Core Removal Techniques for Custom Superalloy Castings: Efficient Solutions for Complex Parts

Core removal is a critical step in the casting process, particularly for high-performance superalloy components. Cores enable the creation of hollow sections or intricate internal geometries that would otherwise be impossible to manufacture using conventional methods. However, removing these cores efficiently, without damaging the casting, poses significant challenges due to the designs' complexity and superalloy materials' high strength.

Effective core removal techniques ensure dimensional precision, material integrity, and functionality, which are vital in applications like aerospace turbines, oil and gas equipment, and power generation components. The selection of the proper technique depends on factors such as the core material, the complexity of the casting, and the specific industry requirements.

Overview of the Manufacturing Process

Superalloy casting involves advanced techniques tailored to meet stringent industry standards. Vacuum investment, directional, and single-crystal casting are widely used for producing components with exceptional heat resistance, mechanical strength, and durability. These processes are integral in aerospace and power generation industries, where performance in extreme environments is critical.

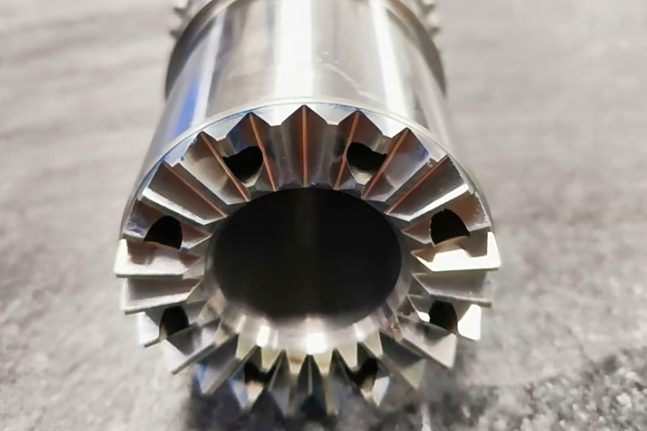

Cores from materials such as ceramics or salt are integral to this process. These materials withstand the high temperatures of molten superalloys while forming complex internal structures. Once the casting solidifies, the core must be removed without altering the precise geometry of the part. Advanced core materials and techniques ensure the integrity of intricate designs.

The choice of core material influences the removal technique:

Ceramic Cores: Commonly used in aerospace applications, these cores require chemical or mechanical methods for extraction. Automated core removal systems precisely handle these high-strength cores without damaging the cast part.

Salt Cores: Typically dissolved using water or chemical leaching, salt cores offer easy removal and are often chosen for components with intricate cooling channels or hollow sections. Efficient salt core dissolution methods ensure both speed and accuracy.

The design intricacies, such as thin-walled sections or complex curves, necessitate advanced methods to ensure accuracy. Leveraging precision core materials and removal techniques ensures that the final components meet strict dimensional tolerances and performance requirements.

Typical Superalloys Used in Custom Casting

Superalloys are engineered to perform under extreme conditions, making them indispensable in critical industries. Nickel-based superalloys, such as Inconel 718 and CMSX-4, are widely used due to their excellent resistance to oxidation and creep at high temperatures. These properties make them ideal for high-performance components, including turbine blades and combustion chambers.

Cobalt-Based Superalloys

Cobalt-based superalloys, like Stellite 6B, are preferred for applications requiring superior wear resistance. These alloys are commonly used for valve seats, mechanical seals, and other components that endure high mechanical friction and wear in harsh environments.

Titanium-Based Alloys

Titanium-based alloys, including Ti-6Al-4V, are utilized for their high strength-to-weight ratio and corrosion resistance. These materials are ideal for components in demanding environments, such as jet engines and gas turbines, whose lightweight properties and performance are critical.

Role of Material Properties in Core Removal

The material properties of these superalloys play a crucial role in core removal. High hardness and resistance to thermal degradation often require specialized post-processes to prevent damage to the component during core extraction. This is particularly important to maintain the structural integrity and performance of complex geometries often cast with superalloys.

Comparison of Post-Processes for Core Removal

Core removal is a post-casting process that ensures the part is ready for further finishing and application. Different techniques are available, each with its advantages and limitations.

