How Argon Atmosphere Prevents Contamination During Superalloy Powder Production

The production of superalloy powders for high-performance components, such as turbine discs, demands an extremely high standard of purity. Contamination at any stage of the manufacturing process can compromise the properties of the final product, leading to failure in demanding applications like aerospace, energy, and defense. One critical factor in ensuring the purity of the powder is using an Argon atmosphere during the atomization process. Argon, an inert gas, plays a key role in preventing oxidation and other forms of contamination, thus ensuring the final superalloy powder is of the highest quality.

This blog explores the role of Argon in preventing contamination during superalloy powder production, the manufacturing process involved, typical superalloys used, post-processes that follow powder production, testing methods for powder quality, and the industries where these high-quality powders are applied.

Manufacturing Process: Argon Atmosphere in Powder Production

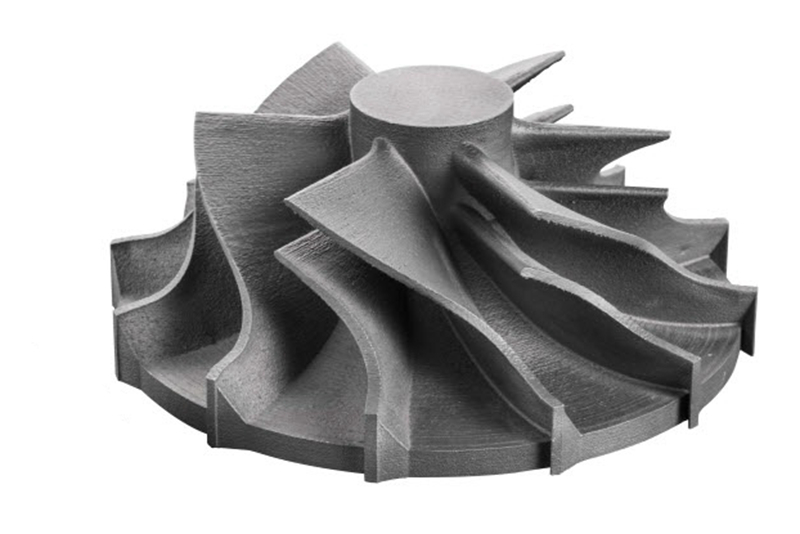

Powder metallurgy (PM) is a vital manufacturing technique for creating complex components that can withstand extreme conditions. The powder production process involves melting the metal and breaking it into fine particles used in various applications, from turbine blades to gas turbine discs. One of the most effective ways to produce these high-quality powders is through atomization, where molten metal is broken up into small droplets, which then solidify into powder.

In an Argon atomization furnace, molten metal is injected into a chamber where high-pressure Argon gas is directed. The high velocity of the Argon stream causes the molten metal to break into fine droplets, which cool rapidly and form solid powder particles. This process is critical for creating superalloy powders, especially in industries requiring high-performance alloys. Argon's control over the atomization environment is key in ensuring the powders meet the stringent quality standards demanded by applications like aerospace turbine disc manufacturing.

Argon, an inert gas, is used in the atomization chamber to prevent oxidation or contamination of the molten metal. This is especially important because many metals in superalloys, such as nickel and cobalt, are highly reactive with oxygen. The metal droplets could react with oxygen without an inert atmosphere, forming oxides that compromise the powder’s purity and quality. Ensuring high-purity powders is crucial for achieving the mechanical properties required in turbine components.

This process is often compared with other atomization techniques, such as water or gas. For example, water jets are used to break up molten metal in water atomization. While this can create fine powders, the interaction with water can lead to impurities and oxidation, especially with high-temperature alloys. Similarly, gas atomization often uses gases like nitrogen or oxygen, which can be reactive with certain alloys, resulting in unwanted contamination. In contrast, Argon’s inert nature ensures that no chemical reactions occur, maintaining the purity of the metal and ensuring that the powder produced is free of contaminants, thus making it the preferred choice for manufacturing superalloy powders used in critical turbine disc applications.

