Custom Superalloy Parts Manufacturing Service

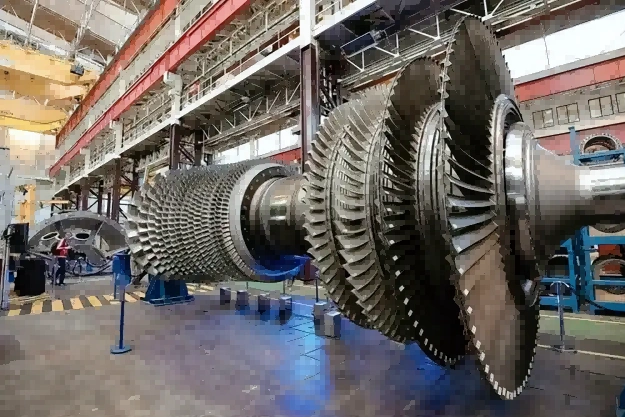

Neway Precision Works specializes in manufacturing high-temperature superalloy parts using advanced processes like vacuum investment casting, single crystal casting, and CNC machining. We provide post-processing services, such as heat treatment and HIP, for aerospace, aviation, and energy industries.

Send us your designs and specifications for a free quotation

All uploaded files are secure and confidential

Superalloy Manufacturing Capabilities and Technologies

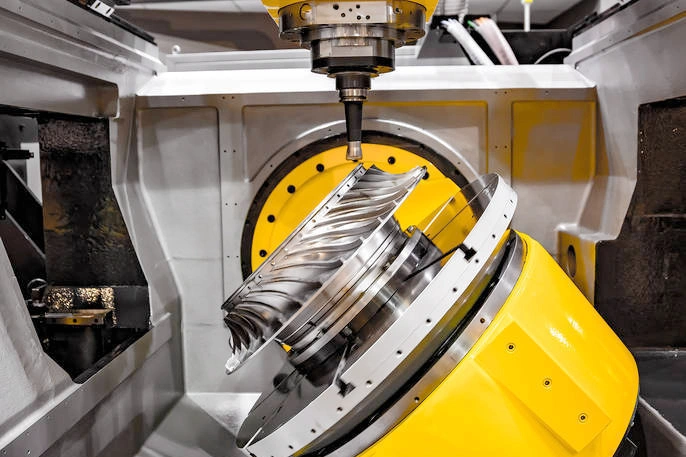

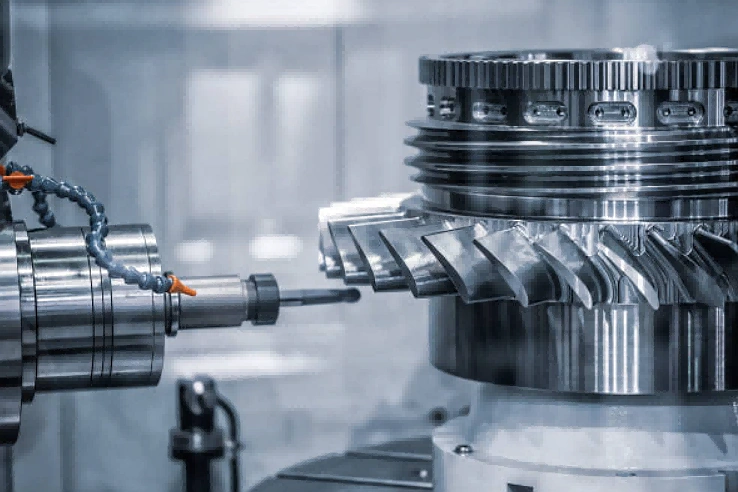

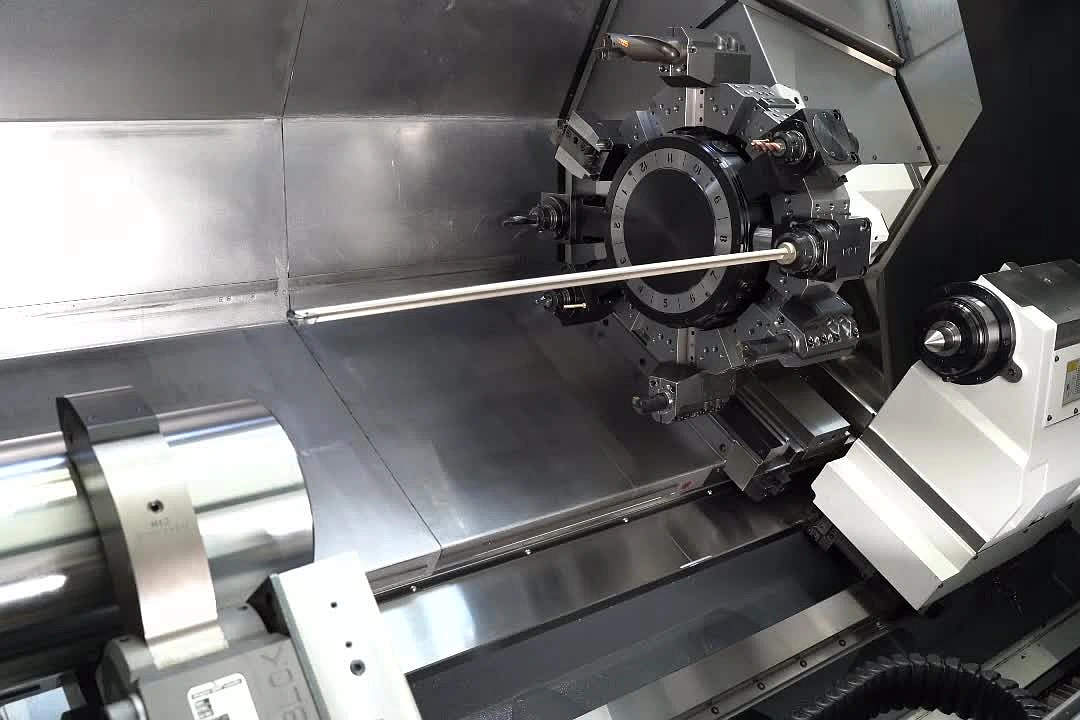

