High-Temperature Resistance in Core Removal: Handling Inconel Alloys for Aerospace Applications

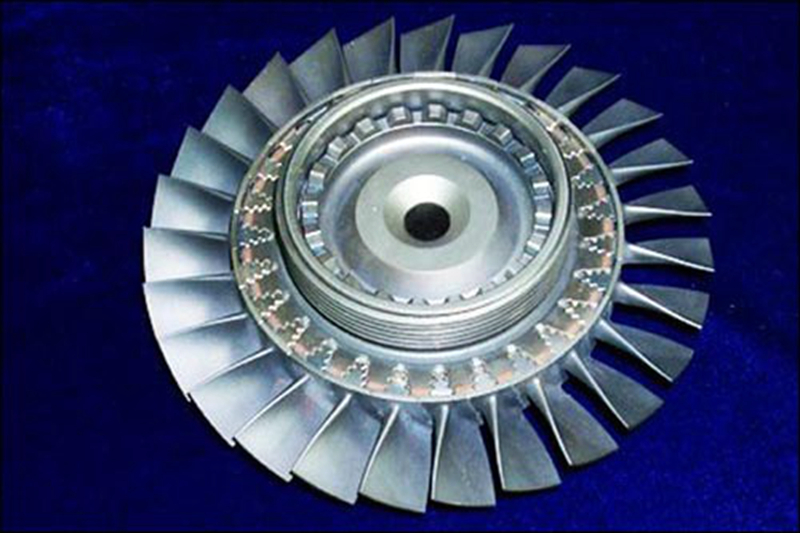

Inconel alloys are considered the cornerstone of high-performance materials in aerospace and other demanding industries. These nickel-based superalloys are known for their exceptional resistance to oxidation, corrosion, and high-temperature deformation. They are ideal for critical components such as turbine blades, combustion chambers, and exhaust systems.

Core removal is a critical post-process in the manufacturing of Inconel alloy components. Inconel's high hardness and thermal stability make this process challenging, requiring advanced techniques to ensure precision without compromising the part's integrity. The success of core removal directly impacts the component’s performance and reliability, especially in aerospace applications where failure is not an option.

Manufacturing Process for Inconel Alloy Components

Manufacturing Inconel alloy components involves advanced techniques to produce parts that meet stringent industry standards. Vacuum investment casting and directional solidification are commonly used due to their ability to create complex geometries with tight tolerances. These methods ensure superior mechanical properties, such as high-temperature strength, corrosion resistance, and thermal stability, making Inconel ideal for demanding applications in aerospace, power generation, and chemical processing.

Cores play an essential role in this process, forming the intricate internal cavities required in aerospace-grade components. Materials such as ceramic and salt are preferred for cores due to their compatibility with high-temperature processes and suitability for removal after casting. Ceramic cores are ideal for applications requiring high dimensional accuracy and stability, while salt cores provide efficient removal options in designs with specific internal geometries.

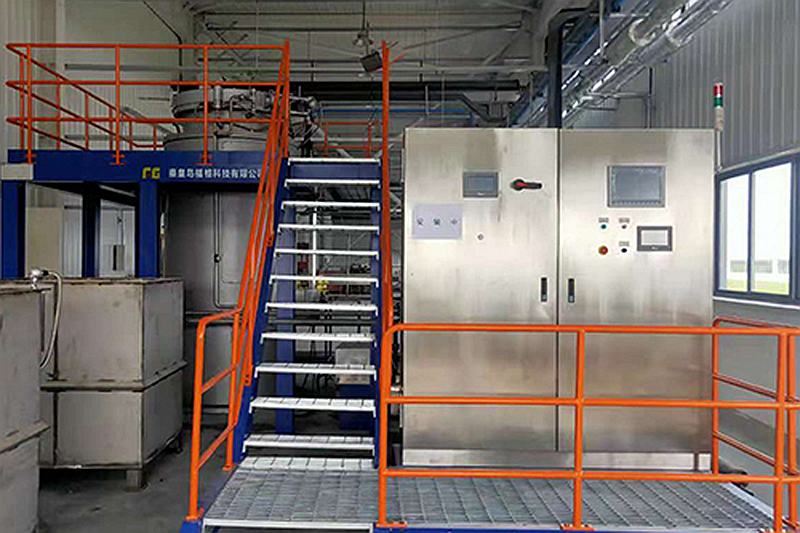

Core removal is seamlessly integrated into the production workflow. For Inconel components, it is vital to use techniques that can handle the alloy’s unique properties without causing damage or deformation. Modern manufacturing facilities often employ a combination of chemical, mechanical, and thermal methods to achieve this balance. Utilizing automated core removal systems ensures precision, consistency, and efficiency in this critical stage.