Leaching Techniques

Chemical leaching is a popular choice for removing ceramic and salt cores. The core dissolves without applying physical force by immersing the casting in a chemical bath. This precise method minimizes the risk of surface damage, making it suitable for thin-walled or intricate components. However, chemical leaching can be time-consuming and requires safe handling of hazardous materials. Maintaining contaminant-free conditions during this process is critical to ensure quality results without introducing unwanted impurities.

Mechanical Core Removal

Mechanical methods use abrasive blasting, vibration, or ultrasonic techniques to dislodge the core physically. This approach is faster than chemical leaching and effective for robust core materials. However, it carries the risk of surface damage and is less suitable for delicate or complex designs. Surface quality plays a key role in the final component's performance, and using mechanical methods requires careful control to avoid compromising the casting's integrity.

Thermal Techniques

High-temperature processes, such as baking out the core, are particularly effective for materials that can withstand secondary heat treatments. Thermal techniques are environmentally friendly and do not involve hazardous chemicals. However, they may introduce thermal stresses, necessitating additional inspection for cracks or deformation. Thermal treatments are beneficial in many post-processing applications, but careful attention must be paid to the effects of repeated heating on the casting's structural properties.

Selecting a core removal technique depends on cost, efficiency, environmental impact, and compatibility with the casting material. Each method must be matched to the specific requirements of the component to achieve the best balance of quality and performance in subsequent applications.

Testing and Quality Assurance in Core Removal

Testing and quality assurance are integral to the core removal process, ensuring the casting meets its intended specifications without defects.

Non-Destructive Testing (NDT)

X-ray and computed tomography (CT) scanning are commonly used to verify the completeness of core removal. These techniques provide detailed insights into internal structures, allowing manufacturers to detect residual core material or internal defects. Ultrasonic testing is another effective method for identifying subsurface anomalies.

Surface and Dimensional Analysis

Coordinate measuring machines (CMM) and 3D scanning instruments are employed to assess the dimensional accuracy of the casting after core removal. These tools ensure that the final part conforms to the design tolerances.

Material Integrity Tests

Metallographic and scanning electron microscopy (SEM) inspect the component's microstructure. These tests help identify any damage caused by the core removal process, such as cracks, surface roughness, or residual stresses.

By combining these testing methods, manufacturers can ensure the quality and reliability of superalloy castings for critical applications.

Industry Applications and Core Removal Needs

Core removal is essential in producing components for industries that demand high performance and reliability. The precise removal of cores allows for manufacturing intricate internal geometries in superalloy parts, vital for meeting the stringent standards of various high-performance sectors.

