Automated Shell Building with Dewaxing Kettle: Efficient Wax Removal for Superalloy Casting

The investment casting process has gained significant importance in manufacturing superalloy components, particularly in aerospace, power generation, oil and gas, and defense. These industries demand parts capable of withstanding extreme conditions, from high temperatures to corrosive environments, with precision that guarantees optimal performance.

One of the critical steps in the investment casting process is shell building, where a ceramic mold is formed around a wax pattern, followed by the dewaxing step, which involves removing the wax to leave a hollow ceramic mold. Automation in shell building and using a dewaxing kettle for wax removal transform these processes, making them more efficient, consistent, and reliable.

This blog explores how automated shell building and dewaxing kettles enhance the investment casting process, their benefits, typical superalloys involved, post-processing techniques, and industry applications.

Manufacturing Process: Automated Shell Building and Dewaxing

Shell building is a fundamental part of the investment casting process. In this step, a ceramic shell is built around a wax pattern, a replica of the final part. The wax pattern is repeatedly dipped in a ceramic slurry, sprinkled with refractory material, and left to dry. This process is repeated until the desired shell thickness is achieved. The result is a hard ceramic mold that can withstand the high temperatures of molten superalloys. The accuracy and consistency of this shell are critical, as it directly impacts the quality of the final cast part. Innovations in automated shell building and advanced ceramic molding techniques are essential for maintaining quality standards.

Using automation in shell building is a significant advancement for the investment casting industry. Automated shell building uses robotics and advanced equipment to control the dipping, sprinkling, and drying processes precisely. Automating these tasks ensures that each ceramic layer is applied with consistent thickness and density, reducing the variability that can occur with manual methods. Automated shell building also accelerates the production process, allowing manufacturers to meet growing industry demands without compromising quality. Manufacturers can improve precision and efficiency by leveraging automatic shell line systems and robotic automation technologies.

After the shell is built, the next critical step is dewaxing. The dewaxing kettle removes the wax from the ceramic shell, leaving a hollow cavity that can be filled with molten metal. The dewaxing kettle uses steam and controlled heat to melt and remove the wax pattern from the ceramic shell. This process must be done carefully to avoid damaging the ceramic shell, as even minor cracks or damage can lead to defects in the final casting. Processes such as controlled dewaxing and efficient wax removal techniques ensure the mold remains intact.

The combination of automated shell building and the dewaxing kettle creates a seamless and efficient process that enhances the overall quality of the casting. By using automated shell building, manufacturers can create consistent and defect-free ceramic molds, which, when paired with efficient wax removal through a dewaxing kettle, ensure that the final mold is ready to cast high-quality superalloy components. This integration between automation and dewaxing leads to reduced scrap rates, fewer defects, and improved performance of the final parts. Enhanced systems like high-precision dewaxing kettles and automation-driven efficiency further solidify the reliability and productivity of this process.

Benefits of Automated Shell Building in Superalloy Casting

One of the primary benefits of automated shell building in superalloy casting is the precision and consistency it brings to the production process. Consistent shell thickness is essential for creating high-quality molds, especially when dealing with complex geometries or thin-walled sections. Automated shell building ensures that each ceramic layer is applied uniformly, reducing the risk of defects arising from uneven thickness or inconsistent ceramic properties. This precision is essential for components such as turbine blades, which must maintain structural integrity under high thermal and mechanical loads. Innovations in automated shell line technology and dimensional control in shell production are crucial to achieving such accuracy.

Automation also significantly reduces human error in the shell-building process. Manual handling of the wax patterns and ceramic shells can result in variations that affect the final casting quality. These variations can include inconsistent dipping times, uneven drying, or accidental damage to the shell during handling. By automating these steps, manufacturers can minimize the risk of such issues, leading to more reliable and higher-quality molds. Robotic automation systems and consistent layer application techniques further enhance reliability.