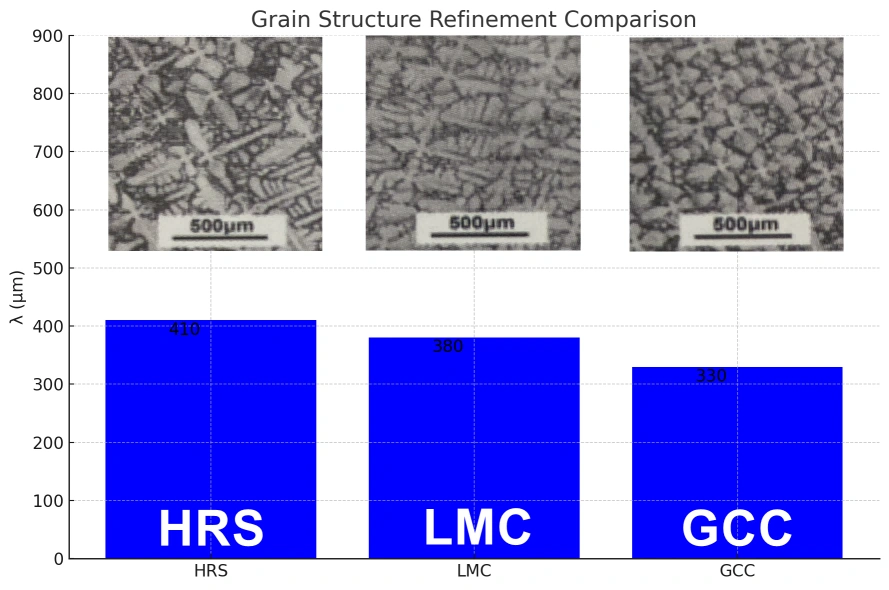

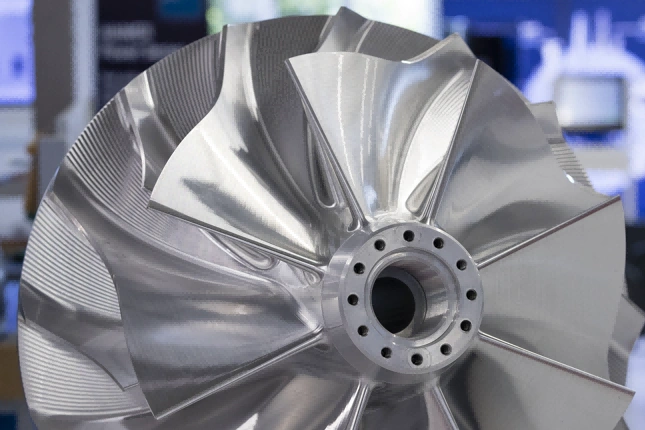

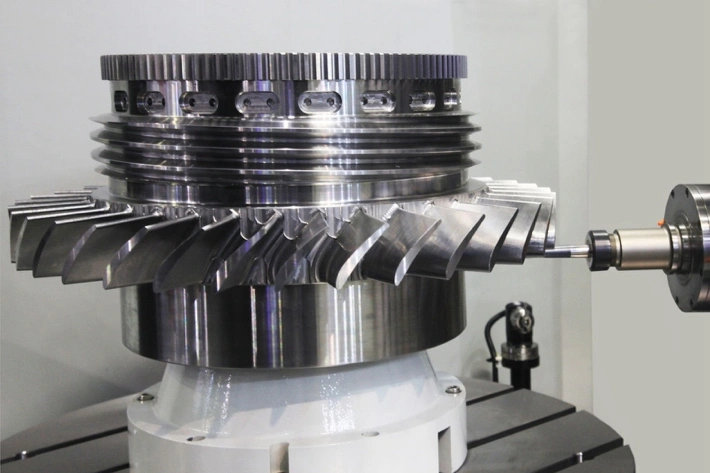

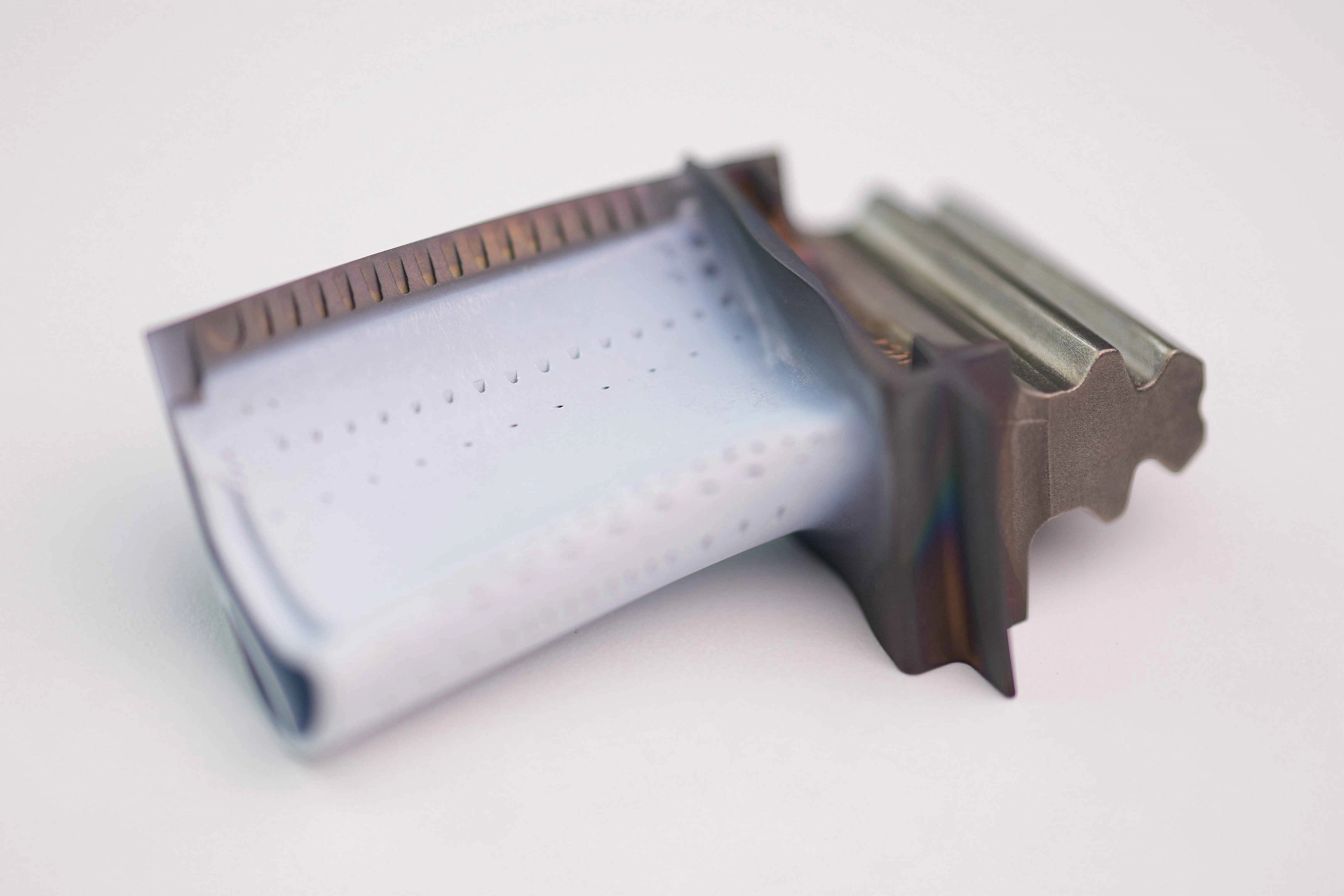

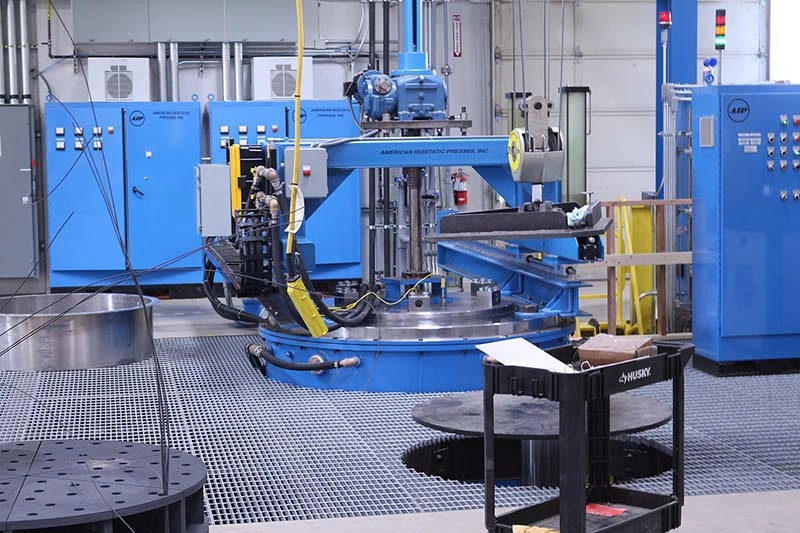

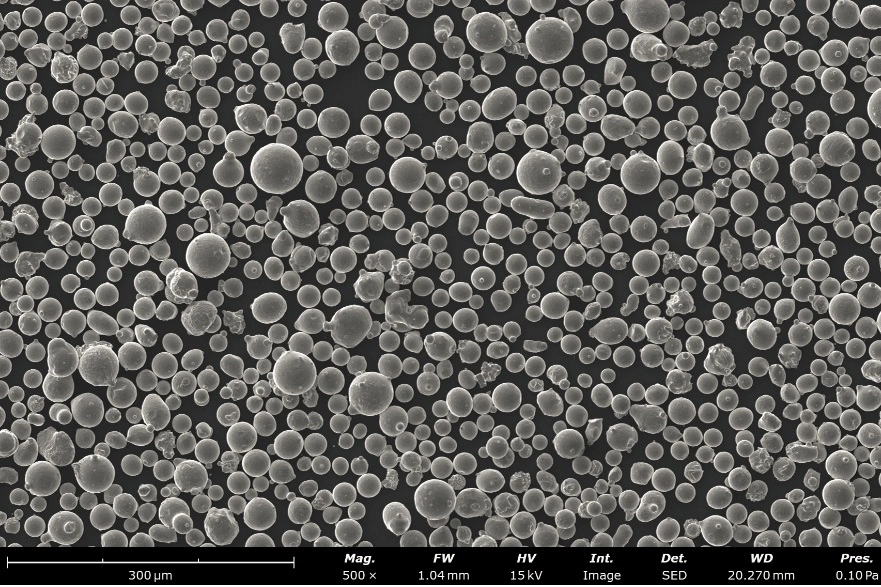

Neway specializes in vacuum casting and forging of high-temperature alloys, including single crystal casting, directional casting, powder metallurgy and equiaxed crystal casting of high-temperature alloys. At the same time, it provides CNC machining, 3D printing rapid proofing services for high-temperature alloys, as well as post-processing processes such as deep hole drilling, EDM, thermal barrier coating, hot isostatic pressing, etc., to provide you with one-stop service.

Our Strength In Manufacturing Superalloy Components

We provide high-temperature alloy casting, forging, powder metallurgy, CNC machining, and 3D printing services. We have advanced manufacturing equipment, testing equipment, and strong R&D capabilities. We provide one-stop manufacturing services for your high-temperature alloy parts.

Superalloys Available At Neway

Neway offers a wide range of superalloys, including Inconel, CMSX, Monel, Hastelloy, Stellite, Nimonic, Rene, and single crystal alloys. Due to their durability, these materials are ideal for high-temperature applications in aerospace, energy, and marine industries.