Typical Superalloys Used in Turbine Disc and Aerospace Applications

Superalloys are crucial for high-performance components operating under extreme conditions, such as jet engines and gas turbine discs. These alloys are designed to maintain high strength, resistance to oxidation, and stability at elevated temperatures. The selection of superalloy is vital because these materials must perform in environments where temperatures can exceed 1,000°C (1,832°F), and they must withstand thermal cycling, mechanical stresses, and corrosion.

The most commonly used superalloys in turbine disc manufacturing include:

Inconel Alloys

Inconel alloys are a series of nickel-chromium alloys, such as Inconel 718 and Inconel 625, known for their excellent resistance to oxidation, high-temperature strength, and fatigue resistance. These alloys are widely used in aerospace and energy applications due to their ability to withstand extreme temperatures and mechanical stresses in turbine discs. Inconel 718, for example, is ideal for the middle-temperature sections of turbines due to its ability to perform at temperatures up to 1300°F (704°C).

CMSX Series

The CMSX series includes single-crystal nickel-based superalloys like CMSX-2 and CMSX-486, designed for high-performance turbine blades and discs. The single-crystal structure of these alloys improves their resistance to creep and fatigue by eliminating grain boundaries, making them ideal for use in demanding aerospace and turbine applications where extreme stresses and high temperatures are encountered.

Rene Alloys

Rene alloys, such as Rene 104 and Rene 80, are nickel-based superalloys optimized for high-temperature strength and oxidation resistance. These alloys are widely used in aerospace and power generation systems due to their excellent thermal stability and ability to withstand extreme operating conditions in gas turbines. Rene 104 is often selected for turbine components that must perform in environments with high thermal stresses and aggressive gas flows.

The Role of Argon in Preventing Contamination During Atomization

Argon is critical in ensuring that the powder produced during atomization remains contaminant-free, primarily by preventing oxidation. During the atomization process, the molten metal is exposed to a high-pressure stream of Argon gas. This gas creates a protective atmosphere around the molten metal, shielding it from exposure to reactive gases like oxygen and nitrogen in the air. The importance of ensuring high purity material in superalloy parts production is a direct consequence of this protective role, particularly in processes like powder metallurgy turbine discs.

In the absence of an inert atmosphere, molten superalloy would readily react with oxygen, forming oxide layers on the surface of the powder particles. These oxides are undesirable because they can affect the mechanical properties of the final part. Oxidized powders typically exhibit poor sintering characteristics, lower tensile strength, and diminished fatigue resistance. Additionally, the oxide inclusions in the final part can lead to failure during high-stress applications, such as those encountered in the aerospace and energy sectors. This highlights the critical role of vacuum induction melting, where a controlled environment helps to prevent contamination during superalloy casting.

By using Argon, manufacturers can prevent oxidation, maintain the purity of the powder, and ensure that the particles retain the necessary characteristics for successful powder metallurgy processing. This is particularly crucial when working with high-performance alloys, which require high purity to maintain their mechanical and thermal properties. Argon’s ability to protect the molten metal from contamination ensures that the resulting powder is free from impurities that could degrade its quality. Processes such as vacuum induction pouring are essential to maintain the integrity of the superalloy components and enhance the final product's performance in aerospace and high-temperature applications.

Post-Processes and the Impact of Contamination

Once the superalloy powder has been produced using Argon atomization, several post-processing steps are required to convert the powder into a finished turbine disc or other high-performance component. These steps often include Hot Isostatic Pressing (HIP), sintering, and forging, which consolidate the powder particles into a solid form.

Hot Isostatic Pressing (HIP) is one of the most essential post-processing techniques for producing turbine discs. In HIP, the powder is subjected to high pressure and temperature, causing the particles to bond together and form a solid material. If the powder contains contaminants such as oxides, the resulting part will have poor bonding and a reduced density, leading to defects like porosity. This can severely affect the mechanical properties of the final part, compromising its ability to withstand high temperatures and mechanical stresses.

