Wax Recycling: Promoting Sustainability in Superalloy Casting Manufacturing

The investment casting process is a cornerstone of superalloy manufacturing, providing the precision required for high-performance components. A vital component of this process is wax, which is used to create patterns that define the final geometry of the parts. However, traditional practices often result in significant wax waste, raising concerns about environmental impact and production costs.

Wax recycling offers a sustainable solution, aligning with the industry’s growing focus on efficiency and environmental responsibility. This blog will explore the benefits of wax recycling in investment casting, how it contributes to cost reduction, and its positive impact on superalloy manufacturing for industries like aerospace and power generation.

The Role of Wax in Superalloy Casting

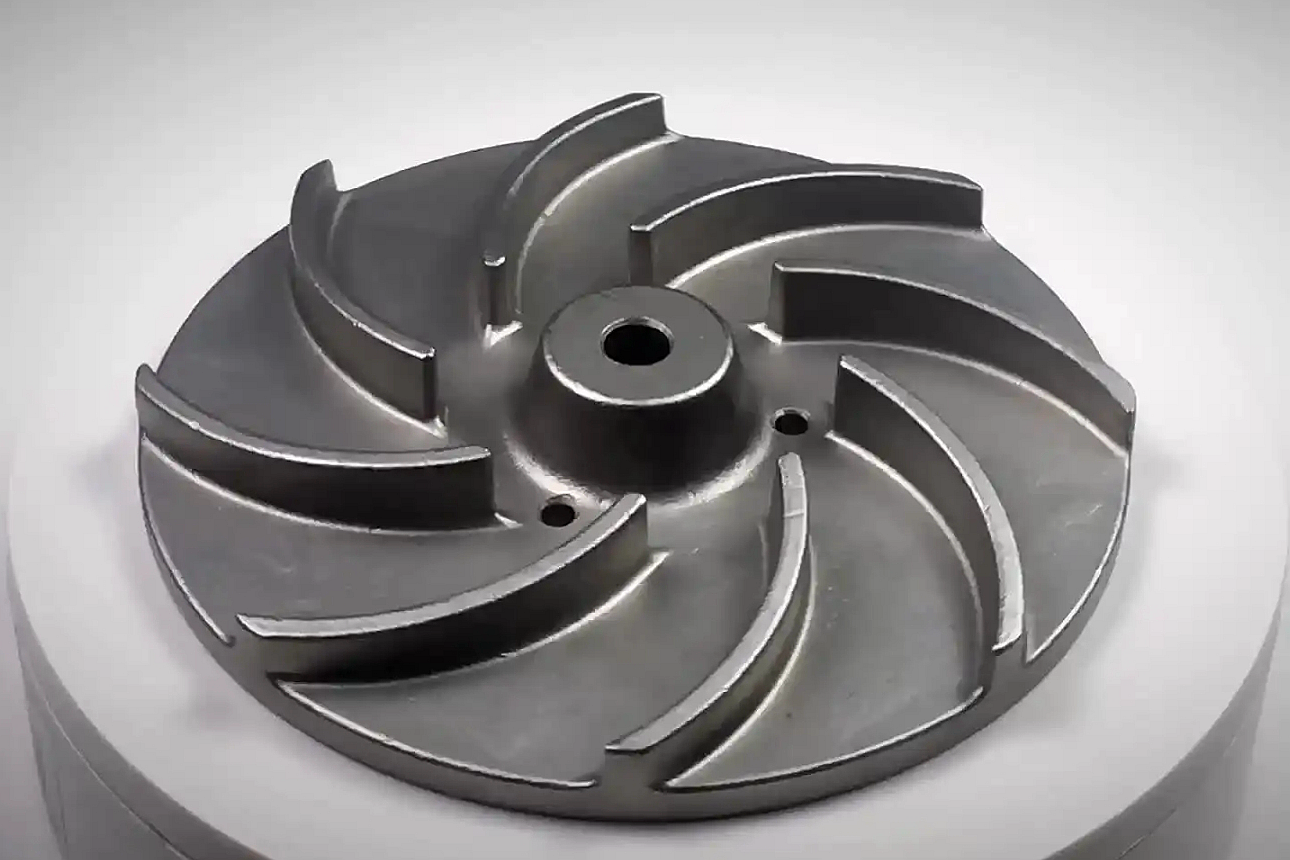

Wax patterns are integral to the investment casting process, forming the basis for the ceramic molds used in manufacturing. These patterns are created by injecting molten wax into molds and assembled into complex tree structures for subsequent processing. The wax is later removed during the dewaxing stage to leave the mold cavity filled with molten superalloy behind.

Waste management becomes a significant challenge due to the volume of wax used in high-production facilities. The discarded wax contributes to environmental issues and wastes valuable material resources without recycling. Therefore, wax recycling is essential to minimize waste, reduce costs, and ensure sustainable production practices.

Environmental and Economic Benefits of Wax Recycling

Wax recycling substantially benefits both the environment and manufacturers, making it an essential component of sustainable superalloy casting operations. Incorporating wax recycling techniques delivers both environmental and financial advantages.