Post Processing and Surface Finishing of Blanks

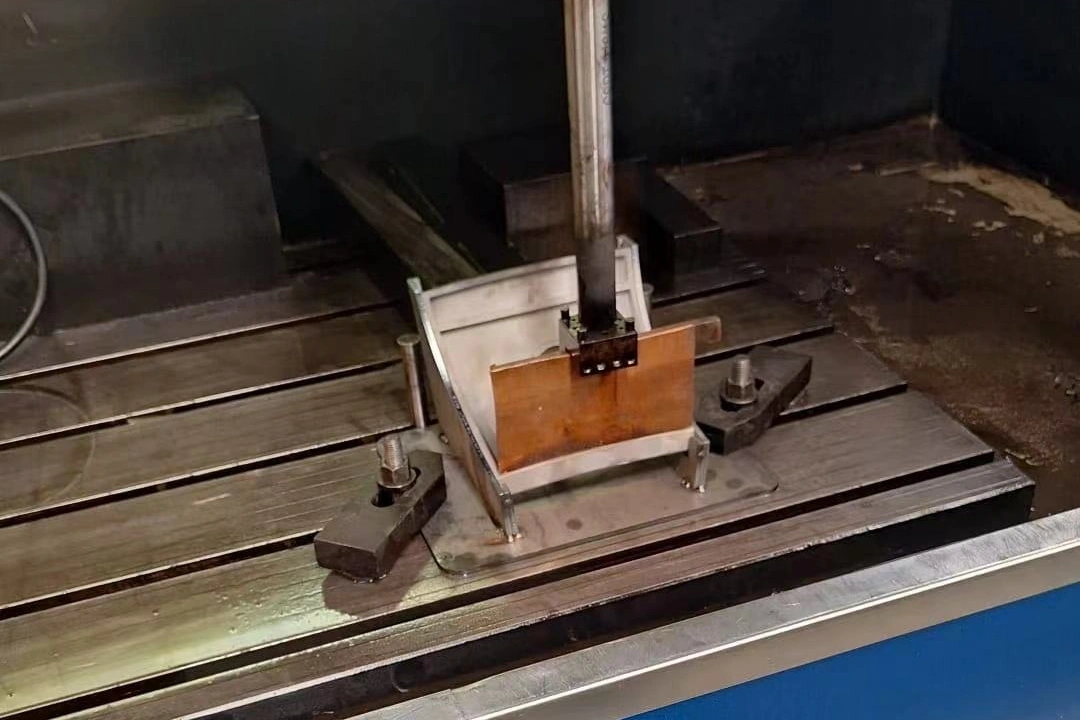

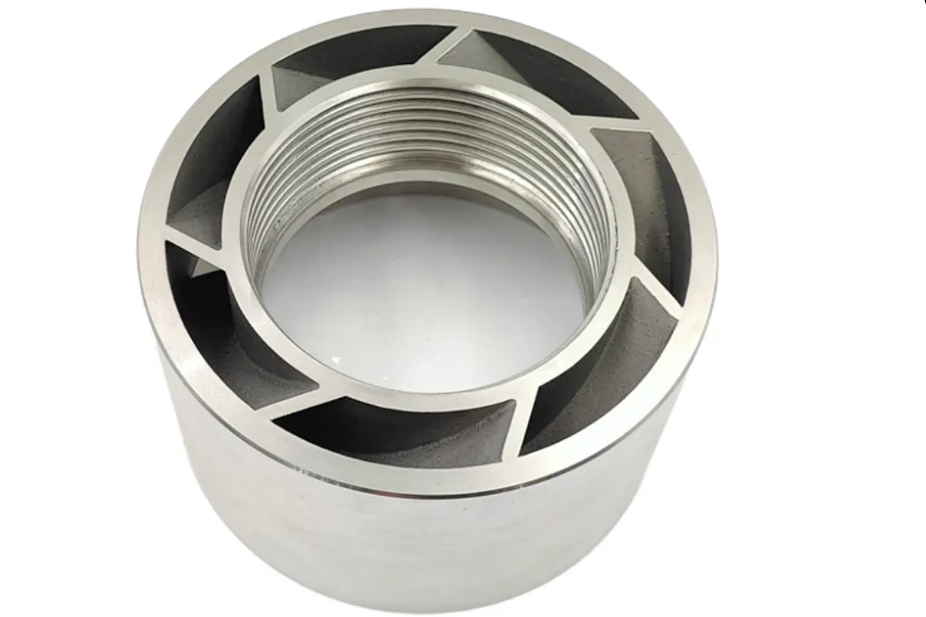

Neway provides post-processing services for high-temperature alloy vacuum castings and 3D-printed parts. For example, Hot Isostatic Pressing (HIP), Heat Treatment, Superalloy Welding, Thermal Barrier Coating (TBC), Material Testing and Analysis, Superalloy CNC Machining, Superalloy Deep Hole Drilling, Electrical Discharge Machining (EDM).

