Microstructure Refinement Through Vacuum Heat Treatment: Boosting Creep Resistance

Superalloys are essential for components that need to operate in extreme environments, such as those found in aerospace and aviation, power generation, and oil and gas industries. These alloys are engineered to perform under high stress and temperature, where traditional materials fail. One of the most critical properties of these alloys is creep resistance—the ability to resist deformation when exposed to constant stress at high temperatures over extended periods. Refining the microstructure of superalloys is a proven method to enhance this property. One of the most effective techniques for achieving this refinement is vacuum heat treatment.

In this blog, we will explore how vacuum heat treatment plays a pivotal role in enhancing creep resistance by refining the microstructure of superalloys. We will look at the process of vacuum heat treatment, the types of superalloys that benefit from this treatment, the post-processing techniques that follow, such as Hot Isostatic Pressing (HIP), testing methods like X-ray checking, and the industries where creep resistance is critical.

Process Explanation

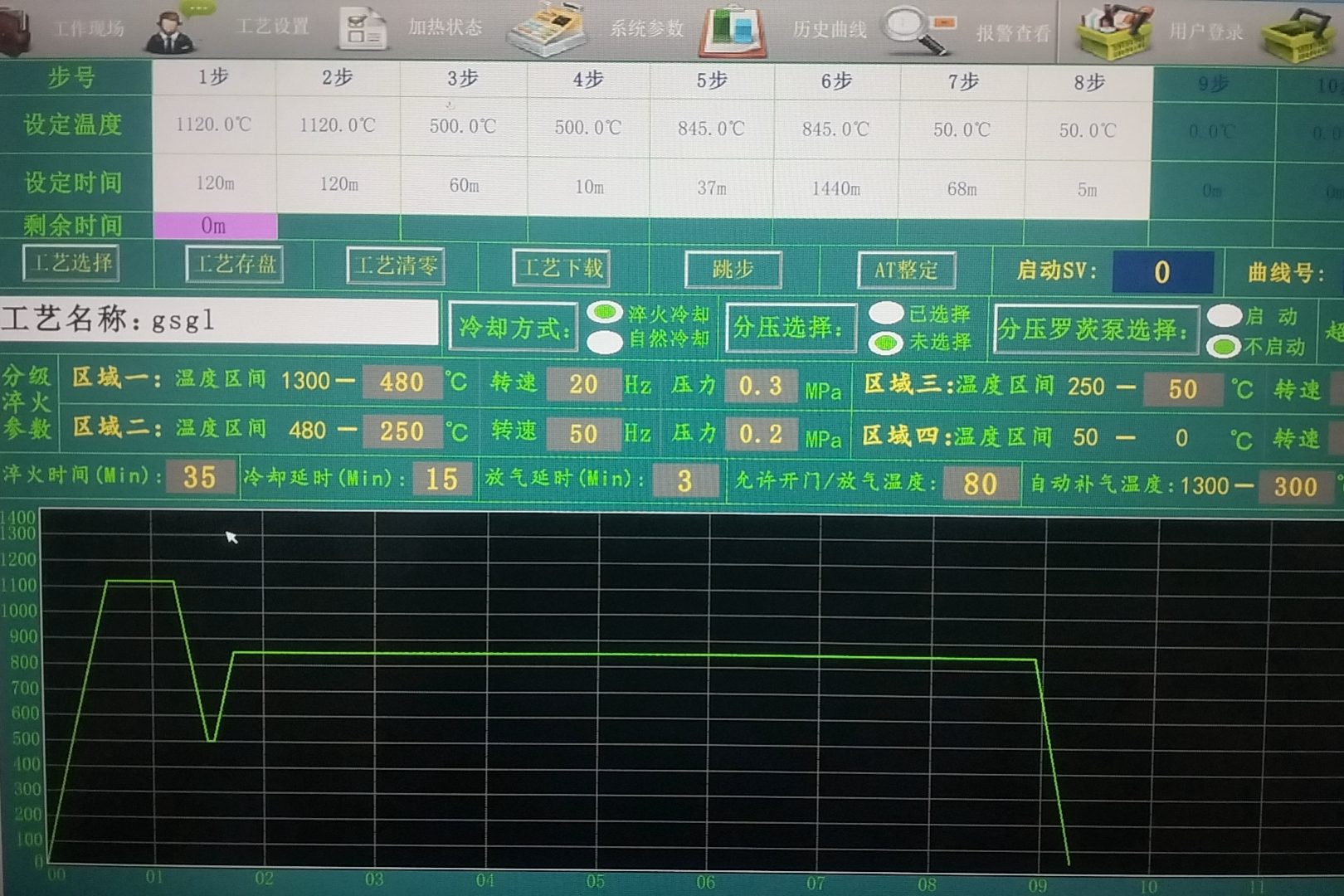

Vacuum heat treatment is a thermal processing technique for heating superalloy components in a vacuum chamber. This controlled environment ensures that the material does not undergo oxidation or contamination, both of which can compromise the material’s mechanical properties. During vacuum heat treatment, the superalloy is heated to specific temperatures, typically between 650°C and 1150°C, depending on the type of alloy and the desired results.

The process begins with the superalloy part being placed inside a vacuum chamber, which is then evacuated to create a near-perfect vacuum. This vacuum environment prevents any atmospheric gases, such as oxygen, from reacting with the material, thus preventing oxidation, decarburization, or the formation of unwanted phases at the surface. Doing so preserves the integrity of the material’s surface and ensures that any subsequent microstructural changes are uniform throughout the part. This is critical in applications such as turbine blades, where surface integrity is paramount to performance in extreme environments.

During vacuum heat treatment, the heating cycle aims to promote grain growth and phase transformations that enhance the material’s properties. For creep resistance, the key focus is on grain boundary strengthening and the formation of stable phases that resist high-temperature deformation. During the heating process, the alloy’s microstructure undergoes transformations that lead to the alignment of grains in a way that minimizes dislocations and slip systems, thereby improving the alloy’s resistance to creep. This is particularly important for alloys used in aerospace, where components are exposed to high stress and temperature.

