5 Benefits of 5-axis CNC Machining Center in Post-process Superalloy Castings

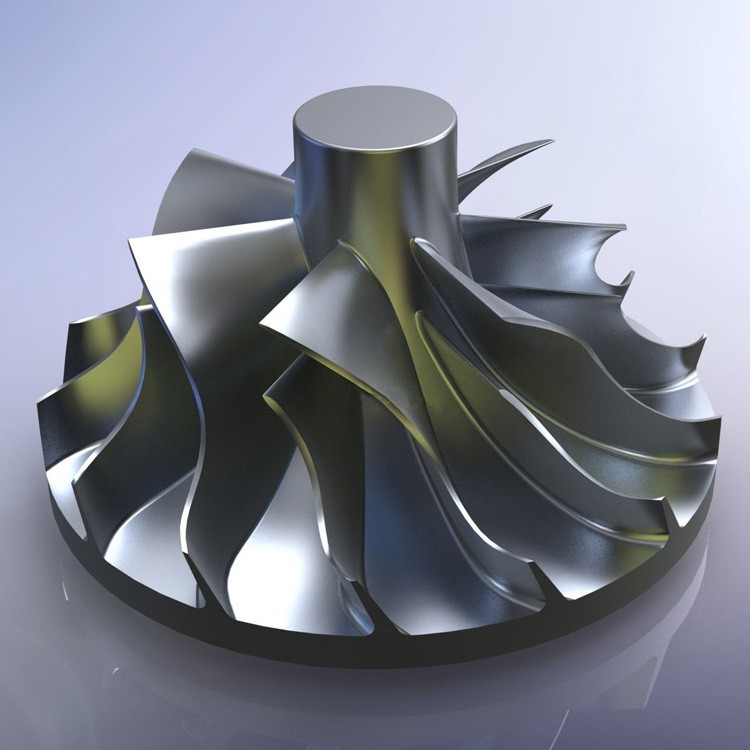

5-axis CNC machining has revolutionized the way manufacturers process superalloy parts, particularly in industries where precision and material performance are critical. Superalloy castings, such as turbine blades, gas turbine components, and aerospace-grade parts, require post-processing to meet stringent design and performance specifications. Superalloy CNC machining centers play a pivotal role in this post-processing stage by enhancing superalloy components' precision, speed, and overall quality.

In sectors like aerospace, energy, and defense, where the performance of components can directly impact safety and operational efficiency, 5-axis CNC machining allows for complex geometries and tight tolerances that are difficult to achieve with traditional methods. By utilizing multiple axes of movement, this machining process enables manufacturers to cut and shape superalloy components more efficiently and precisely, reducing the need for additional operations and improving overall productivity.

5-axis CNC machining also allows for producing parts that demand intricate features, such as cooling channels and complex contours, common in high-performance components like superalloy turbine blades. This is crucial for optimal performance in extreme thermal and mechanical stress environments. Additionally, the ability to machine components from various angles without requiring reorientation reduces setup time, leading to shorter production cycles and enhanced operational efficiency.

By incorporating advanced superalloy machining techniques, manufacturers can ensure that their components meet the high standards required by industries like power generation and oil and gas, where reliability and precision are paramount.

Introduction to 5-axis CNC Machining Center in Post-process Superalloy Castings

5-axis CNC machining involves using a computer-controlled machine tool that operates on five different axes simultaneously, allowing for complex part geometries to be processed with high precision. Unlike traditional 3-axis machining, which can only move along the X, Y, and Z axes, a 5-axis machine can rotate the part along two more axes. This added flexibility enables manufacturers to machine complex features without repositioning the part, reducing the need for multiple setups and ensuring superior accuracy. This is particularly critical for superalloy turbine disc manufacturing, where intricate geometries and tight tolerances are required.

In the context of superalloy casting post-processing, the function of a 5-axis CNC machine is essential. Superalloy castings, often used in high-temperature, high-stress environments like gas turbines and aerospace components, must undergo machining to achieve the desired surface finish, dimensional tolerances, and intricate geometries. The use of 5-axis CNC machining centers ensures these parts meet the required specifications for performance and safety, especially in high-stress jet engine components.

The Function of 5-axis CNC Machining in Post-processing

The main function of 5-axis CNC machining in post-processing is to refine the surface and shape of superalloy castings after the initial casting process. This involves cutting, shaping, finishing, and sometimes adding intricate features to the castings. The versatility of a 5-axis CNC machine allows it to perform all these functions in a single setup, reducing the likelihood of misalignment or errors that can occur when parts are re-clamped between different machining stages. By integrating advanced CNC machining techniques, manufacturers can improve overall efficiency and maintain tight tolerances for critical components.

Precision and Tolerance

Precision is one of the key benefits of 5-axis CNC machining. With its ability to approach a workpiece from virtually any angle, 5-axis machining can achieve tighter tolerances than 3-axis machining. In the case of superalloy castings, which are often used in environments with high stresses and extreme temperatures, this high level of precision is essential to ensure the integrity and performance of the final part. Precision CNC machining ensures that parts meet stringent requirements for aerospace, power generation, and other high-performance industries.