What We Can Do On Custom Superalloy Parts?

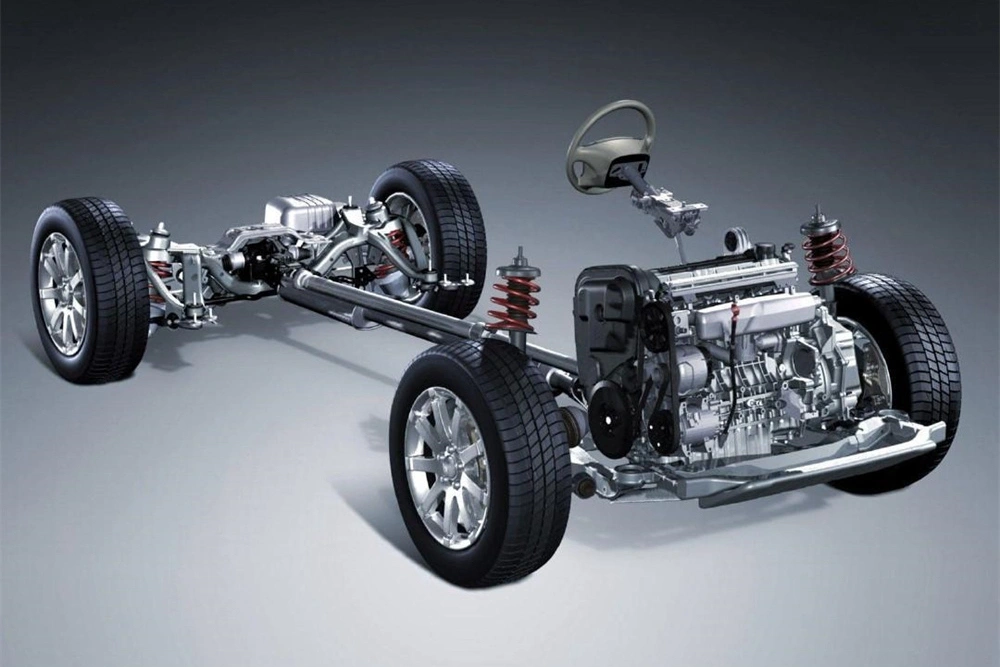

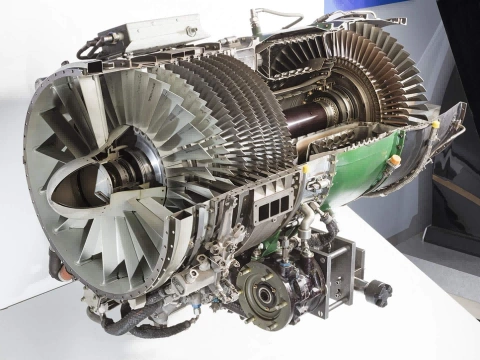

We offer the manufacturing and testing services of superalloy components that are vital in aerospace for jet engine turbine blades and exhaust systems, power generation for gas turbines, chemical processing in reactors, automotive for high-performance engine parts, and medical devices requiring high strength and corrosion resistance.

