Functions of Argon Atomizing Pulverizing Furnace In Powder Metallurgy Turbine Disc

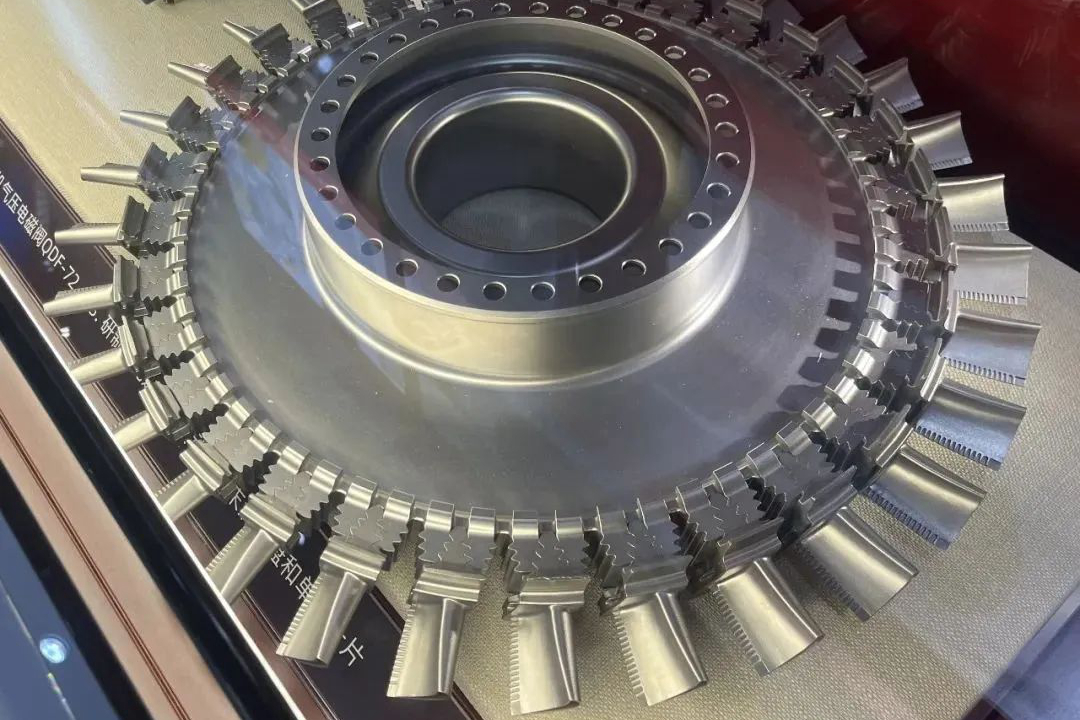

Powder metallurgy (PM) is a vital manufacturing process for producing high-performance components, especially in industries where parts must withstand extreme temperatures, mechanical stresses, and wear. In the aerospace and aviation and energy sectors, turbine discs are among the most critical components of gas turbines, jet engines, and power plants. These components require precision manufacturing methods with high strength, reliability, and performance under harsh operating conditions.

One of the most significant innovations in manufacturing turbine discs is using powder metallurgy, mainly through an Argon atomizing pulverizing furnace. This process is integral in producing the fine metal powders necessary for creating high-performance turbine discs. By understanding the functions of the Argon atomizing pulverizing furnace, we can appreciate how it enhances the powders' properties in turbine disc production and the overall benefits it provides in manufacturing these critical components.

Introduction to Powder Metallurgy in Turbine Disc Production

Powder metallurgy is a manufacturing technique that produces metal parts by compressing and sintering metal powders. This process is precious in producing complex parts with high strength-to-weight ratios, such as turbine discs. Powder metallurgy allows for precise control over material composition, porosity, and microstructure, which is crucial for components that must perform under extreme conditions. The use of advanced superalloys in this process ensures that the final turbine discs can withstand the extreme operating environments found in aerospace and power generation industries.

In turbine disc production, powder metallurgy offers several advantages over traditional casting and forging. These include the ability to create complex shapes without the need for costly molds and the ability to control the distribution of materials more accurately. By utilizing high-temperature alloys and superalloys, powder metallurgy ensures that the turbine discs exhibit the necessary properties—such as high-temperature resistance, fatigue strength, and corrosion resistance—vital for turbine performance and longevity. Additionally, argon atomizing in powder production further enhances material purity, contributing to the improved mechanical properties required in these critical components.