The temperature and time parameters of vacuum heat treatment are carefully controlled based on the specific material properties of the superalloy. For example, alloys with high nickel content, such as Inconel, require different thermal treatment parameters than cobalt-based or titanium alloys. Once the superalloy reaches the desired temperature, it is held for a period to allow sufficient diffusion and phase formation, after which the part is slowly cooled to avoid thermal shock and distortion. This controlled cooling process ensures that the final part maintains dimensional accuracy and mechanical performance, especially for complex geometries in high-performance industries.

Typical Superalloys Used for Creep Resistance

Superalloys used for creep-resistant applications must be able to withstand high temperatures without undergoing significant deformation. The following types of superalloys are commonly used in high-temperature environments and benefit from vacuum heat treatment:

Nickel-Based Superalloys

Nickel-based alloys like Inconel 718, Inconel 625, and CMSX-10 are widely used in aerospace and power generation applications. These alloys are known for their excellent high-temperature strength, oxidation resistance, and stability under thermal cycling. When exposed to high temperatures, nickel-based superalloys undergo phase transformations that enhance their creep resistance. Vacuum heat treatment helps to control the formation of these phases, ensuring that the material maintains its dimensional stability during prolonged exposure to high stresses.

Cobalt-Based Superalloys

Cobalt alloys, such as Stellite 6 and Stellite 21, are often used in applications that require exceptional wear resistance, such as turbine engines and valve components. These alloys exhibit strong creep resistance at high temperatures, making them suitable for demanding conditions. Vacuum heat treatment refines their microstructure by controlling grain boundaries and ensuring uniform phase distribution, boosting their performance in high-temperature applications.

Titanium Alloys

Titanium alloys, such as Ti-6Al-4V and Ti-5553, are widely used in the aerospace and automotive industries for their high strength-to-weight ratio and excellent resistance to creep and fatigue. These alloys are highly sensitive to temperature and environmental factors, so vacuum heat treatment is essential to enhance their microstructure and improve their creep resistance. The process helps prevent the formation of unwanted phases that could degrade their mechanical properties under thermal stress.

Nimonic and Rene Alloys

Alloys like Nimonic 263 and Rene 104 are designed for high-temperature applications where creep resistance is paramount. These alloys are often used in gas turbine engines and other aerospace and power generation components. Vacuum heat treatment is crucial in optimizing these alloys' grain structure and phase composition, helping them perform reliably under extreme conditions.