By leveraging these advanced techniques and core removal technologies, manufacturers ensure that each Inconel alloy component meets the highest quality and performance standards and is ready to excel in extreme operating conditions.

Properties of Inconel Alloys and Their Impact on Core Removal

Inconel alloys are engineered for extreme environments, where components must withstand high stress, temperature, and corrosive conditions. These properties make them invaluable in aerospace, power generation, and oil and gas industries.

Inconel 718

Inconel 718, one of the most commonly used grades, combines high strength and excellent oxidation resistance, making it ideal for turbine blades, exhaust systems, and other high-temperature applications. Its ability to perform under extreme conditions makes it a favorite for critical aerospace and energy components.

Inconel 738

Inconel 738 offers superior creep resistance, enabling components to maintain their integrity under prolonged exposure to high temperatures. This makes it well-suited for use in turbine blades and hot sections of gas turbines where prolonged high-temperature stability is critical.

Inconel 625

Inconel 625 is favored for its outstanding corrosion resistance, particularly in aggressive chemical and marine environments. This alloy is often used in equipment exposed to seawater, chemical processing applications, and other harsh settings where corrosion resistance is key to performance and longevity.

Impact on Core Removal

These properties, while advantageous in service, present challenges during core removal. Inconel’s hardness and mechanical and thermal stress resistance require specialized methods to avoid damaging the part. For instance:

Mechanical Methods: Core removal via mechanical means must be precisely controlled to prevent surface damage. Inconel’s hardness can cause tools to wear out quickly, requiring special consideration of tool material and pressure settings.

Chemical Processes: Chemical methods of core removal must be exact to ensure that cores are fully dissolved without leaving residual contamination. The resistance of Inconel to chemical reactions makes selecting the appropriate chemicals and controlling process parameters critical for successful core removal.

The high-performance characteristics that make Inconel alloys ideal for demanding applications also necessitate advanced and carefully controlled core removal techniques to ensure the integrity and quality of the final part.

Post-Process Comparison: Core Removal Techniques for Inconel Alloys

The selection of core removal techniques for Inconel components is influenced by the material’s unique properties and the part's complexity. Each method has its strengths and limitations, which must be carefully evaluated.

Chemical Leaching

Chemical leaching involves immersing the part in a solution that dissolves the core material. This method removes ceramic and salt cores, particularly in components with intricate internal geometries. The precision of chemical leaching minimizes the risk of damage to Inconel’s surface, preserving the integrity of the casting. However, the process can leave behind chemical residues that require thorough cleaning, adding an extra step to the workflow. Ensuring a contaminant-free environment during chemical leaching is crucial to maintaining the part's quality.

Mechanical Core Removal

Mechanical core removal techniques, such as abrasive blasting and ultrasonic core dislodging, rely on physical force to remove the core material. These methods are fast and efficient, especially for robust cores in simpler geometries. However, they carry a higher risk of surface damage, which can compromise the performance of complex Inconel components. Careful process control is essential to mitigate this risk. Maintaining surface integrity is key to ensuring the mechanical removal process does not introduce defects that could affect the performance of the final component.

Thermal Core Removal

Thermal core removal methods use high temperatures to disintegrate core materials, making them particularly suitable for heat-resistant cores. Inconel’s exceptional thermal stability allows it to withstand the high temperatures in this process, ensuring complete core removal without compromising the part’s structure. However, the thermal stresses introduced during the process may require additional inspection to verify the part’s integrity. The use of post-heat treatment can help relieve these stresses and improve the overall mechanical properties of the Inconel alloy.

Each technique offers distinct advantages, and manufacturers often use a combination of methods to achieve optimal results. The choice of technique depends on factors such as the core material, the complexity of the component, and the desired level of precision.

Testing and Quality Assurance for Inconel Alloy Castings

Rigorous testing and quality assurance are integral to ensuring the success of core removal processes for Inconel alloy components. These measures verify the completeness of the removal process, detect any residual material, and ensure that the casting meets all performance requirements.

