Improving Surface Finish: Achieving Smoother Superalloy Castings Through Cleaner Molds

Superalloy castings are essential for industries where components are exposed to extreme conditions, such as aerospace, power generation, and military applications. These materials are specially engineered to perform under high temperatures, pressure, and corrosive environments. However, the quality of a superalloy casting’s surface finish is critical in its overall performance and lifespan. Achieving a smooth surface finish is often challenging, especially when working with complex geometries and highly reactive materials.

This blog explores the importance of achieving smooth superalloy castings and how cleaner molds contribute to a better surface finish, ultimately enhancing the part's durability, functionality, and performance in demanding applications.

Introduction to Surface Finish in Superalloy Castings

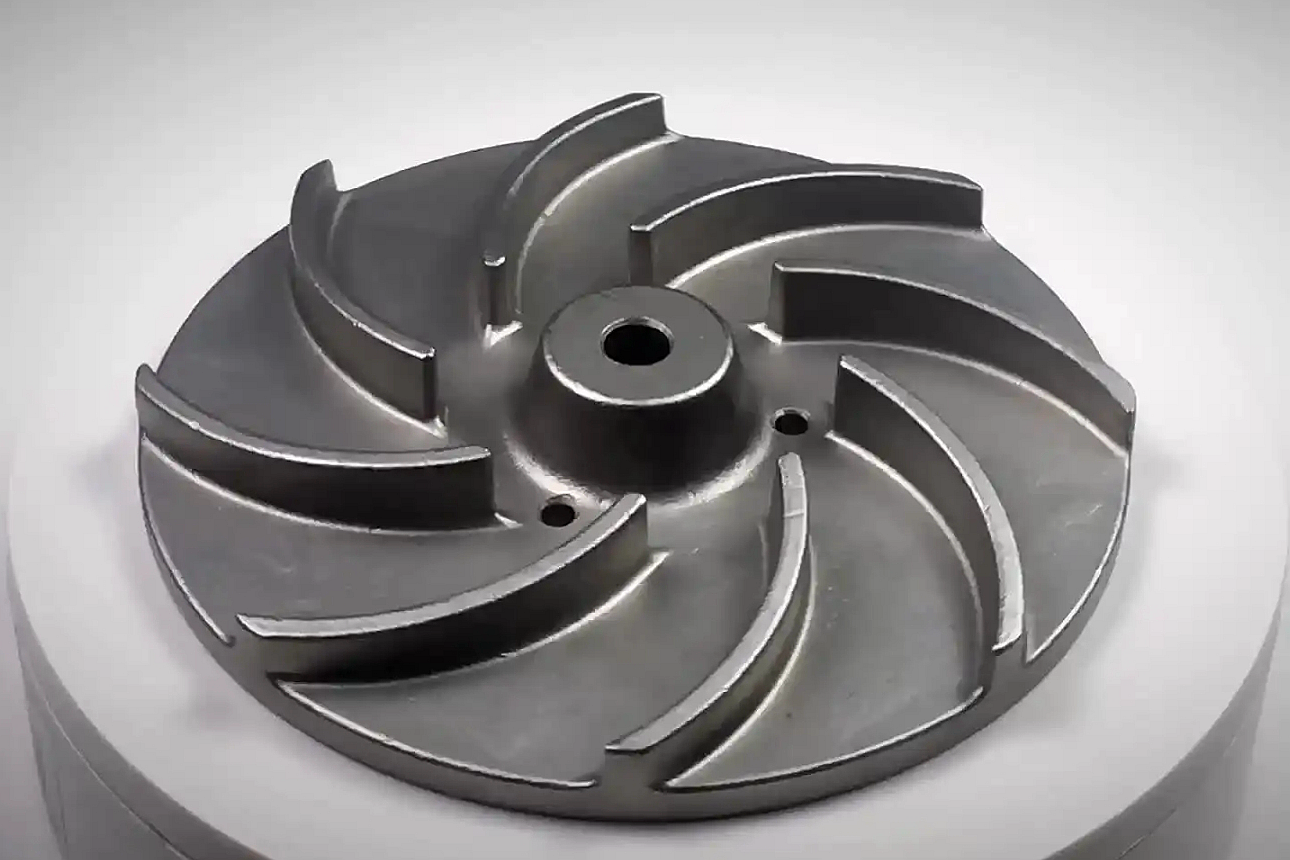

Superalloy castings are used extensively in high-performance applications, such as turbine blades, aerospace engine components, heat exchangers, and nuclear reactor parts. The surface finish of these components is crucial because it directly impacts their mechanical properties, resistance to fatigue, and corrosion resistance. A rough surface can lead to stress concentrations, premature wear, or failure under operational conditions.