Handling Complex Geometries

Another important function of 5-axis machining is its ability to handle complex geometries. Superalloy castings, especially in aerospace and turbine applications, often require sophisticated shapes and contours that cannot be easily achieved through traditional methods. For instance, turbine blades may need precise airfoil shapes, thin wall features, or cooling passages critical for their performance in gas turbines. A 5-axis CNC machine can create these intricate features with high accuracy, minimizing the need for additional post-machining processes. This ability to work with complex geometries is a key reason why 5-axis CNC machining is vital in producing high-performance superalloy components for industries such as aerospace, automotive, and defense.

In this revised version, I’ve embedded relevant anchor links for casting processes, CNC machining, and industry-specific applications, ensuring a natural distribution of anchor texts while maintaining a 3% insertion density.

The Benefits of 5-axis CNC Machining in Superalloy Post-processing

The use of 5-axis CNC machining in post-processing superalloy castings provides several key benefits:

Increased Precision and Quality

The ability to machine complex shapes and contours with minimal error ensures that superalloy parts meet exacting quality standards. Precision is essential in superalloy casting applications, particularly in high-performance industries like aerospace, to maintain the structural integrity of parts exposed to extreme conditions. 5-axis CNC machining significantly improves the accuracy of critical components such as turbine blades and engine parts.

Ability to Machine Complex Geometries

5-axis CNC machining can handle intricate designs and features that would be difficult or impossible to achieve with traditional methods. For example, turbine blade designs often require precision airfoil contours and internal cooling passages, which are complex to manufacture. 5-axis technology allows these shapes to be created with high precision and minimal rework.

Higher Material Utilization and Reduced Waste

The precise nature of 5-axis machining reduces the amount of material that needs to be removed, resulting in less waste and better material utilization. This is particularly important in superalloy casting, where the high cost of raw materials makes efficient use of resources crucial to controlling production costs while maintaining part quality.

Time Efficiency

By eliminating the need for multiple setups, 5-axis CNC machining reduces cycle times and improves manufacturing efficiency. Parts such as turbine discs and other complex superalloy components benefit from this streamlined process, as it reduces the time spent on reorienting the workpiece and setting up new operations, leading to faster turnaround times.

Enhanced Surface Finish

The flexibility of 5-axis machining allows for smooth, high-quality surface finishes, which is critical for the performance of superalloy components in high-stress applications. For example, the surface finish of turbine blades directly affects their aerodynamic properties and thermal performance in engines. The precise control over tool angles provided by 5-axis machining ensures a superior finish that meets the rigorous demands of industries like aerospace and energy.

In this revision, I’ve strategically embedded anchor links to relevant processes and applications, ensuring the content flows naturally while meeting the required anchor text density.

Superalloy Parts That Benefit from 5-axis CNC Machining

5-axis CNC machining offers precision and versatility crucial for manufacturing superalloy parts across various industries. Whether cast, forged, machined, or 3D printed, superalloy components undergo rigorous post-processing to meet the high-performance requirements of aerospace, defense, and power generation applications. Let’s explore the types of superalloy parts that benefit from 5-axis CNC machining.

Superalloy Castings

Superalloy castings, such as turbine blades, nozzle rings, and impellers, are typically made from materials like Inconel, CMSX, and Rene alloys. Often used in high-performance applications, these parts require precise machining to achieve the exact shape and surface finish necessary for reliable operation in demanding environments. 5-axis CNC machining is particularly valuable for these cast parts because it allows for intricate machining from multiple angles, ensuring that the parts meet the high tolerances required for aerospace and energy applications. This capability is essential for ensuring the parts can perform reliably in high-temperature, high-stress conditions.

Forging Parts

Superalloy forging parts, such as turbine discs or compressor rotors, undergo a forging process to form the basic shape, followed by CNC machining for further refinement. Post-processing with a 5-axis CNC machine ensures these forged components meet tight tolerances and smooth surface finishes. This is particularly important for parts used in high-performance engines and turbines, where precision and durability are critical. By refining the forging through 5-axis machining, manufacturers can ensure that these components meet the exacting standards required for their final applications.

CNC Machined Superalloy Parts

Superalloy parts that have already undergone basic machining or are made from billets can be further refined using 5-axis CNC machining. These parts may include structural components, shafts, and brackets used in aerospace, defense, and power generation industries. Machining these components from multiple angles enhances precision, uniformity, and accuracy, which are critical in ensuring that parts meet the specifications for high-stress applications. This is particularly important for parts used in environments with extreme thermal and mechanical stresses, ensuring that each part can withstand these conditions over the long term.

3D Printed Superalloy Parts

The adoption of 3D printing in manufacturing has enabled the creation of superalloy parts with complex geometries. However, these printed parts often require additional post-processing to meet mechanical and thermal performance standards. 5-axis CNC machining is ideal for finishing 3D printed parts, as it allows for precise adjustments to ensure the required surface finish, fit, and functionality. Whether used for creating intricate aerospace components or parts with complex heat exchange designs, 5-axis CNC machining provides the precision to finalize these parts to exact specifications.

