Optimized Tool Access: Overcoming Challenges in Machining Superalloy Castings with 5-Axis CNC

What is 5-Axis CNC Machining for Superalloy Castings?

5-axis CNC machining is an advanced manufacturing process that allows for the movement of tools along five different axes simultaneously. Unlike traditional 3-axis CNC machines, which only operate along the X, Y, and Z axes, 5-axis machines can tilt, rotate, and move the tool along multiple planes, allowing for the precise machining of complex and intricate geometries.

This capability is critical in machining superalloy castings, which often have highly detailed and hard-to-reach features. In aerospace and aviation, power generation, and automotive industries, superalloy components need to be manufactured with tight tolerances, high accuracy, and minimal defects. 5-axis CNC machining offers a solution by providing greater flexibility in tool access, allowing for precise, high-quality machining of parts that would be difficult or impossible to achieve with traditional 3-axis CNC or manual machining methods.

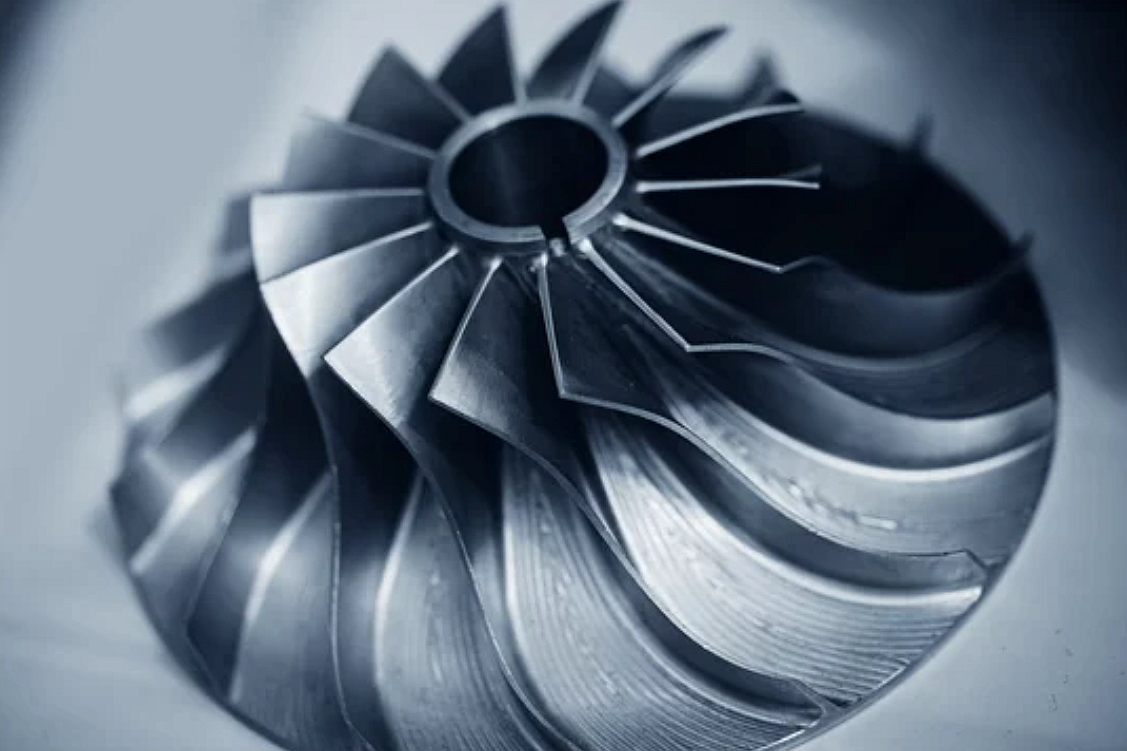

The 5-axis movement allows the tool to approach the part from virtually any direction, ensuring the best possible access to the workpiece. This capability is vital when machining parts with internal cooling channels, complex contours, or challenging angles—characteristics often found in superalloy turbine blades or superalloy turbine discs. The precision required for these components is critical for high-performance applications in industries such as oil and gas and defense, where durability, efficiency, and reliability are paramount.