Surface finish refers to the texture of a material’s surface, which can vary from smooth to rough. It is measured using parameters like Ra (average roughness), Rz (average peak-to-valley height), and other standards that define the quality of the surface. A smoother surface finish improves the part’s performance, enhancing its durability, reducing friction, and minimizing the potential for corrosion or stress fractures.

Precision CNC machining is a primary method to achieve superior surface finishes on superalloy castings. By employing advanced CNC technologies, manufacturers can achieve tight tolerances and high-quality surface finishes that meet the strict requirements of industries like aerospace and energy. Furthermore, superalloy casting processes such as vacuum investment casting ensure a smooth surface, as high-precision molds help reduce imperfections that could impact surface quality.

Challenges in Achieving Smooth Surface Finishes

Achieving a smooth surface finish in superalloy castings is often easier said than done. Various factors contribute to the difficulty of obtaining the desired surface quality. These factors can include the material’s inherent properties, the complexity of the casting process, and mold contamination. For example, the vacuum investment casting process is susceptible to these variables and requires careful control of the casting environment to prevent defects that can affect the surface finish.

Common Defects:

Common surface defects in superalloy castings include porosity, oxidation, inclusions, and roughness. Porosity, which occurs when gas bubbles become trapped during casting, can lead to weak spots on the surface. Oxidation, when the superalloy reacts with oxygen during the casting process, can create a rough, brittle surface. Inclusions are impurities that get trapped inside the casting, leading to surface irregularities. These defects often result from mold design, material handling, or casting environment issues. To combat these issues, advanced superalloy directional casting techniques can help refine grain structure and minimize these defects, contributing to a smoother surface finish.

Impact of Rough Surface Finish:

A rough surface finish in superalloy castings can lead to several issues. First, rough surfaces often have higher stress concentrations, which can reduce the part’s fatigue strength. In the case of turbine blades, for example, these stress concentrations can cause premature failure under repeated thermal and mechanical loading. Additionally, rough surfaces increase the risk of corrosion because they provide more surface area for environmental factors to act on the material. Electrostatic cleaning is one method used to mitigate contaminants that may affect the surface finish during casting, helping to reduce roughness and ensure higher-quality parts. Finally, a poor surface finish affects the aesthetic quality of the part, which is especially important for components in high-visibility applications like aerospace or automotive industries.

The Role of Clean Molds in Surface Finish Quality

One of the most effective ways to improve surface finish quality is to start with cleaner molds. Molds are integral to casting as they shape the superalloy material into the desired component. However, if the mold is contaminated with dirt, oils, or residues from previous casts, the surface finish of the casting will suffer.

Mold Contamination

During casting, molds often pick up contaminants from the environment, prior use, or the casting materials themselves. For example, mold materials like sand can create rough textures on the cast parts if not properly cleaned. Oils, waxes, and other substances used in the mold preparation process can also leave residues that mar the surface of the casting. These contaminants can lead to rougher surfaces as the mold’s imperfections are transferred onto the cast material.

Importance of Mold Cleanliness

Clean molds are essential for producing smooth, high-quality castings. A clean mold ensures the superalloy material flows evenly and does not experience unnecessary turbulence or surface contamination during the casting process. In addition, removing oils, dust, or other residues from the mold prevents defects like oxidation and surface blemishes, which can degrade the final part’s performance. Maintaining mold cleanliness ultimately contributes to superalloy castings that meet the demanding standards of high-performance applications such as aerospace, power generation, and military sectors.

Techniques for Cleaning Molds and Preventing Defects

Several methods are used to clean molds before the casting process, all of which help ensure that the final surface finish of the superalloy casting meets industry standards.

Mechanical Cleaning Methods

Mechanical cleaning involves physically removing debris and contaminants from the mold using tools such as brushes, sandblasters, and abrasives. Sandblasting is a popular method for removing stubborn contaminants, as the abrasive action helps to clear the mold’s surface of dust, dirt, and oils. Other mechanical methods, like brushing, can be used for finer cleaning or for molds that are too delicate to withstand abrasive techniques. These methods ensure a contaminant-free environment for casting, preventing defects in high-precision components like turbine blades.

Chemical Cleaning

Chemical cleaning methods use solvents, acids, or other chemical agents to break down and remove residues from the mold. These solvents dissolve oils, resins, and other contaminants that mechanical methods might miss. Chemical cleaning is effective in removing oxidation or scale buildup on metal molds. Acid baths are often used to remove such contaminants, ensuring that the mold surface is free of any impurities that could negatively affect the casting process. After chemical cleaning, it is essential to thoroughly rinse and dry the mold to avoid introducing new contaminants during the casting process, which can lead to defects like porosity or oxidation.

Drying and Degassing

After cleaning, it is critical to ensure the mold is completely dry and moisture-free. Any moisture trapped in the mold can cause steam or gas bubbles to form during the casting process, leading to defects like porosity. Degassing, or removing trapped gases, is another crucial step. This can be done using vacuum chambers or heating the molds to a specific temperature to expel residual gases. Proper degassing helps maintain the structural integrity of the casting, particularly in applications where high-temperature resistance and durability are essential, such as aerospace components.