Post-Processing Steps Following Vacuum Heat Treatment

After vacuum heat treatment, several post-processing techniques are employed to enhance the material’s properties further and ensure the final component meets stringent performance requirements. One crucial step is Hot Isostatic Pressing (HIP), which involves applying high pressure and temperature in an inert atmosphere to eliminate porosity and improve material density. HIP is significant for high-performance components like turbine blades, where even minor porosity can compromise their fatigue resistance and overall integrity. This process ensures a fully dense, homogeneous material with improved mechanical properties.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a critical post-treatment process that helps eliminate internal voids and improves the material's overall density, ensuring the part is porosity-free. This process is essential for turbine blades and other high-performance components exposed to high-pressure environments. By applying high pressure and temperature in an inert atmosphere, HIP enhances the material's strength, fatigue, and creep resistance, making it ideal for critical applications in the aerospace and energy sectors.

Solutionizing and Aging

After vacuum heat treatment, superalloy components may undergo solutionizing and aging to improve their mechanical properties further. Solutionizing involves heating the alloy to a high temperature to dissolve residues, followed by rapid cooling. Aging then strengthens the material by allowing the formation of precipitates at lower temperatures. This combination enhances the alloy’s creep resistance, fatigue strength, and durability, making it suitable for high-stress applications such as turbines and pressure vessels.

Surface Finishing

After vacuum heat treatment and other post-processes, the component may undergo surface finishing operations such as grinding, polishing, or coating. These processes improve surface integrity and prepare the material for its final use. In high-temperature applications, thermal barrier coatings (TBC) protect the surface from heat and oxidation. This is especially beneficial for components like gas turbine blades, where thermal protection is crucial for extending component lifespan.

Machining and Shaping

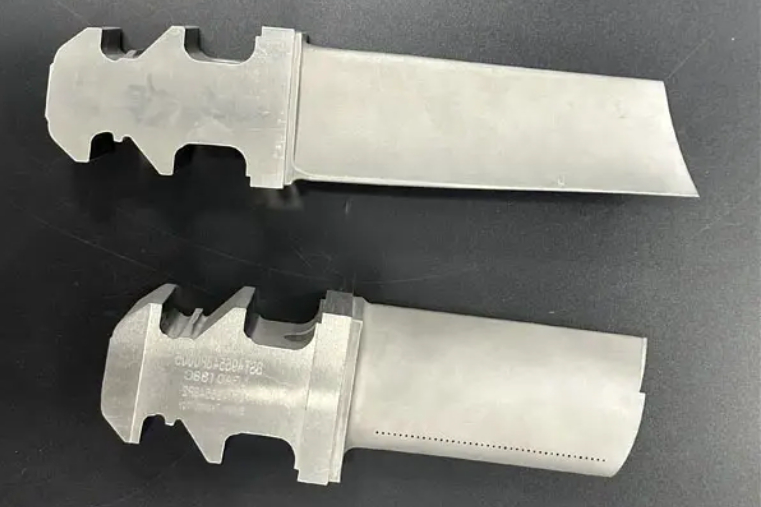

Final machining processes, including CNC machining, are used to achieve the desired shape and dimensions of the superalloy part. After vacuum heat treatment, the material is more stable and less prone to distortion due to residual stresses, making it easier to machine with greater precision. This step is essential for achieving the tight tolerances and complex geometries required for parts like turbine discs, where high accuracy is crucial for performance.

Testing for Creep Resistance

Ensuring that superalloy components maintain their integrity under high-temperature stress is critical. Several testing methods are used to evaluate the effectiveness of vacuum heat treatment and verify the creep resistance of the material:

Creep testing measures the deformation of materials under constant stress at high temperatures. This test helps determine the material’s ability to withstand long-term exposure to thermal and mechanical stresses without significant deformation. It is essential for superalloy components like turbine blades and reactor parts, which are exposed to extreme conditions during operation. Creep testing also ensures that the material remains durable over the component's life in high-temperature environments.