Non-Destructive Testing (NDT)

Non-destructive testing (NDT) methods, such as X-ray and computed tomography (CT) scanning, are essential for inspecting the internal structures of Inconel castings. These techniques help identify residual core material, inclusions, and voids that could compromise the component’s performance. Ultrasonic testing is another valuable tool for detecting subsurface flaws, providing a detailed assessment of the part’s structural integrity.

Dimensional and Surface Inspection

Dimensional accuracy is critical for Inconel components, particularly in aerospace applications where even minor deviations can impact performance. Coordinate measuring machines (CMM) and 3D scanning systems to ensure the part’s geometry matches its design specifications. Surface inspections assess roughness and detect damage caused during core removal, ensuring that the part meets functional and aesthetic standards.

Material Integrity Testing

Material analysis methods, such as metallographic and scanning electron microscopy (SEM), provide detailed insights into the microstructure of Inconel castings. These tests are essential for detecting microcracks, grain boundary anomalies, and other material defects that may arise during core removal. Creep and fatigue testing further evaluate the part’s ability to withstand prolonged exposure to high temperatures and stress.

Advanced Monitoring Systems and AI-Driven Analytics

Advanced monitoring systems and AI-driven analytics are increasingly integrated into quality assurance workflows, enabling real-time process optimization and defect detection. These tools enhance the reliability and performance of Inconel components across all applications.

Industry Applications of Inconel Alloy Components

The exceptional properties of Inconel alloys make them indispensable in a wide range of industries where reliability and performance are critical. Known for their resistance to extreme temperatures, oxidation, and corrosion, Inconel alloys play a crucial role in producing high-performance components that meet the stringent requirements of various sectors.

Aerospace and Aviation

In the aerospace and aviation industry, Inconel manufactures jet engine components such as turbine blades, combustion chambers, and exhaust nozzles. These parts operate under extreme temperatures and pressures, requiring precise core removal to achieve lightweight, heat-resistant designs. Inconel alloys are crucial for ensuring that jet engine components can maintain their integrity and performance even in the most demanding conditions, contributing to improved fuel efficiency and aircraft reliability.

Power Generation

The power generation industry relies on Inconel for gas turbines and heat exchangers, where high-temperature performance is essential for efficiency and durability. Inconel’s ability to withstand prolonged exposure to extreme heat without degradation ensures that gas turbines operate efficiently, leading to more reliable power generation. Additionally, Inconel’s resistance to oxidation contributes to the longevity of critical parts in power systems.

Oil and Gas

Inconel alloys are used for containment systems, high-pressure piping, and other components exposed to corrosive environments in the oil and gas sector. These components, such as pump housings, require exceptional chemical corrosion and mechanical stress resistance. Effective core removal ensures the integrity of these parts, reducing the risk of failure in demanding applications, particularly during oil extraction and refining processes, where reliability is paramount for safe and cost-effective operations.

Military and Defense

Inconel is used for missile segments, armor systems, and other mission-critical components in the military and defense sectors. These applications demand defect-free manufacturing processes to ensure reliability under extreme conditions. Inconel’s high strength and thermal stability are vital for components subjected to significant thermal and mechanical stresses, ensuring mission success and safety in high-risk operations.

Automotive and Chemical Processing

In the automotive and chemical processing industries, Inconel alloys are employed for lightweight exhaust systems, corrosion-resistant mixing equipment, and other high-performance components. Automotive manufacturers utilize Inconel in exhaust systems to achieve high strength and heat resistance while reducing weight and enhancing vehicle performance and efficiency. In chemical processing, components like mixing systems benefit from Inconel’s resistance to harsh chemicals and elevated temperatures, ensuring the durability and safety of processing equipment.

Summary

The widespread adoption of Inconel alloy components across these industries demonstrates the versatility and robustness of this material in applications where high performance is essential. From ensuring the reliability of jet engine parts in aviation to providing the corrosion resistance needed for oil and gas equipment, Inconel’s strength, heat resistance, and corrosion resistance make it a valuable material for advanced manufacturing. Minimizing defects and maintaining stringent quality control standards is critical to using Inconel in these challenging applications, ensuring both safety and long-term operational efficiency.

FAQs

What makes Inconel alloys particularly challenging to handle during core removal?

How does chemical leaching compare to thermal methods for removing cores from Inconel components?

Why is non-destructive testing crucial for ensuring the quality of Inconel castings?

What industries benefit most from the high-temperature resistance of Inconel alloys?

How does effective core removal enhance the reliability of aerospace-grade Inconel components?