Advances in Mold Design to Improve Surface Finish

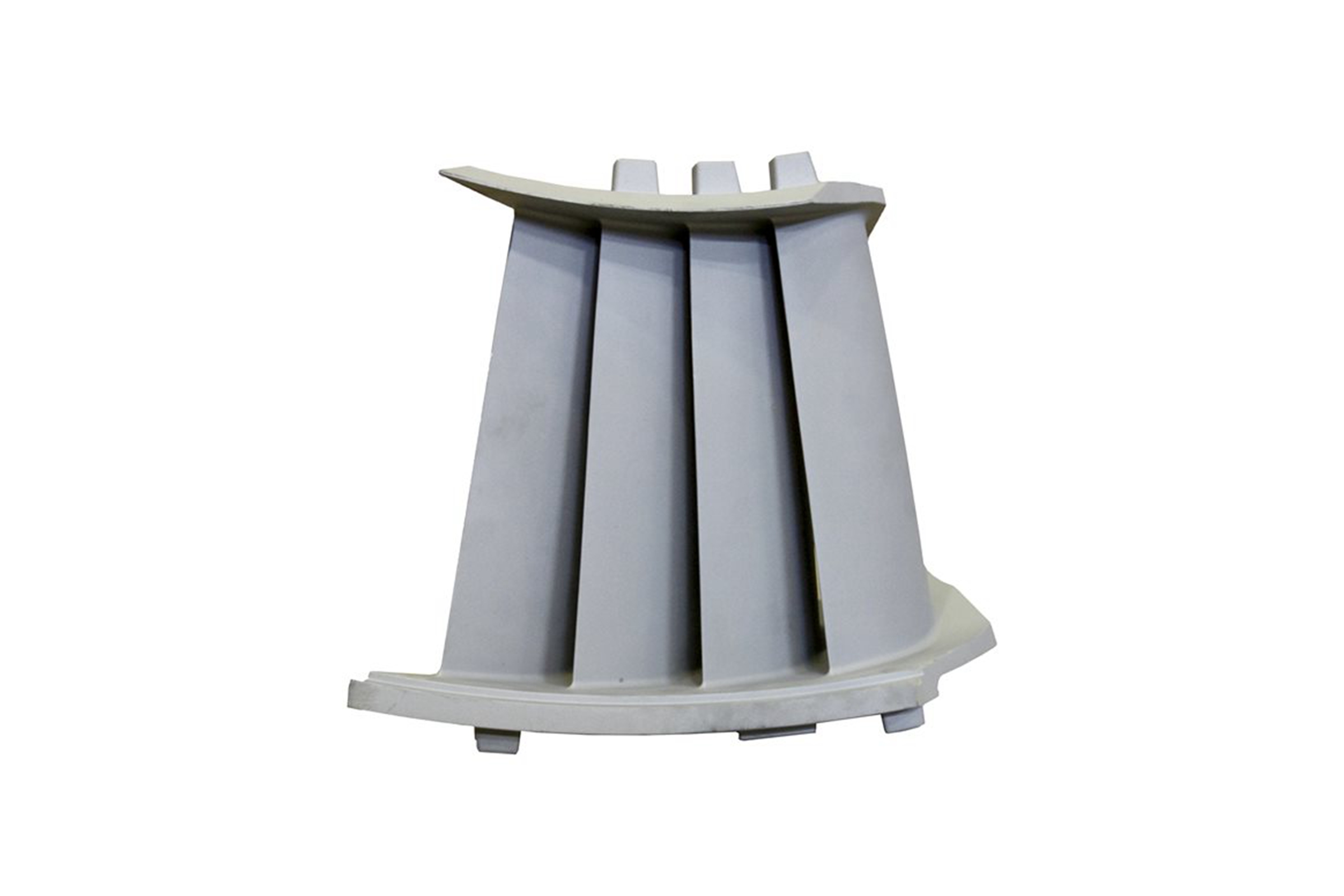

In addition to mold cleaning, improvements in mold design can also play a crucial role in achieving a smooth surface finish for superalloy castings. Modern mold designs focus on minimizing defects by optimizing material flow and ensuring mold material does not interact negatively with the casting. Vacuum investment casting processes, for instance, benefit from these advancements by controlling both material interactions and the casting environment to improve the final surface finish.

Mold Materials:

Choosing the right mold material is essential for achieving high-quality surface finishes. Non-reactive mold materials, such as ceramic or high-grade steel, are often used in superalloy casting to reduce the risk of chemical reactions that can degrade the surface quality. These materials can also better withstand the high temperatures involved in casting, ensuring the mold retains its integrity throughout the process. Applying superalloy precision forging methods to shape the mold can help create intricate geometries with precise surface characteristics that minimize defects during casting.