Tensile testing and fatigue testing are essential to understanding how a superalloy component will behave under real-world conditions. Tensile tests measure a material’s resistance to pulling forces, while fatigue testing simulates repeated loading and unloading cycles that a material might experience in service. Both tests are critical to ensure that the superalloy will withstand long-term stress without failure.

Microstructural analysis using scanning electron microscopy (SEM) and metallographic microscopy helps engineers assess grain size, phase distribution, and material homogeneity. This analysis verifies whether the vacuum heat treatment has successfully achieved the desired changes in microstructure, such as improved grain boundary strengthening, which directly influences creep resistance. Scanning electron microscopy (SEM) is beneficial for visualizing fine details of the material’s internal structure.

Non-destructive testing (NDT) techniques like ultrasonic testing, X-ray inspection, and eddy current testing are employed to identify internal defects and assess the quality of the material without damaging the component. These methods ensure no voids, cracks, or other issues compromise the material’s performance. Especially in critical applications such as aerospace and power generation, where component failure can be catastrophic, X-ray inspection ensures that internal integrity is maintained.

Industry and Application of Superalloys with Enhanced Creep Resistance

Superalloys with enhanced creep resistance are used across many high-performance industries. Their ability to resist deformation and maintain integrity under extreme stress makes them invaluable for critical applications where reliability is paramount.

Aerospace

Superalloy components like turbine blades, compressor disks, and exhaust systems are subjected to extreme thermal and mechanical stresses in the aerospace industry. The ability to withstand high temperatures without significant deformation is critical for the efficiency and safety of jet engines and other aerospace systems. Vacuum heat treatment helps these components maintain their performance over long operational lifetimes by enhancing their creep resistance. Superalloy turbine blades, for example, are designed to endure these extreme conditions while maintaining structural integrity and performance.

Power Generation

In power generation, superalloy castings are used for gas turbines, steam turbines, and heat exchangers. These components must be able to perform under high temperatures for extended periods, and creep resistance is essential for ensuring that the power plant operates efficiently and safely. Vacuum heat treatment ensures that these superalloys can withstand the thermal cycling and mechanical stresses they face during operation, helping to prevent deformation and ensuring long-term durability in critical power generation equipment.

Oil and Gas

Superalloys are used in critical equipment like pumps, valves, and pressure vessels in the oil and gas industry. These parts must be resistant to both high pressure and high temperatures. Vacuum heat treatment enhances the creep resistance of these components, allowing them to maintain their performance and integrity in the most demanding environments. This ensures the longevity and reliability of essential equipment such as superalloy pumps and valves, even under extreme operational stresses.

Automotive

In the automotive industry, turbochargers, exhaust systems, and other high-performance engine components benefit from enhanced creep resistance. Vacuum heat treatment ensures these parts maintain their dimensions and performance under the thermal stresses generated in high-speed engines. Superalloy turbochargers, for example, are treated to resist deformation at high temperatures, ensuring that they operate reliably and efficiently over the long term.

Military and Defense

Superalloys are used to produce missile components, weaponry, and armor systems that must withstand extreme conditions. The enhancement of creep resistance through vacuum heat treatment ensures these parts remain functional and reliable during extended operations in the field. For missile components or other military-grade parts, superalloy materials treated for enhanced creep resistance are crucial for maintaining operational readiness under extreme thermal and mechanical stress.

Marine

In the marine industry, propulsion systems, exhaust systems, and corrosion-resistant piping benefit from superalloys treated with vacuum heat treatment. These materials must withstand high temperatures and the harsh marine environment, where creep resistance is essential for long-term durability. For example, superalloy piping accessories used in marine environments are treated to maintain their strength and integrity despite the combined challenges of thermal cycling and corrosive conditions.

Superalloys with enhanced creep resistance are critical across industries that rely on high-performance materials in extreme conditions. Vacuum heat treatment ensures these materials maintain integrity, strength, and reliability over extended operational lifetimes.

FAQs

How does vacuum heat treatment improve the creep resistance of superalloys?

What types of superalloys are commonly used for high-temperature applications requiring creep resistance?

How does microstructural refinement during vacuum heat treatment enhance the material's performance?

What are the post-processing techniques that follow vacuum heat treatment to optimize creep resistance?

Which industries rely most on the creep resistance of superalloys in their critical components?