Enhanced production speed is another significant benefit of automation in shell building. The automated equipment can apply ceramic layers more quickly and consistently than manual methods, reducing the production time for each shell and allowing for greater throughput. This increased production speed helps manufacturers meet tight deadlines and growing demands for superalloy components in aerospace and power generation industries. Manufacturers can achieve speed and quality by combining high-throughput automated processes with optimized shell-building techniques.

Integrating automated shell building with efficient dewaxing also leads to optimal results in the final casting. Automated shell building creates a mold with consistent and precise layers, making dewaxing more effective. When the shell is consistent, the wax is removed evenly, reducing the likelihood of wax residues compromising the casting's integrity. The result is a cleaner shell that produces higher-quality superalloy parts with fewer inclusions or other defects that can affect performance. Processes like controlled dewaxing and residue-free wax removal techniques complement automated shell building to deliver superior results.

Typical Superalloys Used in Automated Shell Building and Dewaxing

Automated shell building and dewaxing are particularly advantageous in casting superalloys, which are used in demanding applications due to their excellent mechanical properties at elevated temperatures and resistance to corrosion and wear.

Nickel-Based Superalloys

Nickel-based superalloys, such as Inconel 718 and Inconel 625, are among the most commonly used materials in the investment casting process. These alloys are known for their high strength, corrosion resistance, and ability to maintain their mechanical properties at high temperatures. Automated shell building ensures that molds for these components are defect-free, leading to castings suitable for critical applications like turbine blades, exhaust systems, and combustion chambers.

Cobalt-Based Superalloys

Cobalt-based superalloys like the Stellite series are also frequently used in investment casting. These alloys are known for their wear resistance, making them ideal for components that experience friction and wear, such as valve seats and mechanical seals. The precision of automated shell building ensures that these molds are free from defects, resulting in high-quality castings that can withstand harsh conditions.

Titanium-Based Alloys

Titanium-based alloys, such as Ti-6Al-4V, are widely used in aerospace and medical applications due to their high strength-to-weight ratio and biocompatibility. Casting titanium alloys requires precise control over the mold quality, as any defect can compromise the strength and performance of the final part. Automated shell building and efficient dewaxing help ensure that the ceramic mold used for casting titanium components is of the highest quality, leading to reliable and high-performance parts.

Single Crystal Superalloys

Single crystal superalloys, such as the CMSX series, are used in applications that require exceptional resistance to creep and fatigue, such as high-performance turbine blades. These alloys are cast in complex geometries with intricate cooling channels, and any defect in the mold can lead to decreased performance or failure. The use of automated shell building allows for the precise creation of molds that can support these complex geometries, while the dewaxing kettle ensures that the wax is completely and evenly removed, maintaining the integrity of the shell.

Post-Processes After Shell Building and Dewaxing

After the shell building and dewaxing processes are completed, the ceramic mold is ready for casting. However, casting often requires additional post-processing steps to ensure the final superalloy component meets the desired mechanical and performance specifications.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a post-process used to eliminate internal voids and improve the mechanical properties of the cast superalloy. HIP involves placing the casting in a high-pressure, high-temperature environment, which densifies the material and eliminates any remaining porosity. A high-quality shell built using automation and an efficient dewaxing process contributes to the effectiveness of HIP by minimizing the number of initial defects that need to be addressed. The role of HIP in enhancing mechanical properties is crucial for components that must endure extreme conditions and high stresses.

Heat Treatment

Heat treatment is another essential post-process used to modify the microstructure of the superalloy. Through controlled heating and cooling cycles, the properties of the alloy can be enhanced, such as its strength, hardness, and resistance to fatigue. The consistency and quality of the shell created through automation are essential for ensuring that the heat treatment process yields predictable and reliable results, as variations in the mold can lead to inconsistencies in the alloy's response to heat treatment. Refining microstructures through heat treatment maximizes the durability and efficiency of superalloy components.