By utilizing 5-axis CNC machining, manufacturers can achieve the complex geometries necessary for these advanced superalloy components, ensuring that each part meets the exacting standards required for demanding industries. Whether machining parts like superalloy heat exchanger components or aerospace-grade metal fuel system modules, 5-axis CNC machining is essential for producing high-quality, high-performance superalloy parts.

The Function of 5-Axis CNC in Superalloy Machining

One of the main functions of 5-axis CNC machining is optimizing tool access to areas of superalloy castings that would be difficult to reach with traditional machining methods. Superalloy castings, often used in high-temperature, high-stress environments such as jet engines and gas turbines, can have intricate features such as internal cooling channels, fine edges, and complex geometric shapes. Machining these features requires precision and the ability to position the cutting tool at various angles, which 5-axis CNC technology facilitates.

5-axis CNC machining works by simultaneously moving the cutting tool along the X, Y, Z axes while also rotating around two additional axes—typically referred to as the A and B axes. This allows the tool to reach almost any angle on the workpiece, ensuring that all surfaces can be machined with minimal tool changes and fewer setups. The precision and flexibility offered by 5-axis CNC machining are particularly beneficial when working with superalloys, known for their high strength and resistance to heat and corrosion, making them difficult to machine using conventional methods.

The process also improves efficiency by reducing the number of machine setups required to achieve the desired part geometry. In traditional machining, multiple setups are often necessary to machine different faces or features of a part. With 5-axis machining, however, the workpiece can be loaded once, and the tool can be manipulated to reach all necessary areas. This saves time and reduces the risk of part misalignment, which can affect part quality and increase the need for rework.

By utilizing 5-axis CNC for superalloy machining, manufacturers can achieve superior dimensional accuracy and reduce operational inefficiencies. This makes it an indispensable tool for industries requiring high-performance components such as aerospace and power generation.

Which Superalloy Parts Benefit from 5-Axis CNC Technology?

5-axis CNC machining is particularly advantageous for superalloy parts that require high precision, intricate geometries, and complex features. Superalloys, such as those made from Inconel, CMSX, Hastelloy, and Rene alloys, are widely used in high-performance industries like aerospace, power generation, and automotive due to their exceptional ability to withstand extreme temperatures and mechanical stress. The following superalloy parts benefit from the enhanced capabilities of 5-axis CNC machining:

Superalloy Castings

Superalloy castings, such as turbine blades, turbine discs, and gas turbine components, are critical for high-temperature applications in industries like aerospace and energy. These parts often feature complex geometries, such as internal cooling channels, which are challenging to machine with traditional methods. 5-axis CNC machining enables manufacturers to efficiently machine these intricate features, ensuring that the parts meet the tight tolerances required for high-performance and safety-critical applications. The ability to process all angles of a part in a single setup significantly reduces production time and enhances precision.

Forged Superalloy Parts

Superalloy forgings, including impellers, compressor blades, and shafts, are often subjected to post-forging machining to achieve the specifications required for critical applications. 5-axis CNC machining is ideal for refining these forged parts by providing precise dimensional accuracy and surface finish. This process minimizes the need for additional rework or tool changes, making it an efficient solution for high-end superalloy components used in demanding environments like gas turbines and jet engines.

CNC Machined Superalloy Parts

CNC machined superalloy parts are essential in applications where high dimensional accuracy and surface finish are critical. Components like engine parts, aerospace assemblies, and industrial machinery rely on the precision of CNC machining. 5-axis CNC technology allows these parts to be machined from multiple angles in a single setup, ensuring minimal distortion and tight tolerances. This capability is especially valuable for parts with complex geometries or detailed features, such as those found in advanced aerospace and power generation systems.

3D Printed Superalloy Parts

While 3D printed superalloy parts are increasingly popular in industries like aerospace and automotive, they often require additional machining to meet stringent tolerances and surface finishes. 5-axis CNC machining is the perfect solution for refining these 3D-printed components, particularly those with complex geometries, such as lattice structures or intricate internal channels. By machining these parts post-printing, manufacturers can ensure they meet the precise specifications needed for high-performance applications, optimizing the mechanical properties and ensuring reliability in critical systems like aircraft engines and gas turbines.

Compared with Other Machining Processes

Compared to other machining processes, 5-axis CNC machining stands out due to its ability to achieve high precision, reduce setup time, and allow for the machining of complex parts that are difficult to handle with traditional methods.

