superalloys used in vacuum heat treatment depend on the application and the environment for which the parts are designed. Superalloys are engineered to perform in extreme conditions where traditional metals may fail. Below are some typical superalloys used for stress relief:

Nickel-Based Superalloys

Nickel-based superalloys, such as Inconel 718, Inconel 625, and Rene 104, are commonly used in high-temperature applications like turbine blades, combustion chambers, and exhaust systems. Nickel-based alloys offer excellent oxidation resistance and can retain strength at elevated temperatures. Stress relief is significant for these alloys, as it helps maintain their dimensional stability and mechanical integrity during thermal cycling.

Cobalt-Based Superalloys

Cobalt alloys, like Stellite 6K and Stellite 21, are widely used in wear-resistant applications and environments that require corrosion resistance, such as valve components and gas turbines. These alloys also benefit from stress relief, which helps prevent distortion and cracking under high thermal and mechanical loads.

Titanium Alloys

Titanium alloys, such as Ti-6Al-4V and Ti-5553, are used in aerospace and automotive components where lightweight properties and high strength are essential. Titanium alloys are prone to distortion if residual stresses are not adequately relieved, making vacuum heat treatment crucial for maintaining precise tolerances.

Other High-Temperature Alloys

Alloys such as Hastelloy C-276, Monel 400, and Nimonic 263 are employed in industries requiring high corrosion and oxidation resistance, like chemical processing and power generation. These alloys undergo vacuum heat treatment to ensure their dimensional stability and reliability under high thermal stress.

Post-Processing After Stress Relief

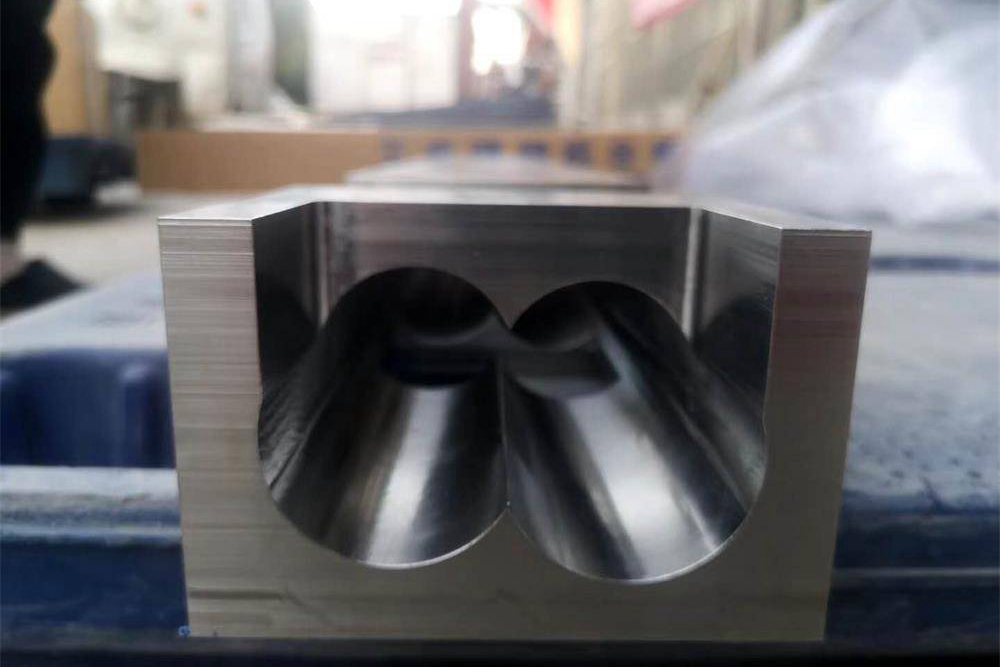

Once the stress relief treatment is complete, several post-processing steps are often applied to enhance the superalloy parts' properties further. One key process is Hot Isostatic Pressing (HIP), which involves subjecting the castings to high pressure and temperature in an inert atmosphere. This process eliminates internal porosity and improves material density, which is particularly useful for high-performance components like turbine blades or pressure vessel components. HIP ensures the final parts exhibit high strength, fatigue resistance, and long-lasting reliability in demanding applications.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a critical post-processing technique for enhancing the mechanical properties of superalloy parts. The process involves subjecting the castings to high pressure and temperature in an inert atmosphere, which helps eliminate internal porosity and improve the material’s density. This is particularly useful for superalloy castings exposed to high pressures, such as turbine blades or components used in reactors or high-stress applications. HIP-treated parts also benefit from enhanced fatigue resistance, making them highly suitable for critical aerospace and energy applications.