This process is particularly suited for industries like aerospace, where precision and durability are essential. With the ability to fine-tune the composition of the metal powders, superalloy turbine discs produced via powder metallurgy achieve superior mechanical properties, making them a key technology in developing high-performance turbine systems.

What is an Argon Atomizing Pulverizing Furnace?

An Argon atomizing pulverizing furnace is a specialized piece of equipment used in the production of metal powders through the process of atomization. In this process, molten metal is broken into fine droplets, solidifying into small, uniform metal particles. These particles are collected and processed to create metal powders with specific properties required for manufacturing high-performance components like turbine discs. Argon atomizing plays a key role in ensuring the production of high-quality metal powders, which is crucial for aerospace and power generation applications.

The atomizing furnace injects a high-pressure stream of Argon gas into a molten metal stream. As the Argon gas impacts the molten metal, the liquid metal breaks up into tiny droplets that cool rapidly into solid particles. Argon is preferred for this process because it is an inert gas that prevents oxidation and contamination of the metal, ensuring high-purity powder production. This is particularly important in manufacturing superalloys used in high-temperature applications, where purity and precise material composition are essential to ensure the final components, such as turbine discs, meet performance and durability standards. The controlled environment created by Argon gas also enhances the properties of the metal powders, making them ideal for advanced manufacturing techniques like powder metallurgy and additive manufacturing.

Function of Argon in the Atomizing Process

Argon plays a critical role in atomization by serving as the inert gas that controls the atmosphere in the pulverizing furnace. Because Argon is chemically inert, it does not react with molten metal during atomization. This is crucial for preventing oxidation, which can degrade the metal powder's quality and affect the final component's performance. Using Argon, the atomization process is conducted in a controlled environment, ensuring that the powders maintain high purity and consistency. Argon is essential when producing superalloy powders for turbine discs, where material purity directly impacts component performance in extreme conditions.

Another key function of Argon is its ability to help control the size and distribution of metal droplets. The pressure and flow rate of the Argon gas determines the size and morphology of the atomized powder particles. Fine control over these parameters is essential for producing powders with the desired properties, such as a narrow particle size distribution and the right level of flowability for subsequent processes like sintering and compaction. Powder preparation using Argon atomization is integral in creating high-performance materials for industries that demand precision and reliability, such as the aerospace and energy sectors.

Argon also provides thermal control during atomization. It helps to cool the droplets quickly as they solidify, which is crucial for ensuring that the powder has the correct microstructure and density. The rapid cooling process results in acceptable, uniform particles ideal for powder metallurgy applications, enabling the production of complex, high-strength turbine disc components that can withstand extreme operational conditions. The use of Argon ensures that these metal powders are ideally suited for applications where performance, durability, and material integrity are critical.

Powder Production: From Metal to Fine Particles

The atomization process begins by melting the desired metal alloy in a furnace, typically a high-temperature superalloy. Once the metal reaches a molten state, the Argon gas is introduced into the furnace at high pressure. This causes the molten metal to break apart into fine droplets, rapidly cooled and solidified into small particles. The size of the droplets is controlled by adjusting the pressure of the Argon gas and the temperature of the molten metal. This precision in atomization ensures that the powder particles maintain uniform properties, essential for producing high-performance turbine discs that must withstand extreme operational conditions.

The atomized powder is then collected, sieved, and sorted according to particle size. The size and morphology of the powder particles are critical because they influence the final properties of the turbine disc. For example, finer powders produce higher-density components with better mechanical properties, while larger particles may be used to reduce porosity or achieve specific structural characteristics. Powder metallurgy techniques are pivotal for producing high-quality turbine discs that meet stringent aerospace industry standards.

Once the powder has been collected and sorted, it is ready for further processing. This may include compaction, sintering, and consolidation, all of which help to transform the powder into a dense, solid part. In turbine disc production, this typically involves a combination of powder consolidation techniques, such as Hot Isostatic Pressing (HIP), and forging, further refining the material and giving it the desired strength and integrity. These processes ensure the final component has the necessary mechanical properties to perform reliably in high-stress, high-temperature environments.