Compared to Traditional 3-Axis CNC Machining:

Traditional 3-axis CNC machines are limited in their ability to access certain workpiece areas. The tool can only move along the X, Y, and Z axes, which can make it difficult to machine parts with complex features or internal channels. 5-axis CNC machining overcomes these limitations by allowing the tool to approach the workpiece from multiple angles, enabling the machining of features that would be challenging or impossible with 3-axis systems. The added flexibility also reduces the need for multiple setups, improving efficiency and accuracy. This makes superalloy castings far more manageable, ensuring precise cuts even in intricate components used in aerospace and gas turbines.

Compared to Manual Machining:

Manual machining is typically slower and less precise than CNC, especially when dealing with superalloy materials. Human error can lead to inconsistencies in part dimensions and surface finishes. 5-axis CNC machining, on the other hand, is fully automated, ensuring high levels of precision and repeatability. Automation also eliminates the need for skilled manual labor, reducing labor costs and increasing production speed. Furthermore, the ability to machine complex geometries with minimal setup time further enhances the efficiency of the process. By improving both dimensional control and part finish, this process complements casting and forging processes in industries like power generation.

Compared to Casting or Forging:

Casting and forging are both essential processes for producing superalloy parts. However, they typically result in parts that need further refinement to meet tight dimensional tolerances and surface finish requirements. 5-axis CNC machining plays a critical role in post-processing cast or forged parts, ensuring that they meet exacting specifications. By machining cast or forged parts to precise dimensions and finishes, 5-axis CNC machining minimizes the need for rework or corrections, improving the overall efficiency of the manufacturing process. This is especially beneficial for superalloy turbine discs or other critical components in aerospace and marine applications where every millimeter matters.

Industry and Application

The ability to achieve complex geometries and tight tolerances with 5-axis CNC machining has made it an indispensable tool across various high-performance industries. Below are some of the critical sectors where this technology is widely applied:

Aerospace and Aviation

In aerospace and aviation, precision and reliability are paramount. Superalloy parts like turbine blades, turbine discs, and combustion chambers are critical to the performance of jet engines and gas turbines. These parts often have intricate internal cooling channels and delicate features that require 5-axis CNC machining for precise manufacturing. The ability to machine parts from multiple angles in a single setup ensures that these critical components are made to the highest standards of accuracy, which is crucial for aerospace-grade fuel systems.

Power Generation

Superalloy components used in power generation, such as gas turbines, heat exchangers, and other power generation equipment, must withstand extreme temperatures and mechanical stresses. 5-axis CNC machining allows for producing complex parts with superior surface finishes and tight tolerances, ensuring that they perform efficiently and reliably in high-stress environments.

Oil and Gas

In the oil and gas industry, components like valves, pumps, and connectors must endure harsh conditions such as high pressure and temperature. Superalloy parts in these applications require precise machining to ensure longevity and reliability. 5-axis CNC machining is essential for producing these critical components with the necessary dimensional accuracy and surface finish, preventing costly downtime and ensuring the performance of critical oil and gas pump components.

Automotive and Defense

The automotive and military and defense industries also rely on superalloy components for high-strength, high-performance applications. Engine parts, transmission components, and missile guidance systems all require precision machining, and 5-axis CNC technology provides the capability to meet these needs efficiently. For example, high-performance missile segment components are machined with tight tolerances to ensure mission reliability.

Marine

Marine turbines, heat exchangers, and other critical components made from superalloys must resist corrosion and perform under extreme environmental conditions. The versatility of 5-axis CNC machining ensures that these components are manufactured to meet the demanding requirements of the marine industry, ensuring their reliability and performance in harsh environments like those found in naval ship modules.

By integrating advanced technologies like 5-axis CNC machining into the production of superalloy components, industries across these sectors can achieve superior precision, faster production times, and the reliability required for high-performance applications.

FAQs

What are the advantages of 5-axis CNC machining over 3-axis CNC machining for superalloy castings?

How does 5-axis CNC machining improve the efficiency of manufacturing superalloy components?

What types of superalloy parts are best suited for 5-axis CNC machining?

How does 5-axis CNC machining compare to traditional manual machining for superalloy components?

What industries benefit the most from using 5-axis CNC machining for superalloy parts?