Surface Finishing

After stress relief, superalloy castings are often subjected to surface finishing techniques such as grinding, polishing, or coating. These processes improve the surface quality and prepare the parts for further treatments, such as applying thermal barrier coatings (TBC) to improve heat resistance and oxidation protection. Surface finishing enhances the part's appearance and functionality, ensuring that gas turbine components and other critical parts maintain optimal performance under extreme conditions.

Additional Heat Treatments

In some cases, further heat treatments, such as solutionizing and aging, are applied to refine the material’s properties. These additional treatments help enhance the superalloy components' strength and hardness. Solutionizing helps dissolve unwanted phases within the alloy, while aging improves mechanical properties, such as hardness and tensile strength. These heat treatments are essential for alloys exposed to thermal cycling and extreme mechanical stresses, ensuring they meet the stringent requirements of industries such as aerospace and energy.

Testing and Quality Control After Stress Relief

Several testing methods are employed to ensure that stress-relieved superalloy castings meet the required specifications. For tensile strength measurement, confirming that the material retains its ability to withstand operational forces after stress relief is essential. Tensile testing ensures that the superalloy components maintain their mechanical strength, confirming they can handle operational stresses without failure.

Fatigue testing is conducted to simulate the effects of cyclic loading on superalloy parts. This is especially important for components such as turbine blades, subjected to repeated thermal and mechanical stresses during operation. Fatigue testing helps determine the material's durability under long-term use, ensuring the components remain reliable over extended service periods.

Creep testing measures the deformation of materials under constant stress at high temperatures. This is particularly crucial for superalloy components used in power generation or aerospace applications, where parts are exposed to high temperatures for extended periods. After stress relief, accurate mechanical property testing ensures that the material can resist creep deformation over time.

Non-destructive testing (NDT) techniques like X-ray and CT scanning detect internal defects or residual stresses that could lead to part failure. These methods ensure that no hidden flaws exist within the material, while ultrasonic inspection ensures that surface and subsurface regions are free from cracks or inclusions.

Microstructural analysis, using metallographic and scanning electron microscopy (SEM), is employed to examine the material's grain structure, phase distribution, and surface features. These techniques provide insights into whether the stress relief process was successful and confirm that the material has the desired properties. Scanning electron microscopy can be particularly effective for visualizing the finer details of microstructure, helping ensure that the final product meets all quality standards.

Industries and Applications of Stress-Relieved Superalloy Castings

Stress-relieved superalloy castings are used across various industries, where their high strength, durability, and dimensional stability are essential.

Aerospace

In the aerospace industry, superalloys manufacture critical components like turbine blades, compressor discs, and structural elements. These parts must maintain precise dimensions and high strength under extreme thermal and mechanical stresses, making stress relief crucial. Components such as superalloy turbine blades undergo stress relief to maintain dimensional accuracy and prevent failure in high-stress aerospace environments.

Power Generation

Superalloy castings used in power generation for gas turbines, heat exchangers, and pressure vessels undergo stress relief to ensure they perform reliably in the demanding conditions of power plants. Vacuum heat treatment helps these parts withstand thermal cycling without distorting or cracking, ensuring optimal performance over long operational lifespans. Stress-relieved components such as gas turbine blades are essential for maintaining efficiency and reliability.

Oil and Gas

Oil and gas industries rely on superalloy castings for pumps, valves, and other critical equipment that must endure high-pressure and high-temperature environments. Stress relief helps prevent distortion and failure in these parts, ensuring their longevity and performance in harsh conditions. Components like superalloy pumps are treated to maintain structural integrity and resist wear over time, even in aggressive operating environments.

Automotive

In the automotive industry, turbochargers, exhaust systems, and engine components made from superalloys benefit from stress relief. This process helps prevent dimensional changes and cracks affecting performance in high-speed, high-temperature environments. Stress-relieved superalloy turbochargers are designed to maintain strength and shape, ensuring they function reliably under demanding conditions in modern automotive applications.

Military and Defense

Stress-relieved superalloy parts are used in military and defense applications for missile components, armor, and weapons systems. These parts must maintain their integrity under extreme thermal and mechanical conditions. Stress relief ensures that superalloy armor system parts retain strength and dimensional stability during high-stress military operations.

Chemical Processing

In the chemical processing industry, superalloys are used in reactors, heat exchangers, and other components exposed to corrosive environments. Stress-relief treatments ensure that these parts maintain dimensional stability and strength during operation. For instance, stress-relieved reactor vessel components help ensure long-term durability and resistance to corrosion, making them vital for processing chemicals under high-temperature conditions.

FAQs

How does vacuum heat treatment help reduce residual stresses in superalloy castings?

What are the key benefits of using vacuum heat treatment for stress relief in superalloy parts?

How does the stress relief process affect the mechanical properties of nickel-based superalloys?

What post-processing techniques are typically used after stress relief in superalloy castings?

How do non-destructive testing methods help ensure the quality of stress-relieved superalloy components?