Similarly, in sintering and forging, any contamination in the powder can lead to defects in the material’s microstructure, resulting in lower strength, fatigue resistance, and creep resistance. These defects can cause premature failure in high-stress applications, which is especially dangerous in critical components like turbine discs. Contamination-free processing and precise handling during the post-processing stages are essential to ensure high-quality results and superior performance in demanding environments.

Powder Testing and Quality Control in Superalloy Powder Production

They undergo rigorous testing and quality control procedures to ensure that the powders produced during Argon atomization meet the required standards. These tests assess various properties of the powder, such as particle size distribution, flowability, purity, and morphology. X-ray inspection and metallographic microscopy are essential for detecting internal defects in the powder and assessing the quality of the sintered part.

Particle Size Distribution

Ensuring the powder has a uniform particle size is essential for achieving good packing density and flowability during the powder metallurgy processes. Powders with a narrow size distribution tend to sinter more uniformly, resulting in better mechanical properties in the final part. 3D scanning is often used to assess the geometric uniformity of powder particles and the overall distribution before processing.

Purity Tests

Purity is one of the most critical factors in superalloy powder production. Contaminants such as oxygen, nitrogen, and sulfur can significantly impact the performance of the final part. Glow Discharge Mass Spectrometry (GDMS) is commonly used to analyze the chemical composition of the powder and detect any impurities. GDMS provides accurate depth profiling, enabling manufacturers to identify any trace contaminants that could compromise the material's properties.

SEM Imaging

Scanning Electron Microscopy (SEM) is used to examine the morphology of the powder particles. It provides detailed images that help manufacturers assess whether the particles are spherical and uniform in size, which is essential for achieving the desired properties in the final component. SEM, combined with Energy Dispersive X-ray Spectroscopy (EDS), helps to evaluate the powder's particle shape and elemental composition.

X-Ray Inspection

This method detects any internal defects, such as porosity, that may be present in the powder or the sintered part. Porosity can weaken the material and affect its performance, especially in high-stress applications. X-ray inspection is also crucial for assessing the internal integrity of the powder before and after sintering.

Tensile and Fatigue Testing

These tests are used to measure the mechanical properties of the final turbine disc or component. The part's strength, fatigue, and creep resistance are crucial for ensuring that it can withstand the extreme operating conditions it will be subjected to. Tensile testing and fatigue testing are key tests for verifying the material's ability to endure high-stress environments, ensuring the longevity and reliability of superalloy components in demanding applications such as aerospace and power plants.

Industry Applications: Why Contamination Control Matters in Aerospace and Energy

Argon atomization and preventing contamination are particularly important in aerospace and aviation, energy, and defense industries, where turbine discs and other high-performance components are critical to system reliability and safety. In the aerospace sector, turbine discs in jet engines are subjected to extreme temperatures, centrifugal forces, and thermal cycling. Contamination in the powder used to create these discs can result in poor material performance, leading to premature failure of the engine and posing significant safety risks.

In the energy sector, turbine discs in gas turbines for power generation also operate in extreme conditions. These turbines must maintain their strength and resistance to thermal degradation over long periods. The contamination-free powder is essential to ensuring that these components can withstand the stresses and temperatures encountered in power plants.

Other industries, such as defense, require turbine discs and other critical components from high-performance superalloys to operate under harsh conditions. Whether for naval propulsion systems, missile systems, or high-performance machinery, the purity of the superalloy powder used in these components is vital to their success and safety.

FAQs

What is the role of Argon in preventing contamination during superalloy powder production?

How does contamination affect the mechanical properties of turbine discs made from superalloy powders?

What are the benefits of using Argon over other atomizing gases in powder metallurgy?

What post-processes follow superalloy powder production, and how does contamination impact these processes?

What are the most common testing methods used to ensure the purity of superalloy powders?