Surface Treatments and CNC Machining

Surface treatments and CNC machining are used to achieve the final surface finish and dimensional accuracy required for superalloy components. The automated shell-building process creates a mold with minimal defects, which results in castings that require less machining and surface finishing. This reduces the time and cost of post-processing and helps preserve the superalloy's material properties. Achieving tight tolerances through precision machining is essential for parts used in critical applications like aerospace and energy systems.

Thermal Barrier Coatings (TBC)

Another common post-process is the application of Thermal Barrier Coatings (TBC). These coatings are used to protect superalloy components from high temperatures, particularly in applications like gas turbines. The effectiveness of TBCs is highly dependent on the surface quality of the part, which is directly influenced by the quality of the shell. Automated shell building and efficient dewaxing help ensure a smooth and clean surface, providing an ideal base for applying TBCs and improving adhesion and longer-lasting coatings. Proper TBC application is vital for extending the lifespan of superalloy components in extreme operational environments.

Industry Applications and Benefits of Automated Shell Building with Dewaxing

The combination of automated shell building and dewaxing is particularly beneficial in industries where superalloy components' quality, reliability, and performance are critical. Automated shell building improves consistency and efficiency in creating molds, while dewaxing ensures these molds are free from defects, enabling the production of high-quality investment-cast components. These processes are crucial across various sectors, including aerospace, power generation, automotive, defense, oil and gas, and medical industries, all requiring precision and reliability in their components.

Aerospace and Aviation

In the aerospace and aviation industries, the precision and consistency of automated shell building are essential for producing components such as turbine blades, nozzle guides, and engine casings. These parts must operate under high temperatures and pressures, and any defect can lead to reduced efficiency or catastrophic failure. The combination of automated shell building and dewaxing ensures that these components are produced to the highest quality standards, resulting in reliable, high-performance parts that contribute to the efficiency and safety of aircraft engines. For example, superalloy jet engine components rely heavily on the flawless molds produced through these technologies to maintain their structural integrity during extreme flight conditions.

Power Generation

The power generation industry also benefits significantly from automated shell building and dewaxing. Components such as gas turbine blades, heat exchangers, and combustion parts must withstand high thermal and mechanical loads while maintaining their performance over extended periods. Automation in shell building ensures that these components are produced with minimal defects, improving their thermal performance and operational reliability. Parts like superalloy heat exchanger parts must be manufactured with precision and high-quality molds to ensure optimal thermal efficiency and minimize downtime in power generation plants.

Automotive and Defense

In the automotive and defense and military sectors, the demand for lightweight and high-strength components is met through the use of superalloys produced by investment casting. Components such as turbocharger housings, engine parts, and structural elements are cast precisely to ensure optimal performance. Automated shell building and dewaxing reduce the likelihood of defects, ensuring these parts meet stringent quality standards. This is particularly important for military applications where reliability is crucial for mission success. Components like superalloy missile segments are produced consistently to ensure durability under extreme operational conditions.