Learn More

Aerospace and Aviation

Learn More

Power Generation

Learn More

Oil and Gas

Learn More

Energy

Learn More

Marine

Learn More

Mining

Learn More

Automotive

Learn More

Chemical Processing

Learn More

Pharmaceutical and Food

Learn More

Military and Defense

Learn More

Nuclear

Learn More

More Cases

Learn More

New Technology

Learn More

Products Gallery

Learn More

Various Industries

Learn More

Surface Finishings

Learn More

Post-Process

Learn More

Manufacturing Technology

Learn More

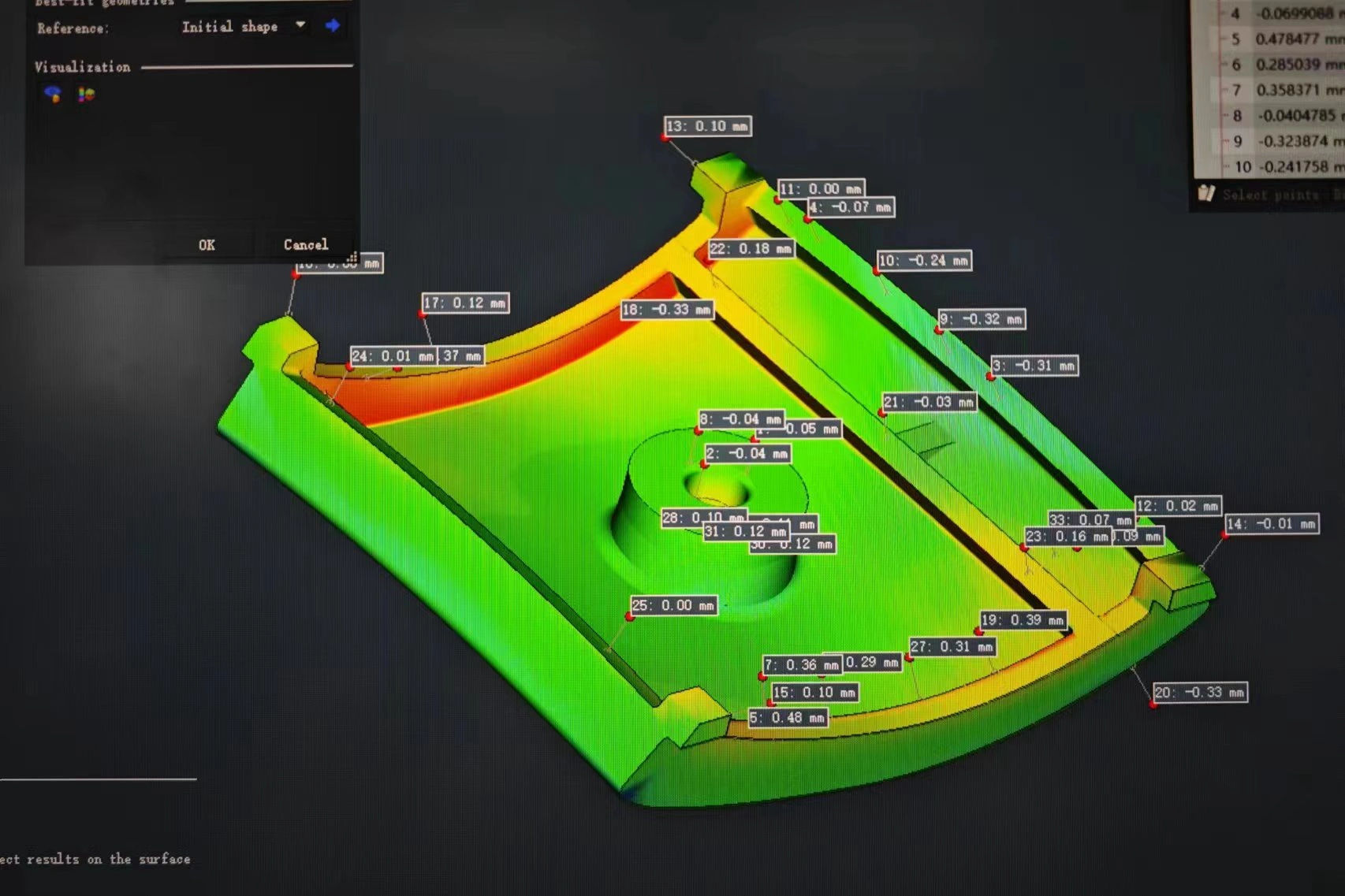

R&D and Simulation

Learn More

Manufacturing Equipments

Learn More

Testing Equipments

Learn More

BLOGS

Learn More

FAQs

Learn More

Contact

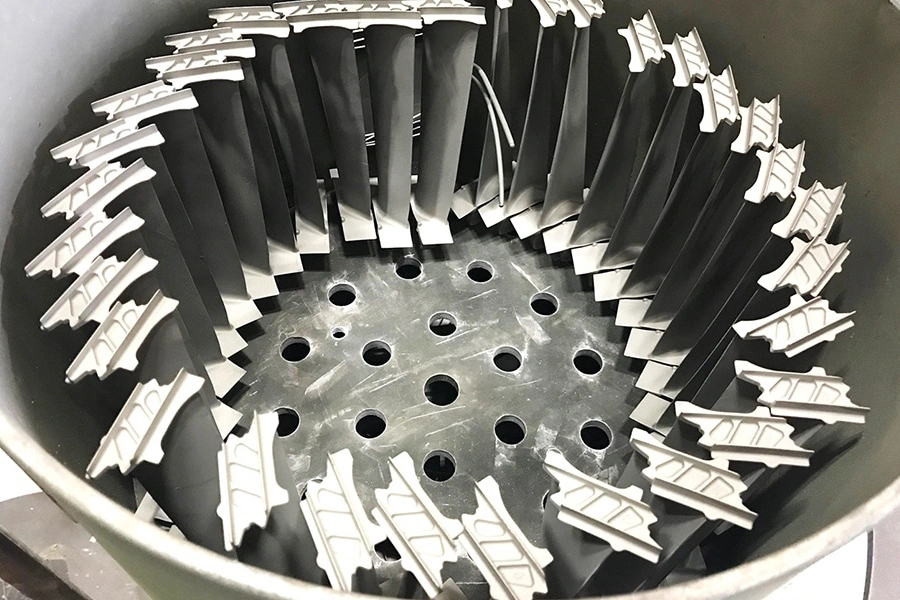

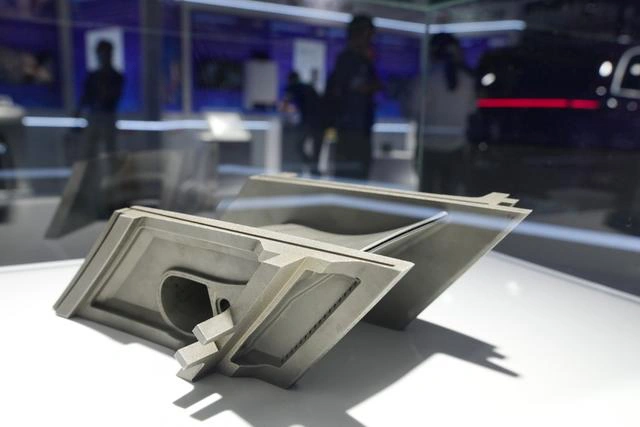

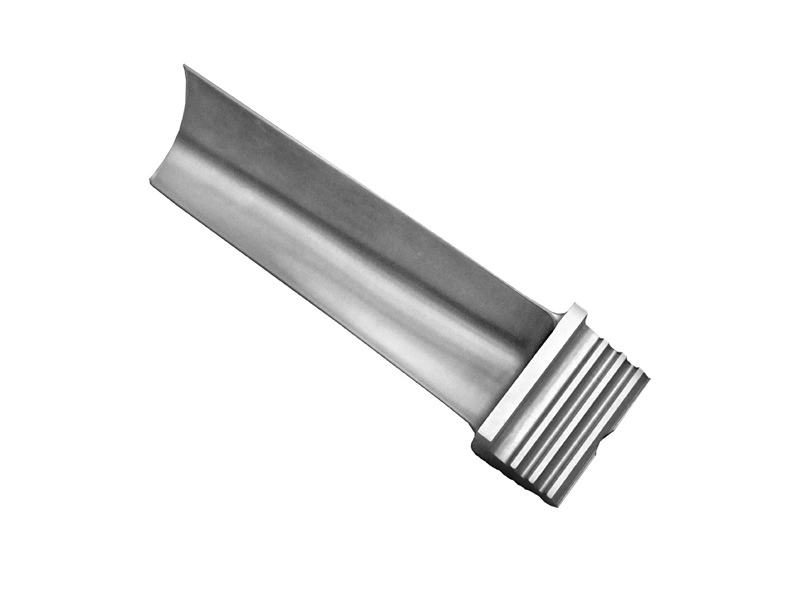

Inconel Alloy Vacuum Investment Castings Gallery

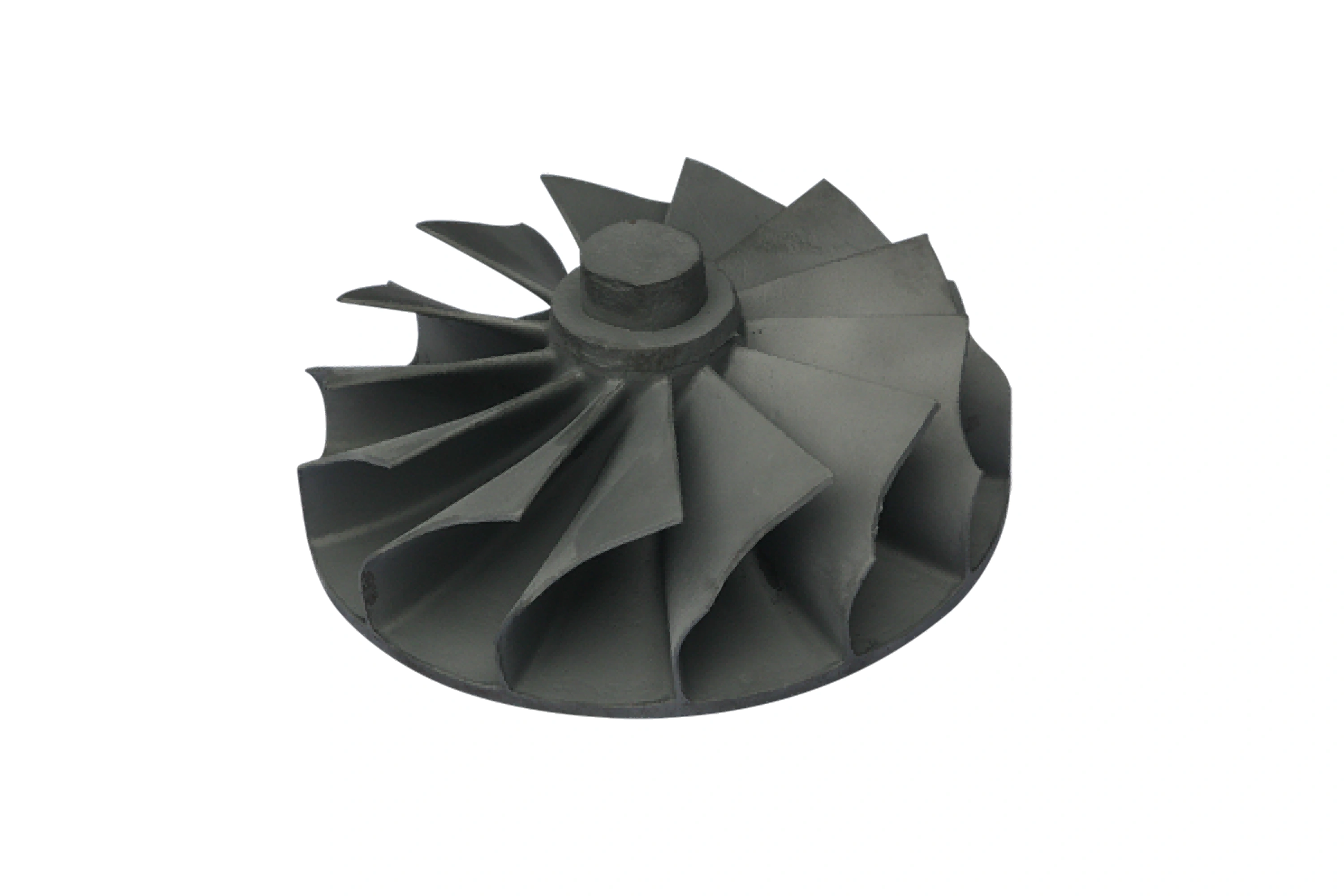

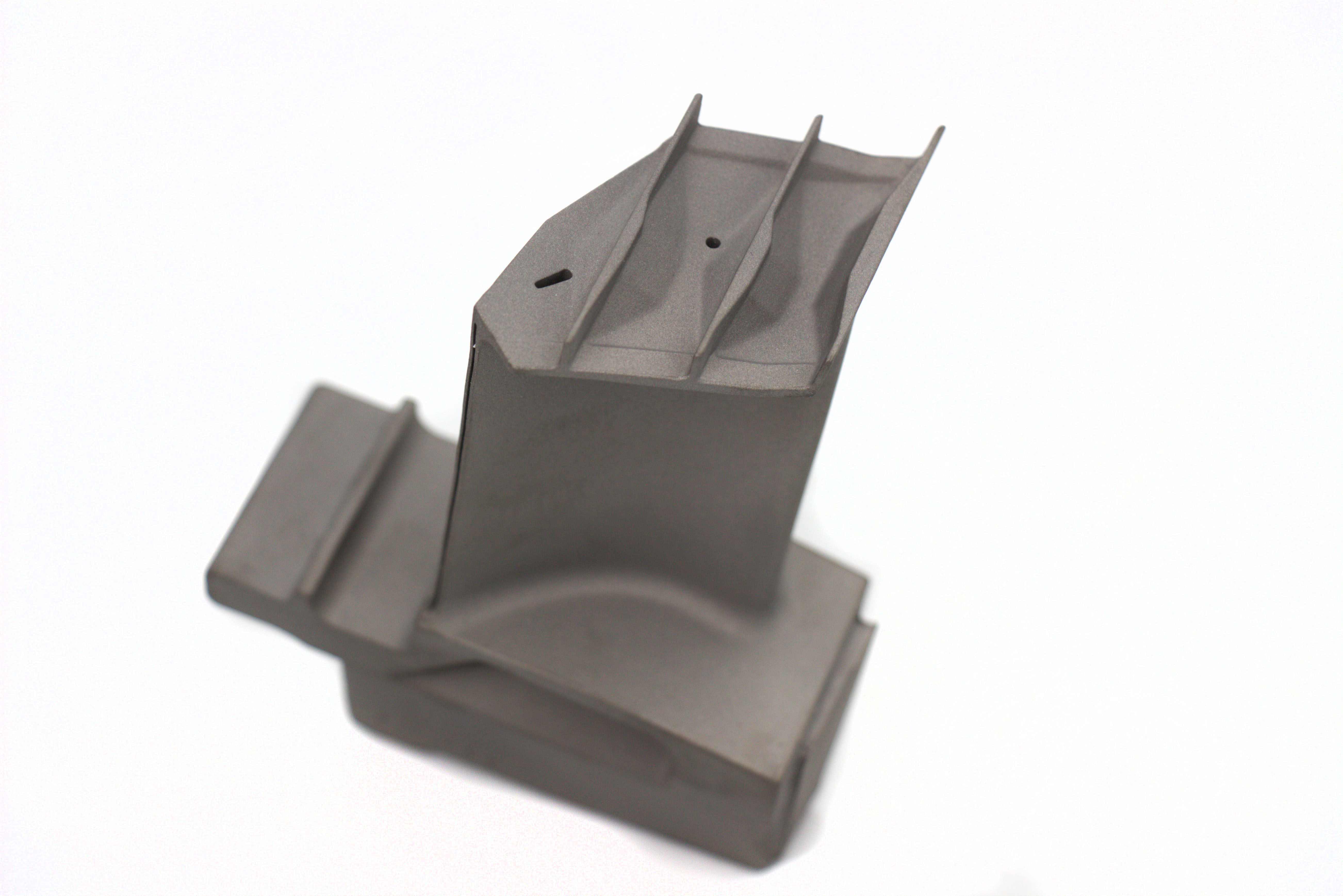

We mainly provide high-temperature alloy parts for aerospace, gas oil industry, mining, and other industries, such as Turbine Blades, Turbine Wheel, Turbine Segments, Gas Turbine Parts, Turbine Disks, Turbine Accessories, Turbine Impellers, Gas Turbine parts, Turbine Disc, Combustion Chamber, Gas Turbine Stator and Rotor, Turbine Nozzle, Etc.

Let's Start A New Project Today

Explore Related Blogs

Explore Related Resources

Services

Solutions

Copyright © 2026 Aero Precision Works Ltd.All Rights Reserved.