Role of Powder Properties in Turbine Disc Performance

The properties of the metal powder used in powder metallurgy directly impact the performance of the turbine disc. One of the most important characteristics is the particle size, which influences the powder's packing density, sintering behavior, and final mechanical properties. Smaller particles typically lead to higher density and more uniform microstructures, which can improve the strength and durability of the turbine disc.

Powder morphology—how the particles are shaped—also plays a role in the final properties of the turbine disc. Spherical powders, often produced through Argon atomization, tend to have better flowability and can achieve higher packing densities during the compaction process. This produces a more uniform material with fewer voids and defects, which is essential for high-performance turbine blades and discs.

The composition of the powder is another critical factor. Since the powders are made from high-temperature alloys, they must maintain specific characteristics, such as oxidation resistance and strength at elevated temperatures. Using Argon during the atomization process helps maintain the purity of the metal powder, ensuring that these desirable properties are preserved in the final part.

Integration of Argon Atomized Powders in Turbine Disc Manufacturing

Once the fine powders have been produced, they are typically consolidated through a process like Hot Isostatic Pressing (HIP) or sintering. In HIP, the powder is subjected to high pressure and temperature, causing the individual powder particles to bond into a solid material. Using Argon atomized powder in this process helps produce turbine discs with higher density, better mechanical properties, and improved resistance to fatigue and wear. The powder's precision in particle size and uniformity plays a significant role in achieving these enhancements, ensuring that the final product can withstand the harsh operating conditions in gas turbines.

After consolidation, the turbine disc undergoes further processing, including precision machining, to achieve the final shape and surface finish. Using Argon atomized powders results in fewer internal defects and a more homogeneous material, improving the final part's performance in high-temperature and high-stress environments. In turbine disc production, these advantages translate into better fatigue resistance, longer service life, and enhanced operational efficiency. This makes Argon atomized powders a critical element in producing turbine discs that meet the rigorous demands of aerospace and power generation applications.

Comparison with Other Powder Production Methods

While Argon atomization is one of the most popular methods for producing metal powders, other techniques, such as gas atomization and water atomization, can also be used. However, these methods often introduce higher contamination levels or less control over the powder's particle size and distribution.

In gas atomization, gases such as nitrogen or oxygen break up the molten metal. While effective, this method may not offer the same purity level as Argon atomization, as reactive gases can cause oxidation. Similarly, water atomization uses high-pressure water jets, but it is typically less effective in producing fine, uniform powders, especially for high-performance alloys used in turbine disc manufacturing.

The advantage of using Argon in atomization is its inert nature, which ensures that the powders produced are of the highest purity and quality. This makes Argon atomization the preferred method for producing metal powders for turbine disc applications, where material properties like oxidation resistance, fatigue strength, and density are critical. This process produces powders with more consistent particle size and morphology, which significantly impacts the performance and longevity of the final turbine disc components.

Applications and Industry Relevance

Using Argon atomized powders is particularly beneficial in industries like aerospace and aviation and energy, where turbine discs must perform under extreme conditions. In the aerospace sector, turbine discs made from high-temperature superalloys are critical components of jet engines, which must withstand high temperatures and mechanical stresses from rapidly changing engine conditions. Argon atomized powders ensure these components have the desired mechanical properties, such as resistance to creep, fatigue, and oxidation.

In the energy industry, turbine discs are used in gas turbines for power generation, where they must maintain high efficiency and reliability over extended periods. The durability and performance enhancements provided by Argon atomized powders make them ideal for aerospace and power generation applications, where failure is not an option.

Argon atomization is also valuable in other industries requiring high-performance metal components, such as defense and automotive applications, where parts must withstand extreme wear and thermal cycling.

FAQs

How does the use of Argon improve the quality of the powder in turbine disc production?

What is the difference between Argon atomization and other powder production methods like gas and water atomization?

How does particle size influence the performance of turbine discs made from powder metallurgy?

What are the key advantages of using Argon atomized powders for turbine disc manufacturing in aerospace and energy industries?

How does Hot Isostatic Pressing (HIP) integrate with Argon atomized powders to enhance turbine disc properties?