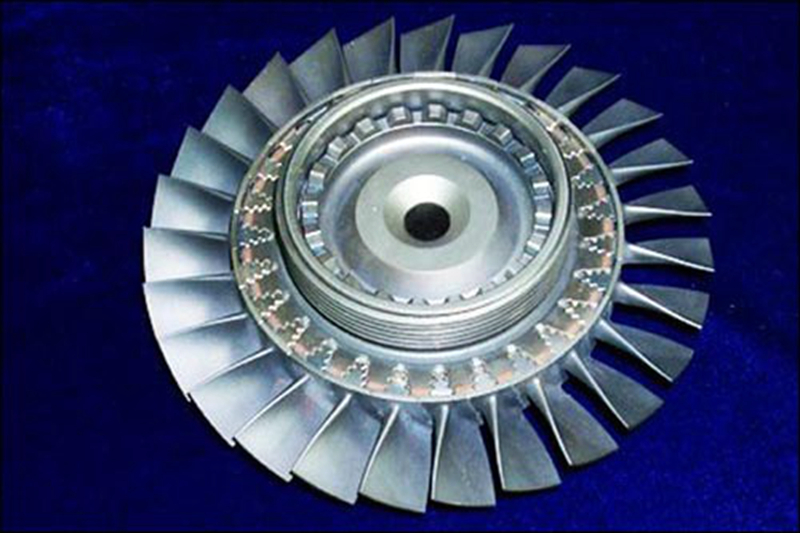

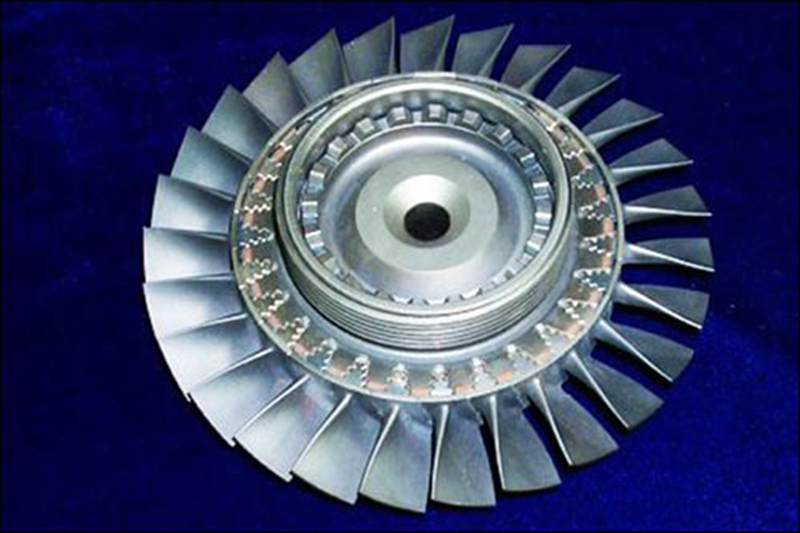

Aerospace and Aviation

In aerospace and aviation applications, precision is paramount. Core removal is critical for manufacturing jet engine components such as turbine blades and combustion chambers, where intricate hollow sections enhance performance and efficiency. Components like jet engine parts are manufactured with extreme precision to achieve the desired aerodynamic properties, directly contributing to improved fuel efficiency and reliable engine performance.

Power Generation

Power generation applications, such as gas turbines and heat exchangers, require components with complex geometries to optimize thermal efficiency. Core removal techniques enable the production of these components with tight tolerances and superior material properties, ensuring maximum thermal performance and reliability in gas and steam turbine systems.

Oil and Gas

In the oil and gas, components must withstand harsh environments characterized by extreme temperatures, pressures, and corrosive substances. Core removal is essential for creating complex internal geometries in parts such as pump components, containment systems, and other critical equipment, ensuring exceptional corrosion and heat resistance under demanding operational conditions.

Military and Defense

Military and defense applications rely on high-strength superalloy components, such as missile segments and armor systems, which require precise core removal to maintain structural integrity and performance under extreme conditions. By ensuring the accuracy of these critical components, core removal techniques help maintain the effectiveness and safety of defense technologies in the most challenging environments.

Automotive

In the automotive industry, advanced brake systems and exhaust components in high-performance vehicles benefit from the intricate geometries made possible by core removal. For instance, high-temperature alloy brake systems must handle high mechanical loads and thermal stress. The use of precise core removal enables the production of parts that contribute to enhanced braking efficiency and reliability.

Chemical Processing

Chemical processing and pharmaceutical and food industries require components like heat exchangers, sterilization equipment parts, and corrosion-resistant piping systems with highly complex internal structures. Core removal methods are crucial for achieving these intricate designs, ensuring that the components can endure the corrosive environments and high-temperature conditions commonly encountered in these industries.

Importance of Efficient Core Removal

These diverse applications highlight the importance of efficient and reliable core removal methods in producing high-quality superalloy components for demanding industries. Whether it's achieving the aerodynamic precision required in aerospace, optimizing the thermal efficiency in power generation, or ensuring the durability of equipment in oil and gas environments, core removal is a critical process that directly impacts the performance, reliability, and efficiency of superalloy components across various sectors.

FAQs

What are the main challenges in removing cores from complex superalloy castings?

How does chemical leaching compare to mechanical methods for core removal?

What role do non-destructive testing methods play in ensuring core removal quality?

Why are nickel-based superalloys commonly used in aerospace applications?

How do core removal techniques impact the overall performance of superalloy components?