Reduction of Waste: Recycling wax prevents large quantities of material from ending in landfills. This reduces the casting operations' environmental footprint and aligns with waste management regulatory requirements. Adopting sustainable casting practices further enhances compliance and eco-friendliness.

Cost Savings: Recovering and reusing wax reduces the need for virgin material purchases. Over time, these savings can significantly lower the operational costs of superalloy production. Efficient wax recovery and reuse systems enable manufacturers to achieve long-term cost reductions.

Operational Efficiency: Recycling systems streamline waste management processes, reducing the labor and resources required for disposal and procurement. Manufacturers can improve operational efficiency by integrating automated recycling technologies into their workflows.

Manufacturers can enhance their environmental stewardship by incorporating wax recycling into their operations while achieving measurable economic advantages. These practices support a circular economy approach, where resources are maximized, waste is minimized, and sustainability is prioritized.

Industry Standards and Best Practices for Wax Recycling

Recycling wax in superalloy manufacturing must adhere to stringent industry standards to maintain part quality and reliability. Key best practices include:

Maintaining Quality and Consistency

Maintaining Quality and Consistency: Recycled wax must meet specific physical and chemical properties to perform similarly to virgin wax. Parameters such as melting point, viscosity, and thermal stability must be closely monitored.

Balancing Sustainability with Performance

Balancing Sustainability with Performance: While the goal is to maximize recycling, the performance of the final parts must not be compromised. Mixing recycled wax with a percentage of virgin material is often a practical approach to achieve this balance.

Implementing Robust Recycling Protocols

Implementing Robust Recycling Protocols: Establishing clear collection, cleaning, and testing protocols ensures that recycled wax meets production standards consistently.

Manufacturers who follow these best practices can achieve sustainability goals while maintaining the quality and precision required in superalloy casting.

Challenges in Implementing Wax Recycling Systems

Despite its advantages, wax recycling presents several challenges that manufacturers must address:

Compatibility with Mold Materials

Compatibility with Mold Materials: Recycled wax may interact differently with ceramic molds, potentially affecting the casting process. Ensuring compatibility through rigorous testing is crucial.

Equipment Costs and Scalability

Equipment Costs and Scalability: The initial investment in recycling equipment can be substantial, particularly for smaller operations. Scaling these systems for high-volume production requires careful planning.

Impurities and Wax Integrity

Impurities and Wax Integrity: Managing contaminants and maintaining the physical properties of recycled wax is a constant challenge. Advanced filtration and reformulation methods are often necessary to address these issues.

By understanding and mitigating these challenges, manufacturers can implement effective wax recycling systems that integrate seamlessly into their operations.

Real-World Applications and Success Stories

Industries that rely on superalloy casting have increasingly adopted wax recycling to improve their sustainability and efficiency:

Aerospace and Aviation

In the aerospace and aviation industry, manufacturers of turbine blades and jet engine components have successfully implemented wax recycling systems to reduce material costs while maintaining strict quality standards. This recycling decreases production expenses and minimizes waste, contributing to a more environmentally responsible manufacturing process.

Energy and Power Generation

Companies involved in power generation, particularly those producing reactor vessels and heat exchangers, have benefited from operational efficiencies gained through wax recovery. By implementing wax recycling, these manufacturers optimize resource use and reduce their environmental impact, which is critical in the energy sector.

Automotive

In the automotive industry, wax recycling has been instrumental in reducing production costs for high-temperature alloy components like brake systems and transmission component assemblies. Reusing wax significantly lowers raw material costs, enabling more sustainable production while still ensuring the durability and quality required for automotive applications.

These success stories demonstrate the tangible benefits of adopting wax recycling practices in high-performance manufacturing environments, leading to cost savings, operational efficiencies, and reduced environmental footprints.

Key Metrics for Measuring Success in Wax Recycling

To evaluate the effectiveness of wax recycling systems, manufacturers track several key metrics:

Wax Recovery Rate

The percentage of wax successfully recovered and reused is a critical indicator of system efficiency. Industries like energy and aerospace rely on maximizing wax recovery to ensure sustainability without compromising quality.

Cost Savings

Quantifying the reduction in material procurement costs highlights the financial impact of recycling initiatives. For example, reducing costs for components such as high-temperature alloy brake systems directly influences competitiveness and profitability in the automotive industry.

Environmental Impact Metrics

Metrics such as waste diversion rates and reductions in carbon footprint provide insights into the environmental benefits of recycling. Adopting wax recycling in sectors like chemical processing, pharmaceuticals, and food plays a significant role in achieving sustainability goals and reducing the overall carbon emissions associated with production.

Performance Consistency

Ensuring that parts produced with recycled wax meet quality standards is essential for long-term success. Industries such as military and defense require stringent quality adherence, particularly for components like armor system parts, which must perform reliably under extreme conditions.

FAQs

What are the main steps involved in recycling wax for superalloy casting?

How does recycled wax impact the performance of ceramic molds in the casting process?

What advanced technologies are available to improve the quality of recycled wax?

What are the key challenges manufacturers face when adopting wax recycling systems?

How can wax recycling contribute to the sustainability goals of industries like aerospace and energy?