Oil and Gas

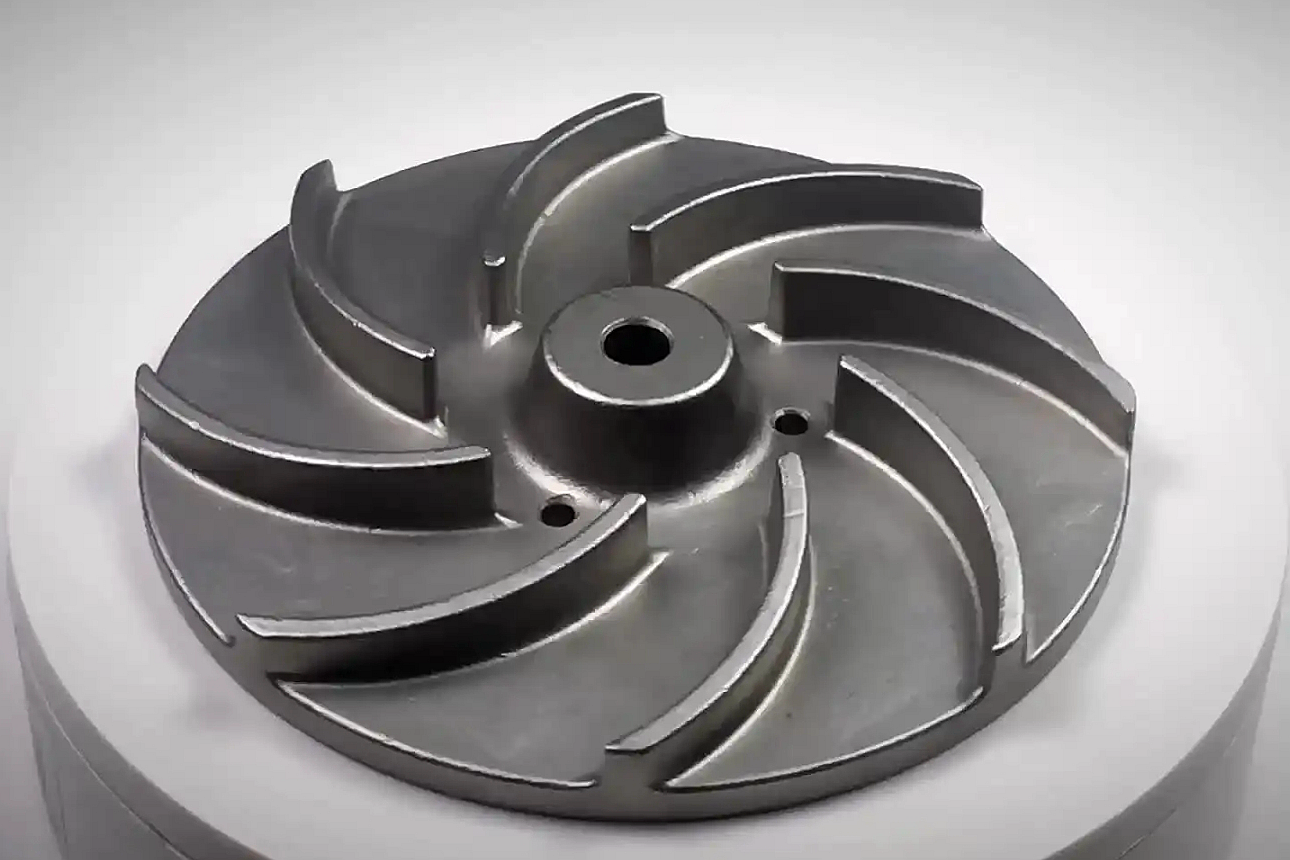

The oil and gas industry requires components that withstand high pressures, corrosive environments, and significant mechanical stress. Valves, pump bodies, and downhole tools are often made from superalloys, and the quality of the mold used to cast these components directly affects their performance. Automated shell building ensures that the molds for these components are of the highest quality, leading to castings capable of withstanding harsh environments, resulting in longer service life and reduced maintenance needs. For instance, superalloy pump system assemblies benefit from the precision casting provided by automated shell and dewaxing processes, ensuring operational reliability in challenging drilling conditions.

Medical and Marine

The medical and marine industries also leverage the benefits of investment casting for components such as surgical implants and marine engine parts. In medical applications, precision is crucial, as any casting defect could compromise the safety and effectiveness of an implant. Automated shell building and dewaxing help ensure that the molds used for these components are of the highest quality, resulting in reliable and biocompatible implants essential for patient safety. In marine applications, superalloys provide excellent corrosion resistance, which is critical for components operating in saltwater environments. The casting quality produced through automated shell building ensures that marine parts, such as superalloy naval ship modules, can withstand harsh marine conditions, ensuring durability and reliability.