Mold Coatings:

Applying coatings to molds can help reduce surface roughness by creating a smoother interface between the mold and the casting material. These coatings act as a barrier, preventing oxidation and reducing the friction between the mold and the superalloy. Some coatings also help to minimize material buildup, ensuring a more even material flow and preventing defects like inclusions. By utilizing single crystal casting technology, coatings can be further optimized to maintain the purity and integrity of the casting, particularly in highly demanding applications like turbine blade production.

Refining Mold Geometry:

The shape and design of the mold are crucial to achieving a high-quality surface finish. By optimizing the mold geometry, it is possible to control the flow of molten superalloy during casting, reducing turbulence that can lead to surface defects. Properly designed molds can also ensure uniform cooling, which helps to reduce thermal stresses that could lead to cracking or rough surfaces. Advanced equiaxed crystal casting techniques can be integrated into mold designs to enhance grain structure control further and promote more uniform solidification, minimizing defects in the final cast.

Post-Casting Processes to Improve Surface Finish

Even after the casting process is completed, several post-casting processes can improve the surface finish of superalloy parts, ensuring they meet the high standards required for demanding applications.

Surface Grinding and Polishing

Surface grinding and polishing are standard techniques used to smooth out imperfections on the cast part. Grinding uses abrasive wheels to remove rough spots and irregularities from the surface, while polishing with finer abrasives refines the surface to achieve a smooth, mirror-like finish. These processes ensure that superalloy parts, such as turbine blades and impellers, meet the stringent surface finish requirements for high-performance applications. The improved finish enhances the part's appearance and functionality, reducing drag and improving aerodynamic efficiency in aerospace applications.

Heat Treatment

Heat treatment processes like annealing or stress-relieving can also play a crucial role in improving the surface finish of superalloy parts. By carefully controlling the temperature and cooling rate, these processes help reduce residual stresses within the material, preventing surface cracking or distortion. In addition, heat treatment can refine the material's microstructure, enhancing its mechanical properties, such as strength, toughness, and corrosion resistance. For example, heat treatment can improve the resistance of nickel-based alloys' resistance to creep and oxidation at high temperatures, such as Inconel, commonly used in aerospace and power generation.

Shot Peening and Coating

Shot peening is a process in which small metallic balls are blasted at the part's surface to improve its finish and surface integrity. This method is particularly effective at smoothing out micro-irregularities while imparting compressive stress to the material, improving fatigue resistance. In addition to shot peening, coating techniques such as thermal spraying or anodizing can provide additional surface protection. For example, thermal barrier coatings (TBC) are commonly applied to superalloy components used in high-temperature environments, such as turbine blades, to protect them from extreme thermal stresses and oxidation, extending the lifespan of critical aerospace parts.

Industry Standards and Best Practices for Superalloy Surface Finish

To ensure that superalloy castings meet the high standards required for critical applications, it is essential to follow industry guidelines and best practices for surface finish.

Quality Standards

Various quality standards, such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization), provide guidelines for acceptable surface finish levels. These standards define the acceptable roughness parameters and help ensure that castings meet the required mechanical properties and aesthetic standards. For example, superalloy components like turbine blades and engine components in the aerospace industry must adhere to stringent surface finish requirements to ensure optimal performance under extreme conditions.

Inspection Methods

Various inspection methods verify that the surface finish meets the required standards. Coordinate Measuring Machines (CMM) are commonly used to assess the geometry of a part and detect surface imperfections. This method ensures that critical dimensions and surface smoothness are consistent across batches of castings. Scanning Electron Microscopes (SEM) can provide a detailed analysis of the surface at a microscopic level, revealing hidden defects like porosity or oxidation. For example, in industries like oil and gas, where superalloy components like valves and pumps are exposed to extreme corrosion and wear, SEM can detect even the smallest surface flaws that could compromise performance.

X-ray and other non-destructive testing methods are also used to ensure castings are free from internal flaws. These techniques are essential for verifying the integrity of components used in high-stress environments, such as reactor vessel components in nuclear power plants or missile segments used in military applications. Non-destructive testing ensures that components can safely and reliably perform without undergoing costly or damaging post-manufacturing failure.

By adhering to industry standards and employing precise inspection methods, manufacturers can ensure that superalloy castings meet the highest quality requirements for their intended applications, whether in aerospace, oil and gas, defense, or nuclear industries.

FAQs

What is the impact of mold contamination on surface finish quality in superalloy castings?

How can chemical cleaning methods be used to improve the surface finish of superalloy molds?

Why is mold temperature control important for achieving smooth superalloy castings?

What are some of the post-casting processes that help improve the surface finish of superalloy parts?

How do industry standards for surface finish affect the overall quality of superalloy castings?