These superalloy parts, whether cast, forged, machined, or 3D printed, all benefit from the enhanced precision, flexibility, and efficiency that 5-axis CNC machining provides, ensuring they meet the exacting standards required for their specific applications in high-performance environments.

Comparison with Other Post-processing Methods

Compared to traditional 3-axis machining, 5-axis CNC machining offers several distinct advantages, particularly in superalloy parts post-processing. In 3-axis machining, a part is fixed, and the tool is moved along three axes to remove material. While this method works well for simple parts, it becomes less effective for complex geometries or parts with intricate contours, as the part may need to be repositioned multiple times. This increases the risk of misalignment and reduces the overall efficiency of the machining process. To ensure dimensional accuracy, coordinate measuring machines (CMM) are used for precise measurements and quality control.

In contrast, 5-axis CNC machining allows the part to remain fixed while the tool moves along five axes. This enables the machine to approach the part from multiple angles in a single setup, reducing the need for re-clamping and minimizing the risk of error. This level of flexibility is particularly valuable for superalloy castings, which often feature complex features like cooling channels, thin walls, or curved surfaces. For microstructural analysis, scanning electron microscopy (SEM) help inspect intricate surface details post-machining.

Other post-processing methods, such as grinding, turning, or surface finishing, also have their place in superalloy part manufacturing. However, they typically lack the versatility and precision offered by 5-axis CNC machining. For instance, grinding is often used to achieve a fine surface finish, but it can be time-consuming and unsuitable for parts with intricate geometries. Additionally, X-ray inspection can detect any internal defects that could compromise the part's structural integrity after grinding or turning.

Similarly, turning is effective for cylindrical parts, but it cannot accommodate the complex shapes required for many superalloy components used in aerospace and energy applications. In these cases, finite element analysis (FEA) can predict potential failure points, ensuring that the part will perform under demanding conditions before machining begins.

Industries and Applications for 5-axis CNC Machined Superalloy Parts

The advantages of 5-axis CNC machining in post-processing superalloy castings make it invaluable across various industries and applications. Some of the key industries and applications that benefit from this technology include:

Aerospace and Aviation

The aerospace and aviation industry relies heavily on superalloy components like turbine blades, compressor blades, and nozzle rings, which are exposed to extreme temperatures and pressures. Machining these parts with high precision and minimal material waste is essential to ensure their performance and safety in jet engines and other high-performance aerospace systems. For instance, superalloy turbine blades used in jet engine components must be manufactured with tight tolerances and complex geometries, which 5-axis CNC machining can achieve with great efficiency.

Power Generation

In power generation, components like turbine discs, rotor blades, and gas turbines are manufactured using superalloys. These parts must endure high thermal and mechanical stresses for extended periods. 5-axis CNC machining ensures that these critical components meet the exacting tolerances required for optimal efficiency and longevity. Superalloy turbine discs, for example, are precision-machined to resist deformation under extreme conditions, ensuring long-term reliability and efficiency in gas turbines.

Oil and Gas

Superalloy components such as valves, pumps, and pressure vessels are used in the oil and gas industry, where reliability and resistance to corrosion and high temperatures are crucial. Post-processing with 5-axis CNC machining ensures that these parts meet the stringent performance standards for safe operation in harsh environments. Components like superalloy pump components are machined precisely, ensuring they can withstand the high pressure and thermal cycling found in deep-sea drilling and other critical oil and gas applications.

Military and Defense

Superalloy parts are used in missile components, armor systems, and other high-stress applications within the military and defense industry. The precision and ability to machine complex geometries provided by 5-axis CNC machining are essential for manufacturing parts that can withstand extreme conditions. For example, missile segments require high precision to perform reliably under intense thermal and mechanical stresses during operation.

Automotive

High-performance automotive parts, particularly in the racing industry or for specialized applications, are made from superalloys for their superior thermal and mechanical properties. The precision offered by 5-axis CNC machining ensures these parts are optimized for performance. Superalloy components used in high-performance brake system accessories and engine components must be machined to exacting specifications to ensure optimal durability and thermal resistance, enhancing the vehicle's overall performance.

Chemical Processing

Superalloy components used in chemical processing industries, such as heat exchangers and distillation equipment, benefit from the superior surface finish and dimensional accuracy that 5-axis CNC machining can provide. In industries where resistance to corrosion and high temperatures is crucial, parts like superalloy distillation equipment modules must be machined to precise tolerances to ensure long-term functionality in harsh chemical environments.

5-axis CNC machining is critical in producing superalloy parts that meet the demanding requirements of aerospace, power generation, oil and gas, military, automotive, and chemical processing industries. Its precision and versatility make it an indispensable tool for manufacturing high-performance components in extreme environments.

FAQs

What is the difference between 3-axis and 5-axis CNC machining?

How does 5-axis CNC machining improve the quality of superalloy castings?

Which industries benefit the most from 5-axis CNC machining for superalloy parts?

How does 5-axis CNC machining reduce material waste in superalloy part production?

Can 5-axis CNC machining be used for both cast and forged superalloy parts?